Electromagnetic feeding device

A feeding device and electromagnetic technology, applied in the direction of metal processing, etc., can solve the problems that cannot meet the needs of small and medium-sized enterprises, complex structure, high cost, etc., and achieve the effect of simple structure, stable and reliable transmission, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

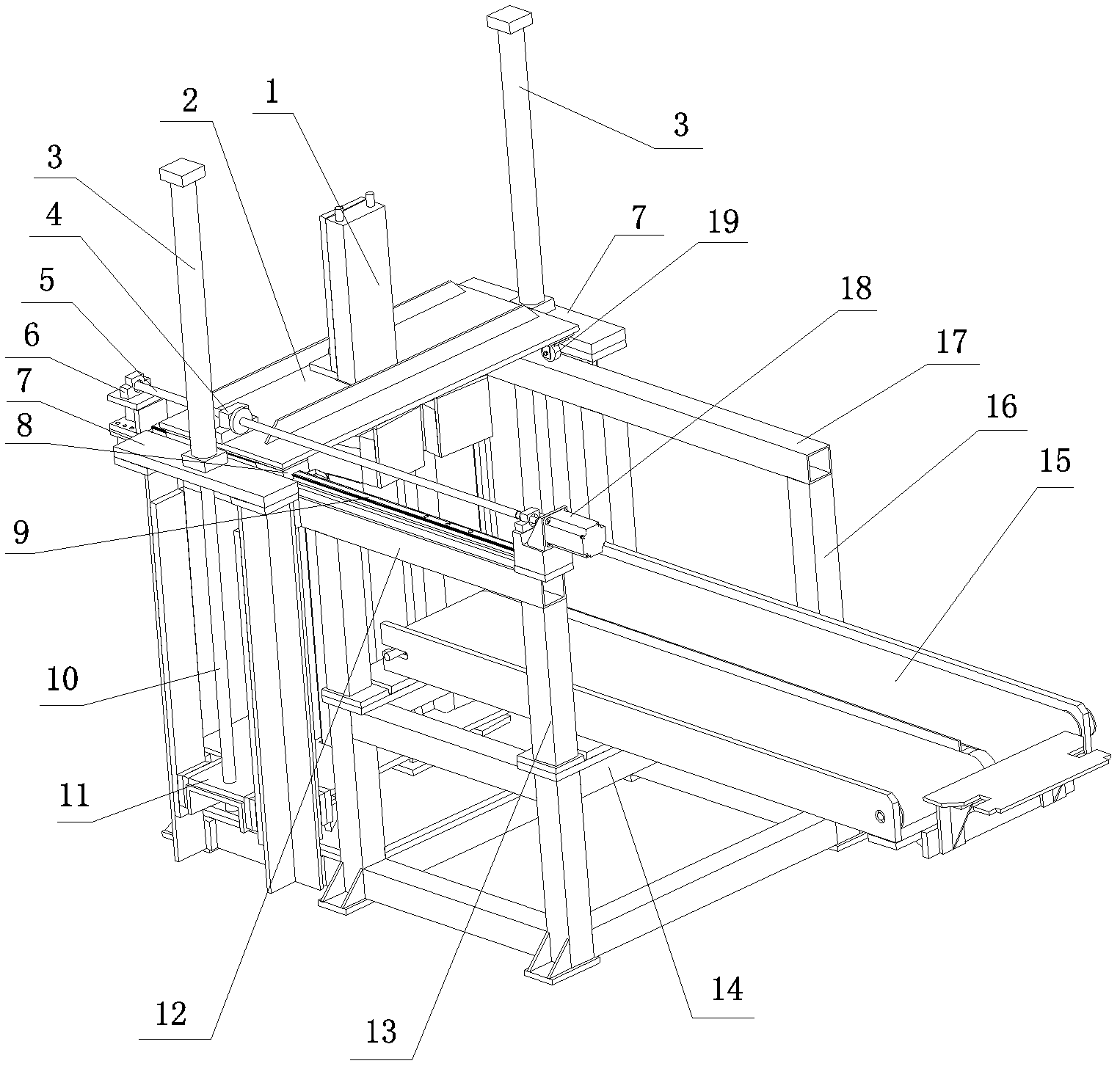

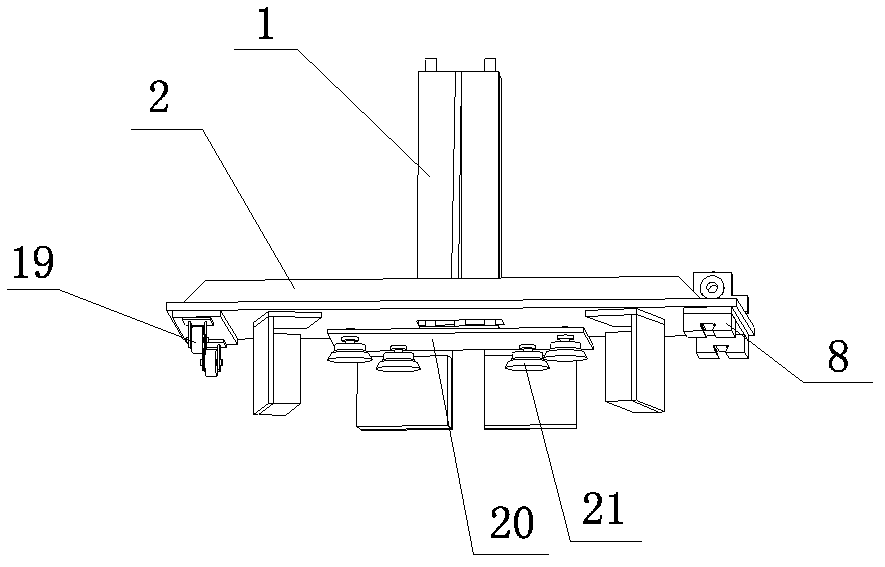

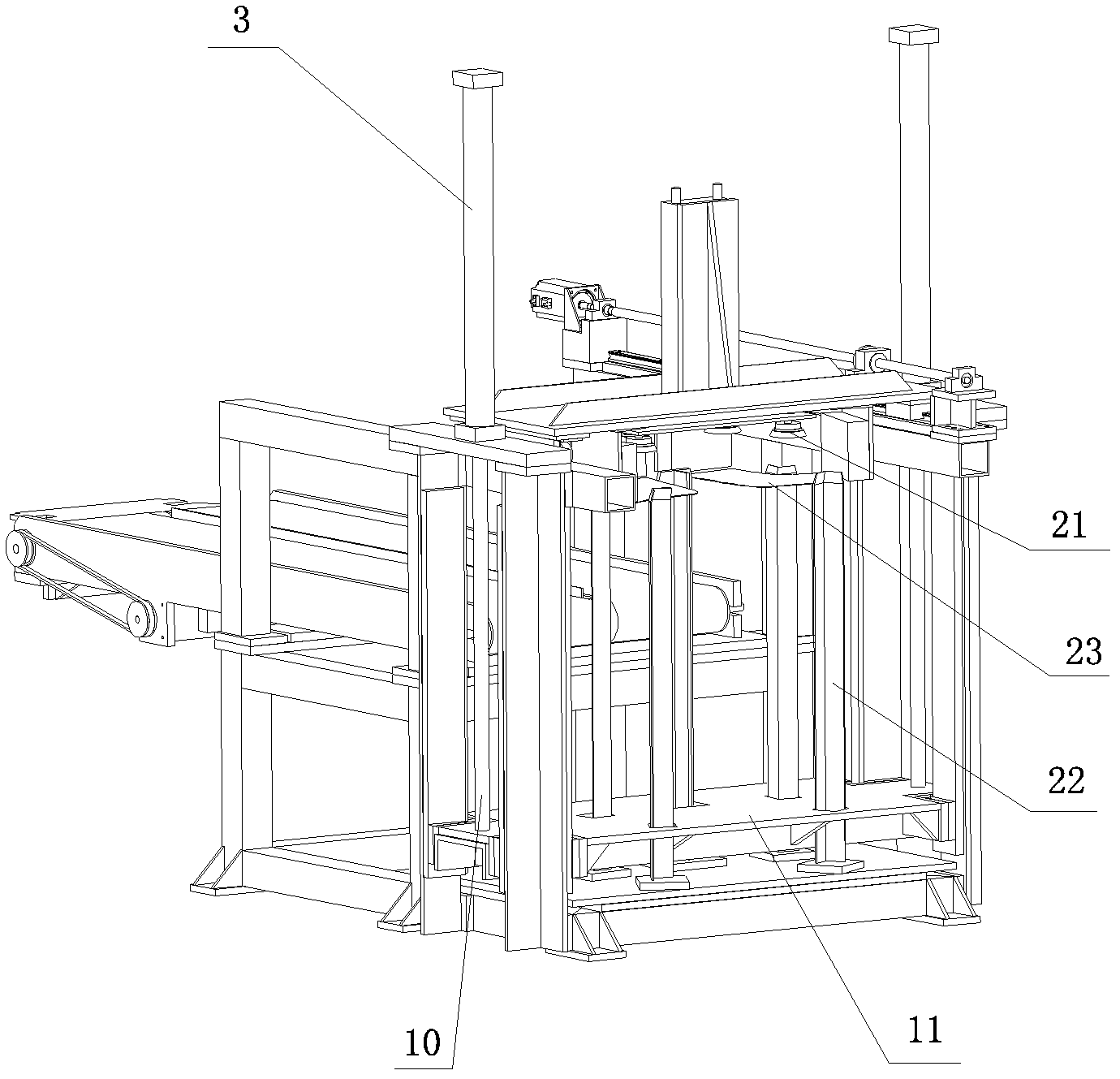

[0017] Such as Figures 1 to 3 As shown, the electromagnetic feeding device of the present invention includes two rows of support frames 13, 16, a support beam I12 and a support beam II 17 that are respectively arranged on the tops of the two rows of support frames 13, 16 and are parallel to each other, supported on the support beam I12 And the mobile platform 2 on the support beam II17, the middle part of the mobile platform 2 is connected with the cylinder I1, the piston push rod of the cylinder I1 passes through the mobile platform 2 and connects with the connecting plate 20 at the bottom of the mobile platform 2, the bottom surface of the connecting plate 20 is connected with The electromagnet 21 that sucks the workpiece is fixedly connected with the slide rail 9 on the support beam I12, and the bottom surface of the side of the mobile platform 2 corresponding to the support beam I12 is fixedly connected with the slider 8 that is set on the slide rail 9 and can slide relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com