Differential gear train of double circular arc modified cycloid gear

A technology of cycloidal gear and differential gear train, which is applied in the direction of gear transmission, belt/chain/gear, transmission device, etc. It can solve the problems of short life and low contact strength, and achieve small contact stress, large contact area, The effect that is not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

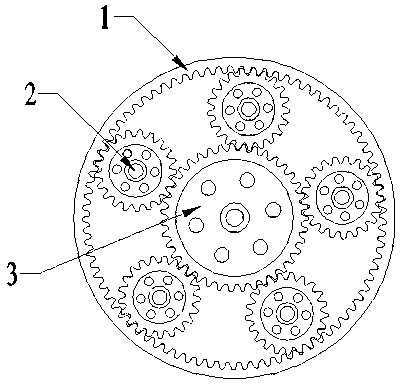

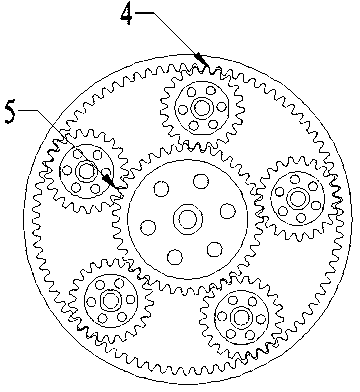

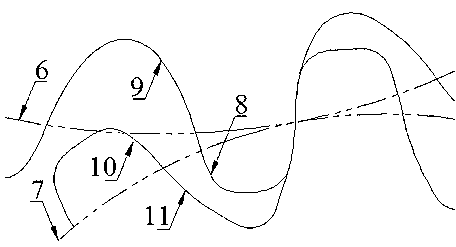

[0028] Embodiment 1: as Figure 1-4 As shown, a double arc correction cycloidal gear differential gear train includes an inner ring gear 1, a planetary gear 2, and a center wheel 3; the planetary gear 2 is installed between the inner ring gear 1 and the center wheel 3, and the planetary gear 2 Including corrected epicycloid I8, corrected hypocycloid I9, and pitch circle I6; center wheel 3 includes corrected epicycloid II10, corrected hypocycloid II11, and pitch circle II7; inner ring gear 1 includes corrected epicycloid III13, corrected Hypocycloid III14, pitch circle III12; the corrected hypocycloid I9 of the planetary gear 2 and the corrected epicycloid II10 of the center wheel 3 are in concave-convex meshing, the corrected hypocycloid II11 of the center gear 3 and the corrected epicycloid I8 of the planetary gear 2 Concave-convex meshing, that is, external contact and internal meshing 5, the correction hypocycloid I9 of the planetary gear 2 and the correction epicycloid III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com