Washing machine speed reduction clutch and washing machine

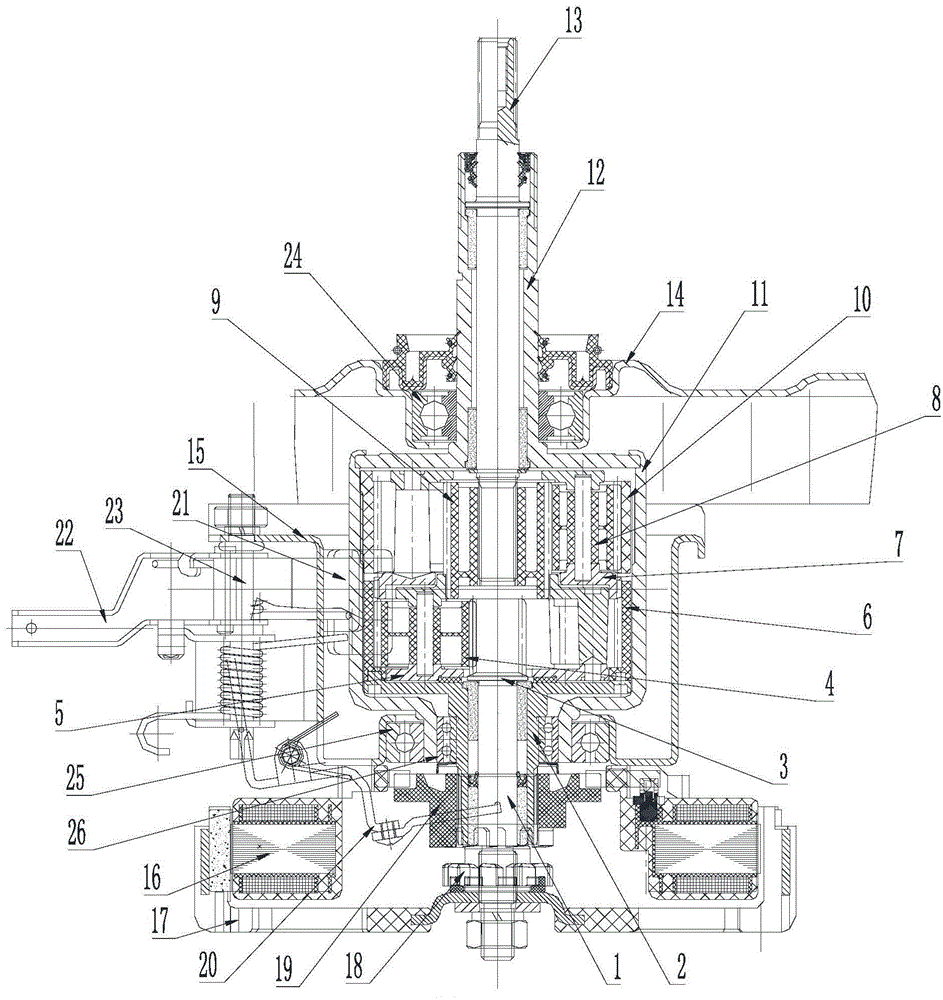

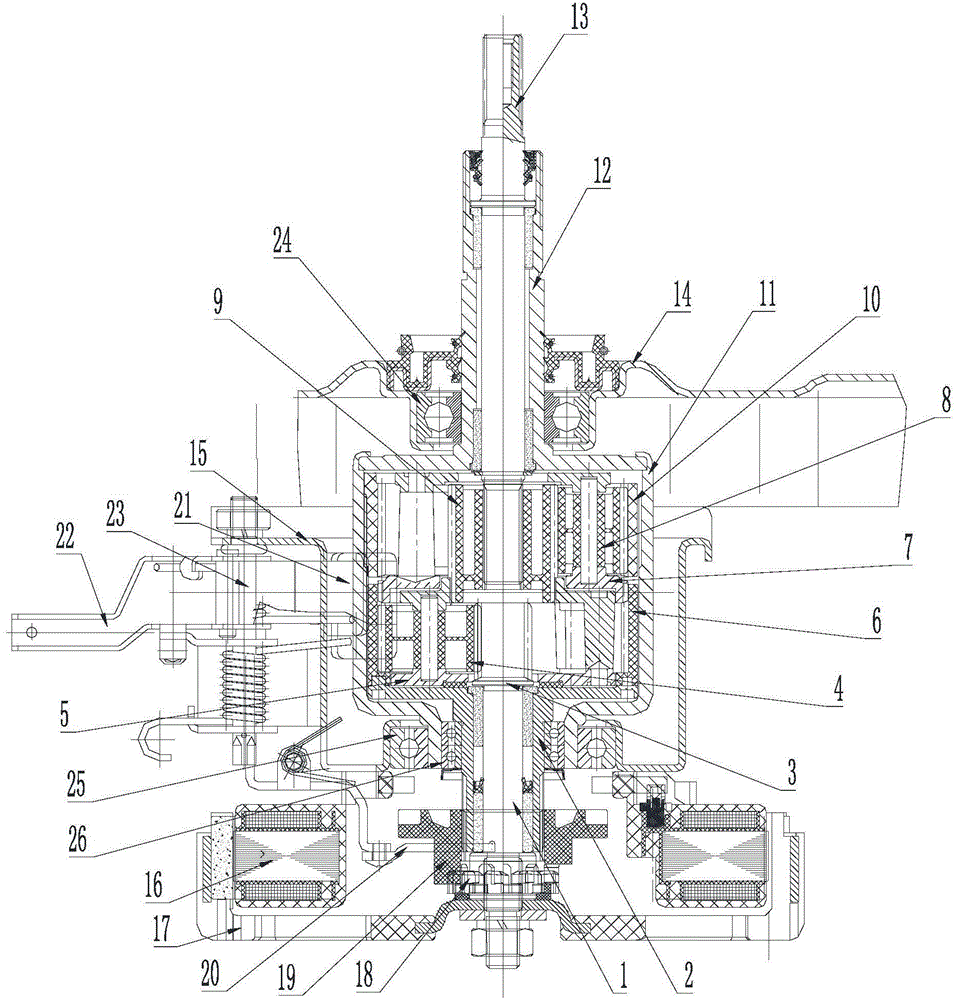

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve the problems of increased washing machine vibration, poor overrunning clutch, one-way bearing failure, etc., and achieve the effects of long service life, good market promotion value, and stable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

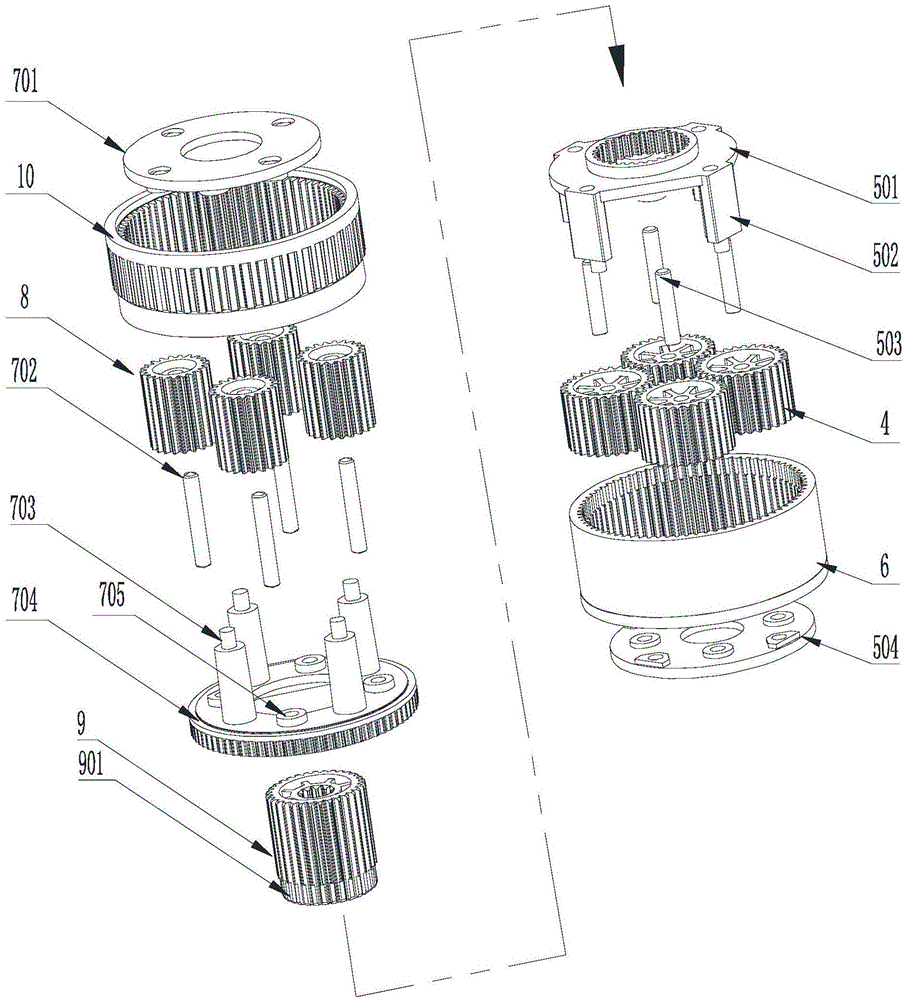

[0066] Such as Figure 8 As shown, the difference between this embodiment and the above-mentioned specific embodiments is only that: the upper planetary carrier 7 and the lower ring gear 6 of this embodiment are fixedly connected by means of hole pin assembly.

[0067] A plurality of first fixed pins 706 are arranged along the circumferential direction on the end of the upper planetary carrier seat 704 of the upper planetary carrier 7 near the end of the lower gear train in this embodiment, and the lower inner ring gear 6 is close to the upper gear train A plurality of first installation holes 603 are provided on the end of one end corresponding to the first fixing pins 706 , and the first fixing pins 706 are inserted into the first installation holes 603 to realize a fixed connection in the way of hole pin assembly.

[0068] Further, the upper planetary gear carrier 7 is fixedly connected to the lower ring gear 6 through key connection or hole pin assembly.

[0069] The firs...

Embodiment 2

[0074] The difference between this embodiment and the above specific implementation is only that the lower ring gear connection part 602 is the inner tooth of the lower ring gear 6, and the connecting key on the upper planetary gear carrier 7 is the inner tooth of the lower ring gear. The inner teeth of the ring 6 mesh with the outer teeth, and the upper planetary carrier 7 at the end of the outer teeth is provided with a convex step for limiting the axial displacement of the upper planetary carrier 7 .

[0075] The advantage of adopting this method is that the structure of the lower inner ring gear 6 remains unchanged, and there is no need to separately process splines or open installation holes on the lower inner ring gear 6, and set the upper planetary gear carrier 7 with the lower inner ring gear. The outer teeth of the ring gear 6 have the same tooth shape. After meshing the outer teeth of the upper planetary gear carrier 7 with the inner teeth of the lower inner ring gear...

Embodiment 3

[0077] Such as Figure 9 , Figure 10 , Figure 11 The dehydration shaft of the washing machine in this embodiment includes a shaft body 1201 and a shaft seat 1202, the upper end of the shaft body 1201 is fixedly connected to the washing tub of the washing machine, and the lower end of the shaft body 1201 is fixedly connected to the shaft body 1202 or the shaft body 1201 The lower end is integrally formed with the shaft seat 1202; the dehydration shaft is connected with the reducer of the washing machine through the shaft seat; the shaft body is provided with a shaft through hole 1203 for the output shaft 13 to pass through.

[0078] Since the brake wheel 11 of the deceleration clutch of the present invention is fixedly connected to the dehydration shaft, this embodiment provides a dehydration shaft with a brand new structure, which consists of two parts, the shaft body 1201 and the shaft seat 1202, which are integrally formed or fixedly connected separately. Composition, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com