Circular-arc concave-convex engaged gear and rack mechanism without relative slide

A technology of arc gears and arc racks, which is applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., and can solve problems such as low bending strength and contact strength, and limited carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

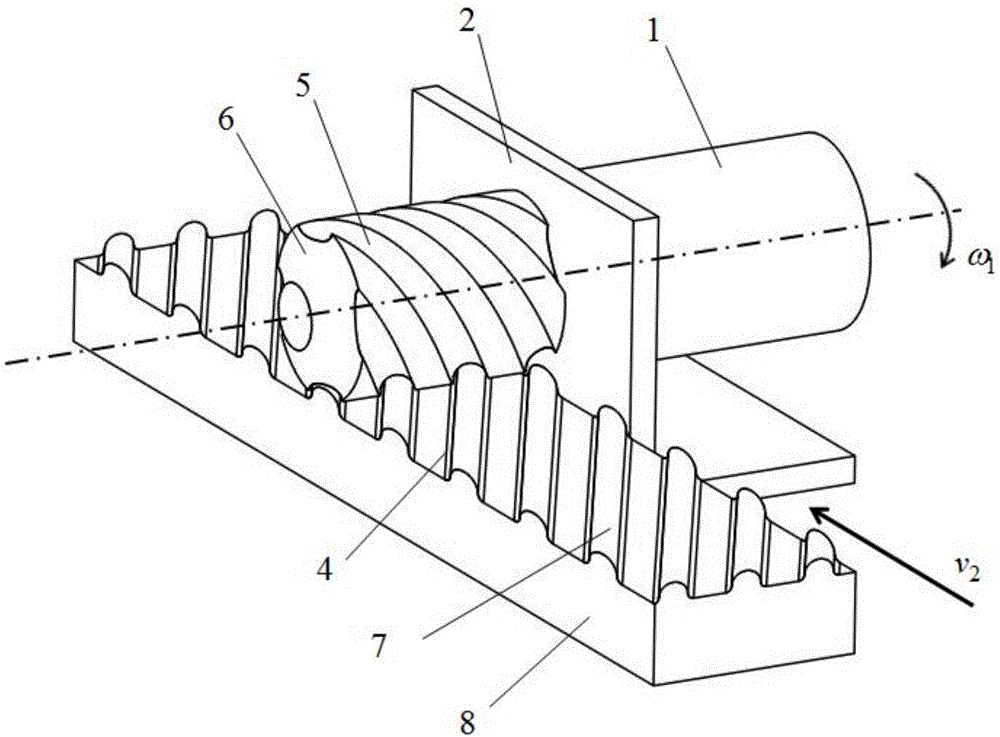

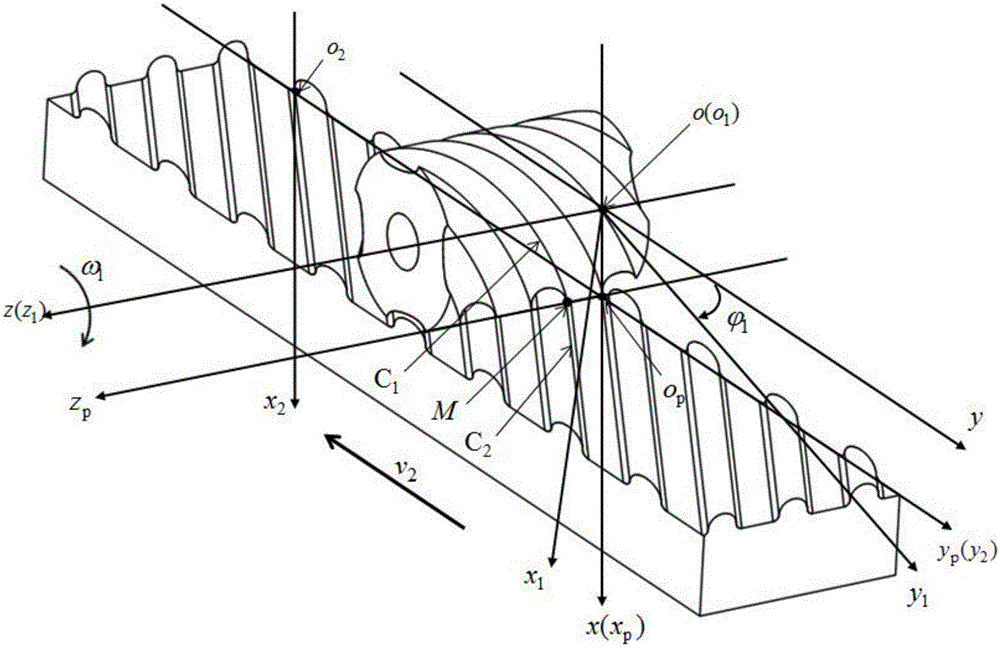

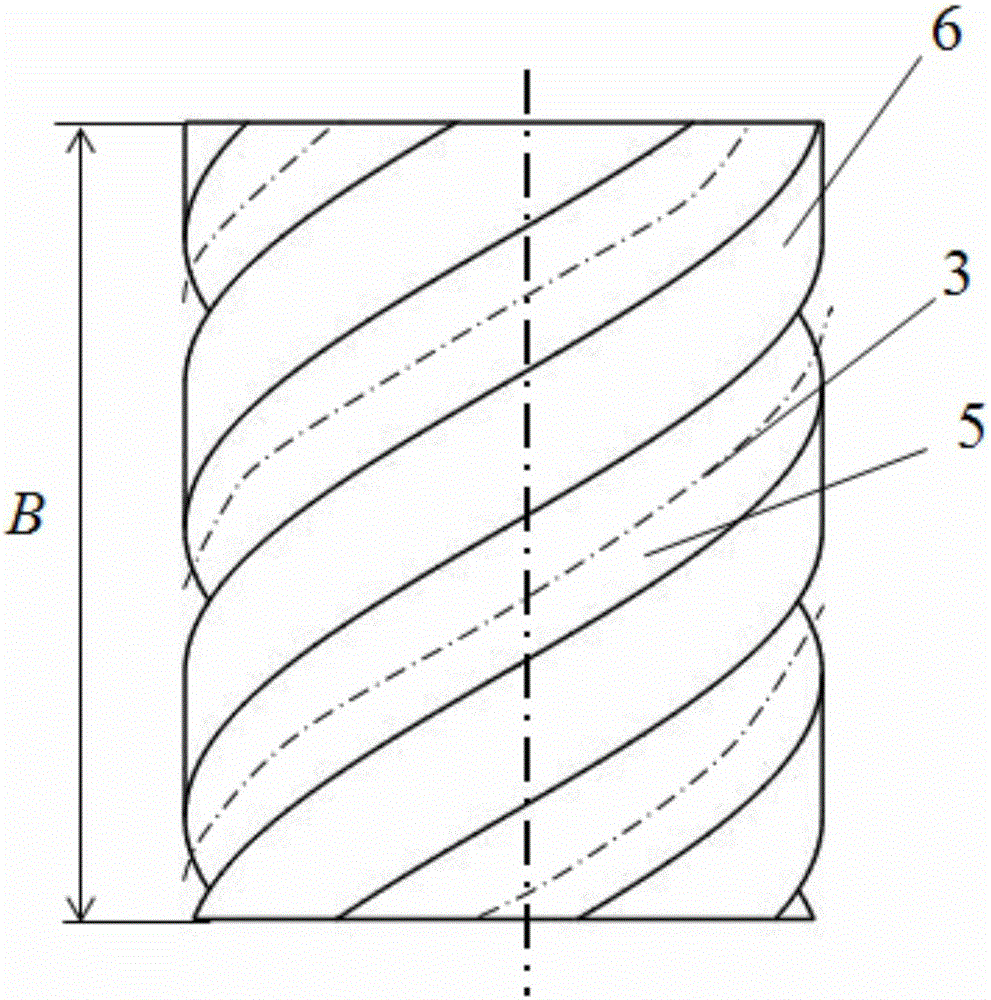

[0067] Embodiment 1: The present invention provides a kind of concave-convex meshing arc gear and rack mechanism without relative sliding, its structure is as follows figure 1 As shown, a pair of transmission pairs consisting of a spiral arc gear 6 with spiral concave arc tooth grooves 5 evenly distributed on the outer surface and an arc rack 8 with convex arc teeth 7 evenly distributed on the upper surface, the spiral arc gear The rotating shaft of the driver 1 is connected through the central hole 10 of the spiral arc gear. In this embodiment, the driver is a motor, and the rotation direction of the motor is counterclockwise, which drives the spiral arc gear to drive counterclockwise to realize the horizontal movement of the arc rack to the left. The driver is installed on the driver mounting base 2, and the driver mounting base is fixed.

[0068] The installation method of the spiral arc gear 6 and the arc rack 8 is as follows: the upper surface of the arc rack with the co...

Embodiment 2

[0121] Embodiment 2: The present invention provides a kind of concave-convex meshing arc gear and rack mechanism without relative sliding, such as Figure 7 shown. In this embodiment, the arc rack 8 is fixed, and the spiral arc gear 6 is connected to the rotating shaft of the driver 1 through the center hole 10 of the spiral arc gear. Due to the continuous meshing between the groove 5 and the convex arc tooth 7, the spiral arc gear moves in parallel while rotating, that is, the spiral arc gear purely rolls on the arc rack. When installing the spiral arc gear and the arc rack, the spiral concave arc tooth groove 5 on the spiral arc gear is in meshing state with a convex arc tooth 7 on the arc rack, and as the spiral arc gear rotates, the spiral The coincidence degree of concave arc tooth slots and convex arc teeth meshing is greater than 1, thereby realizing continuous and stable meshing transmission of the concave-convex meshing circular arc rack and pinion mechanism without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com