Parallel serial multi-molded surface gear planetary gear compound aviation transmission system

A transmission system and face gear technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of not being able to meet the special transmission form and the simple form of the transmission system, and achieve a novel transmission principle and broad business The effect of prospect, big social benefit and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

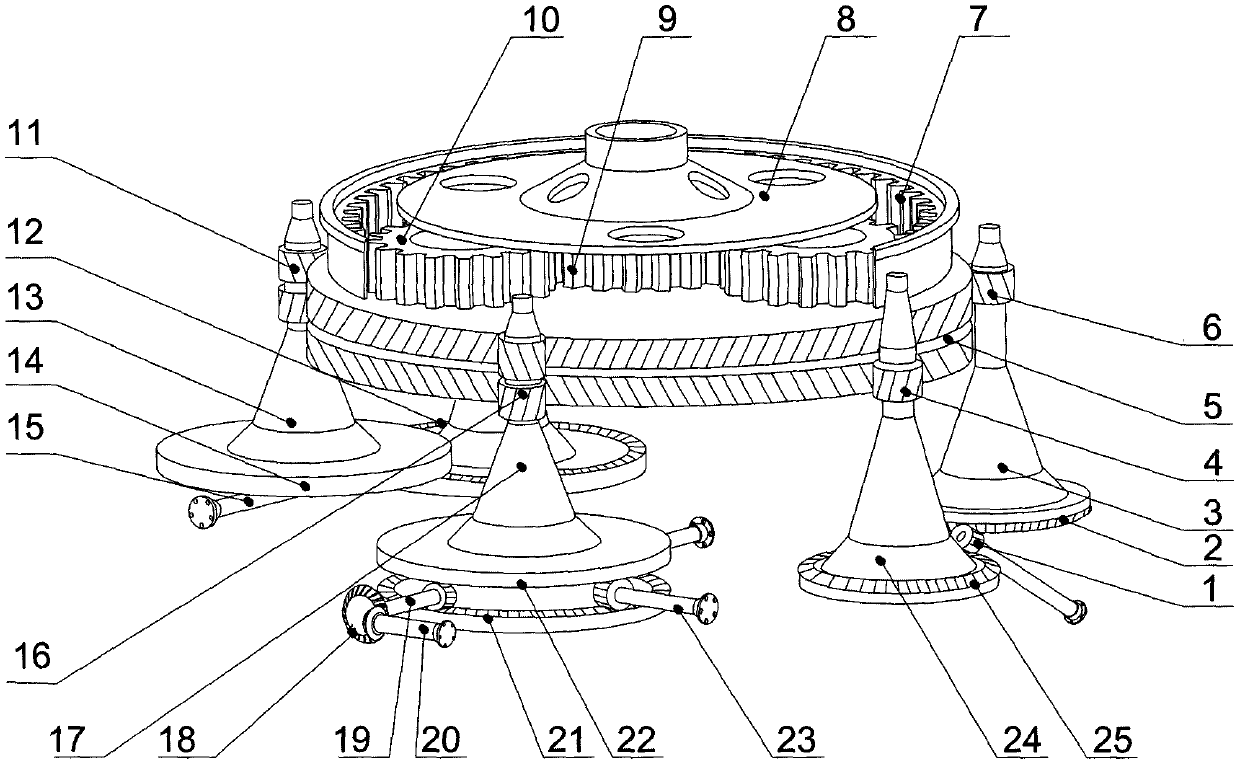

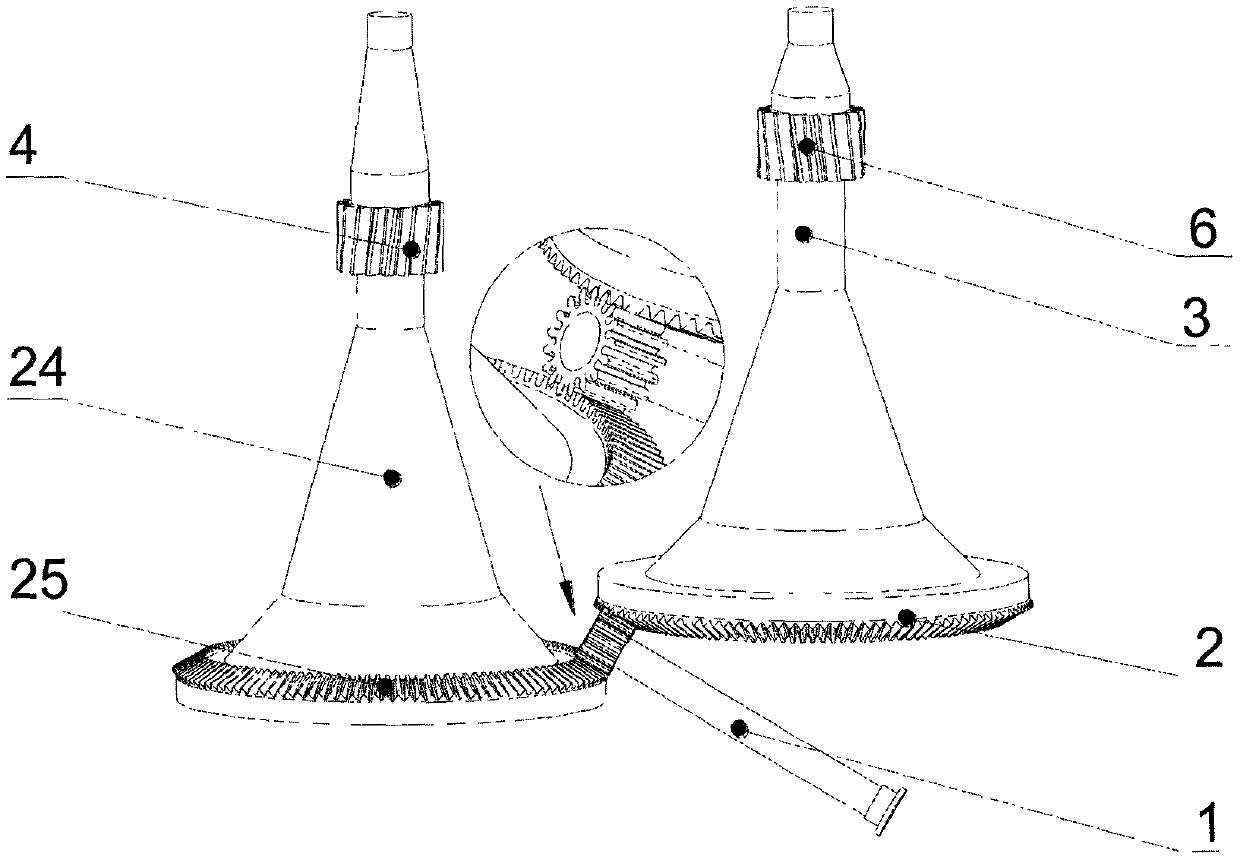

[0028] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with Figure 1-Figure 6 The present invention will be specifically described.

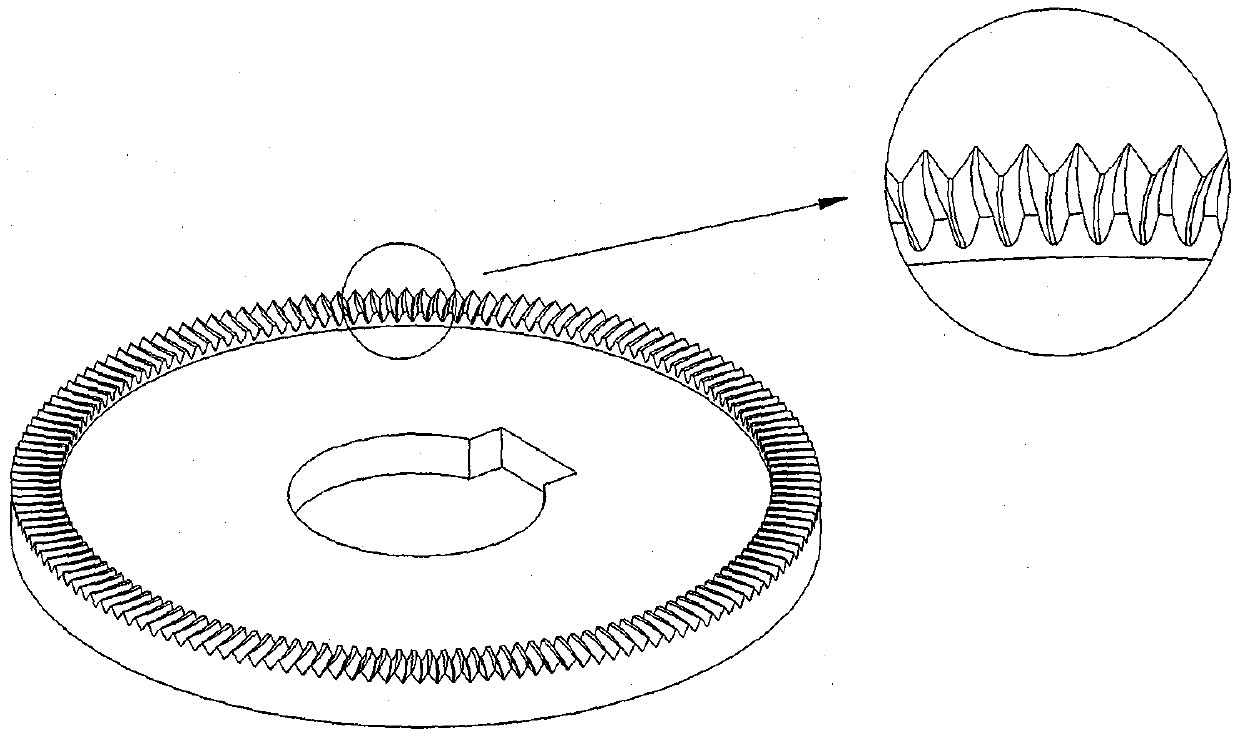

[0029] A hybrid multi-configuration face gear planetary composite aviation transmission system, including a right input shaft 1, a lower non-orthogonal face gear 2, a second connecting shaft 3, a lower helical gear 4, a center herringbone gear 5, and an upper helical gear 6 , spiral tooth inner ring gear 7, planet carrier 8, spiral tooth sun gear 9, spiral tooth planetary gear 10, second herringbone gear 11, upper spur gear 12, fourth connecting shaft 13, lower spur gear 4 , left input shaft 15, third herringbone gear 16, fifth connecting shaft 17, large bevel gear 18, gear shaft 19, left output shaft 20, upper arc tooth surface gear 21, lower arc tooth surface gear 22, right output shaft 23. The first connecting shaft 24, the upper non-orthogonal face gear 25, the third conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com