Canning equipment

A technology of filling equipment and driving device, which is applied in the field of food production equipment, can solve problems such as unfavorable, inability to cut a single food, improve the appearance of a single food, etc., and meet the requirements of reasonable structure, improved cutting effect, and good transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

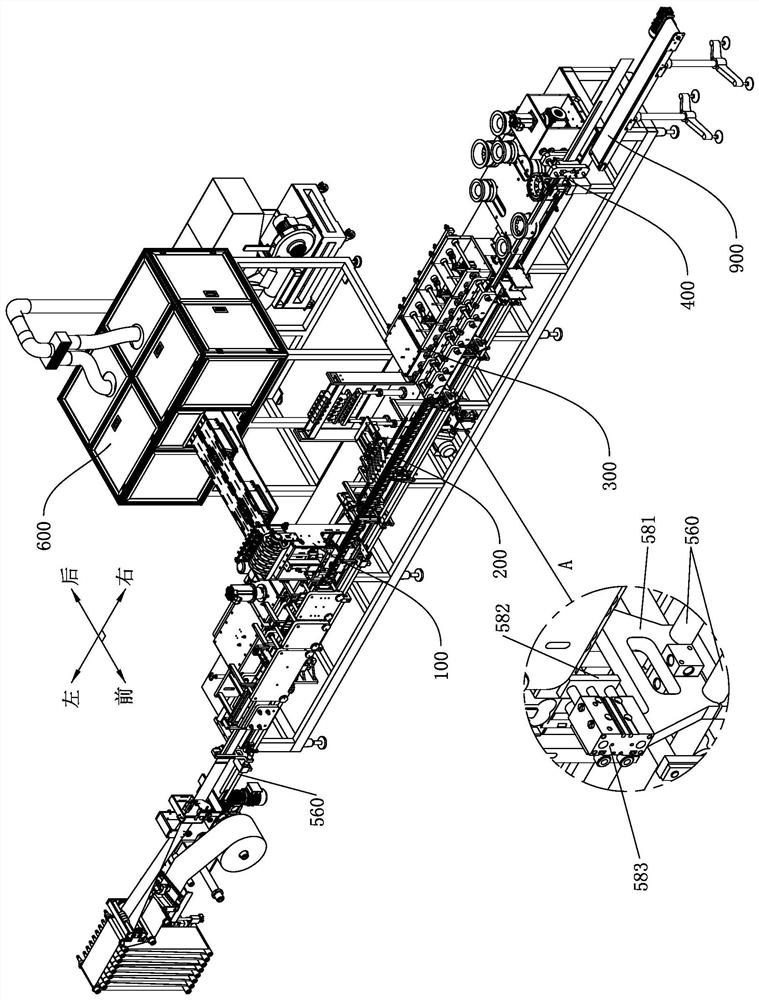

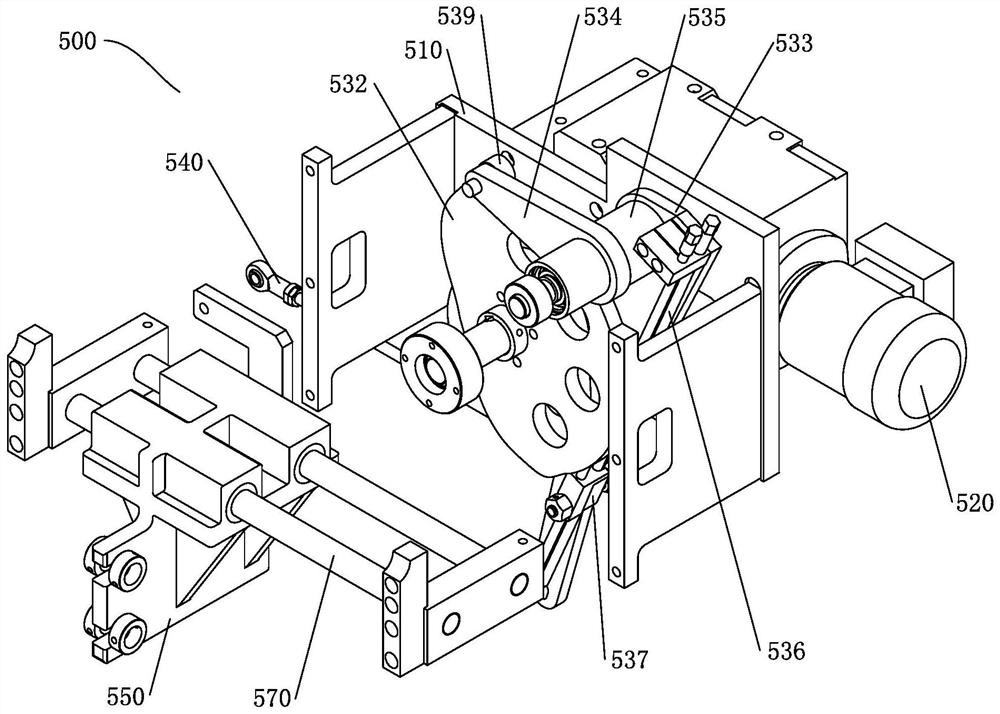

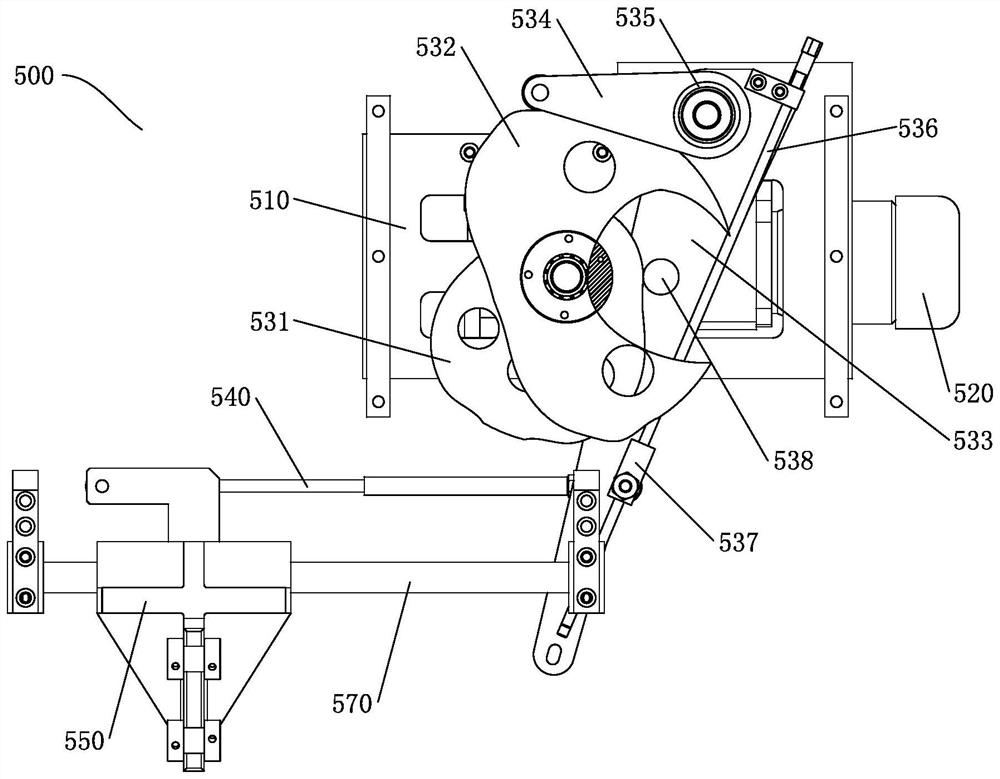

[0051] Such as Figure 1 to Figure 24 As shown, Embodiment 1 provides a filling device, including a horizontal dragging device 500 and a cutting device 400. The horizontal dragging device 500 includes a dragging bracket 510 , a dragging motor 520 , a dragging transmission mechanism and a clamping mechanism. The dragging motor 520 and the dragging transmission mechanism are respectively arranged on opposite sides of the dragging bracket 510 . The drag transmission mechanism comprises a cam link transmission assembly, a guide rod 570, a drag seat 550 and a drag rod 560. Consistent with the conveying direction, the drag seat 550 is sheathed on the guide rod 570 and the drag seat 550 is connected to the cam link transmission assembly, and the drag bar 560 is fixed on the drag seat 550 . The clamping mechanism is fixed on the drag rod 560, and has a clamped state and a loosened state. When the clamping mechanism is in the clamped state, the dragging motor 520 drives the clamping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com