Roller-type hydraulic rocking arm component

A rocker arm assembly and roller-type technology, which is applied to the lubrication of engine components, valve accessories, and machines/engines. noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

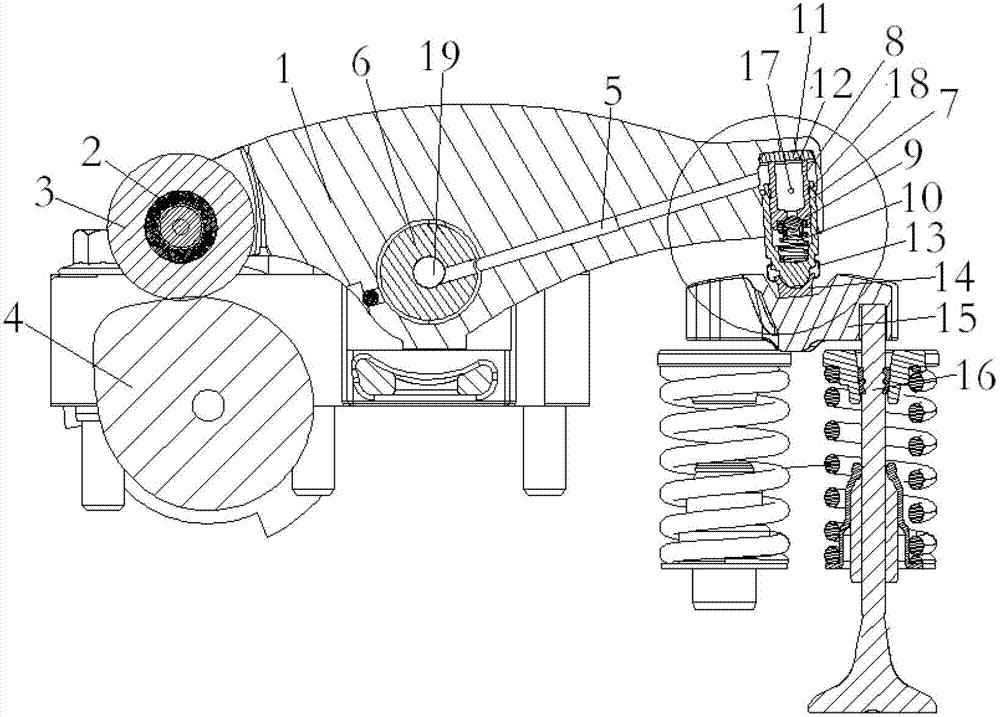

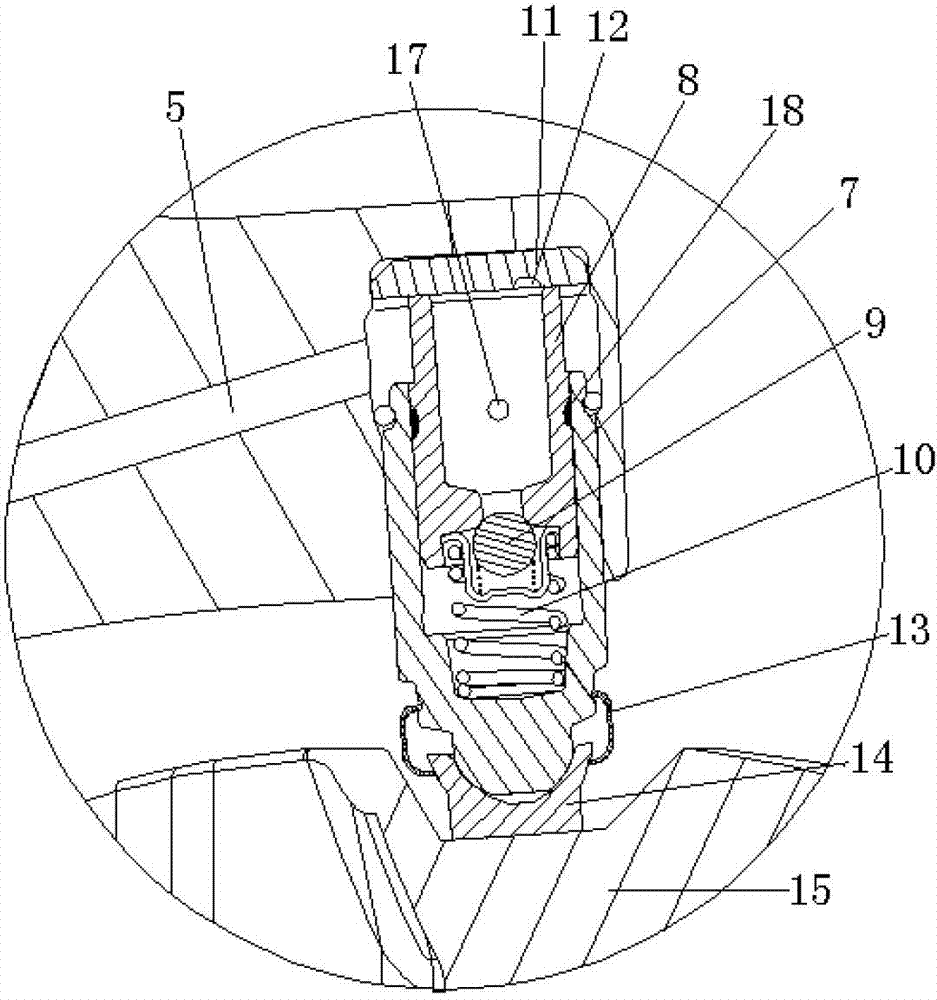

[0014] The principle and structure of the present invention will be further described below with reference to the accompanying drawings and through specific embodiments.

[0015] Roller type hydraulic rocker arm assembly, one end of the rocker arm 1 is provided with a short shaft, the short shaft is embedded with a bearing 2, the bearing is embedded in the roller 3, and the roller and the camshaft 4 form a transmission pair. The rocker arm is provided with an oil passage 5, and the middle part of the rocker arm is provided with a rocker shaft 6 (such as figure 1 ). The other end of the rocker arm is provided with a plunger sleeve 7, the plunger sleeve is sequentially equipped with a plunger 8, a check valve 9 and a return spring 10, the upper end of the plunger sleeve is provided with a plunger cover plate 11, and the plunger cover plate is provided with Oil return channel 12. The plunger sleeve is connected with the slide block 14 through the ferrule 13, the slide block is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com