V-shaped slot follower plate of speed reducer

A technology of follower plate and V-groove, which is applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of low processing precision of transmission parts, unstable output of reducer, and influence on output accuracy, so as to eliminate design The effects of defects, smooth output, and low mechanical wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

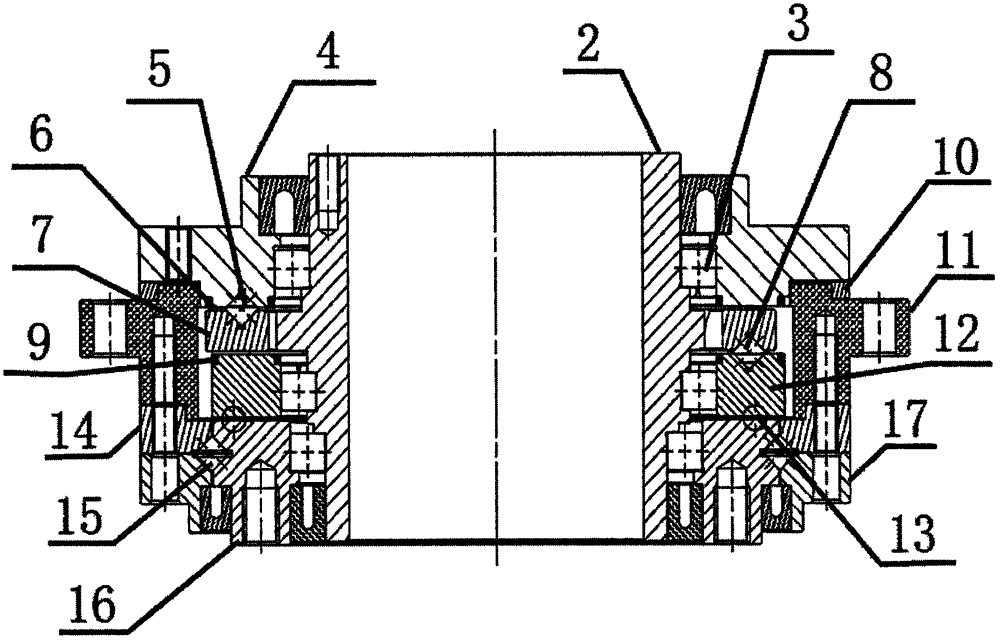

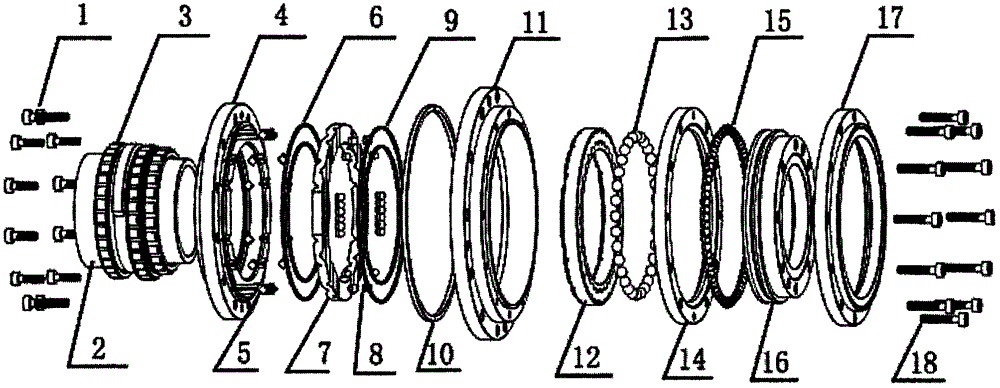

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

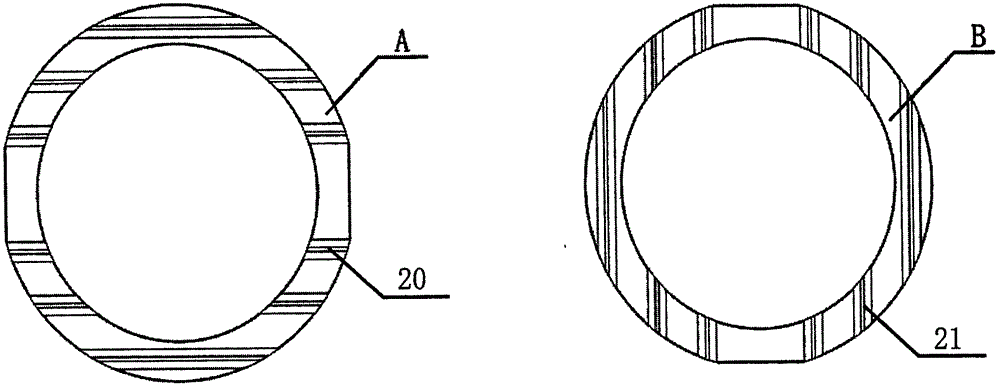

[0017] see image 3 , Figure 5 , the V-shaped groove follower plate of the reducer of the present invention includes a follower plate body 7, and one side (A surface) of the follower plate body 7 is provided with a transverse V-shaped track 20 (a plurality of parallel, also known as A face V-shaped groove), its other face (B face) is provided with vertical V-shaped track 21 (for parallel many, claims B face V-shaped groove). The first cross rollers 5 (several pieces) are installed on the transverse V-shaped track 20 , and the second cross rollers 8 (several pieces) are installed on the longitudinal V-shaped track 21 .

[0018] The transverse V-shaped track 20 and the longitudinal V-shaped track 21 on the follower plate body 7 form a cross shape (multiple corresponding ones) in plane space, and the crossing angle is 87.5 degrees to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com