Crosshead shoes driving reducer for multi-joint robot

A cross slider and reducer technology, which is applied in the direction of mechanical equipment, transmission devices, transmission device parts, etc., can solve the problems of low processing precision of transmission parts, unstable transmission, high wear rate, etc., and achieve the elimination of design defects and stable transmission Reliable, low mechanical wear rate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

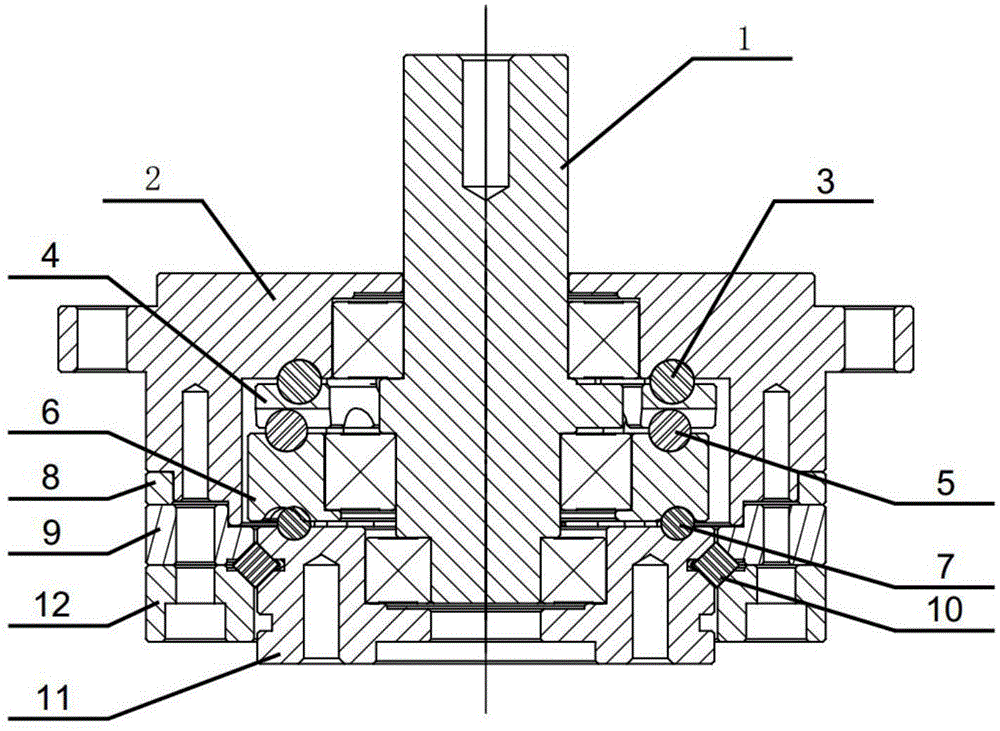

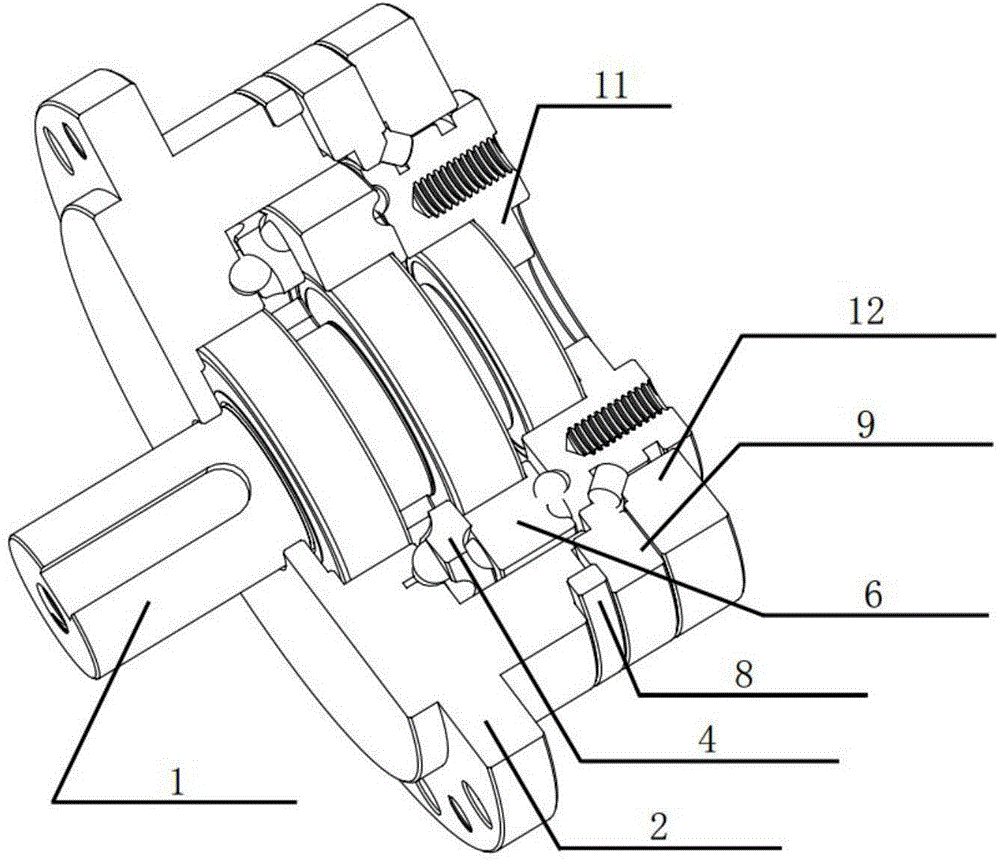

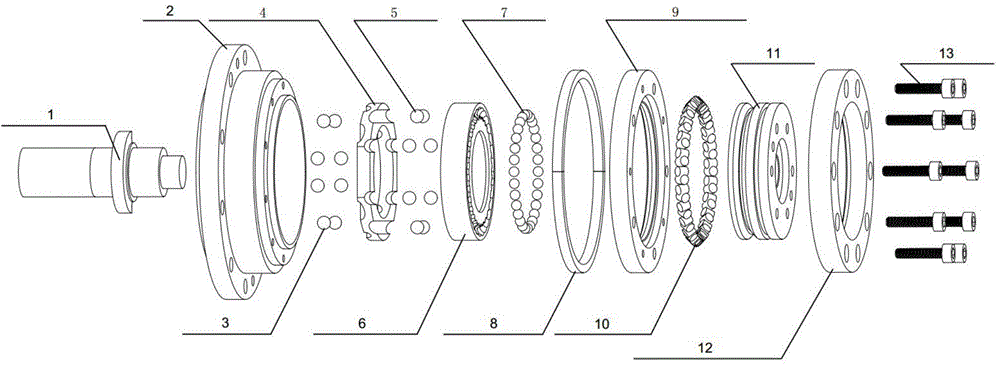

[0016] see Figure 1-3 , the present invention is used for the cross slider drive reducer of the multi-joint robot, including the input eccentric shaft 1, the body 2, the driving ball 3 on the A surface, the cross slider 4, the driving ball 5 on the B surface, the trajectory controller 6, and the driving ball 7 , Clearance adjustment plate 8, cross roller bearing upper cover 9, cross roller 10, output shaft 11, cross roller bearing lower cover 12 and fastening screw 13.

[0017] An input eccentric shaft 1, an Oldham slider 4, a trajectory controller 6, a cross roller bearing and an output shaft 11 are installed in the body 2. According to the rigidity and stability requirements of the reducer, the structure of the cross slider 4 is provided with an A surface for installing the transmission ball 3 on the A surface and the transmission ball 5 on the B surface on the upper and lower surfaces (ie, the A and B surfaces) respectively. The transmission track and the B-side drive tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com