Ceramic tile seam-sealing machine

A technology for ceramic tiles and beautiful seams, applied in the field of ceramic tile beauty sewing machines, can solve the problems of reducing the service life of ceramic tiles and tile activities, and achieve the effects of enhancing construction accuracy, reducing workload, and improving construction accuracy and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

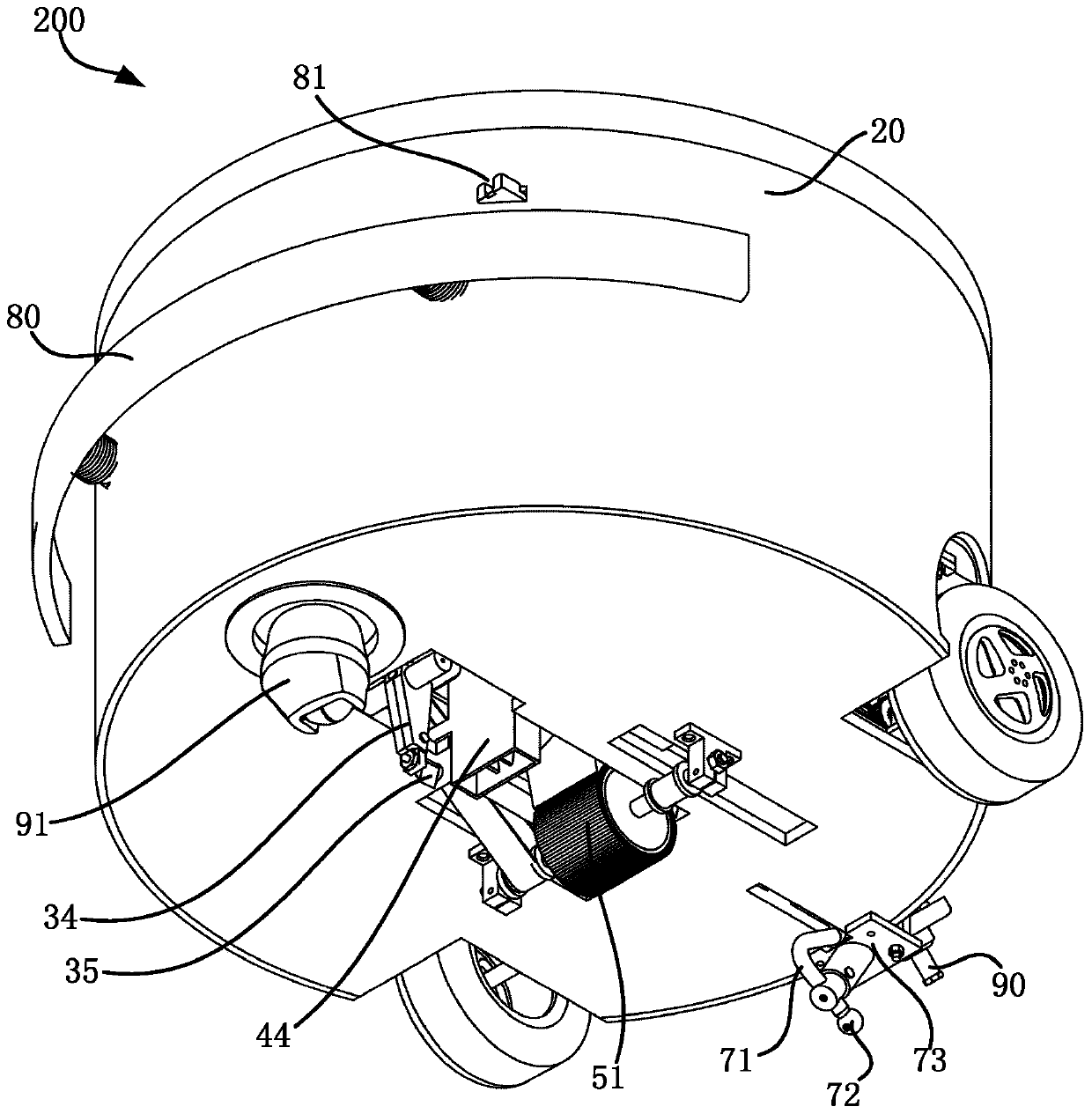

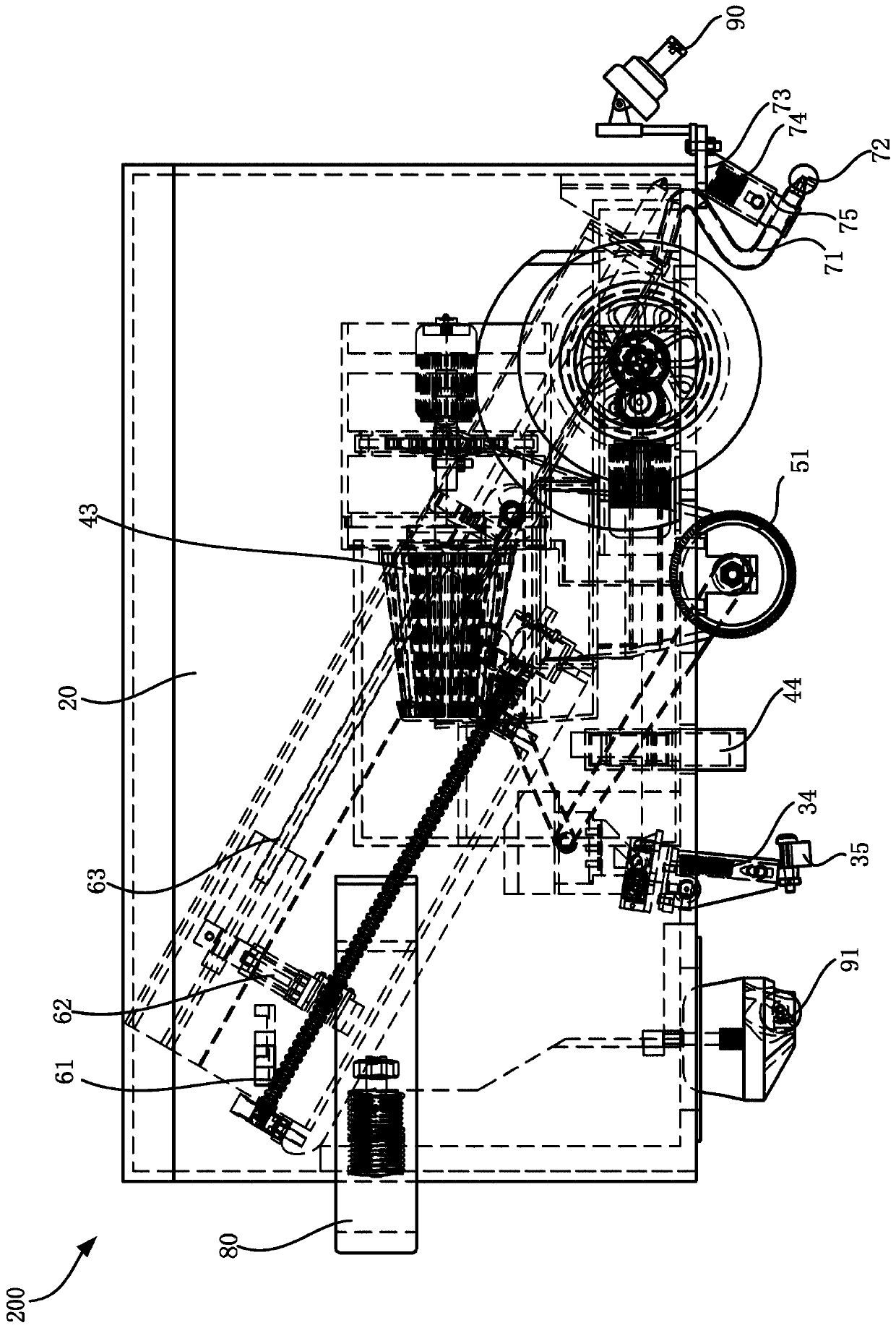

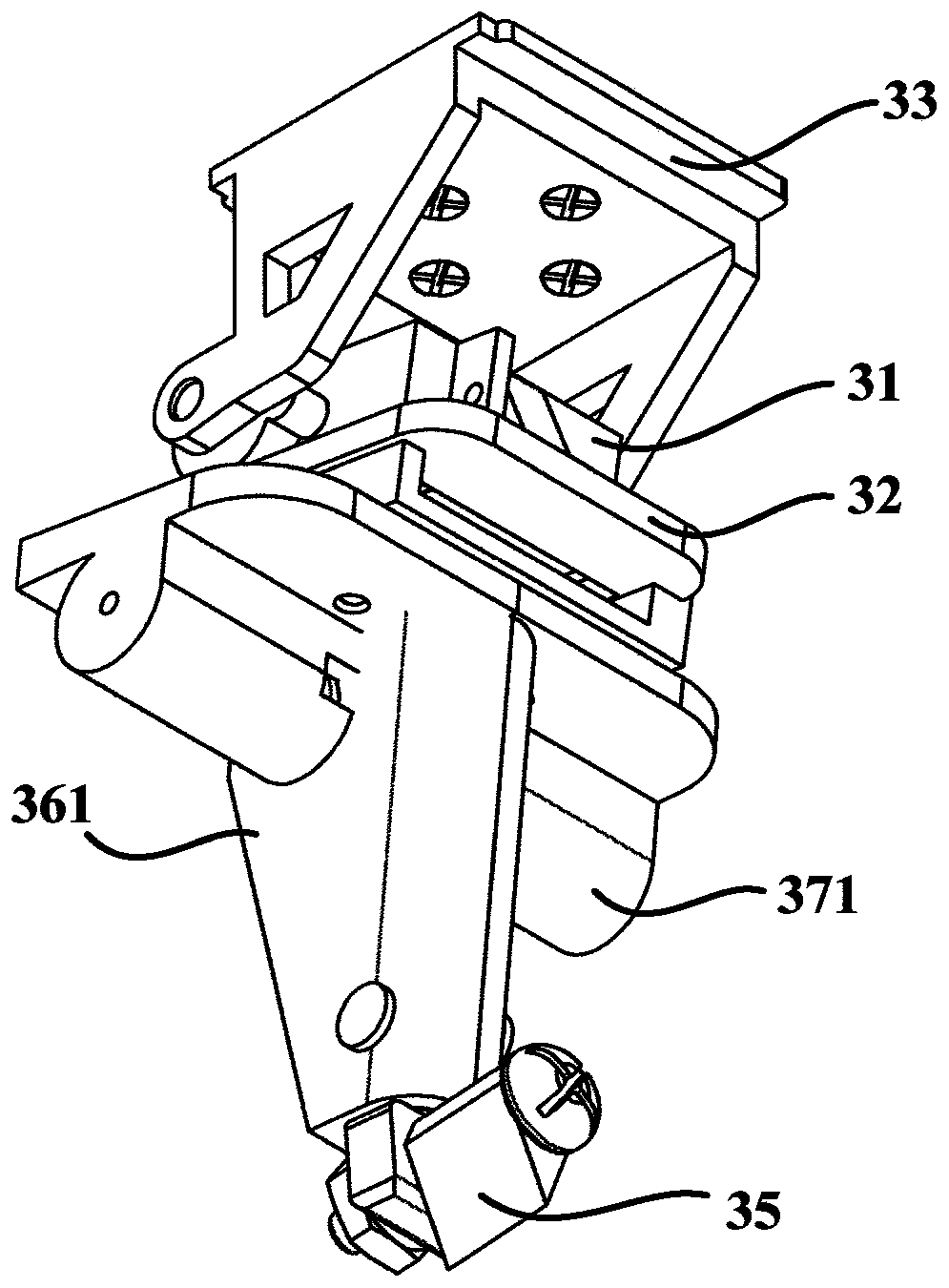

[0056] figure 1 It is a structural diagram of a ceramic tile sewing machine 200 according to an embodiment of the present invention. Such as figure 1 shown and refer to Figure 2 to Figure 14 , the embodiment of the present invention provides a ceramic tile sewing machine 200 . The beautiful tile sewing machine 200 includes a car body 20 , a slotting module 30 , a vacuum module 40 , a waxing module 50 , a filling module 60 , a single-chip microcomputer and a camera 90 . The car body 20 is configured to move along the tile gaps, that is, the car body 20 drives various components on it to move along the tile gaps, so as to process the tile gaps. The vehicle body 20 may include universal wheels 91 dispo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com