Patents

Literature

42results about "Packaging lollipops" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

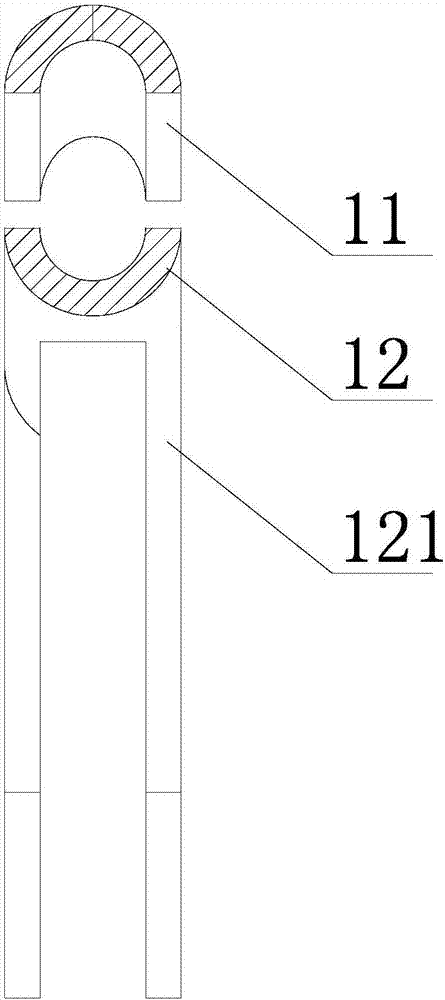

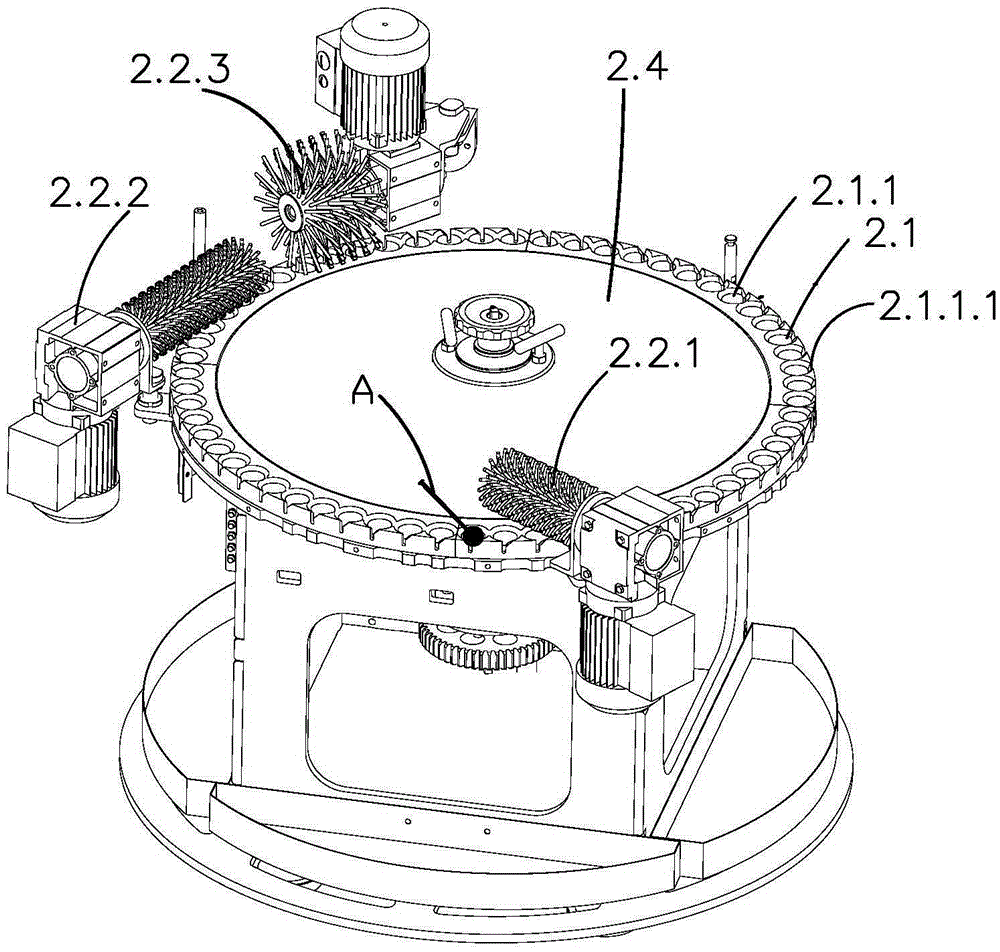

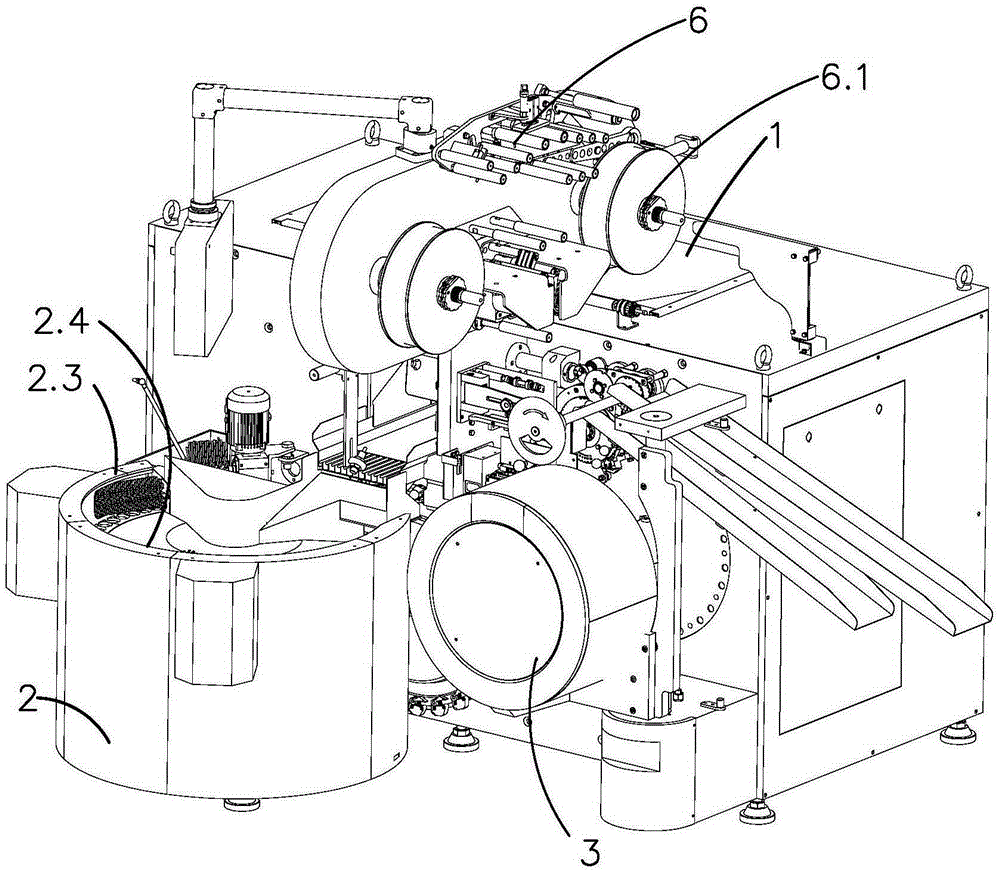

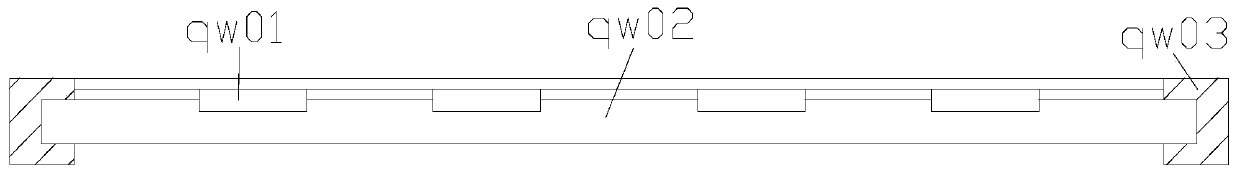

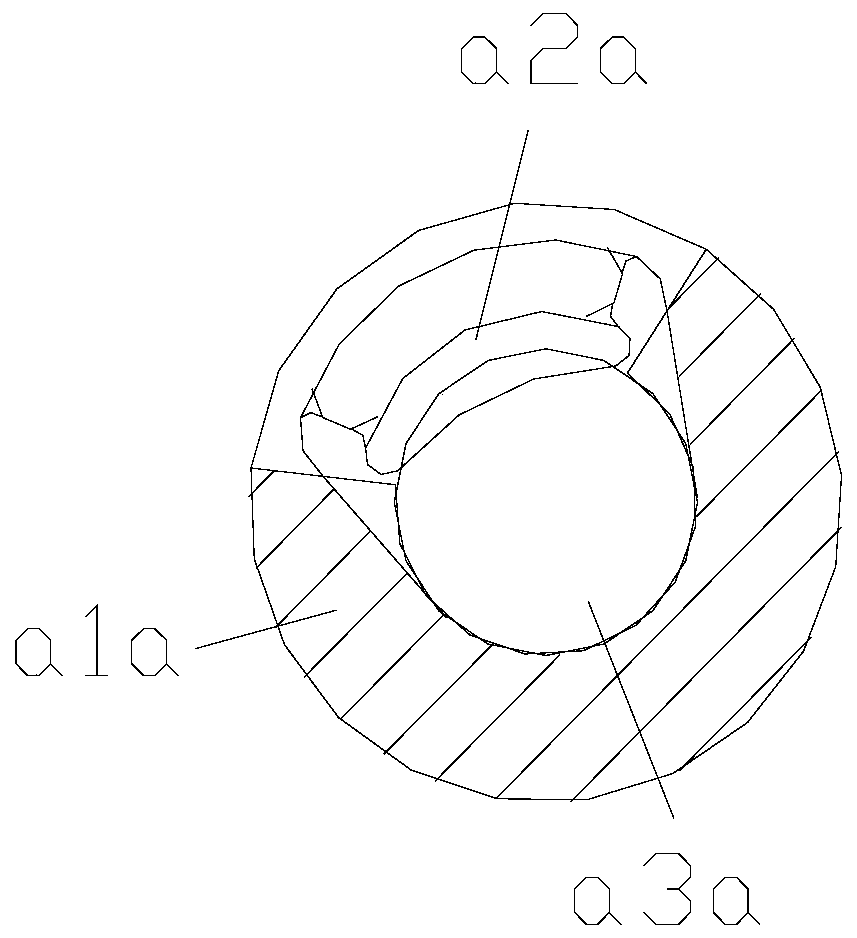

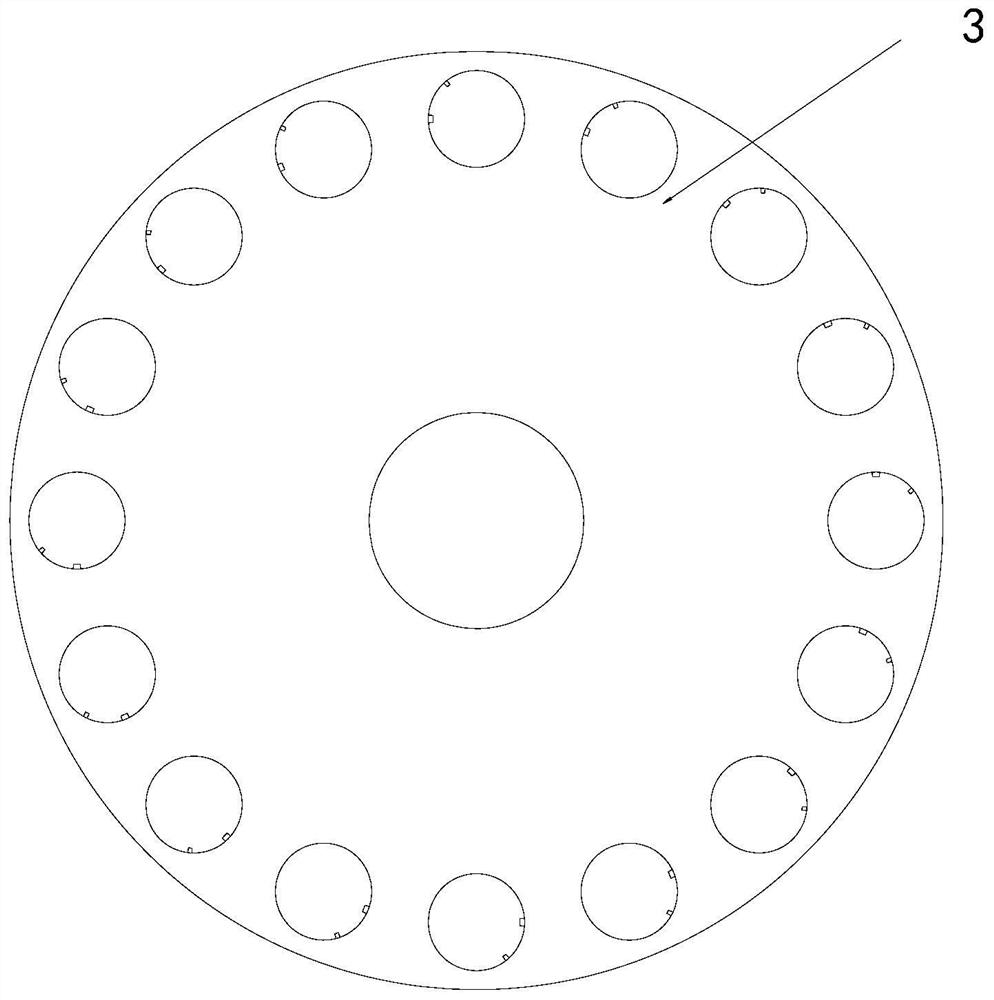

Loading disc of feeding conveying device of candy wrapping machine

ActiveCN103625686AIncrease productivityEffective filteringPackaging lollipopsEngineeringMechanical engineering

The invention relates to a loading disc of a feeding conveying device of a candy wrapping machine. The loading disc comprises a distribution disc capable of rotating and a bearing ring, the bearing ring is located below a containing hole and used for supporting candies contained in the containing hole to prevent the candies from dropping out from the containing hole, the distribution disc depends on rotation to convey the candies in the containing hole to the target position, a notch is formed in the target position of the bearing ring, and the candies in the containing hole in the position can drop out from the notch. The loading disc of the feeding conveying device is characterized by further comprising a transferring disc capable of rotating, at least one protrusion is arranged on the transferring disc, the protrusion capable of rotating along with the transferring disc can serve as a support located below the containing hole in the position of the notch of the bearing ring when needed, and the candies in the containing hole cannot drop out from the position of the notch of the bearing ring and can reenter the loading process along with the rotation of the distribution disc.

Owner:BOSCH PACKAGING TECH HANGZHOU

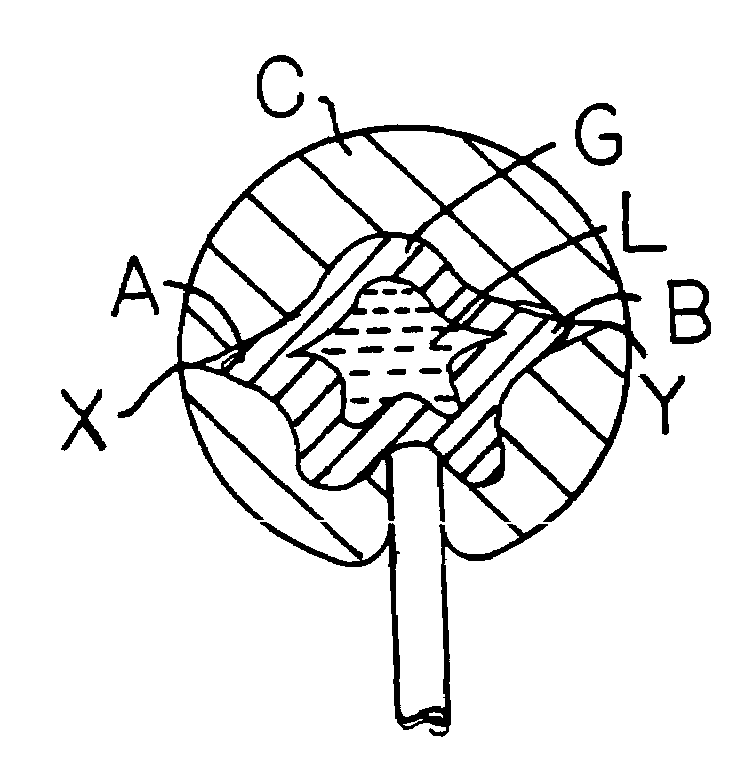

Three-layered centerfilled gum product with candy shell

InactiveUS7452558B2Enhance sensory effectSatisfy the tasteConfectioneryChewing gumFilling materialsEngineering

A three-phase center-filled gum or bubble gum candy lollipop product. An extruded gum or bubble gum material has a semi-liquid center-fill material added to it in a batch forming mechanism simultaneously with the formation of an exterior candy shell. The three-phase rope of material is formed into lollipop candy members in a forming machine and lollipop sticks are inserted into them. The formed lollipop products are then cooled, tumbled and prepared for further processing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

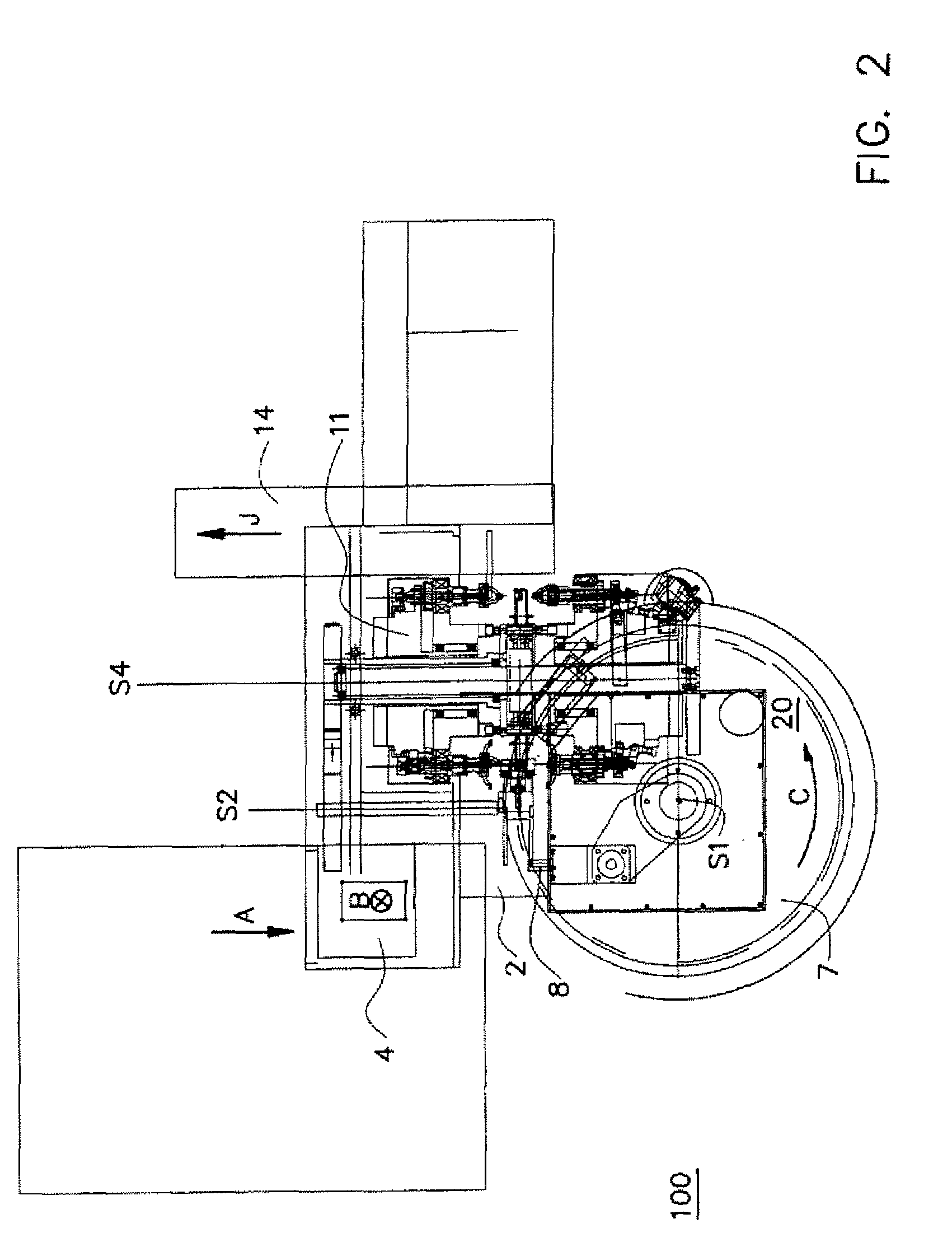

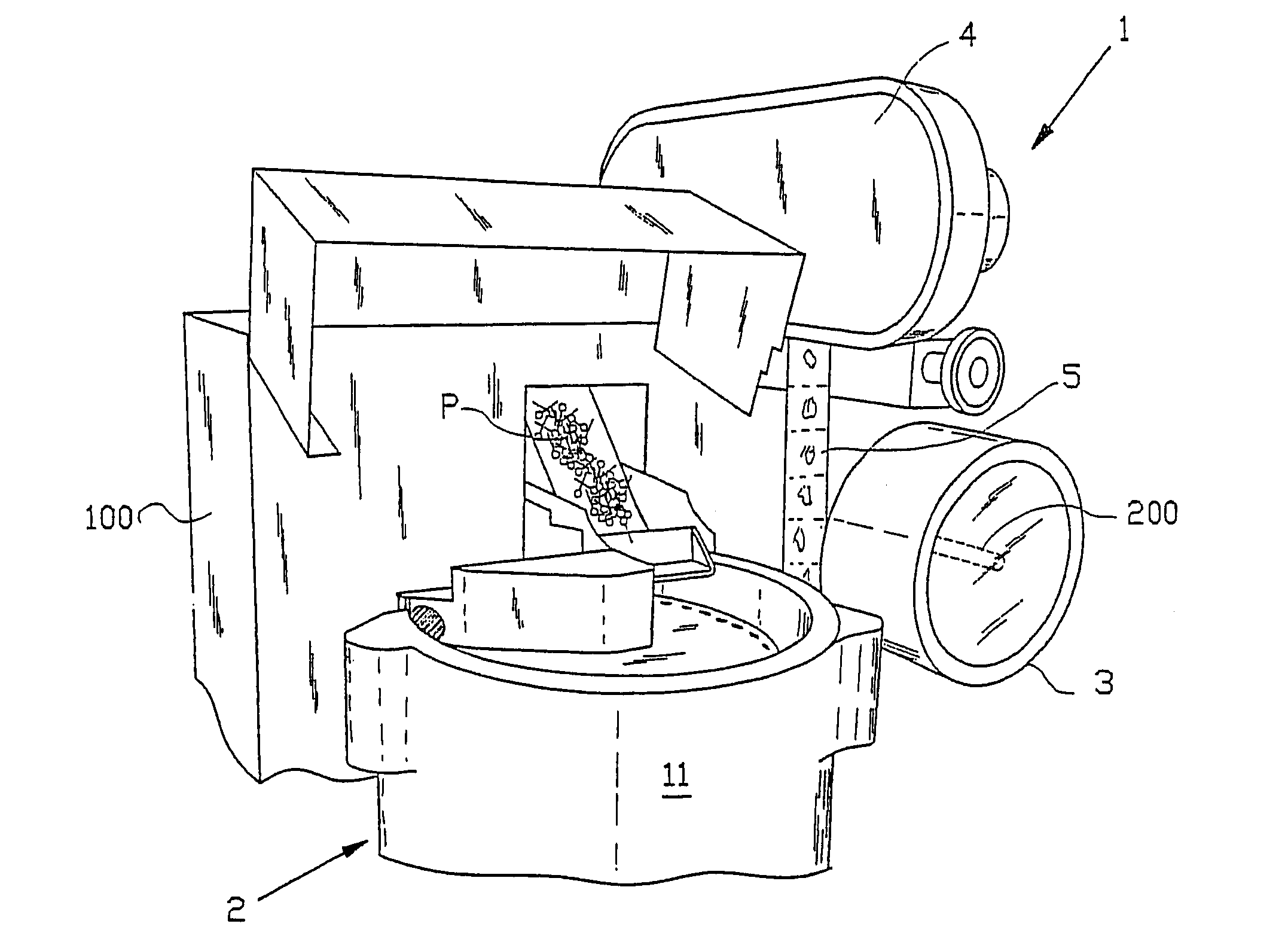

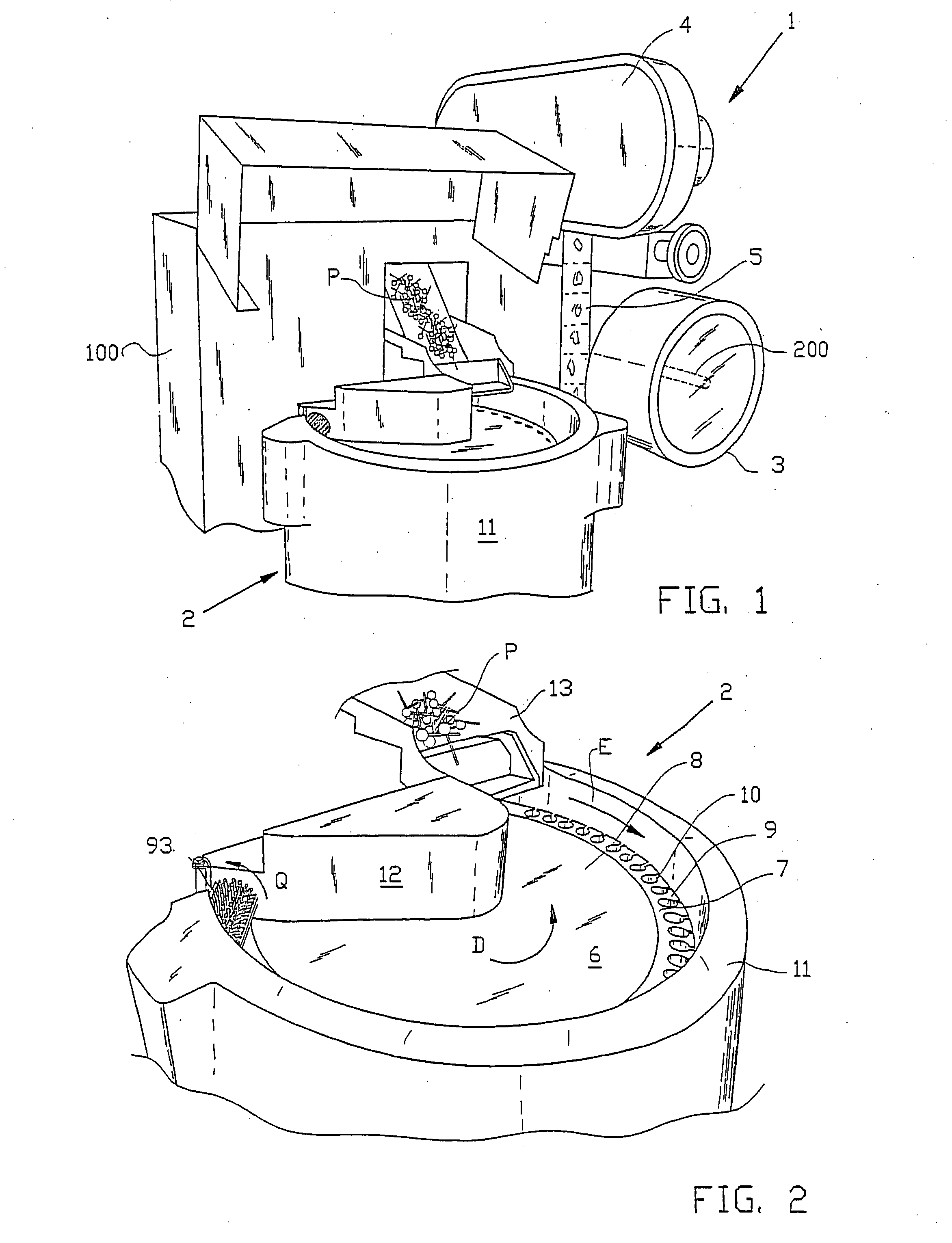

Packaging machine for lollipops and other confectionery

ActiveUS7730699B2Increase clamping forceReliable and high outputWrapper folding/bending apparatusConveyor wrappingPackaging machineEngineering

Packaging machine for packaging lollipops provided with a stick and a head in a film / foil sheet, comprising a rotatably driven drum having a series of lollipop holders thereon, the drum furthermore being provided with a series of film / foil folding means for folding a respective film / foil sheet around the head around a longitudinal center axis substantially parallel to the stick, the device furthermore comprising a series of twisters for twisting a film / foil tube section protruding in the longitudinal direction of the lollipop head while continuing to clamp the lollipop head and while the drum continues to rotate.

Owner:CFS WEERT BV

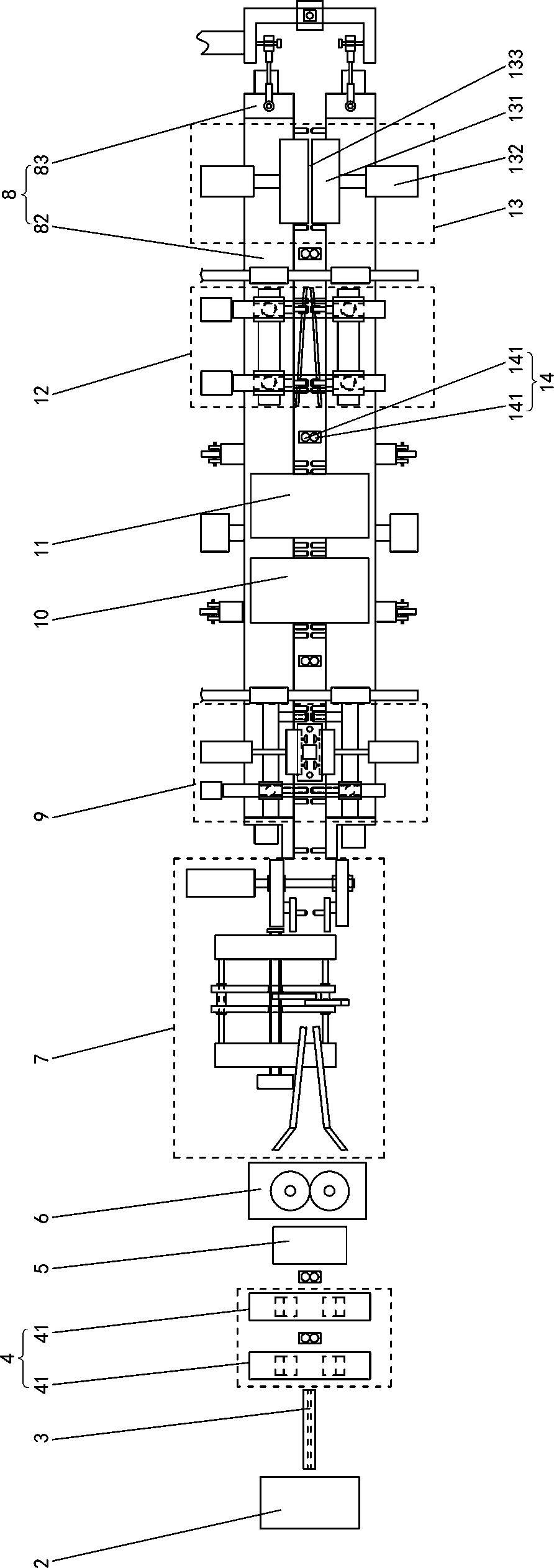

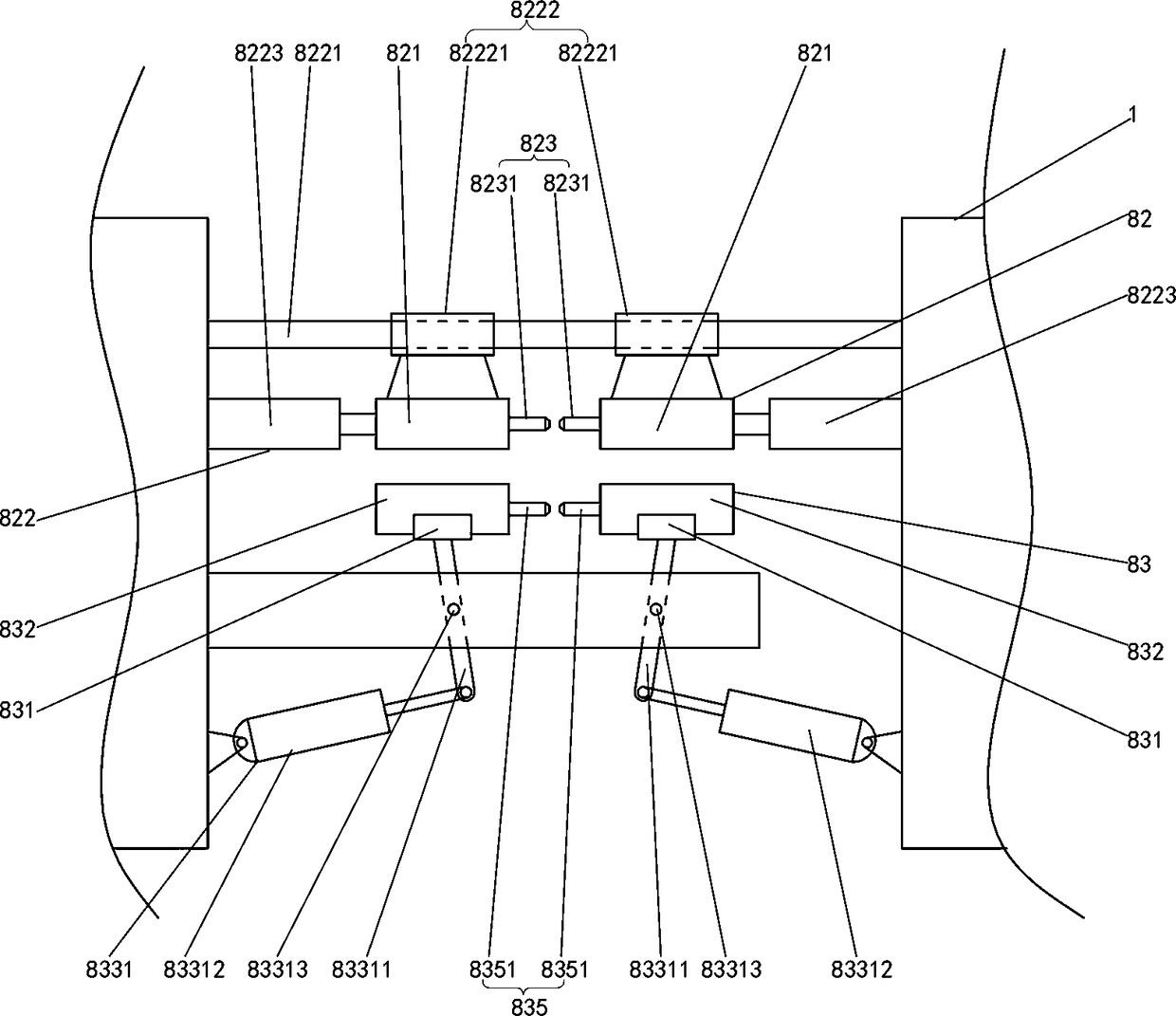

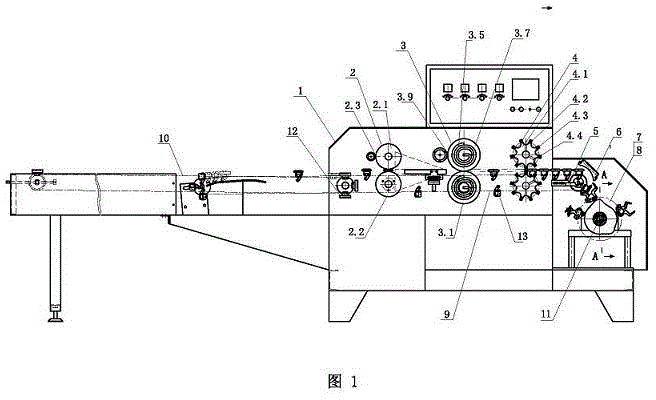

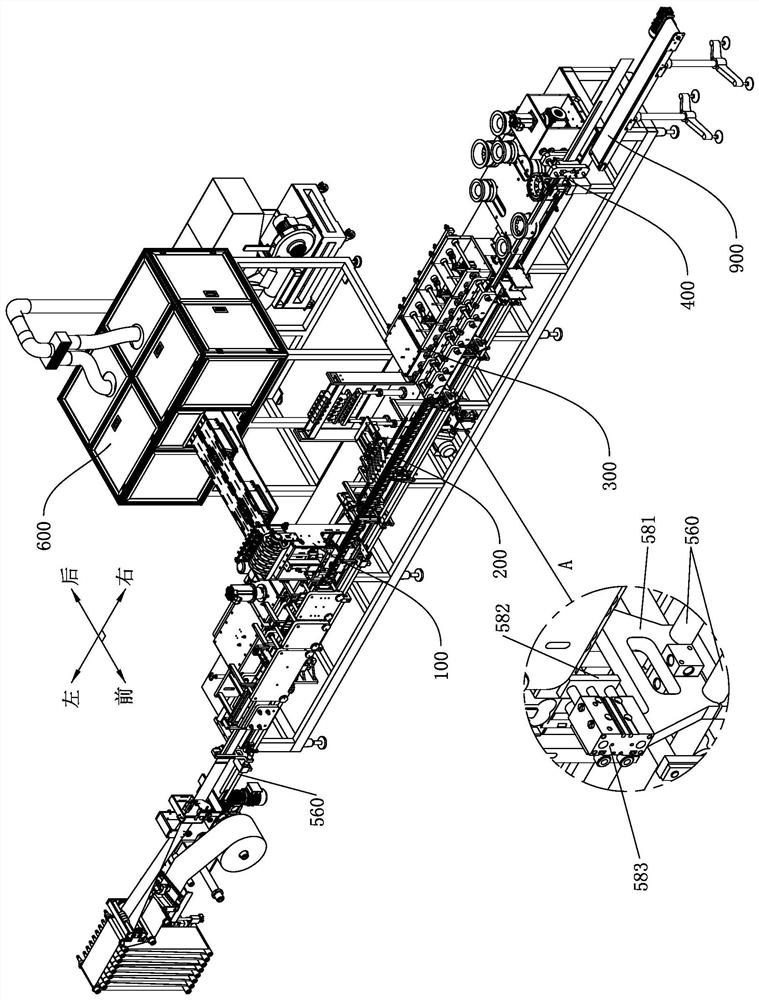

Whistling lollipop packaging machine

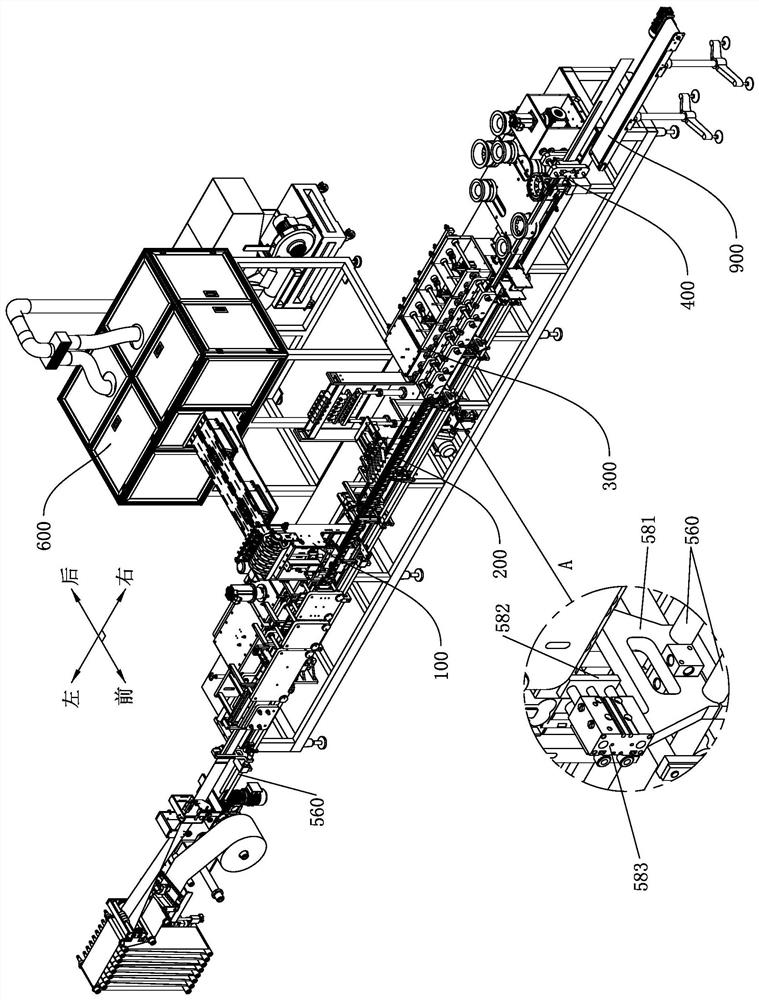

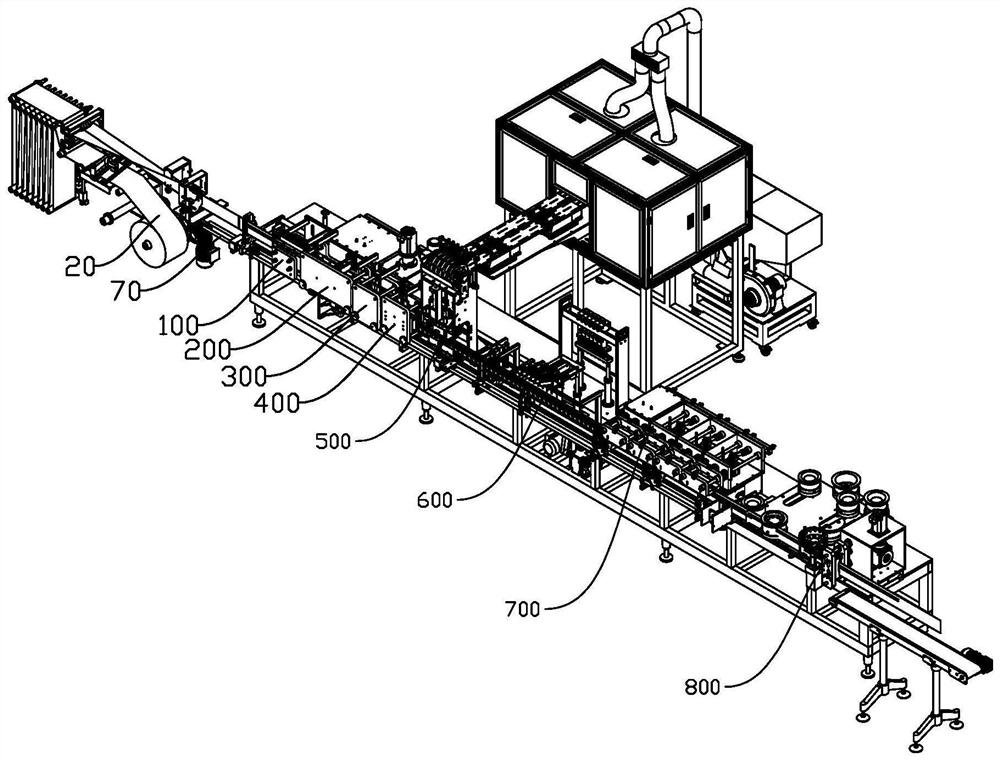

PendingCN108639422ARealize stepping movementNeatly combinedWrapper twisting/gatheringPackaging lollipopsPackaging machine

The invention disclose a whistling lollipop packaging machine which comprises a machine frame, a packaging film unrolling device, a packaging film folding device, a sealing device, an easy-to-tear opening shear device, a clamping conveying device, a bag body cutting device, a horizontal bag conveying mechanism, a bag opening device, a lollipop powder filling device, a lollipop filling device, a bag opening straightening device, a sealing device and a bag return device. The packaging film unrolling device, the packaging film folding device, the sealing device, the easy-to-tear opening shear device, the clamping conveying device and the bag body cutting device are sequentially arranged in the conveying direction of packaging films, the bag opening device, the lollipop powder filling device,the lollipop filling device, the bag opening straightening device, the sealing device and the bag return device are sequentially arranged in the bag conveying direction of the horizontal bag conveyingmechanism, and the horizontal bag conveying mechanism is arranged between the bag body cutting device and the sealing device. The horizontal bag conveying mechanism organically integrates bag makingand lollipop filling into a whole, the whole machine is compact in structure, low in overall manufacturing cost and small in occupied space, and it is ensured that bag openings of packaging bags are sealed in order.

Owner:汕头市茂发食品有限公司 +1

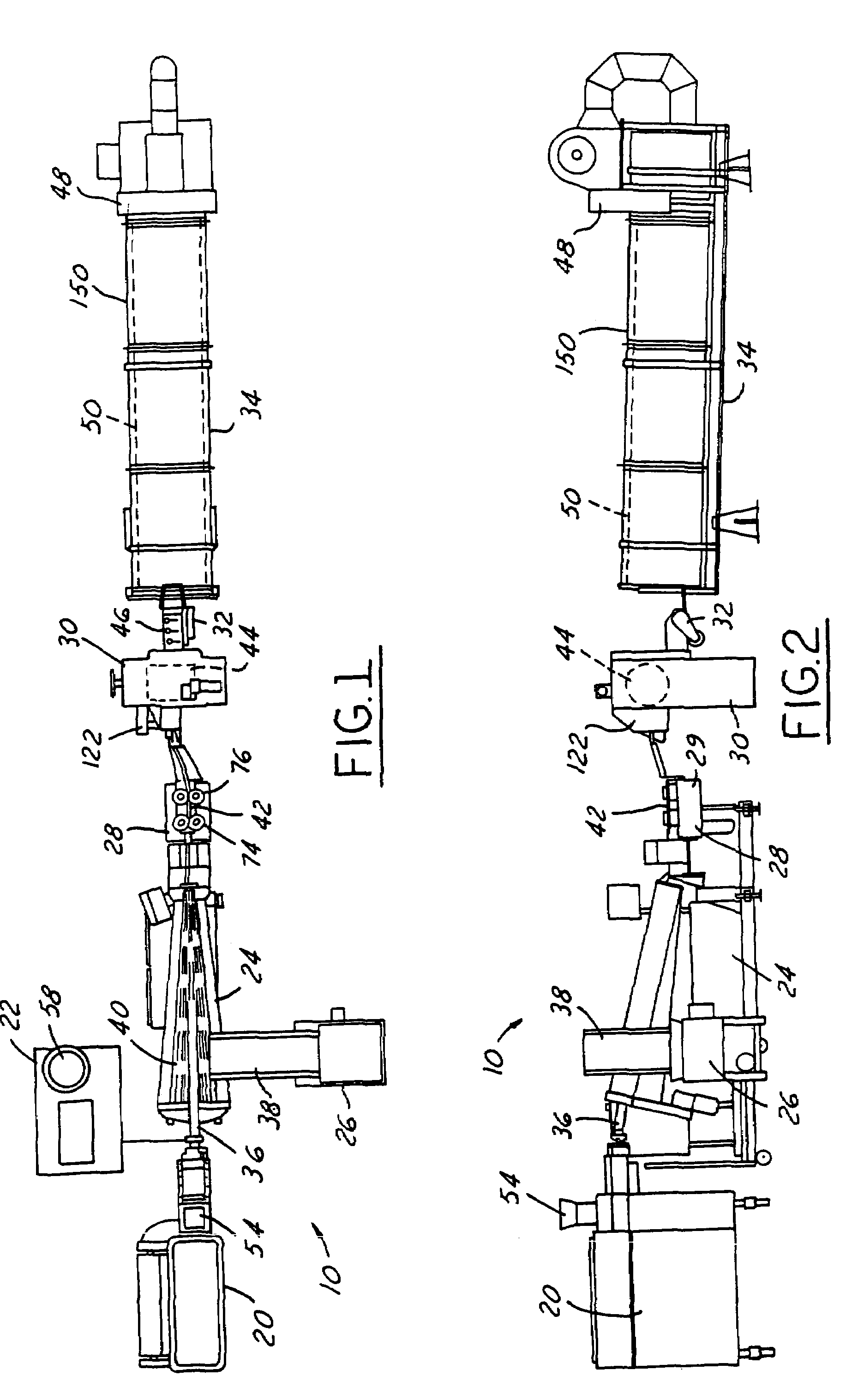

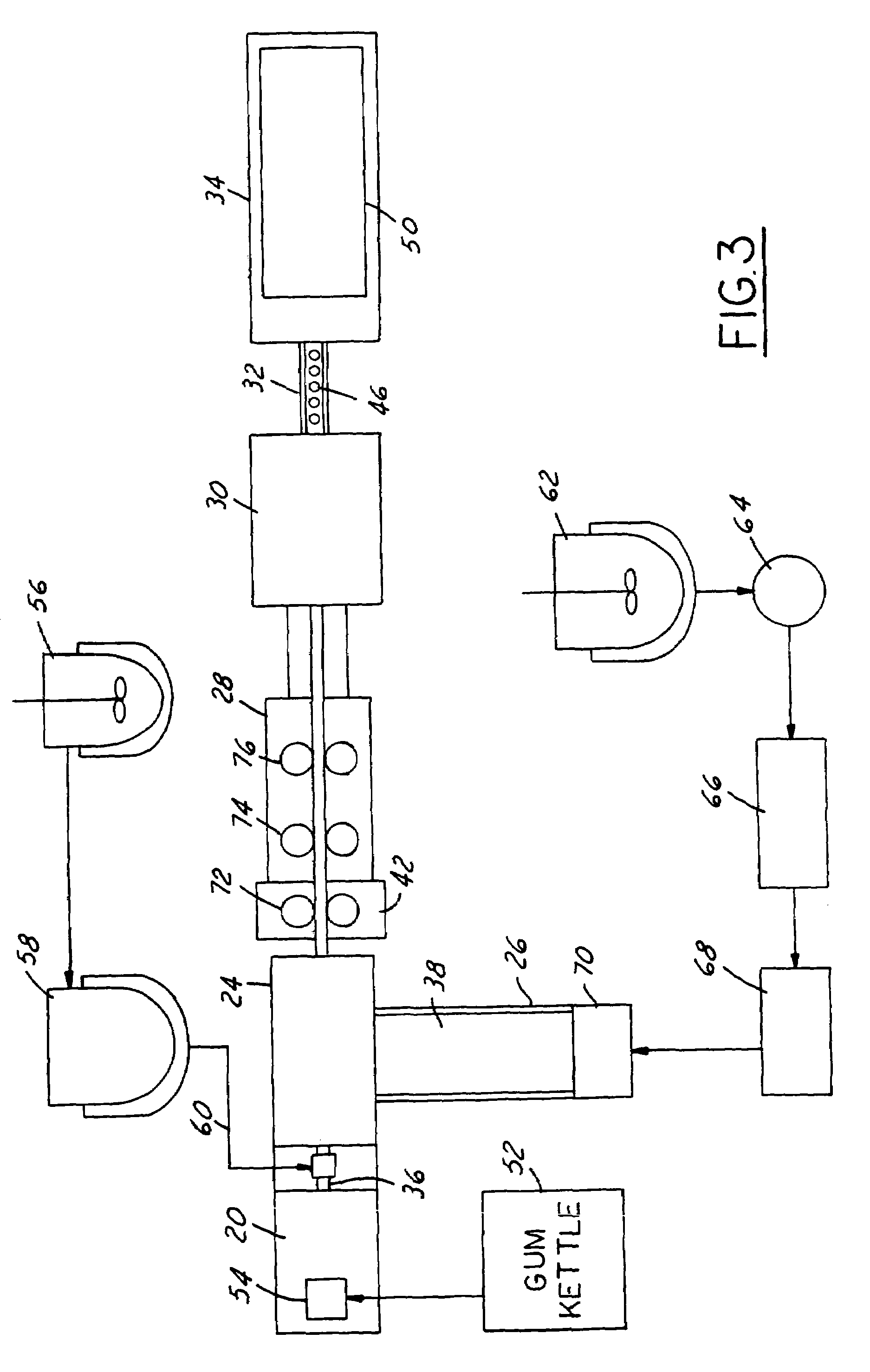

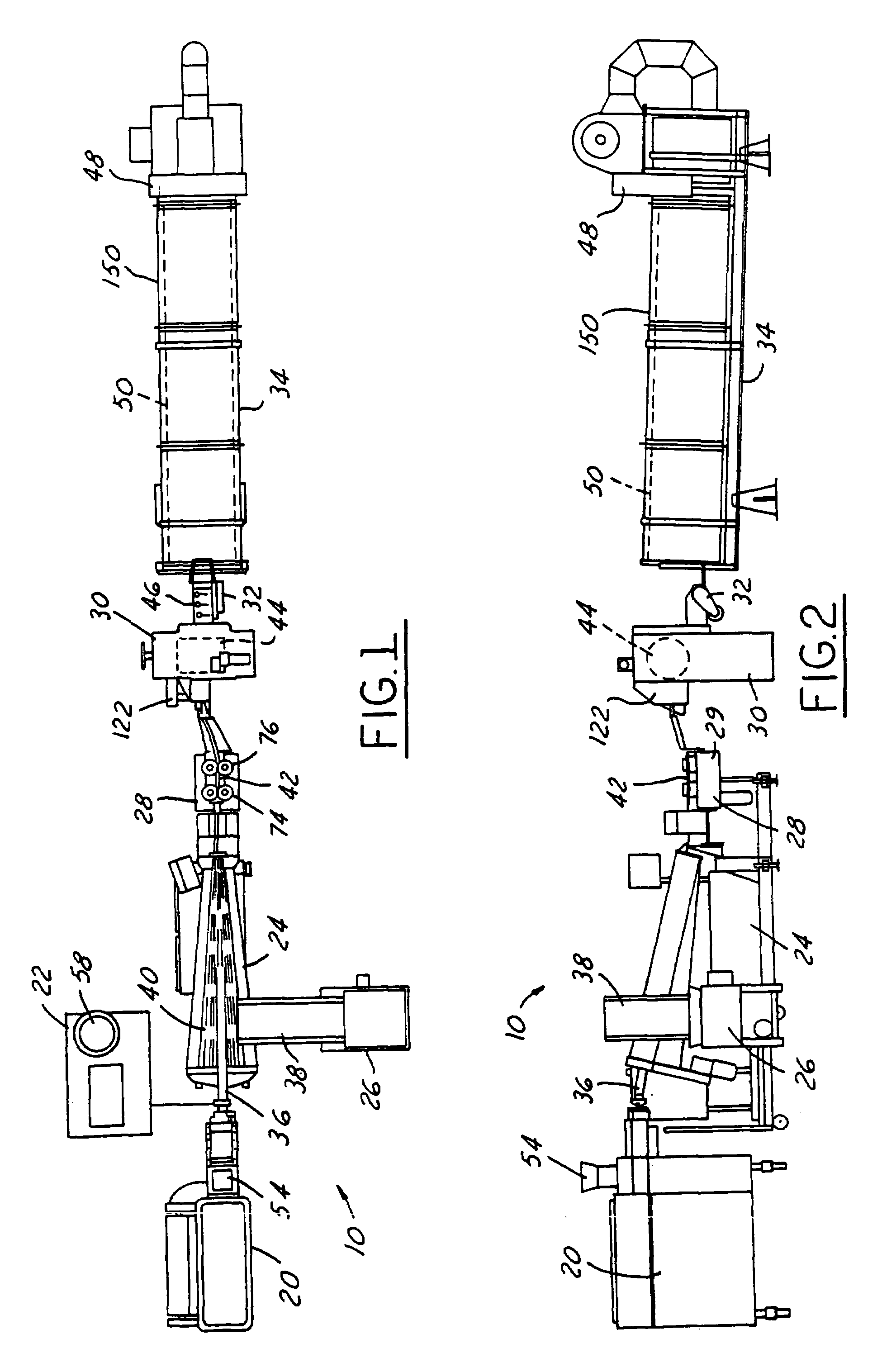

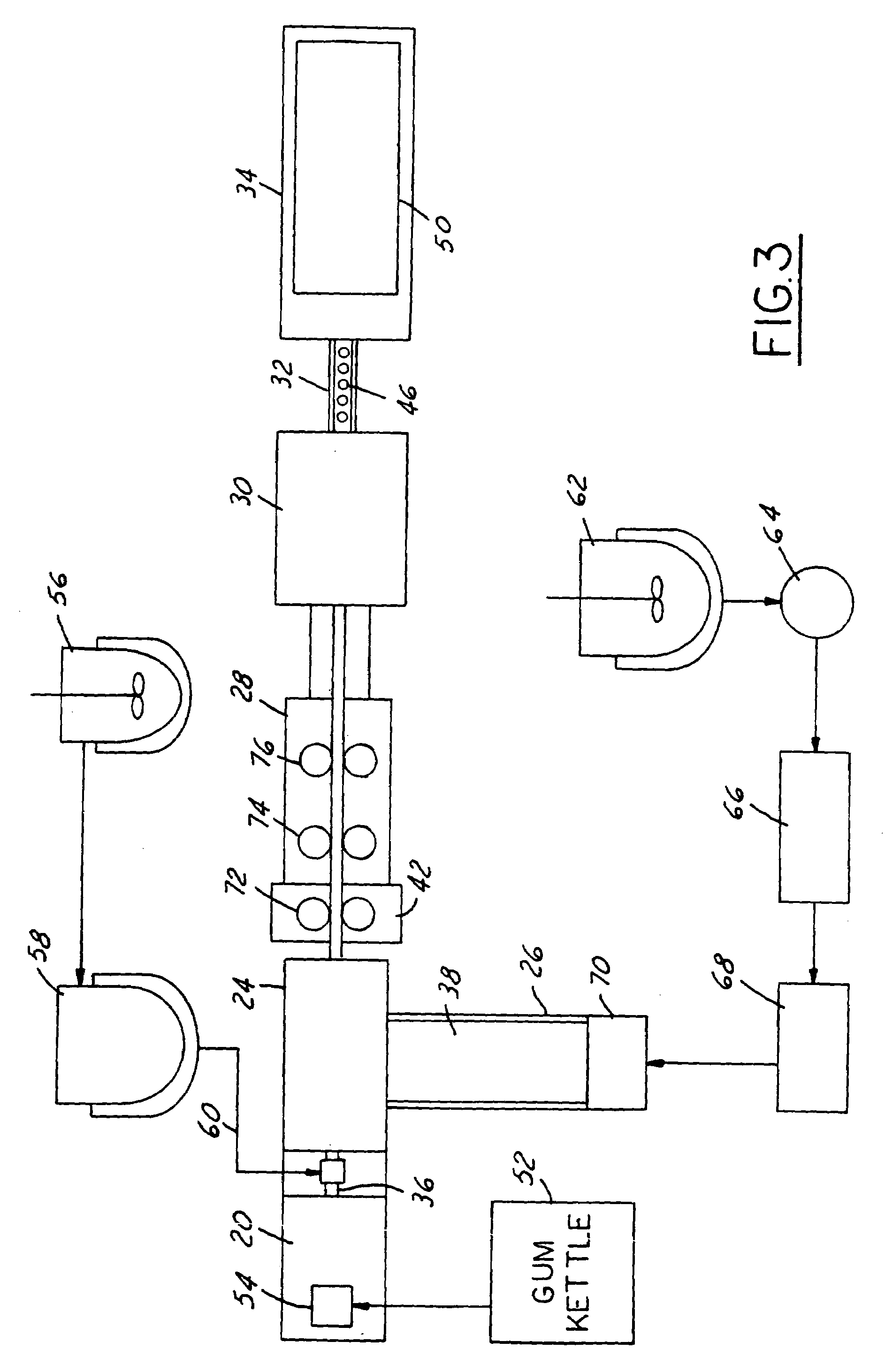

Method of making centerfilled gum product with candy shell

InactiveUS7332186B2Enhance sensory effectSatisfy the flavorFrozen sweetsConfectioneryFilling materialsMechanical engineering

A three-phase center-filled gum or bubble gum candy lollipop product. An extruded gum or bubble gum material has a semi-liquid center-fill material added to it in a batch forming mechanism simultaneously with the formation of an exterior candy shell. The three-phase rope of material is formed into lollipop candy members in a forming machine and lollipop sticks are inserted into them. The formed lollipop products are then cooled, tumbled and prepared for further processing.

Owner:INTERCONTINENTAL GREAT BRANDS

Lollipop ribbon kinking and packing machine

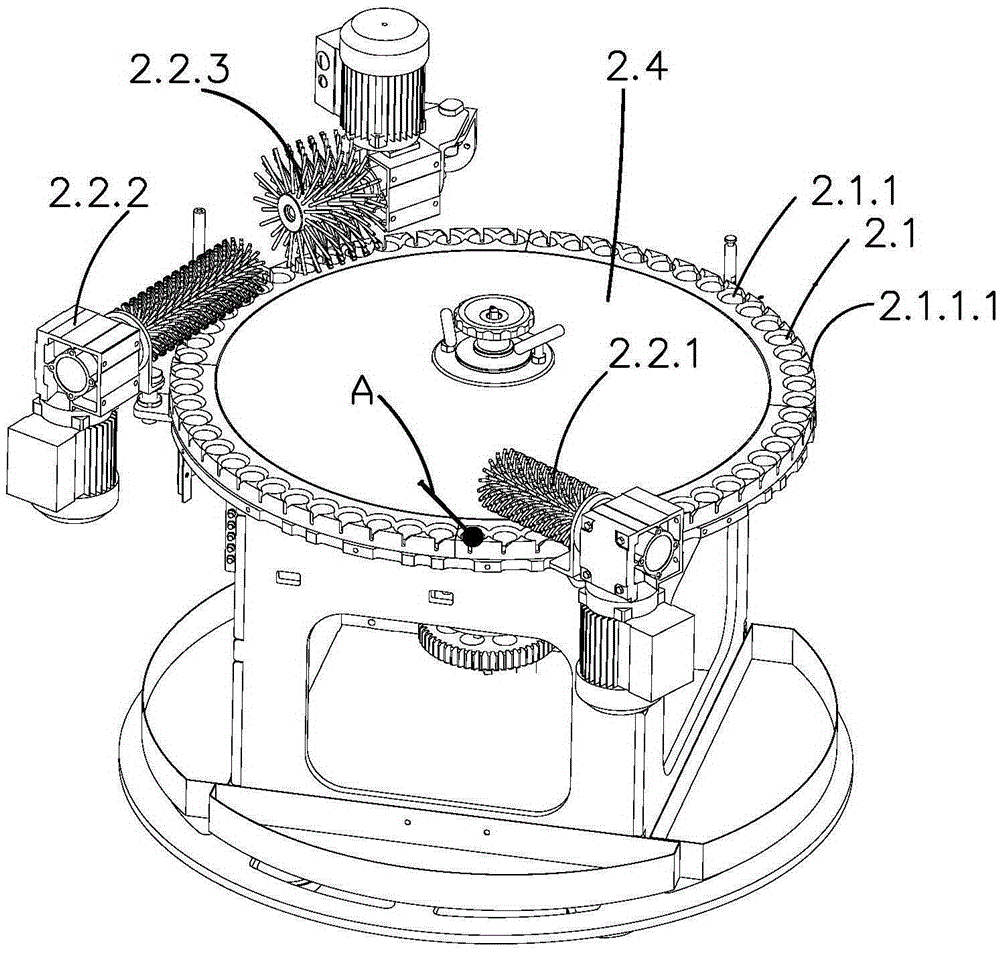

ActiveCN106882413AImprove aestheticsImprove work efficiencyPackaging lollipopsMechanical engineeringEngineering

The invention discloses a lollipop ribbon kinking and packing machine which comprises a lollipop bar fixing device, an arc-shaped bent pipe, a ribbon conveying device, a ribbon correcting device and a ribbon kinking device; the lollipop bar fixing device comprises a rotating disk and lollipop bar fixing seats uniformly arranged along the circumference of the rotating disk; the ribbon kinking device comprises a binding hand wheel assembly coaxially arranged with the rotating disk and kinking hands uniformly arranged along the circumference of the binding handle wheel assembly; the ribbon conveying device is arranged above one end of the arc-shaped bent pipe for ribbon conveying; the rotating disk is rotated to drive a lollipop bar on each of the lollipop bar fixing seats to push a ribbon through an arc-shaped channel to bend in the arc-shaped channel; the ribbon correcting device is arranged above the other end of the arc-shaped bent pipe and is used for correcting the ribbon on the lollipop bar to the corresponding opened kinking hand, and the kinking hand is closed to lock the ribbon and is rotated to bind. The lollipop ribbon kinking and packing machine disclosed by the invention realizes automatic binding of the lollipop ribbon through continuous mechanical operation and has the advantages of being reasonable in structure, high in production efficiency, stable in equipment and the like.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

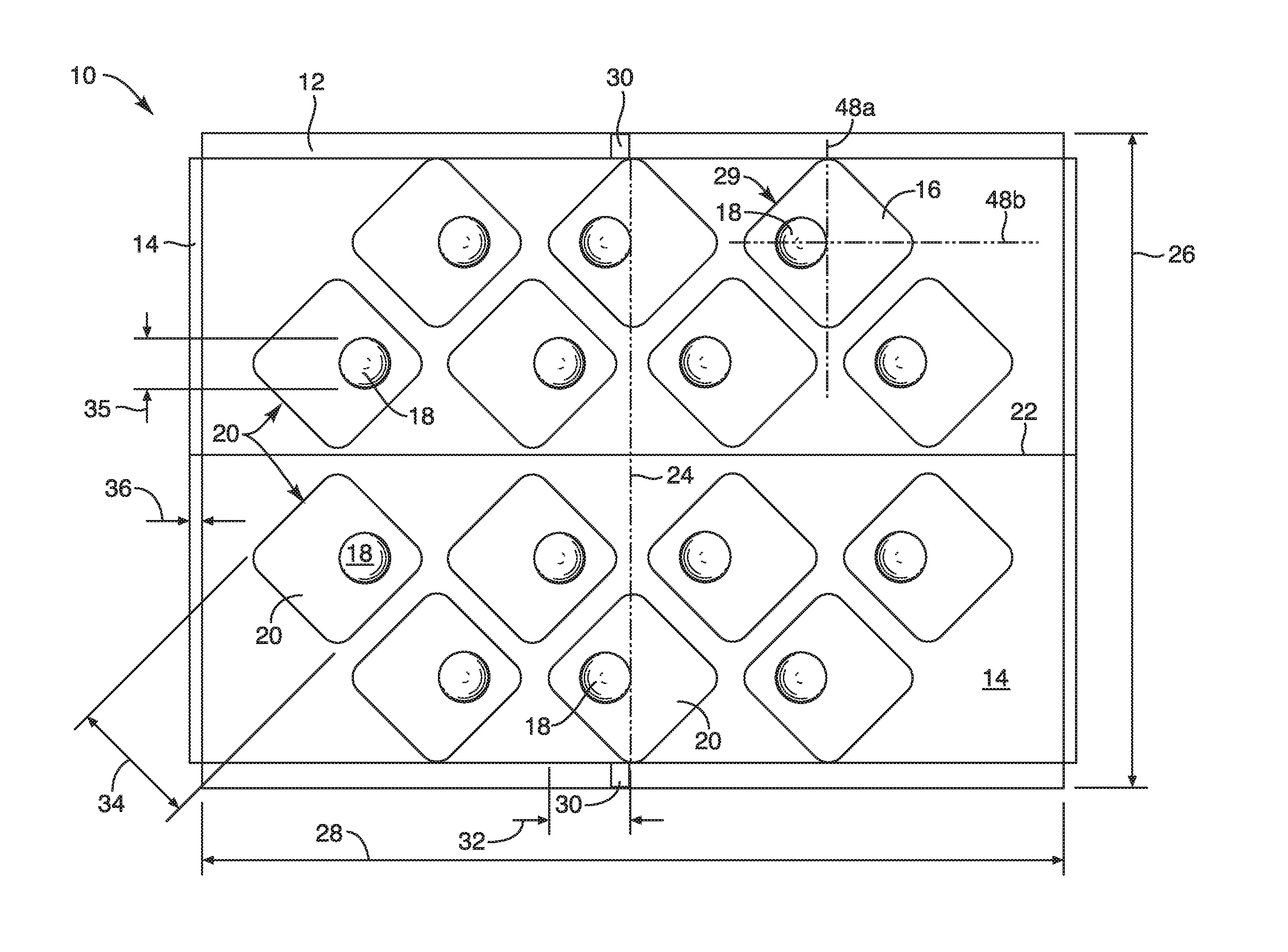

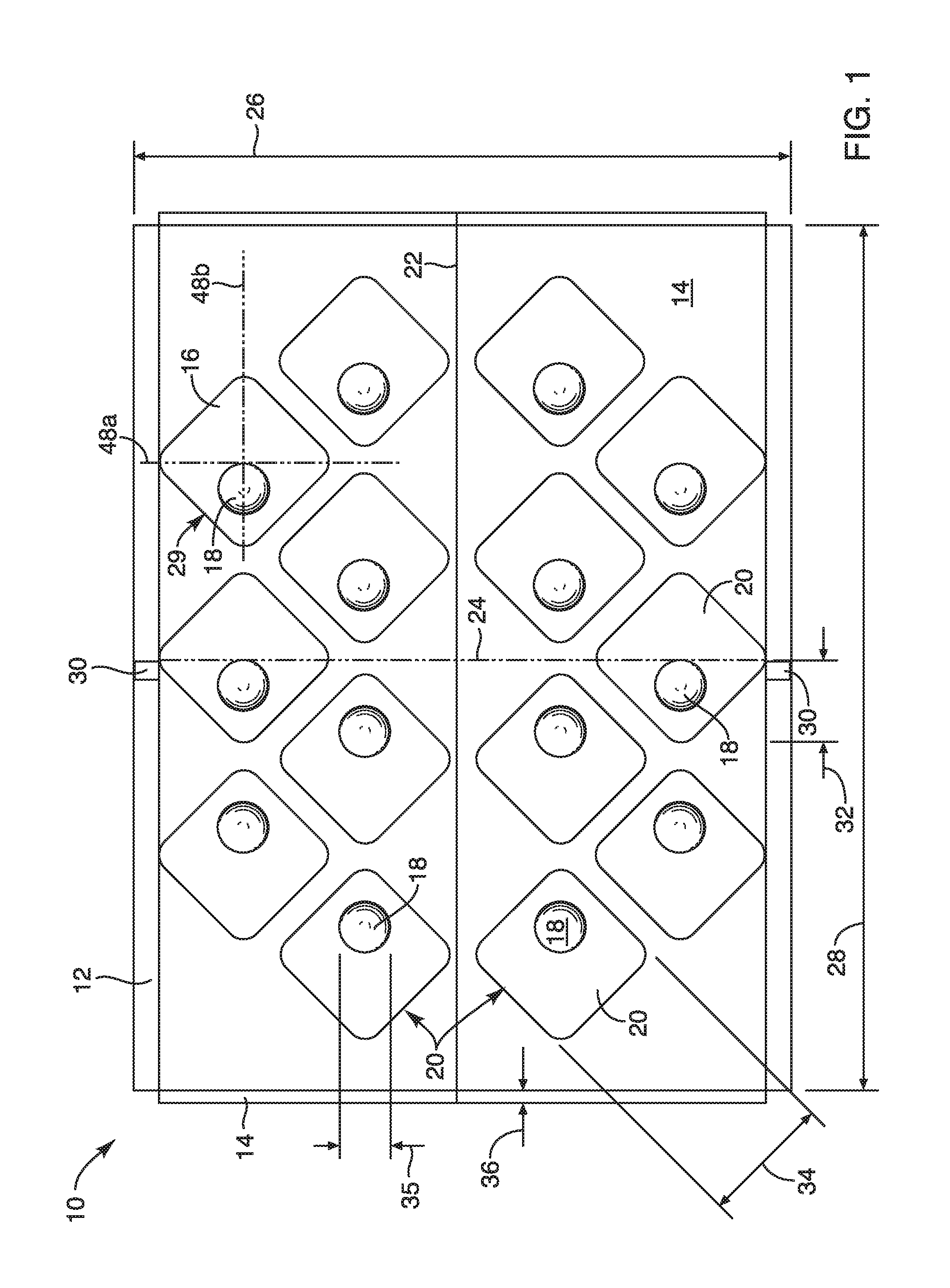

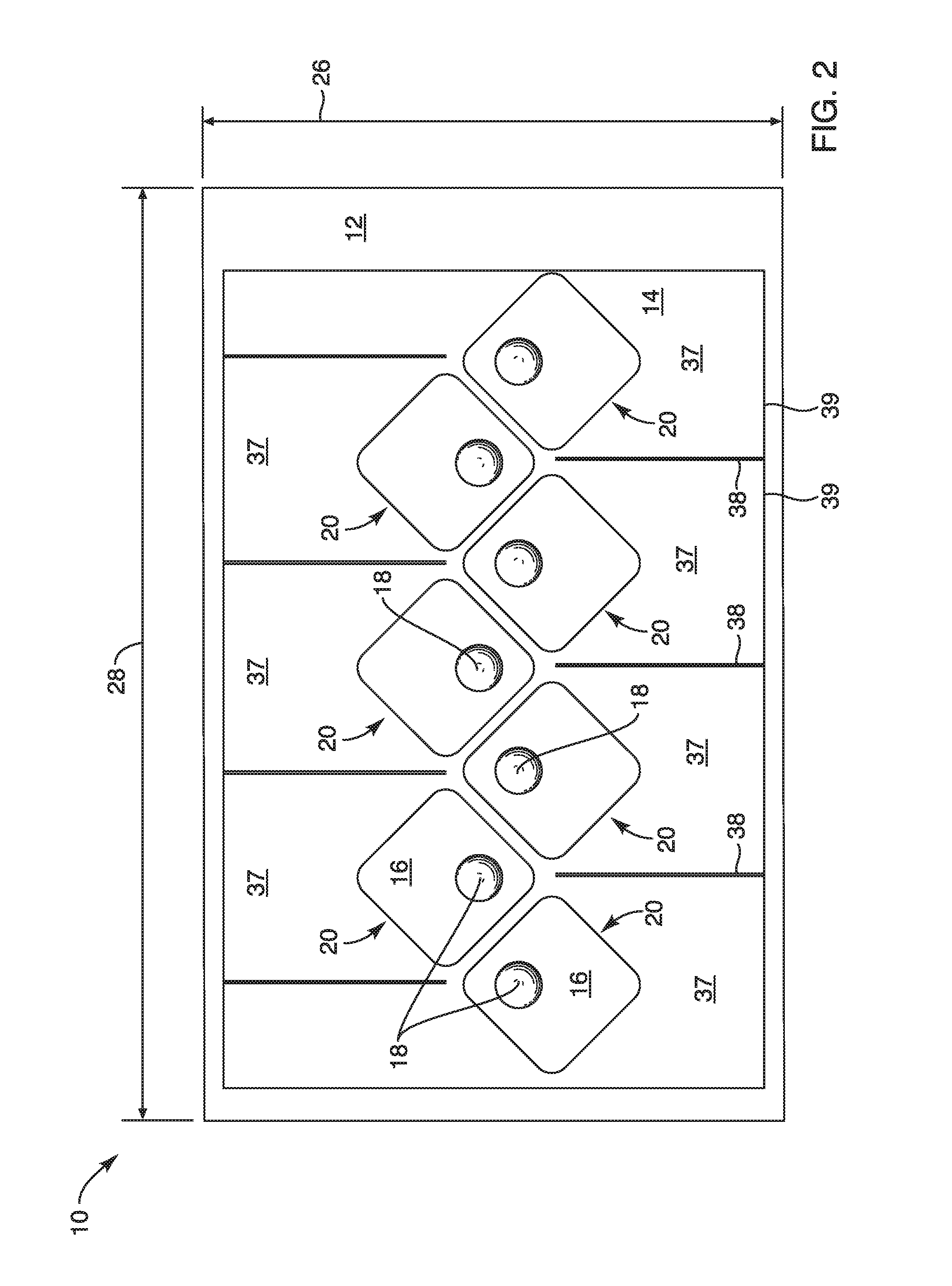

Pet-medicine-capsule wrapper apparatus and method

ActiveUS20170042805A1Maintain the shape of the treat wrapPharmaceutical delivery mechanismAccessory food factorsBiomedical engineeringPutty

Methods and compositions for obscuring medicines formed as tablets, capsules, pills, and so forth may be presented in clean packaging, with built-in work space on a substrate, film layer. A flexible paste, gum, putty, or malleable and formable treat material may be folded without touching the actual treat composition on its outermost surface. A medicament set onto a location on a surface of the composition may then be folded inside by folding, molding, or otherwise manipulating the composition, thus forming a sealed morsel, leaving no residue (e.g., powder, scent, taste, etc.) of the medicament on the outer surface of the composition when administered to a pet.

Owner:GOLDBERG MARY ELIZABETH

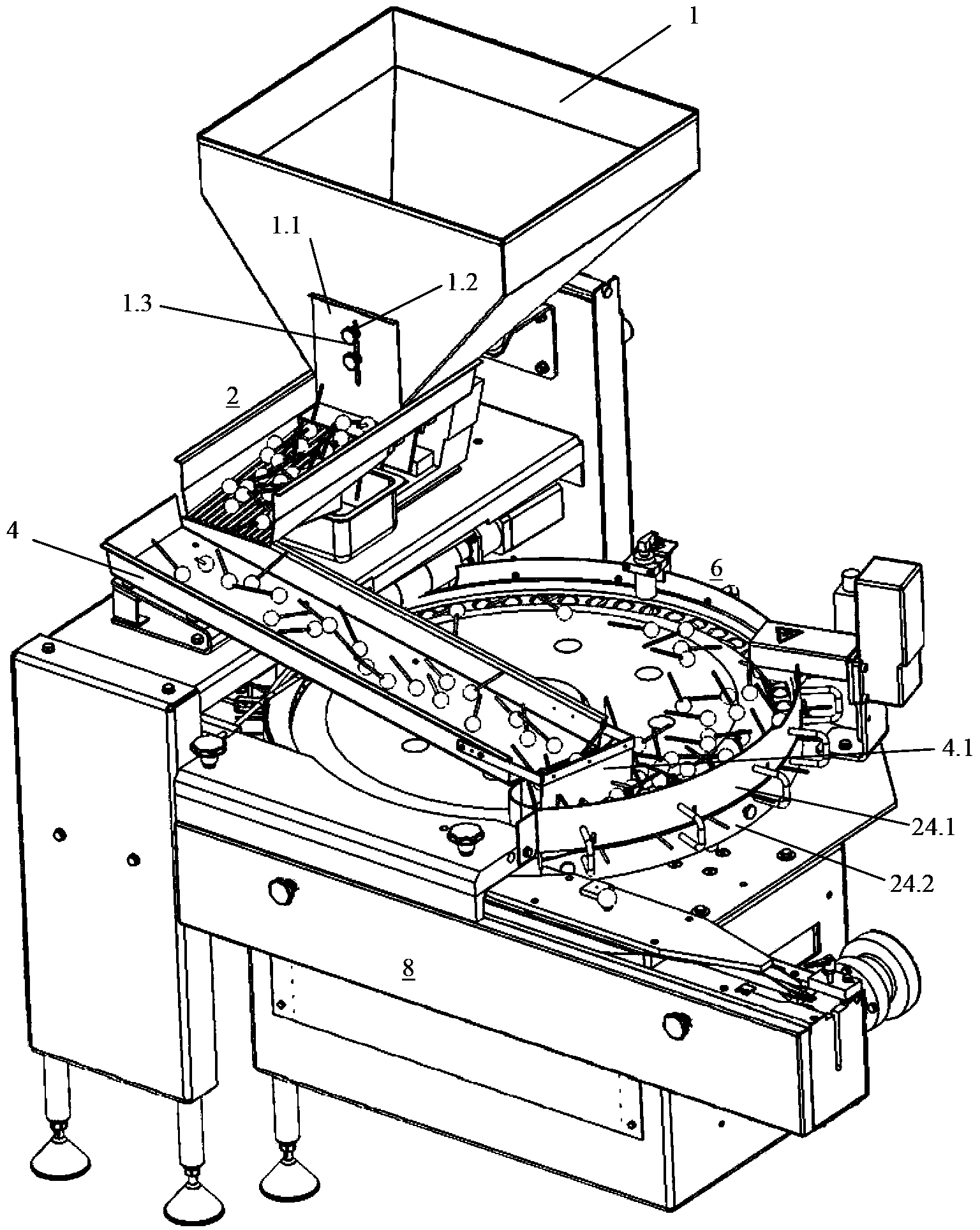

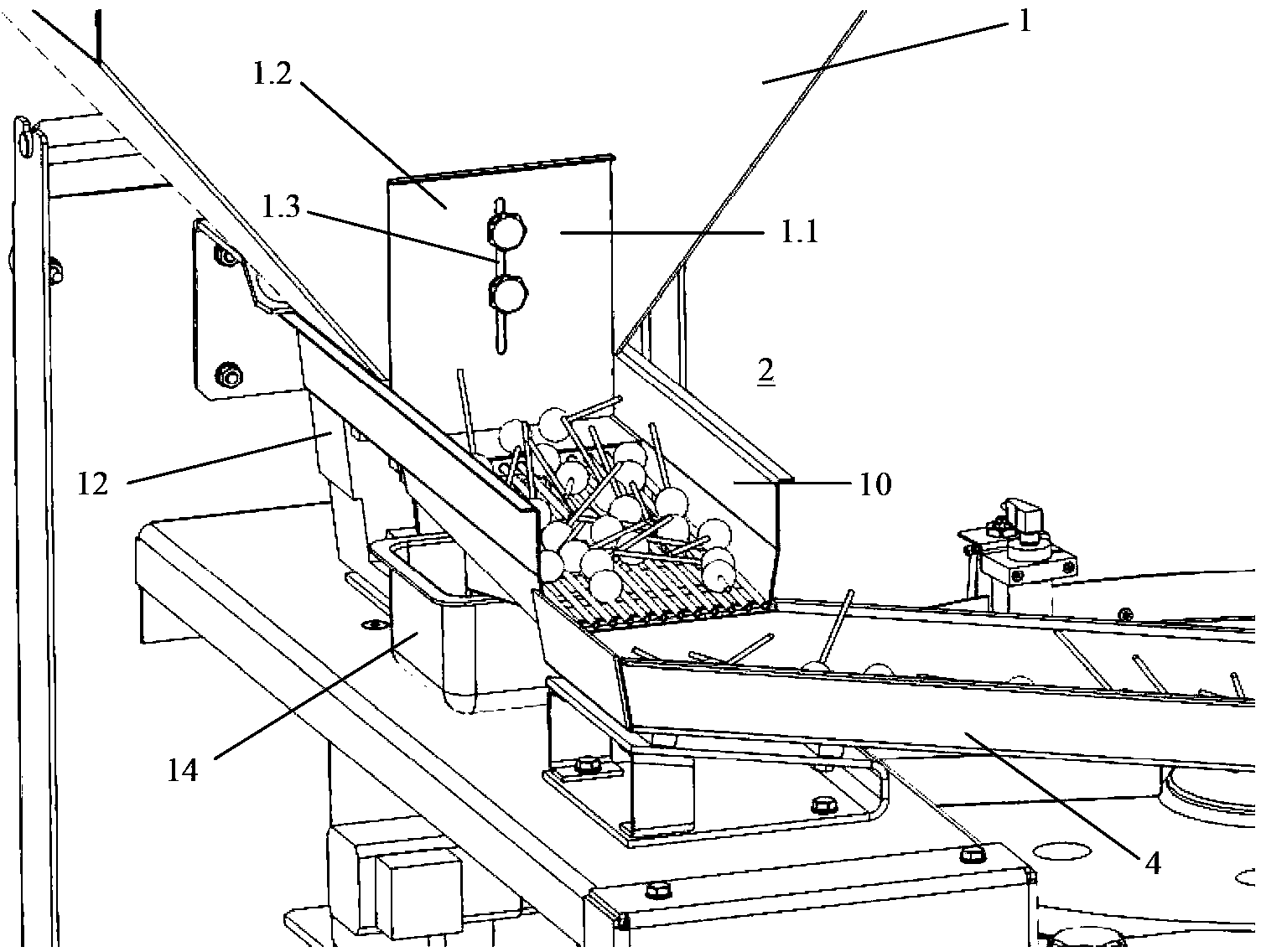

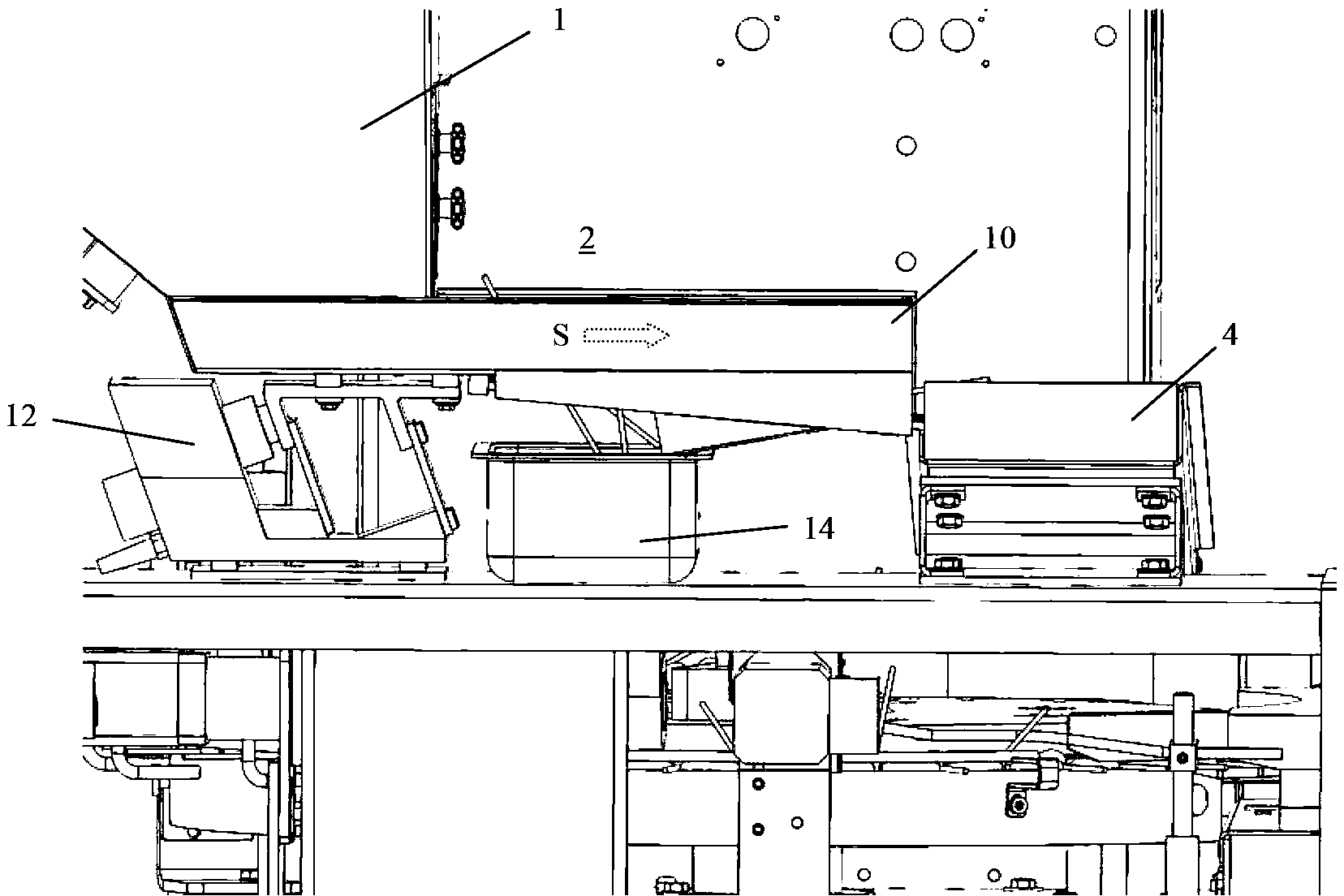

Machine for packaging products

InactiveUS7454886B2Accurate acquisitionSpaceWrapper folding/bending apparatusConveyor wrappingEngineeringMechanical engineering

Owner:CFS WEERT BV

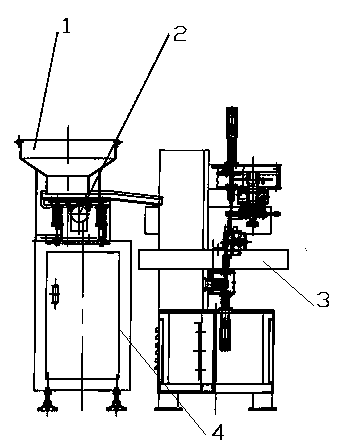

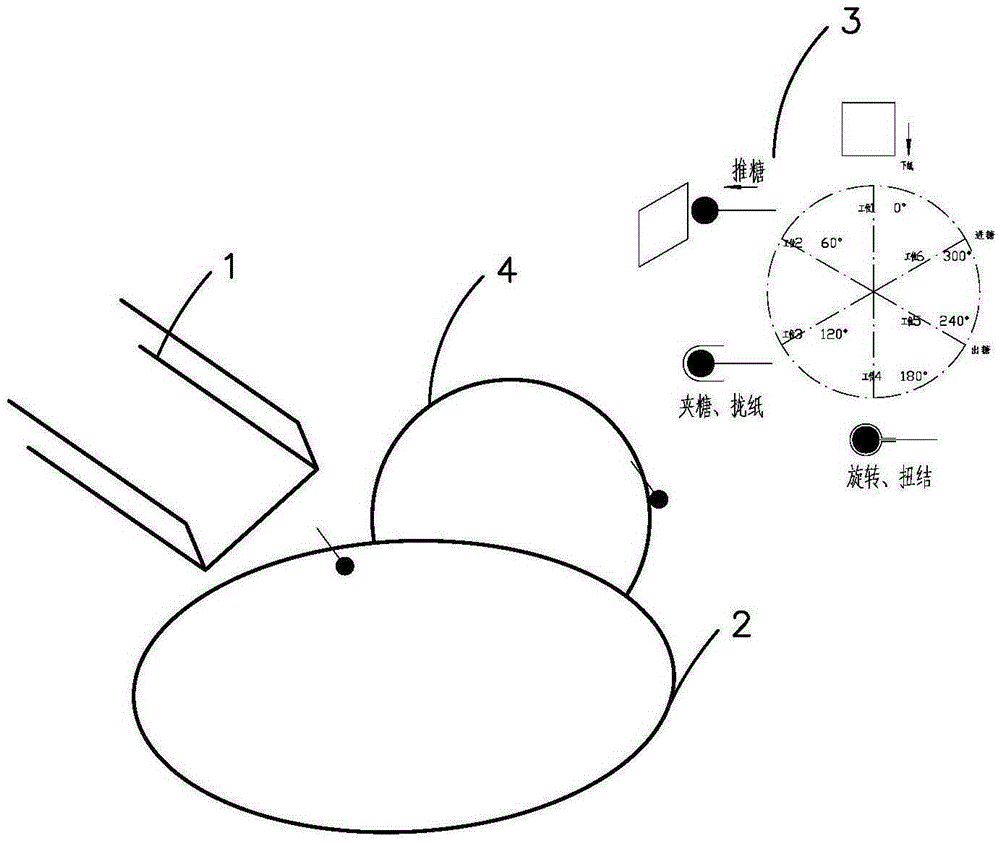

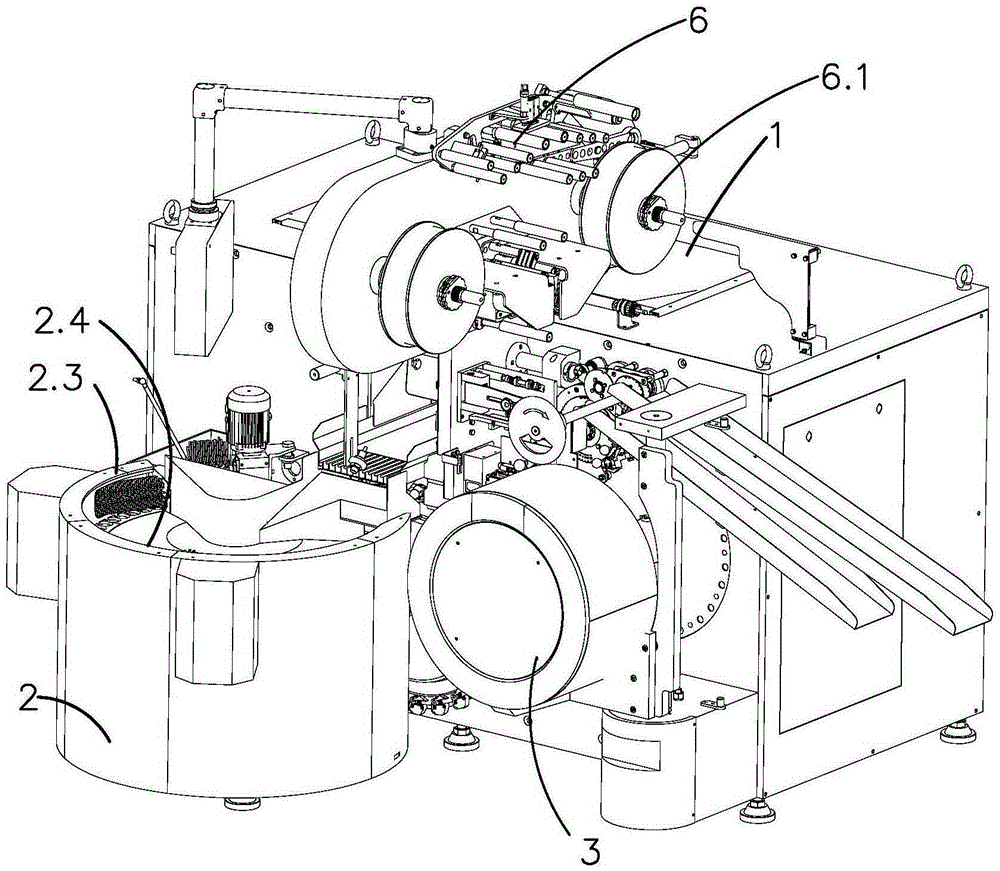

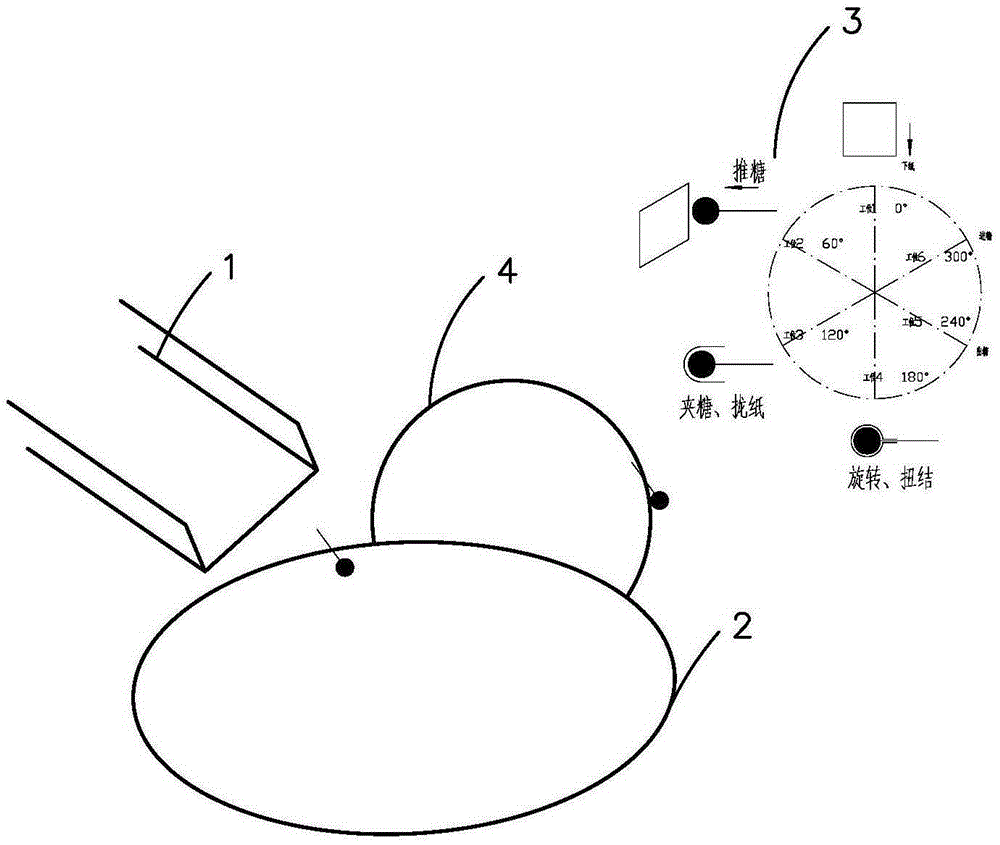

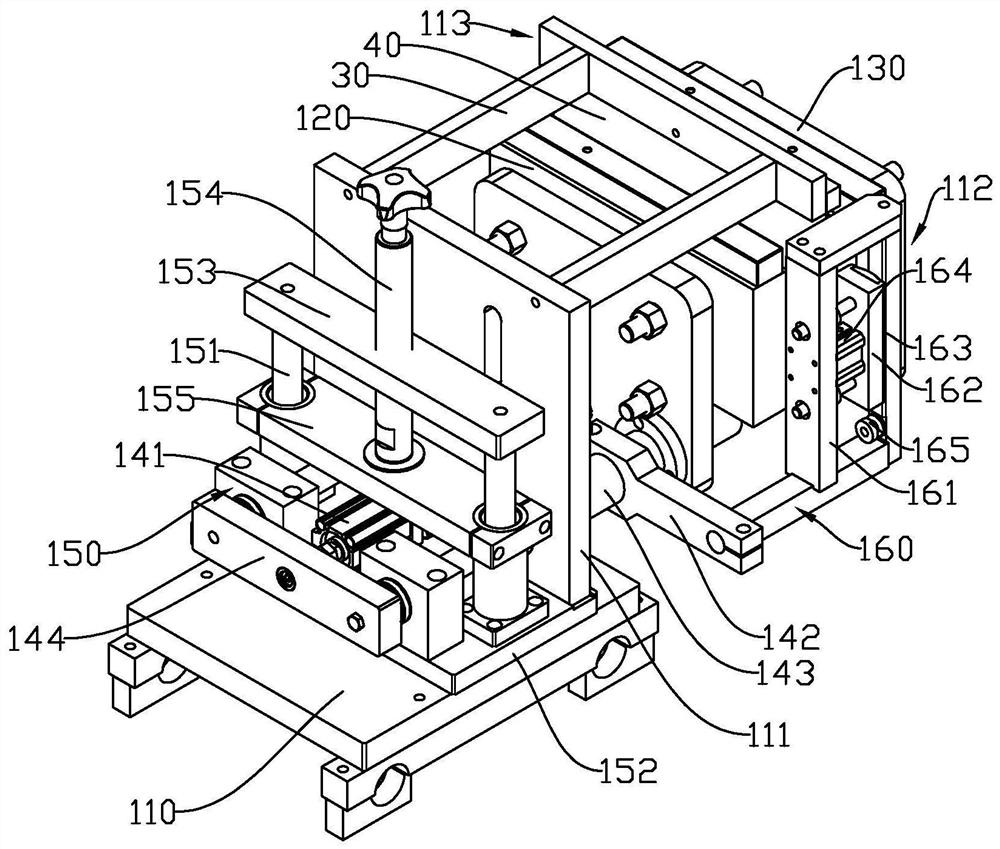

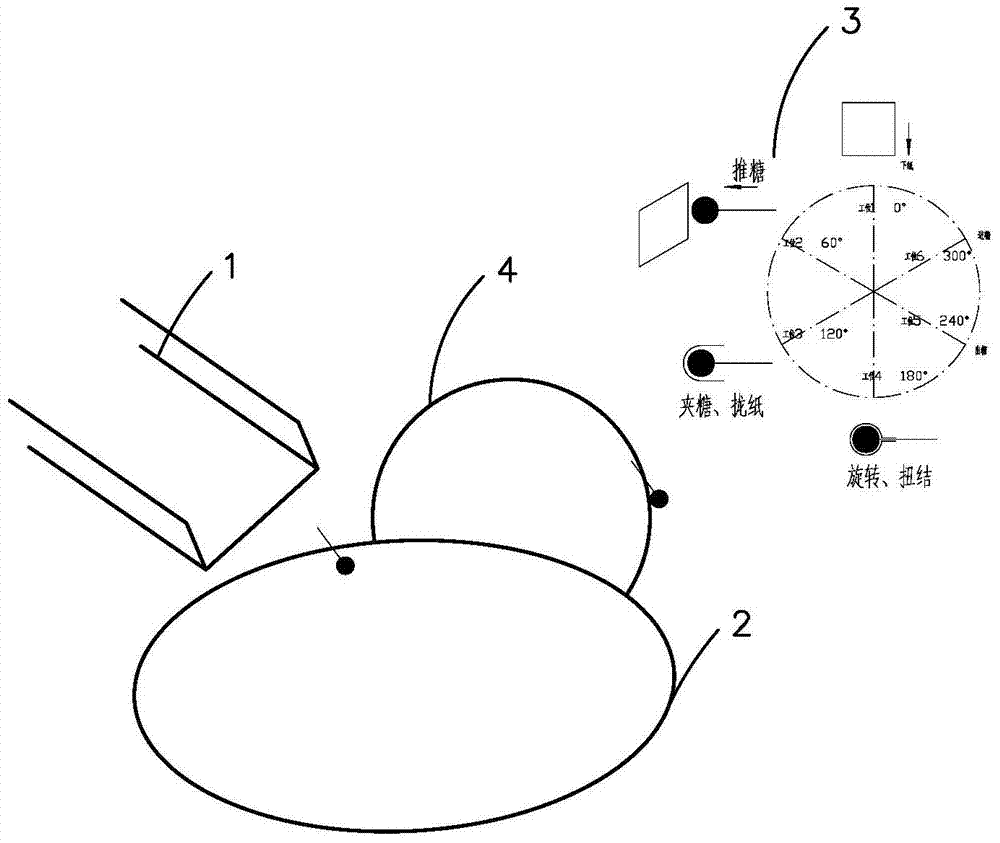

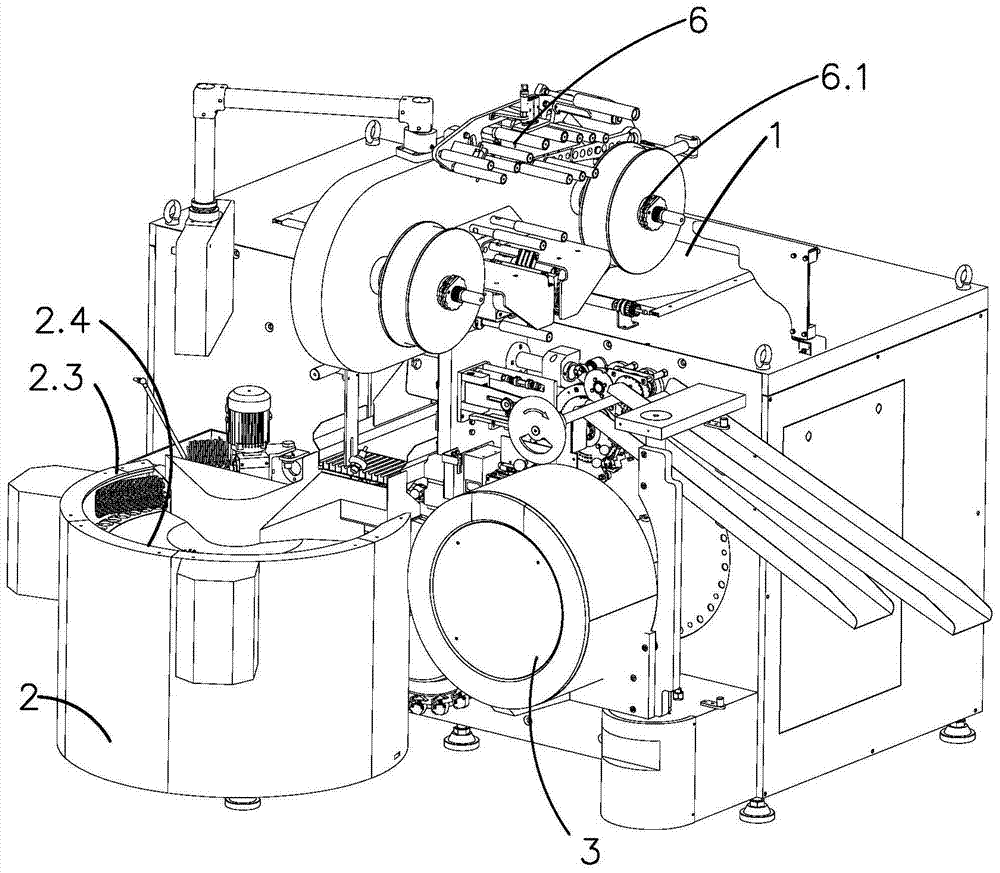

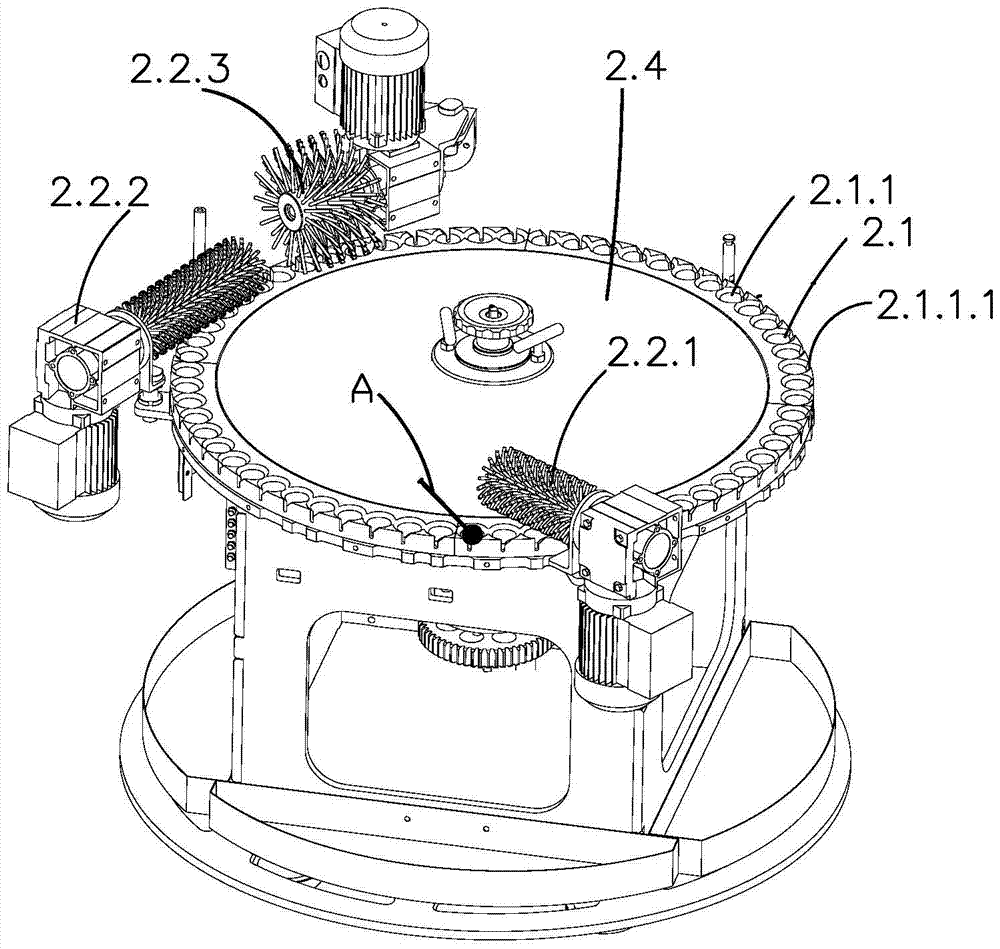

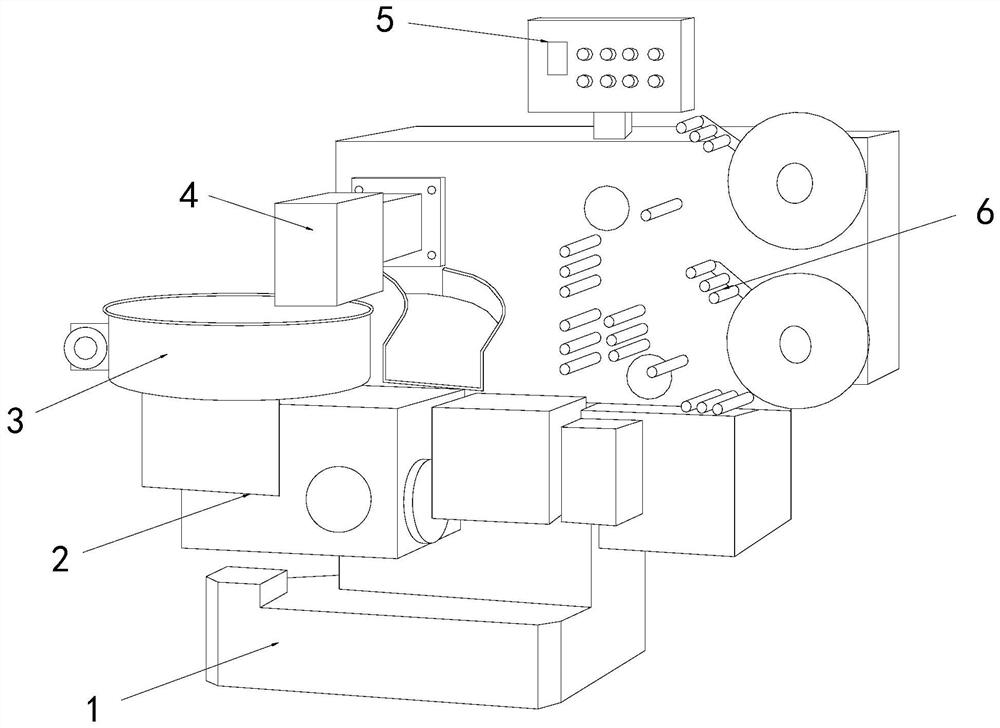

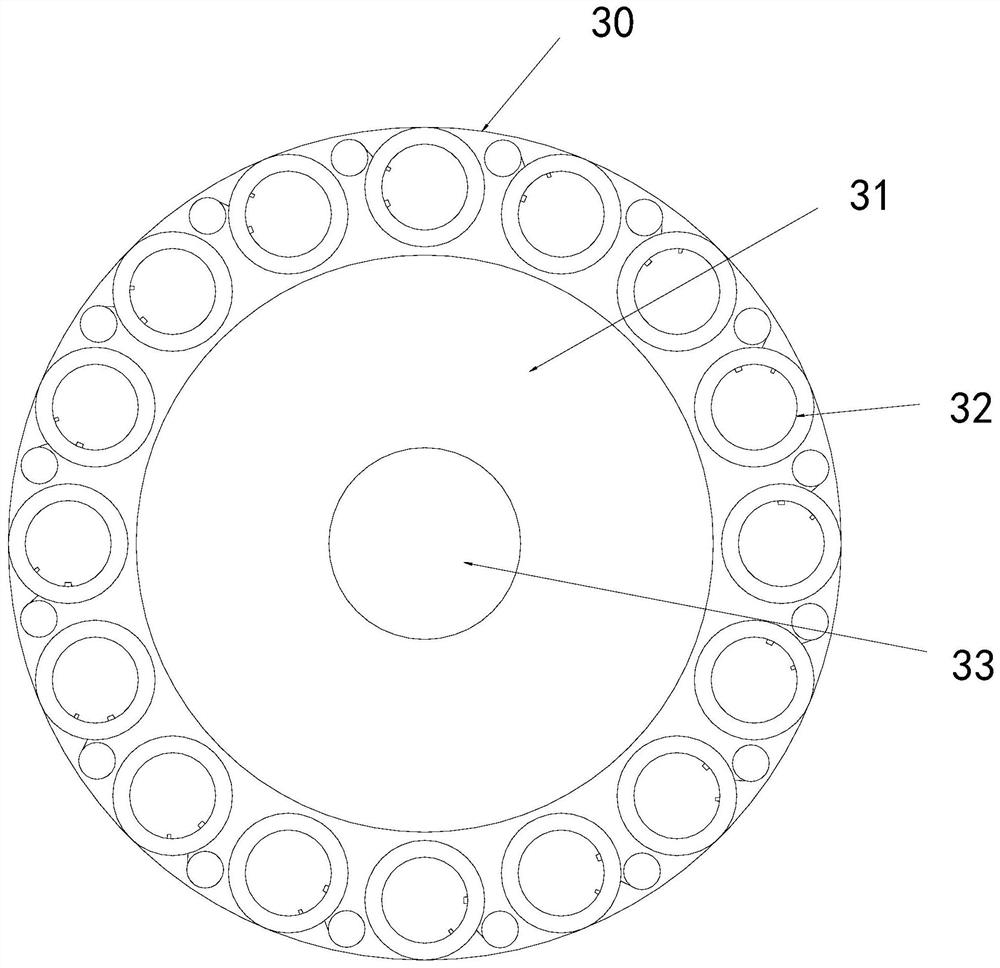

Spherical sweet single-twisting packaging device

InactiveCN104369891AAvoid the Sugar Free PhenomenonPrevent overflowConveyor wrappingPackaging lollipopsEngineeringManipulator

The invention relates to a spherical sweet single-twisting packaging device. The device comprises a rack, a sweet discharging mechanism, a sweet sorting disk mechanism, a conveying mechanism, a paper conveying and cutting mechanism and a packaging rotating machine head, wherein the sweet discharging mechanism, the sweet sorting disk mechanism, the conveying mechanism, the paper conveying and cutting mechanism and the packaging rotating machine head are all installed on the rack, the conveying mechanism comprises a conveying chain located between the sweet sorting disk mechanism and the packaging rotating machine head, and a plurality of sweet pushing rods which are installed on the conveying chain and extend in the conveying direction of the conveying chain, the sweet pushing rods correspond to spherical sweets respectively, each sweet pushing rod is a sector block, and the sweet pushing rods are movably connected with the conveying chain. The spherical sweet single-twisting packaging device has the advantages that an original manipulator is replaced with the sweet pushing rods hinged to the conveying chain, when the spherical sweets are conveyed, the sweet pushing rods will automatically move downward when making contact with a clamping rod manipulator, the original phenomenon is avoided, after the sweets are conveyed by the conveying chain by one circle, the sweet pushing rods will automatically move upwards again due to the action of gravity, and normal work is guaranteed.

Owner:RUGAO PACKING FOOD MACHINERY

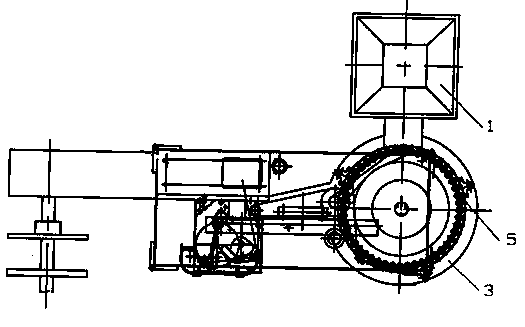

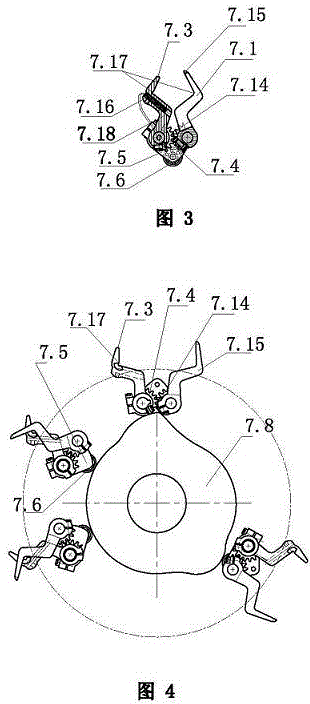

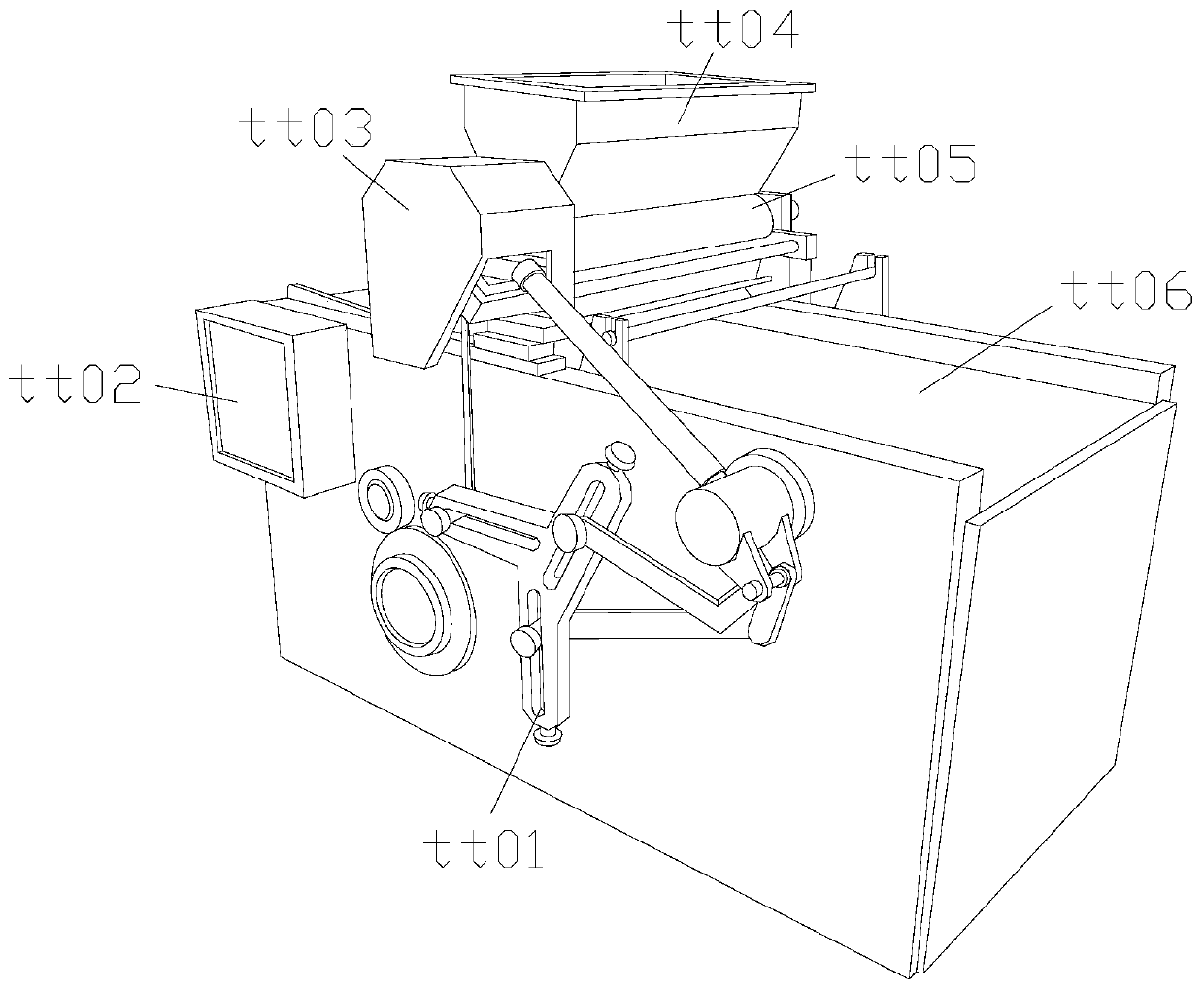

Twisting packing machine for special-shaped candy sticks

ActiveCN104627408AImprove sealingQuick compensationWrappingWrapper twisting/gatheringEngineeringFuselage

The invention discloses a twisting packing machine for special-shaped candy sticks. The twisting packing machine comprises a machine body, a conveying chain, a clamping chain, an upper paper feeding wheel, a lower paper feeding wheel and a transverse sealing and cutting device, and the upper paper feeding wheel and the lower paper feeding wheel are arranged in an oppositely rolling mode. A clamping arm disc and a twisting arm disc are coaxially arranged on the machine body, a plurality of pairs of inner clamping arms and outer clamping arms are evenly arranged on the disc face of the clamping arm disc, electric heating elements are arranged on the inner clamping arms, a plurality of pairs of twisting arms are arranged on the disc face of the twisting arm disc, the number of pairs of the twisting arms on the twisting arm disc is equal to the number of pairs of the inner clamping arms and outer clamping arms on the clamping arm disc, and the twisting arms on the twisting arm disc correspond to the inner clamping arms and outer clamping arms of the clamping arm disc one to one. According to the twisting packing machine for the special-shaped candy sticks, twisting packing can be carried out on candies in the continuous motion process, therefore, the defects due to the fact that only one pair of twisting arms is applied to be matched with an intermittent mechanism on an existing machine are overcome, and the advantages of being reasonable in structure, small in mechanical vibration, high in production speed and high in efficiency are achieved.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

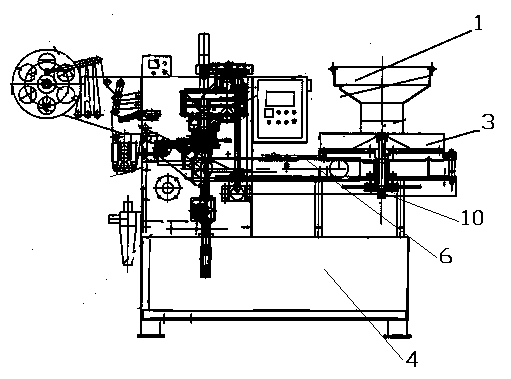

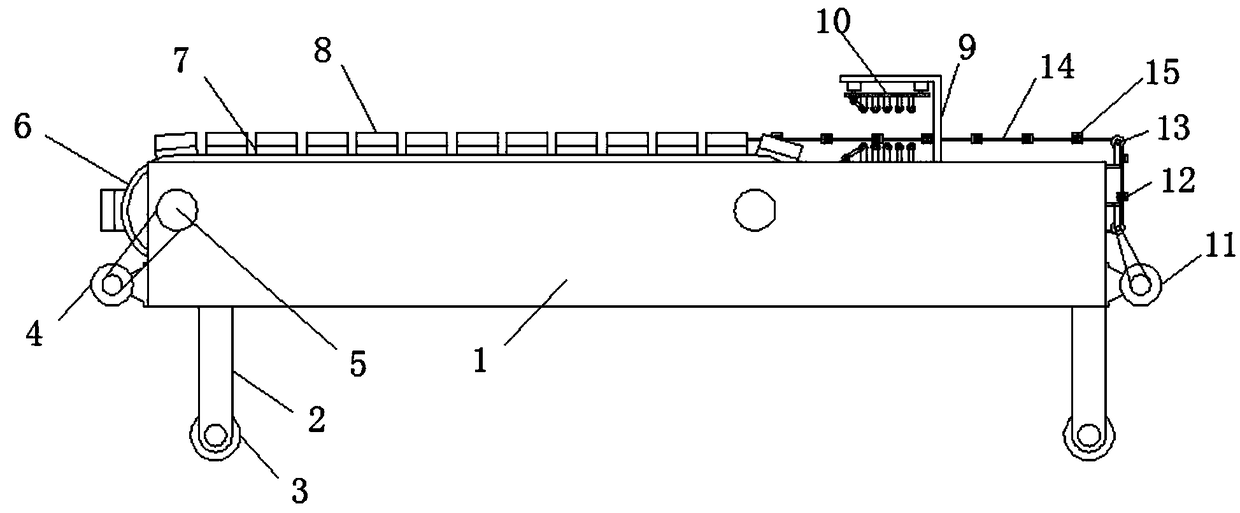

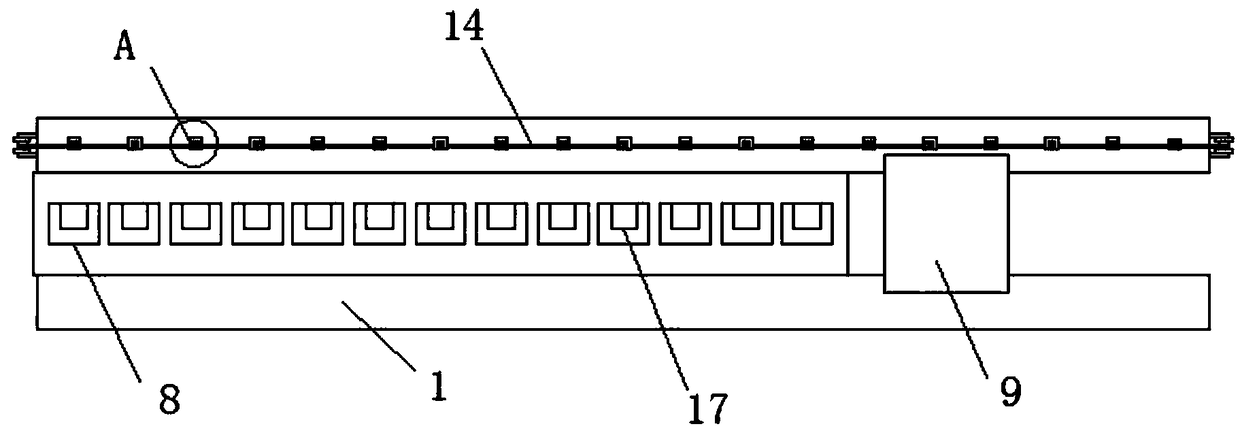

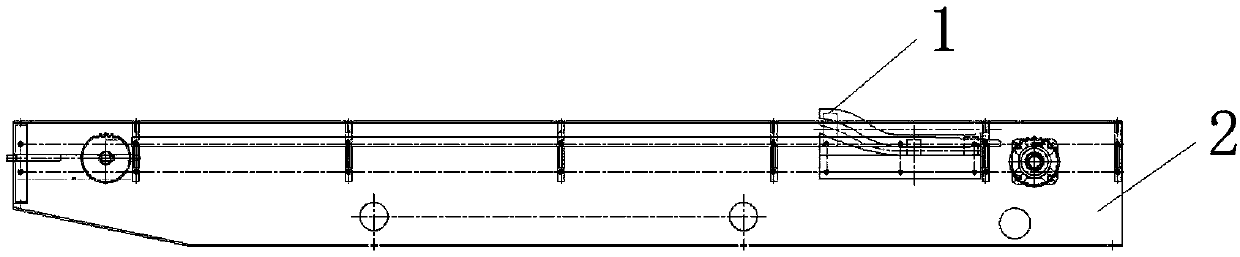

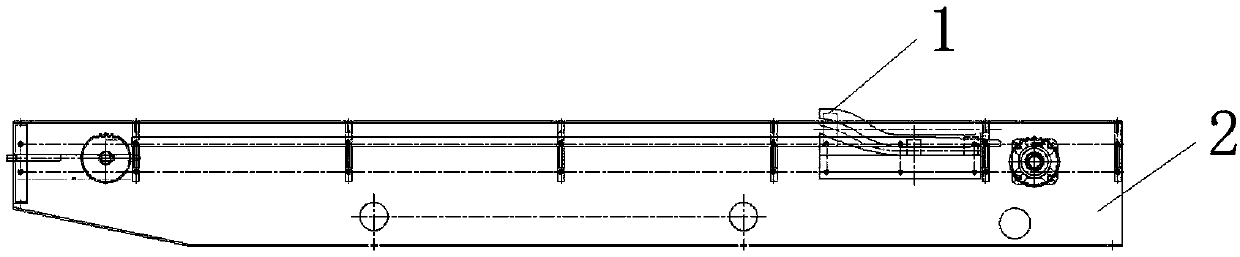

Feeding and packaging mechanism used for processing edible lollipops

ActiveCN109229510AEasy to disassemble and replaceEasy to processPackaging lollipopsHydraulic cylinderEngineering

The invention discloses a feeding and packaging mechanism used for processing edible lollipops. The mechanism includes a machine frame and support legs arranged on the bottom of the machine frame, twosets of conveying rolls are installed on the machine frame, one side of each conveying roll is in drive connection with a first motor installed on one side of the machine frame through a belt, the two sets of conveying rolls are in drive connection through a conveying belt, the conveying belt is in threaded connection with a mold block through an elastic rubber block, the bottom of a support frame arranged on one side of the machine frame is provided with a roller press mechanism, and the roller press mechanism includes a hydraulic cylinder, a supporting plate, a first guide rod, a drive roll, a driven roll, a second guide rod and a second motor. One side of a guide wheel is in drive connection with a third motor, fixtures are installed on a steel wire rope at equal intervals, and an opening of a grooved clamp block is connected with two sets of symmetrically arranged clamp plates through springs. According to the mechanism, different types of lollipop food is easy to process and package, the packaging effect and quality are guaranteed, the lollipop food can be continuously packaged at a time, and the packaging efficiency is improved.

Owner:ANHUI BAOZHITANG PHARMA

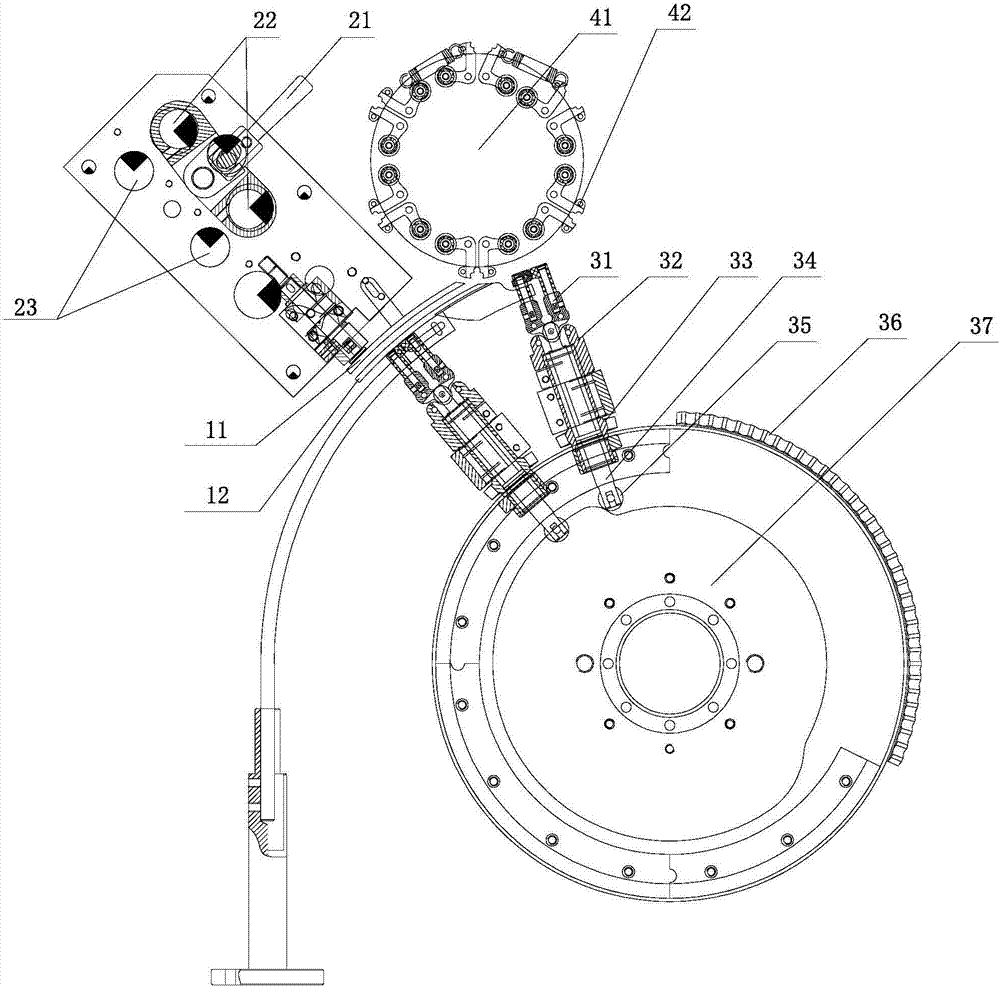

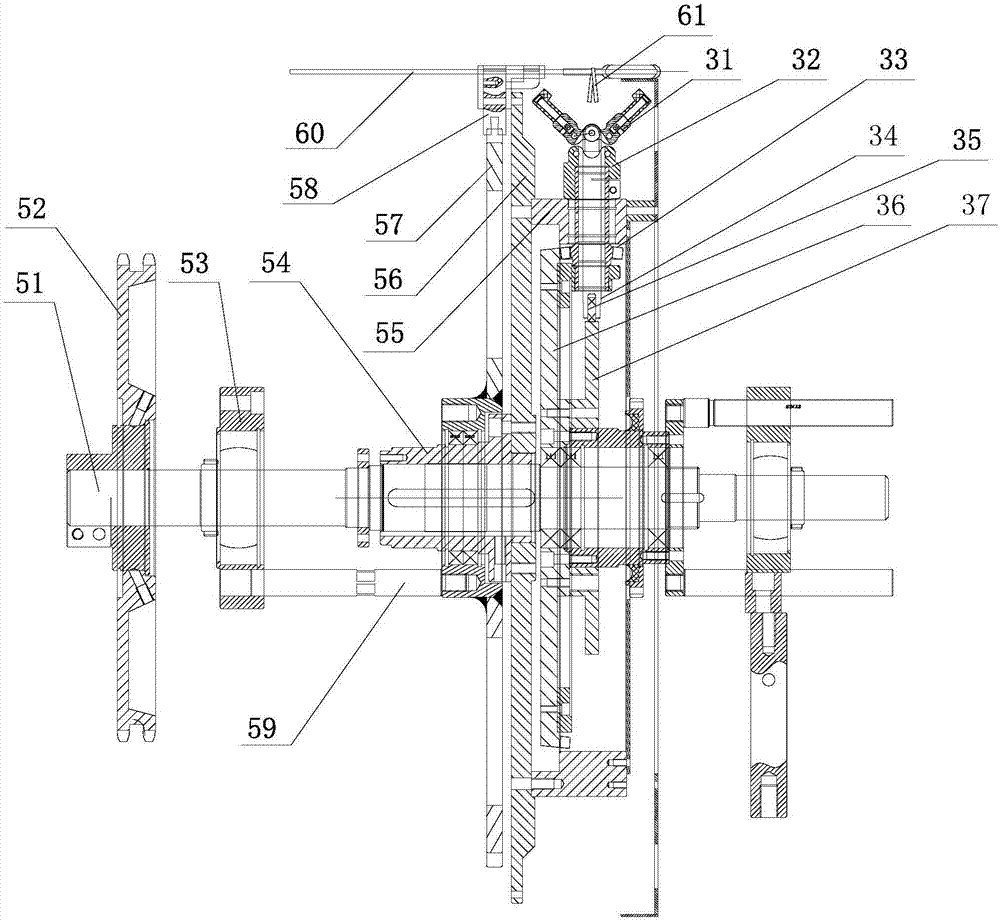

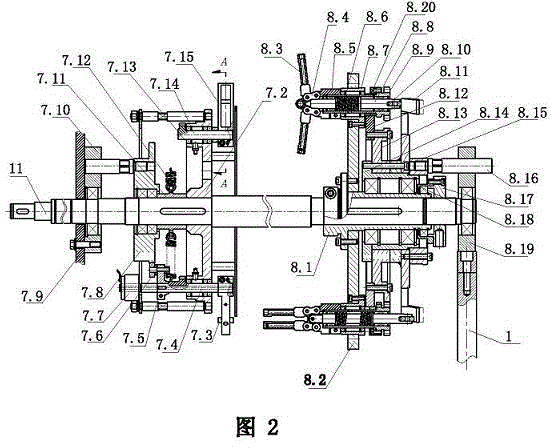

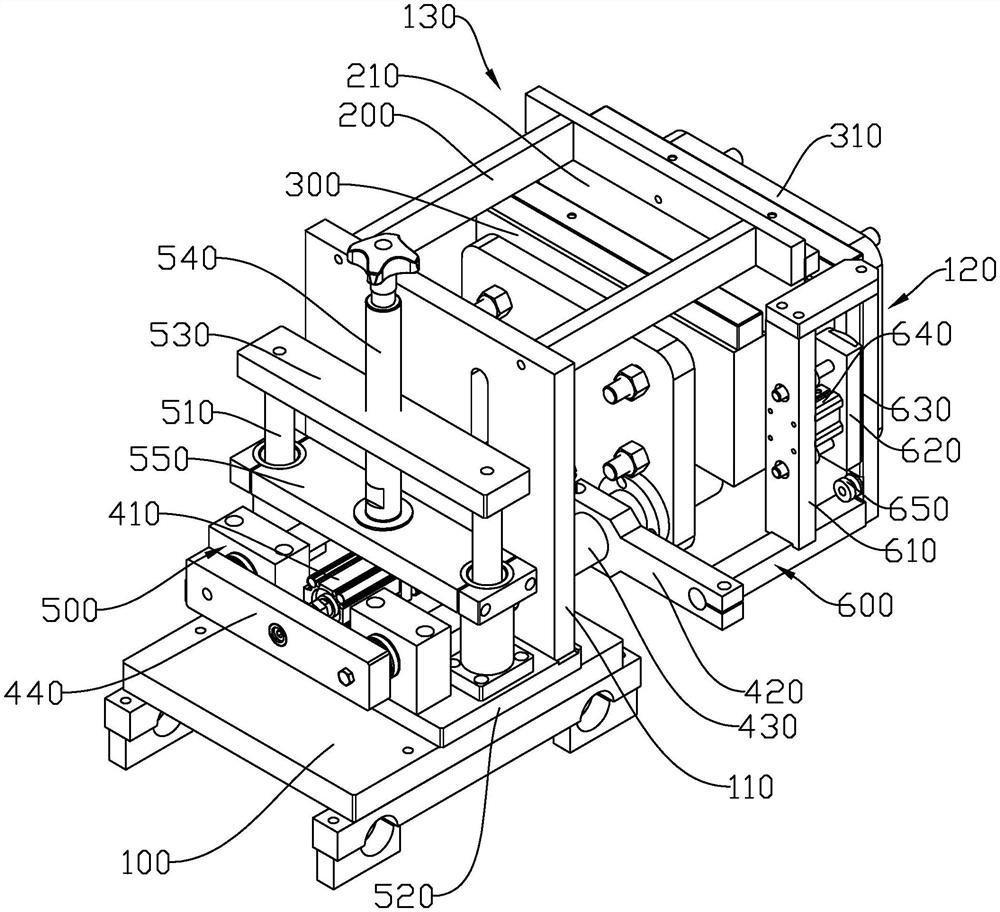

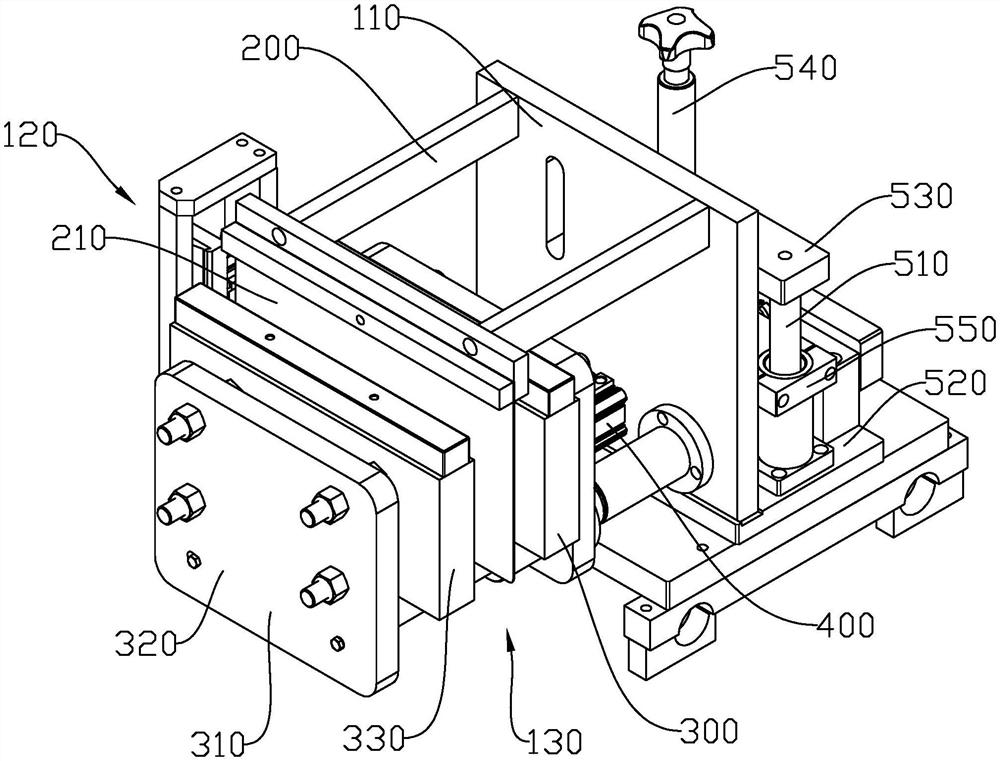

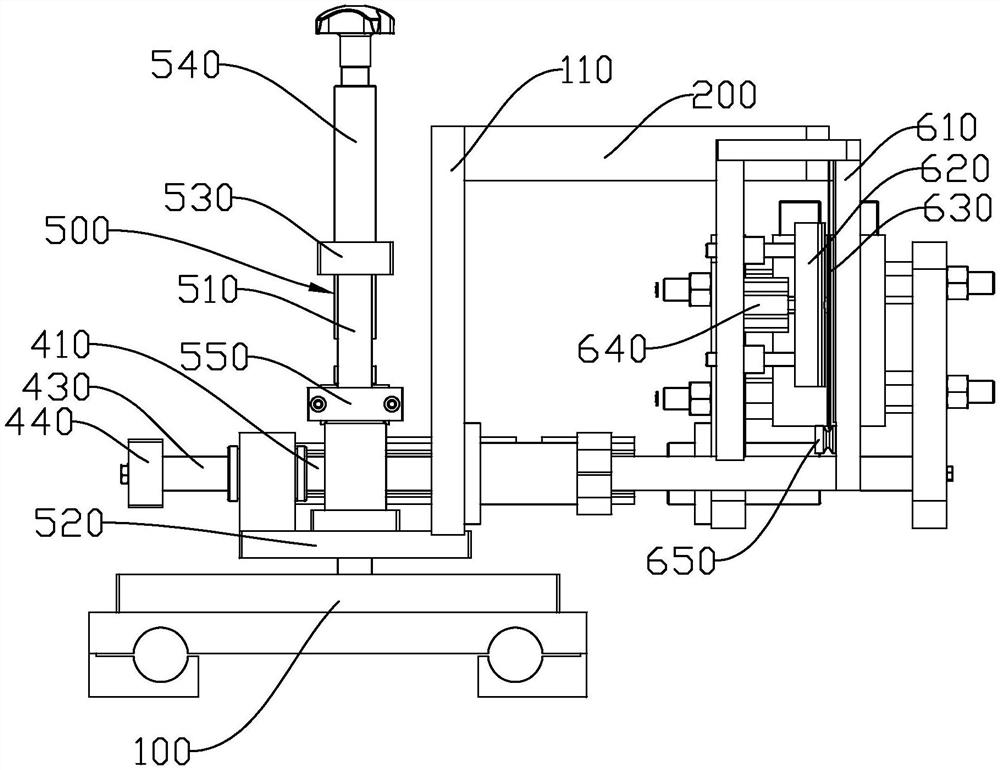

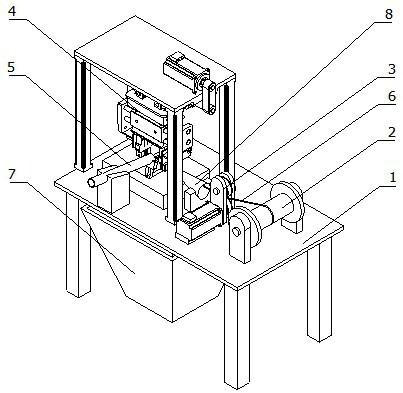

Lollipop packaging device for lollipop packaging machine

InactiveCN105416645AIncrease the level of automationWrappingWrapper twisting/gatheringEngineeringPaper sheet

The invention discloses a lollipop packaging device for a lollipop packaging machine. The lollipop packaging device comprises a lollipop clamping rotating and paper drawing assembly, a twisting and heat sealing assembly and a lollipop pushing assembly. The twisting and heat sealing assembly is coaxially arranged between the lollipop clamping rotating and paper drawing assembly and the lollipop pushing assembly and comprises a heat sealing disc and twisting and heat sealing clamps. The lollipop clamping rotating and paper drawing assembly comprises a paper drawing disc and rotating and paper drawing clamps. The twisting and heat sealing clamps are annularly arranged on the rotating paper drawing clamps on the heat sealing disc in an array manner. The rotating and paper drawing clamps are annularly arranged on the paper drawing disc in an array manner. The heat sealing disc and the paper drawing disc are coaxially fixed, and the twisting and heat sealing clamps correspond to the rotating paper drawing clamps in position. The lollipop packaging device has the beneficial effects that the lollipop clamping rotating and paper drawing assembly, the twisting and heat sealing assembly and the lollipop pushing assembly are included, the twisting and heat sealing assembly is coaxially arranged between the lollipop clamping rotating and paper drawing assembly and the lollipop pushing assembly and comprises the heat sealing disc and the twisting and heat sealing clamps, and therefore the automation level of the lollipop packaging machine is improved.

Owner:成都三可实业有限公司

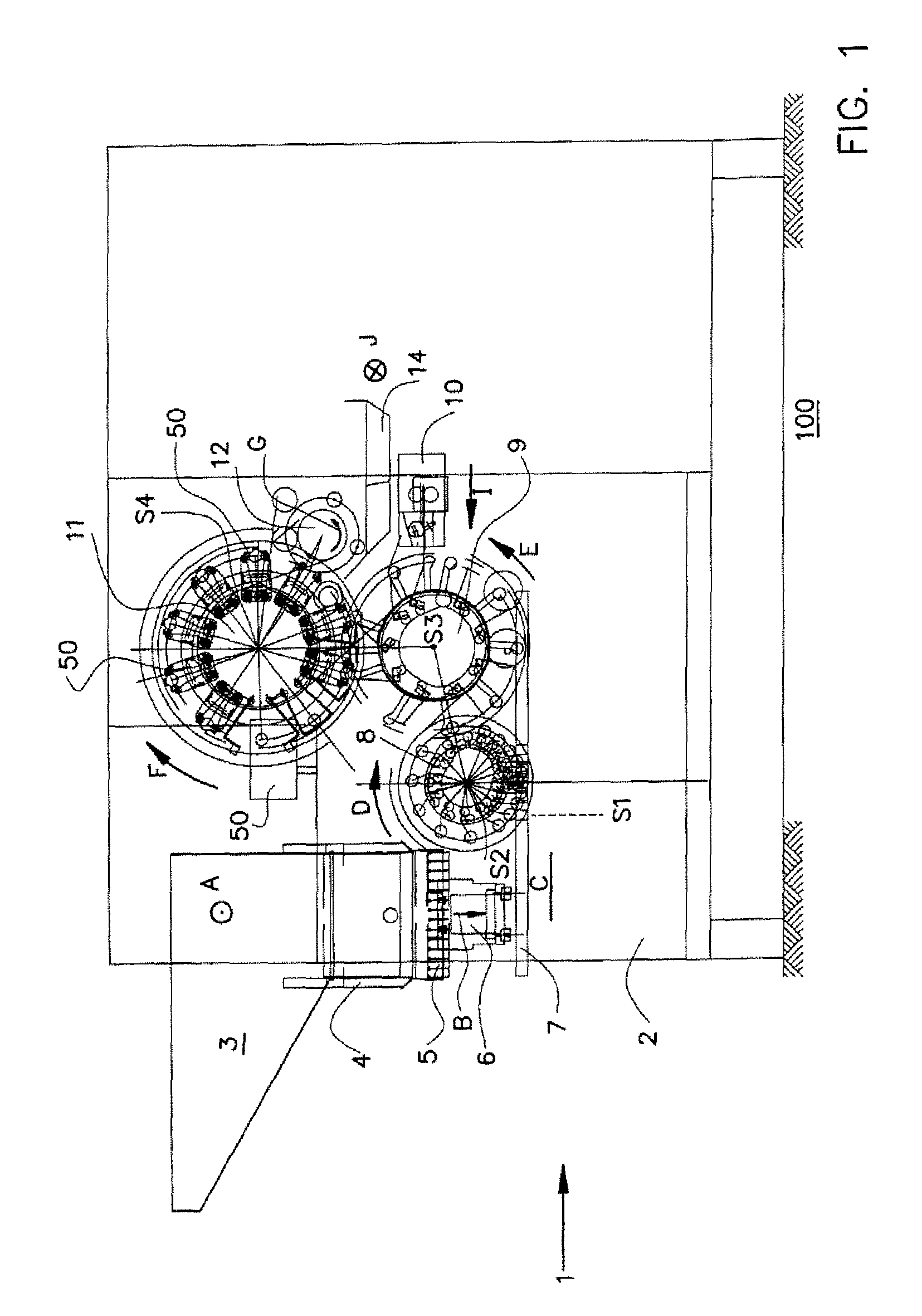

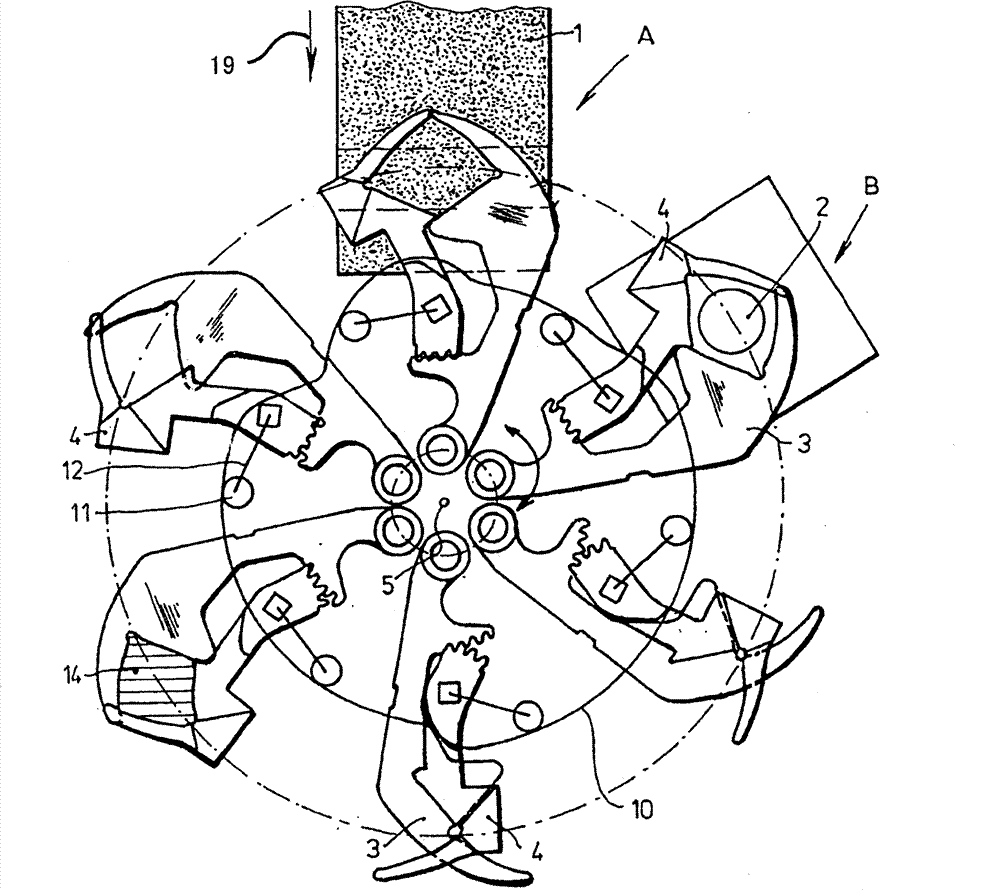

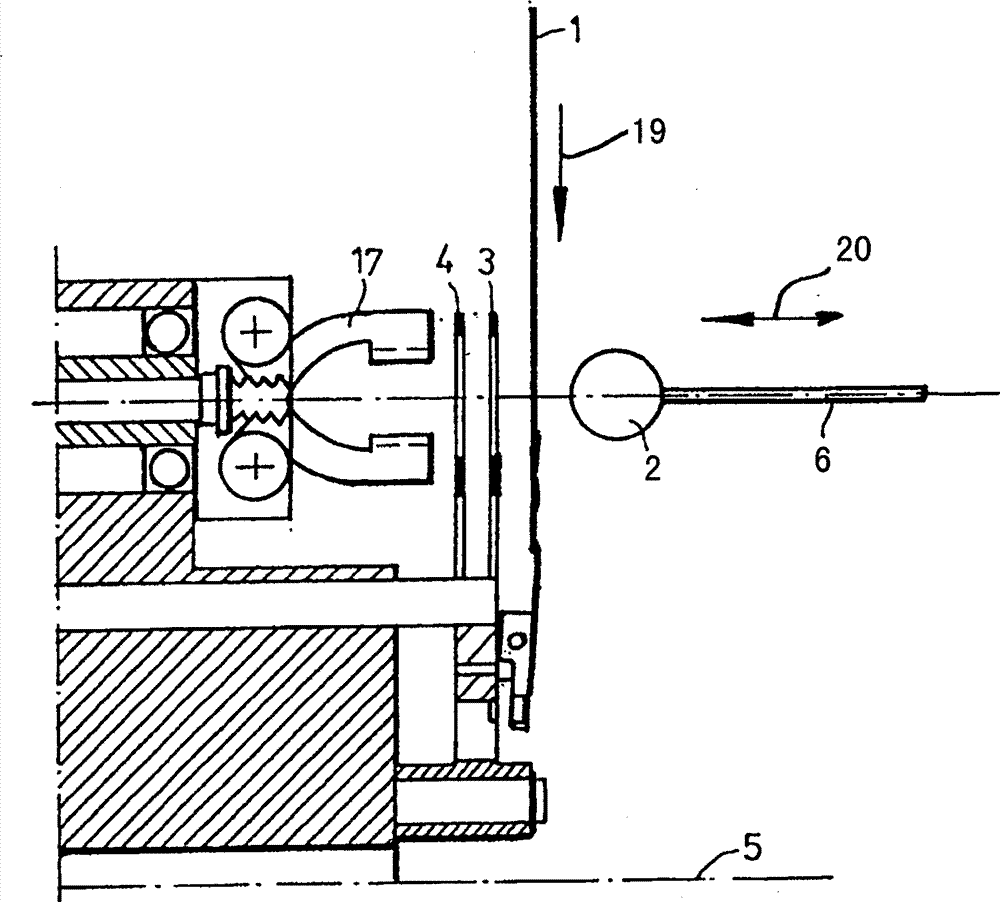

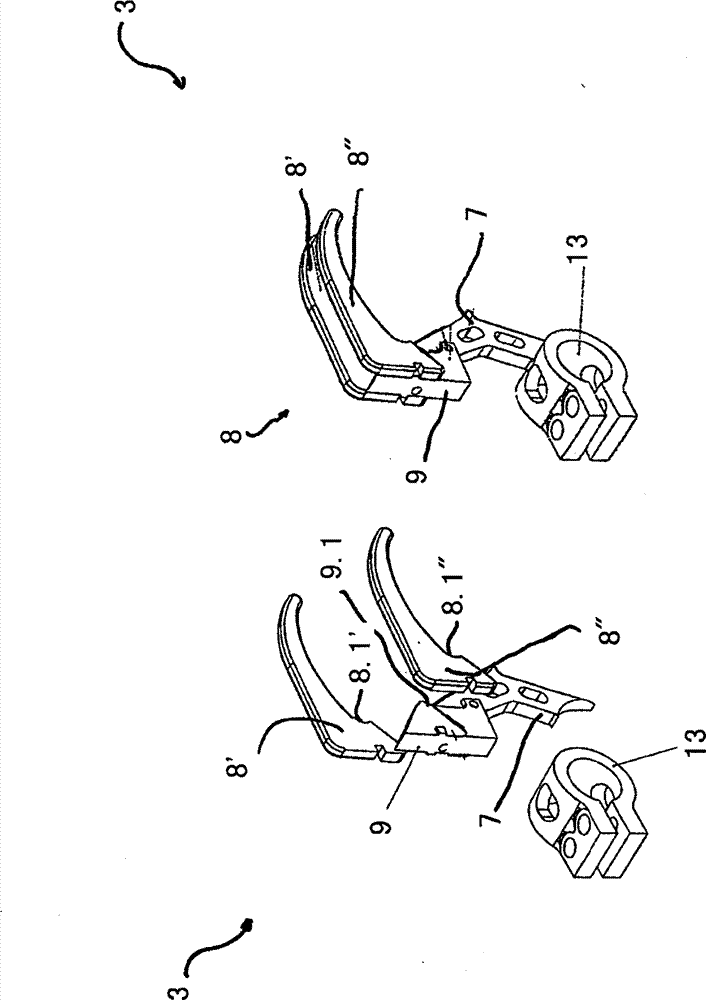

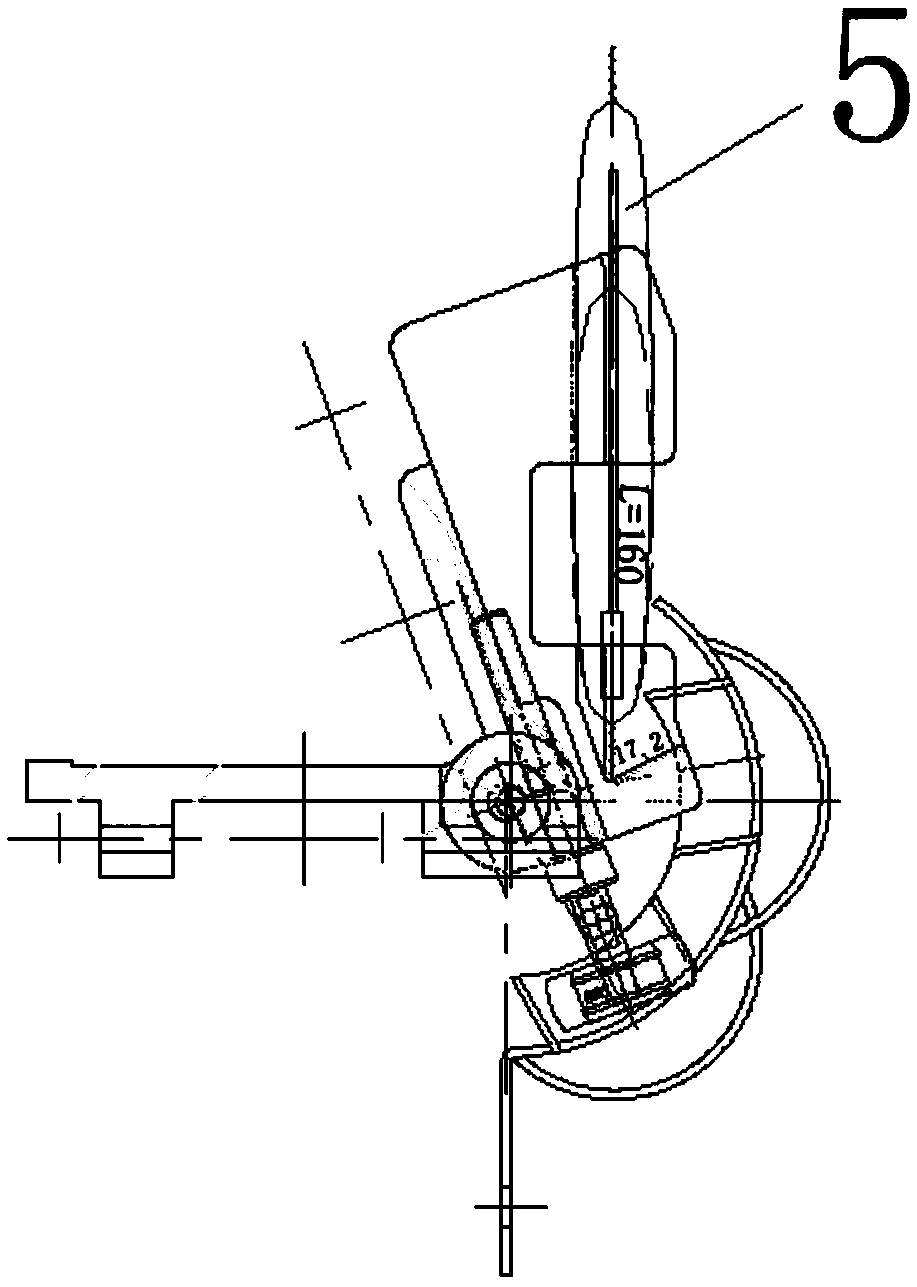

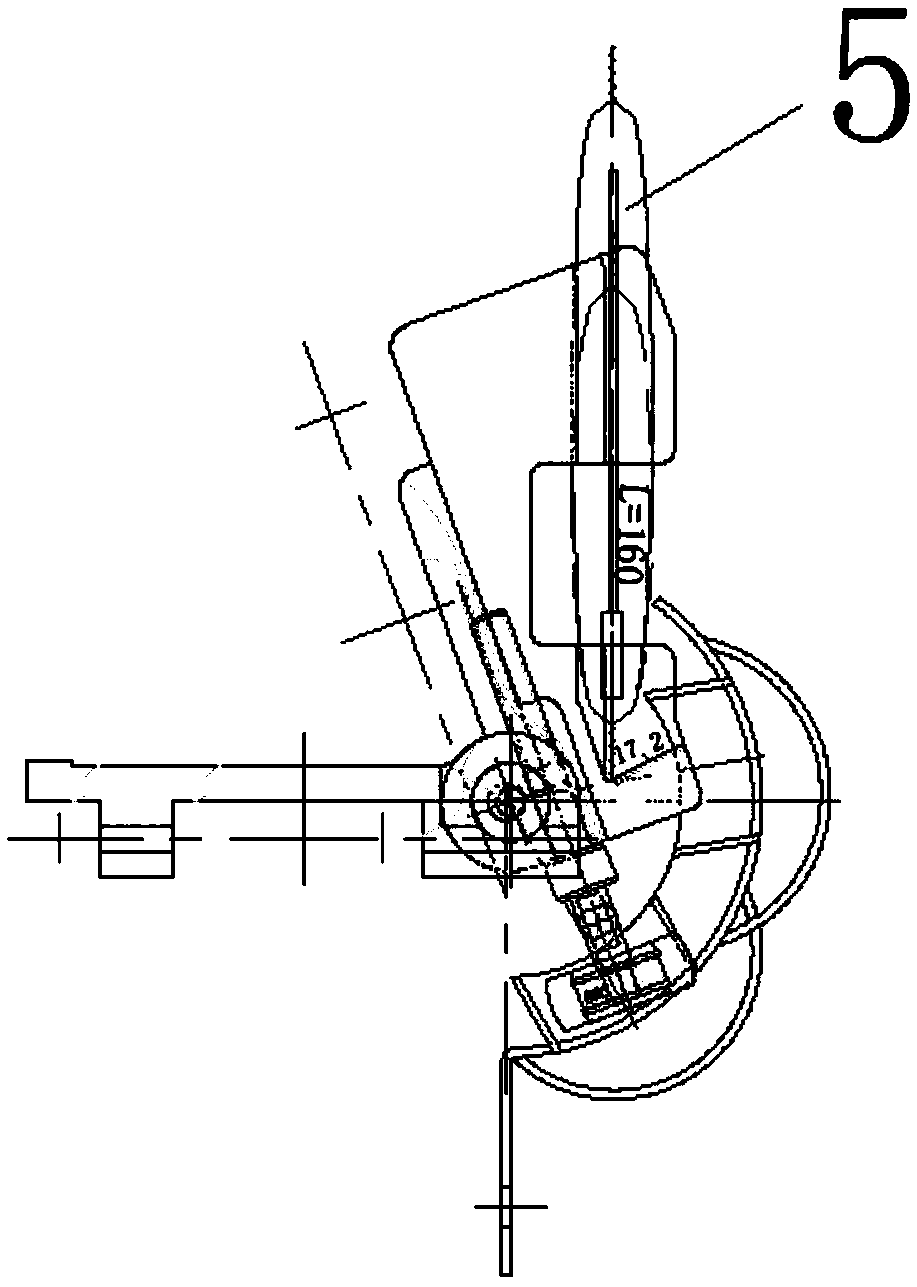

Apparatus and folding means for wrapping a lollipop

The present invention is related to an apparatus for wrapping a lollipop with a stick in a wrapping material by twisting, said apparatus being provided with: a lollipop-holder, which is rotatable around an axis and which is preferably axially movable to and fro, a pair of folding means being continuously rotatable, synchronously with the lollipop holder around the axis, the folding means defining both a folding opening and are movable relative to each other to increase and reduce the folding opening means for feeding wrapping material between the folding means and the lollipop holder and for cutting the wrapping material and twisting means, continuously rotatable around axis, synchronously with the lollipop holder, for twisting one end of the wrapping material round the lollipop stick. The present invention is further related to an apparatus for wrapping a lollipop with a stick in a wrapping material by twisting said apparatus being provided with a lollipop-holder, which is rotatable around an axis and which is preferably axially movable to and fro, a pair of folding means being continuously rotatable, synchronously with the lollipop holder around the axis, the folding means defining both a folding opening and are movable relative to each other to increase and reduce the folding opening.

Owner:CFS WEERT BV

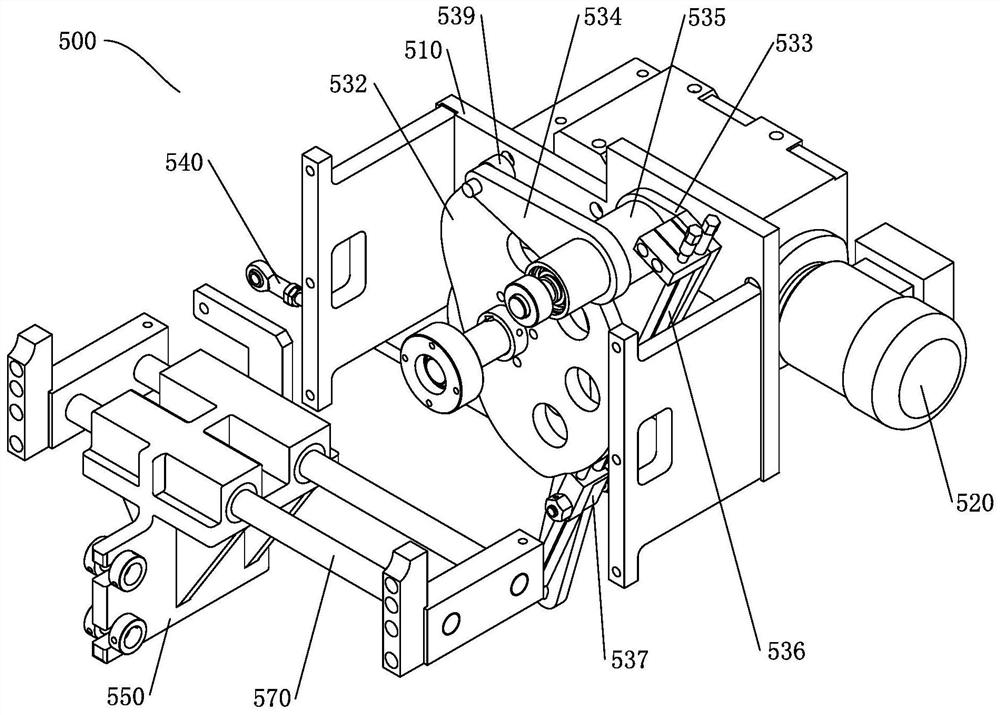

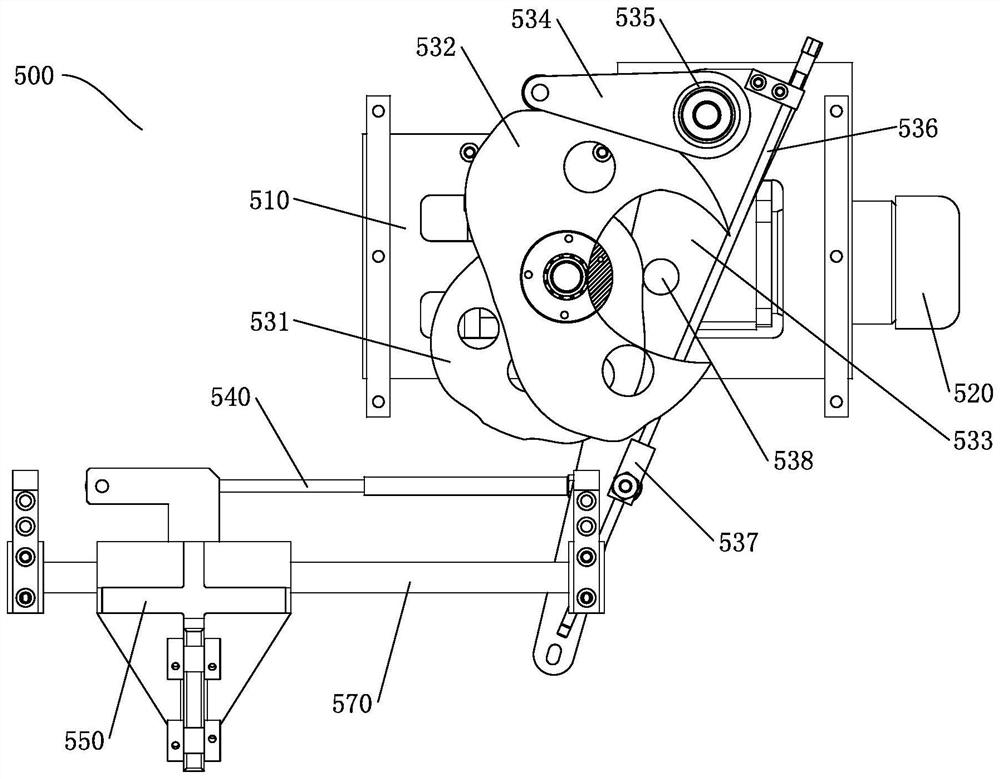

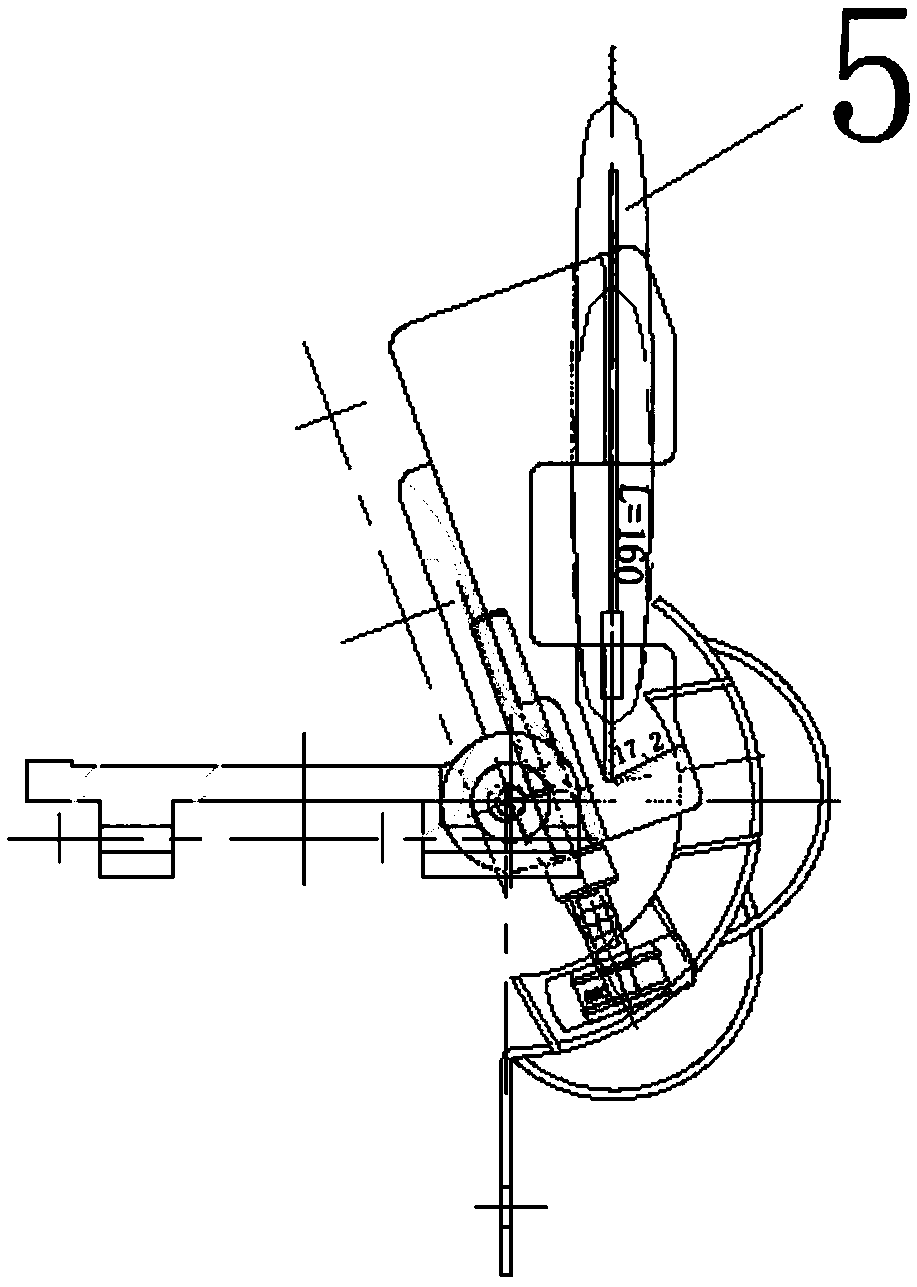

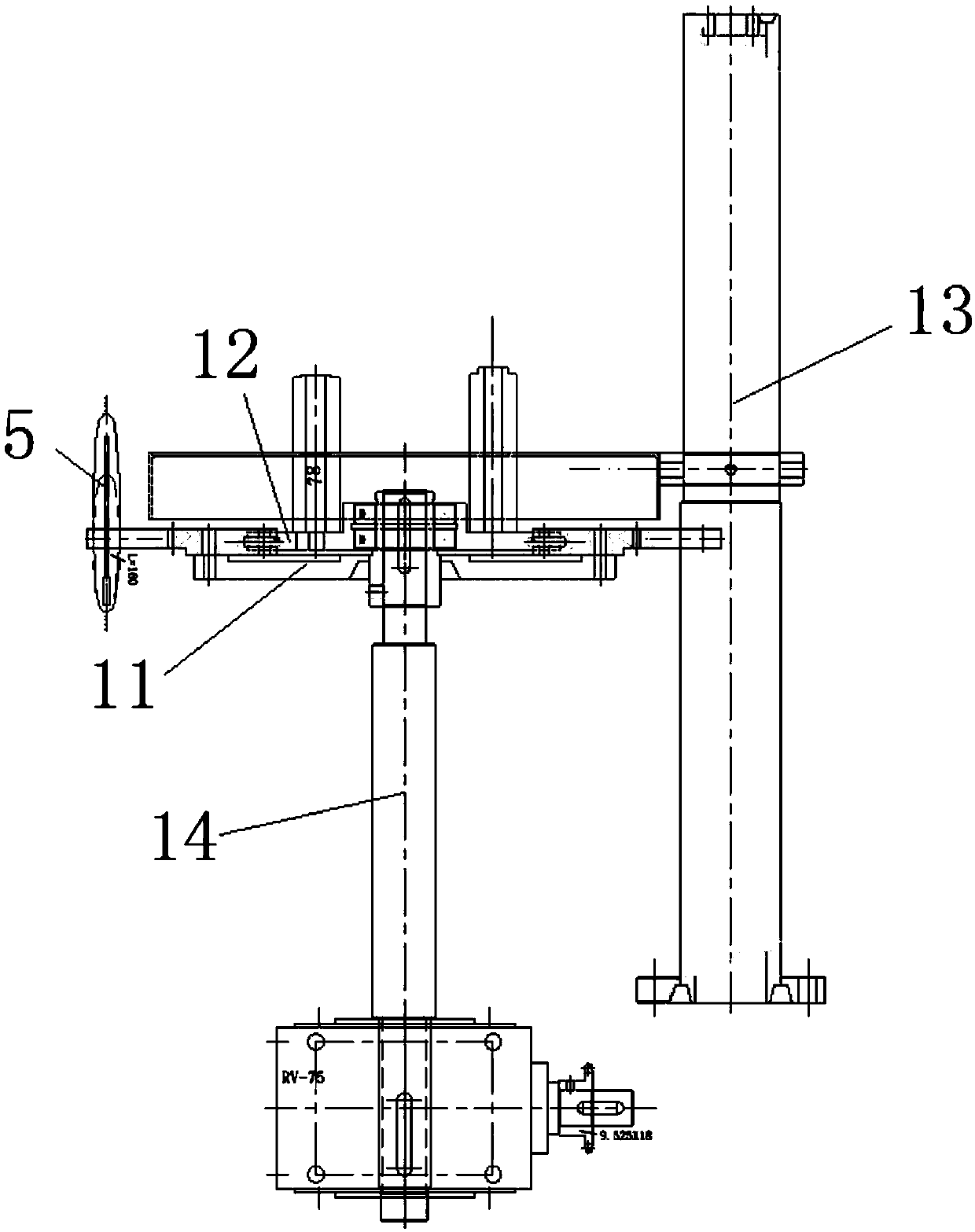

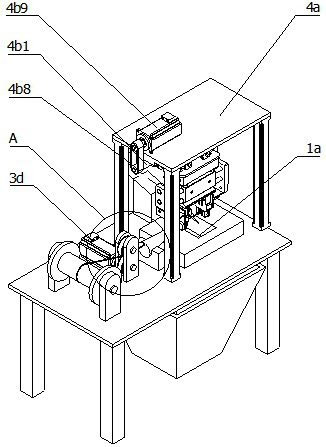

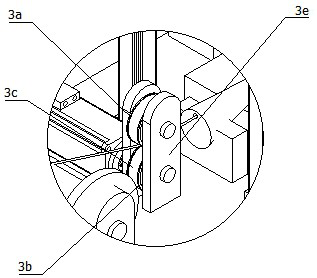

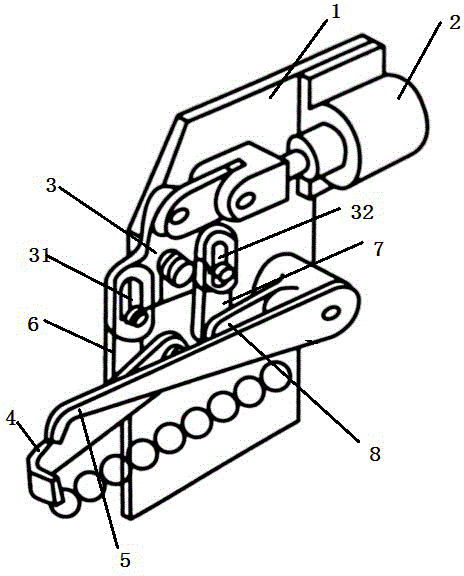

Lollipop pushing device for lollipop packing machine

ActiveCN105346765AChanging the length of the chute trackChange stretch pointPackaging lollipopsEngineeringMechanical engineering

The invention discloses a lollipop pushing device for a lollipop packing machine. The device comprises a cam, a pushing rod, a pushing rod fixing plate, and a lollipop pushing clamp which is arranged at one end of the pushing rod, wherein the cam and the pushing rod fixing plate are coaxially arranged through a rotating shaft; the cam is fixedly mounted on the rotating shaft, and the pushing rod fixing plate can rotate on own axis on the rotating shaft; the pushing rod is movably mounted along the circumference of the pushing rod fixing plate; a slide block which is positioned in a chute of the cylindrical cam is fixed in the middle part of the pushing rod; the pushing rod fixing plate can rotate on own axis to drive the pushing rod to move along the circumference of the cam, and the slide block can move along a track of the chute of the cylindrical cam. The device has the beneficial effects that the cam is formed by combining an 100-degree sector block and a 260-degree sector block; the 100-degree sector block can rotate in 0 to 5 degrees by using the rotating shaft 3.3.5 as a center, so as to change the length of the track of the chute of the cylindrical cam, and as a result, a telescoping point of the pushing rod can be changed.

Owner:成都三可实业有限公司

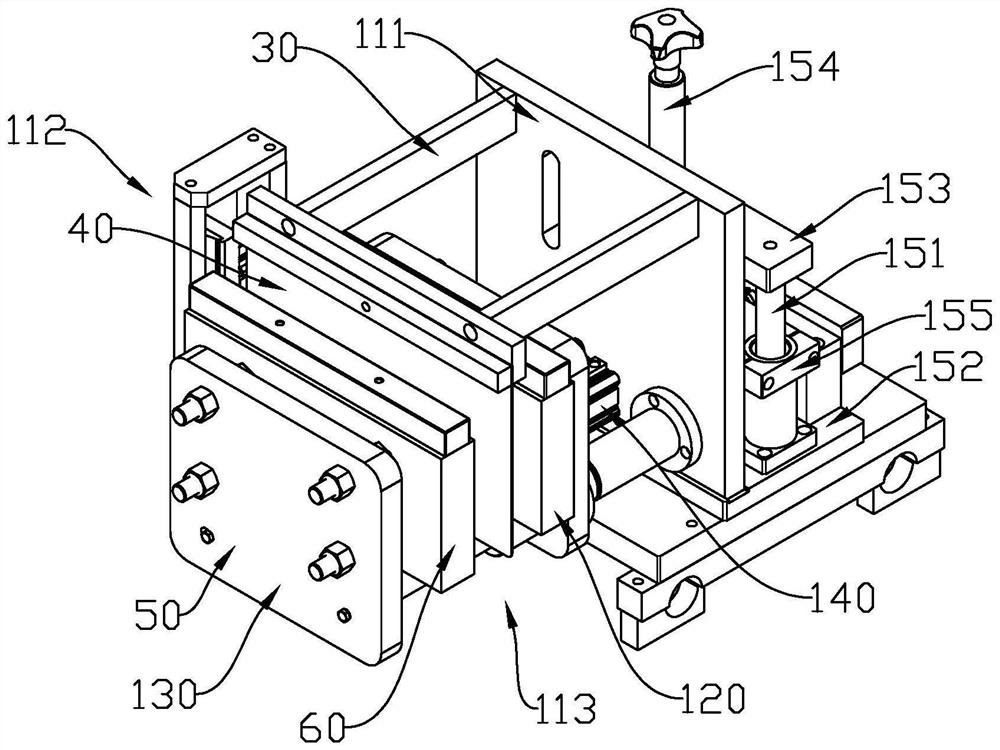

Filling equipment

PendingCN112623328AEliminate the risk of contaminationImprove rod insertion efficiencyWrapping material feeding apparatusFrozen sweetsElectric machineryEngineering

The invention discloses filling equipment, and belongs to the technical field of food production equipment. The equipment comprises a horizontal dragging device and a rod inserting device. The horizontal dragging device comprises a dragging support, a dragging motor, a dragging transmission mechanism and a clamping mechanism, the dragging transmission mechanism comprises a cam connecting rod transmission assembly, a guide rod, a dragging base and a dragging rod, the dragging base is arranged on the guide rod and connected to the cam connecting rod transmission assembly, the dragging rod is fixed to the dragging base, and a clamping base is fixed to the dragging rod. The rod inserting device comprises a rod inserting support, a material storage part, a material conveying part, a connection assembly, a rod inserting assembly and a guide assembly. The horizontal dragging device drags sheets to move in the conveying direction, so that the sheets to be subjected to rod inserting enter a rod inserting station, the rod inserting device inserts rod bodies into material cavities where materials are not poured, then the materials are poured into the material cavities, the materials do not need to be carried in the production process, and the risk that the materials are polluted in the carrying process is effectively eliminated.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

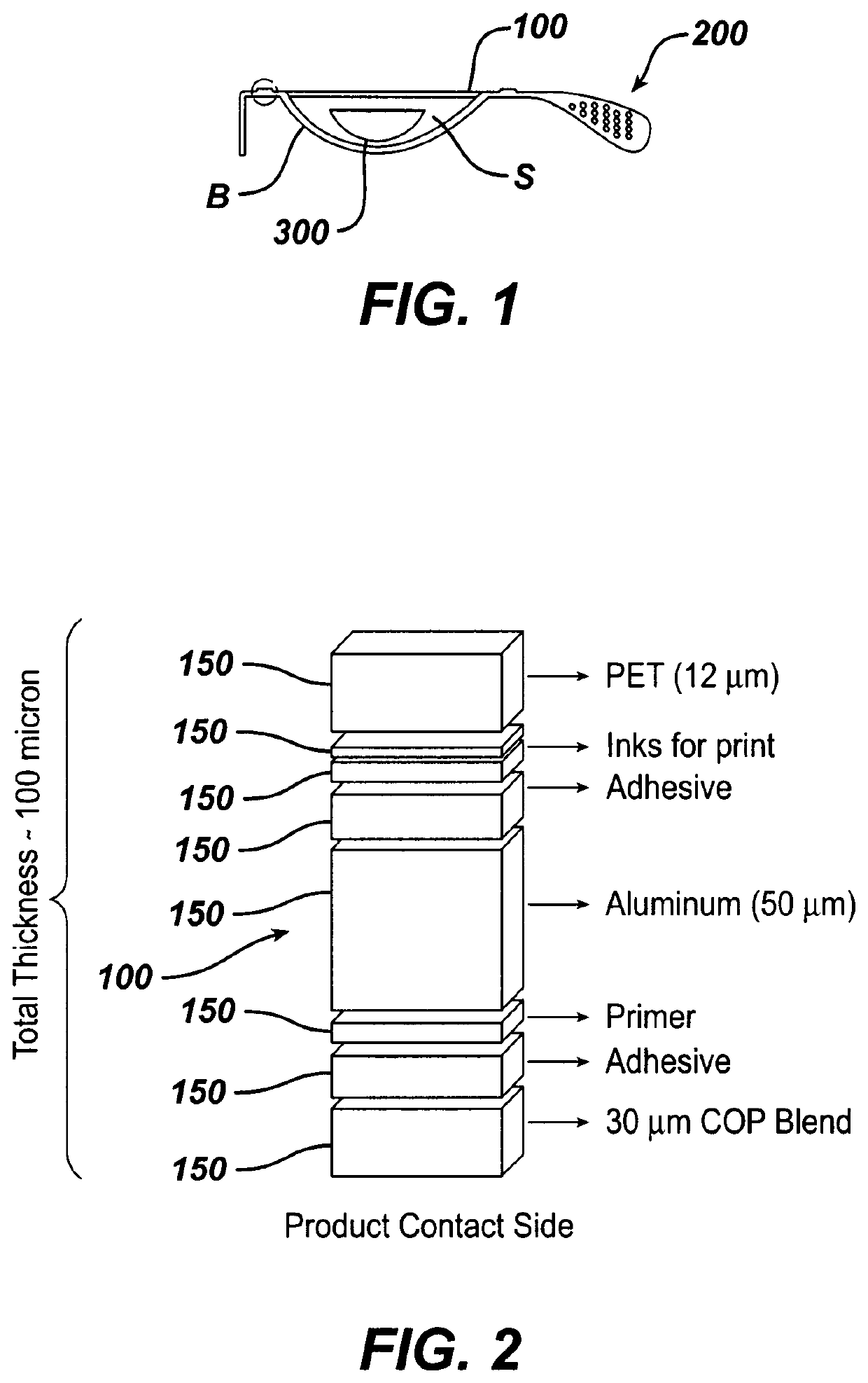

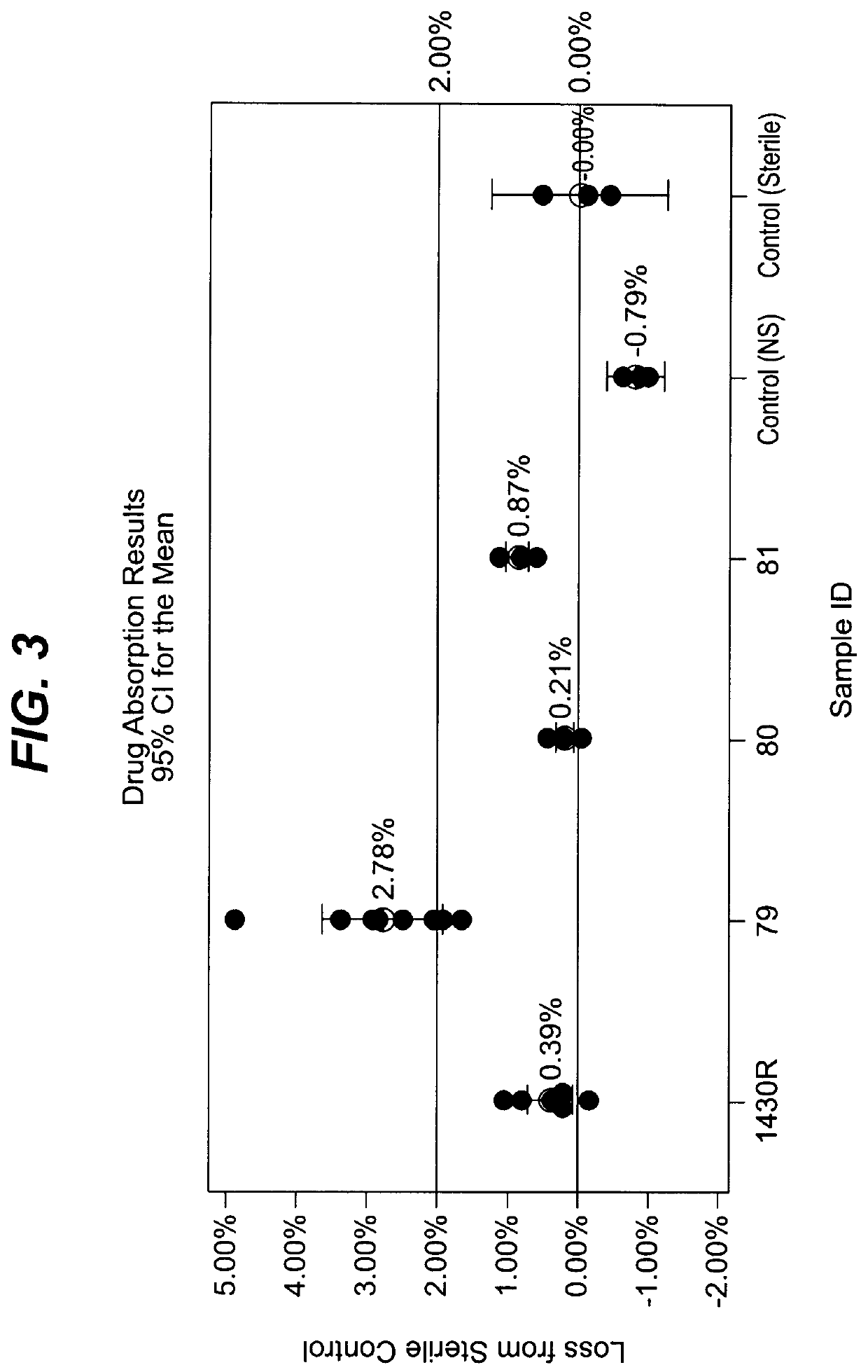

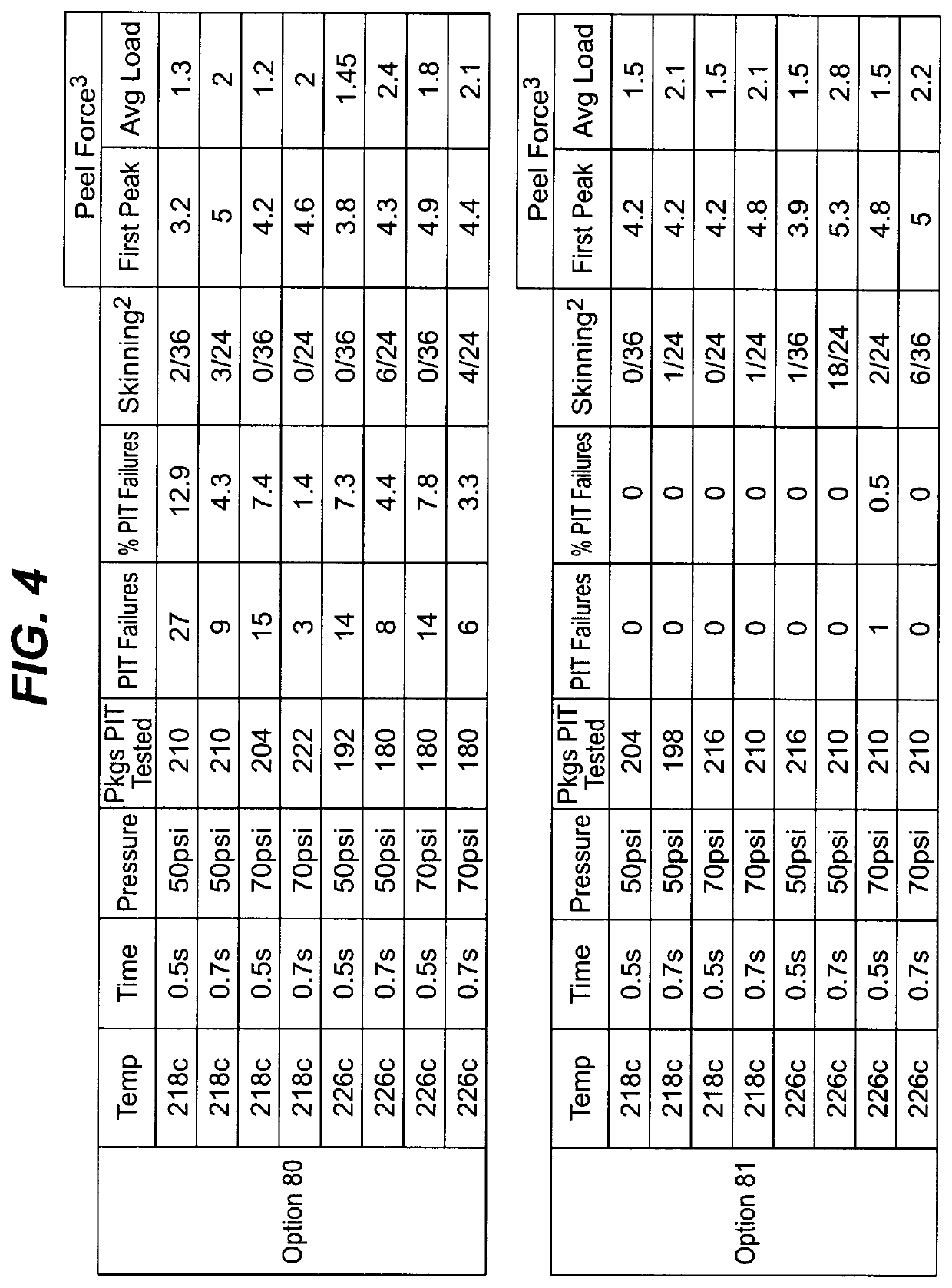

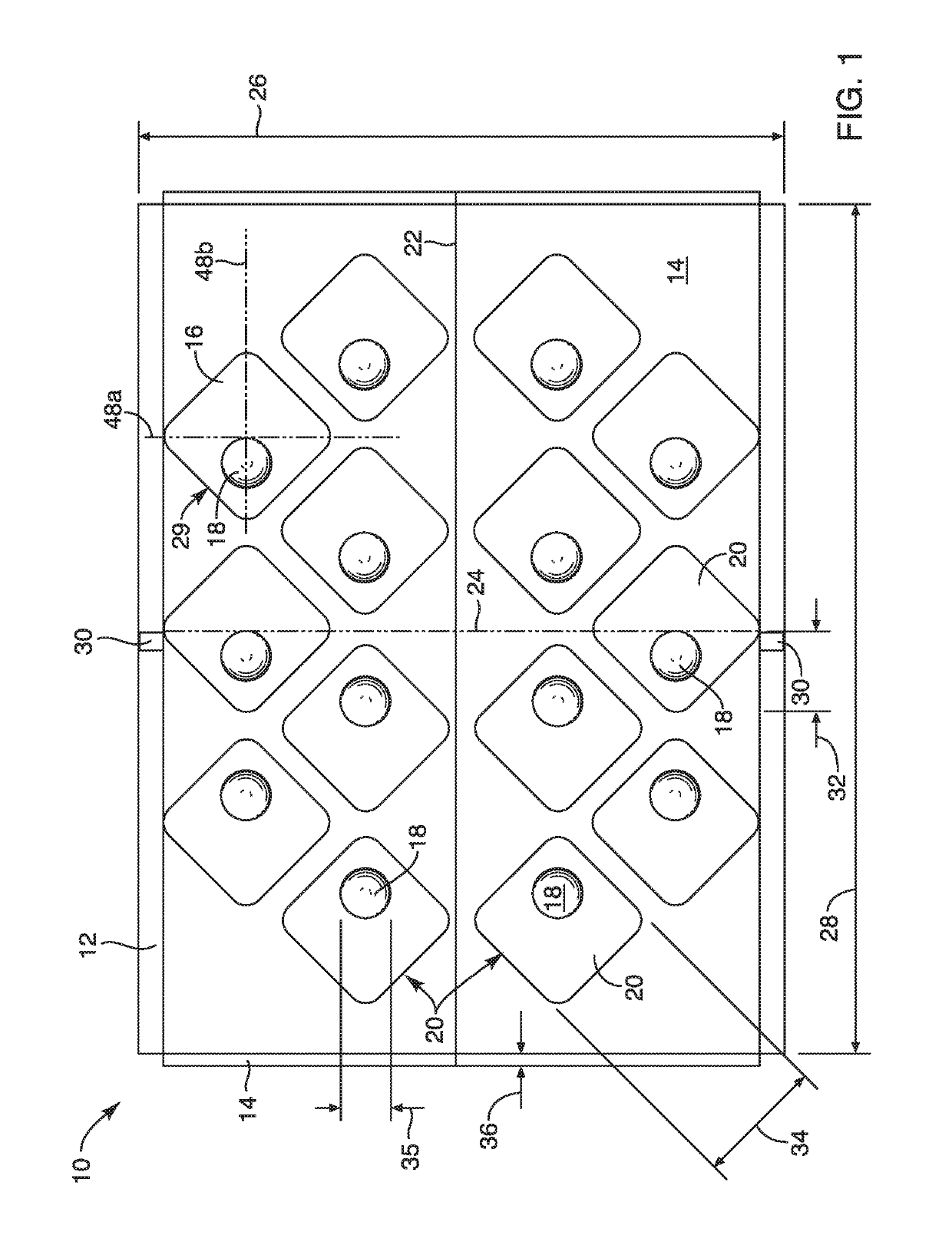

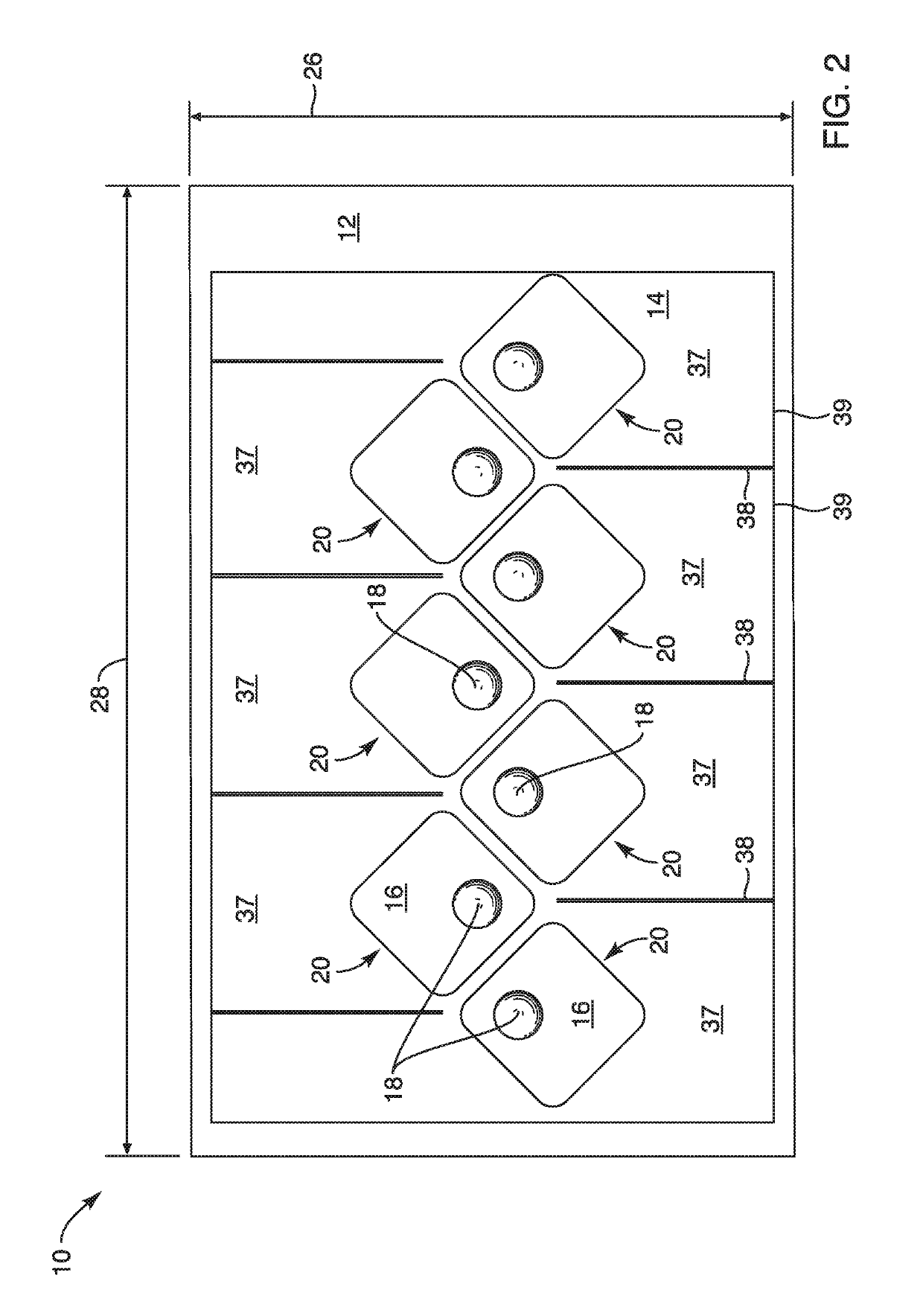

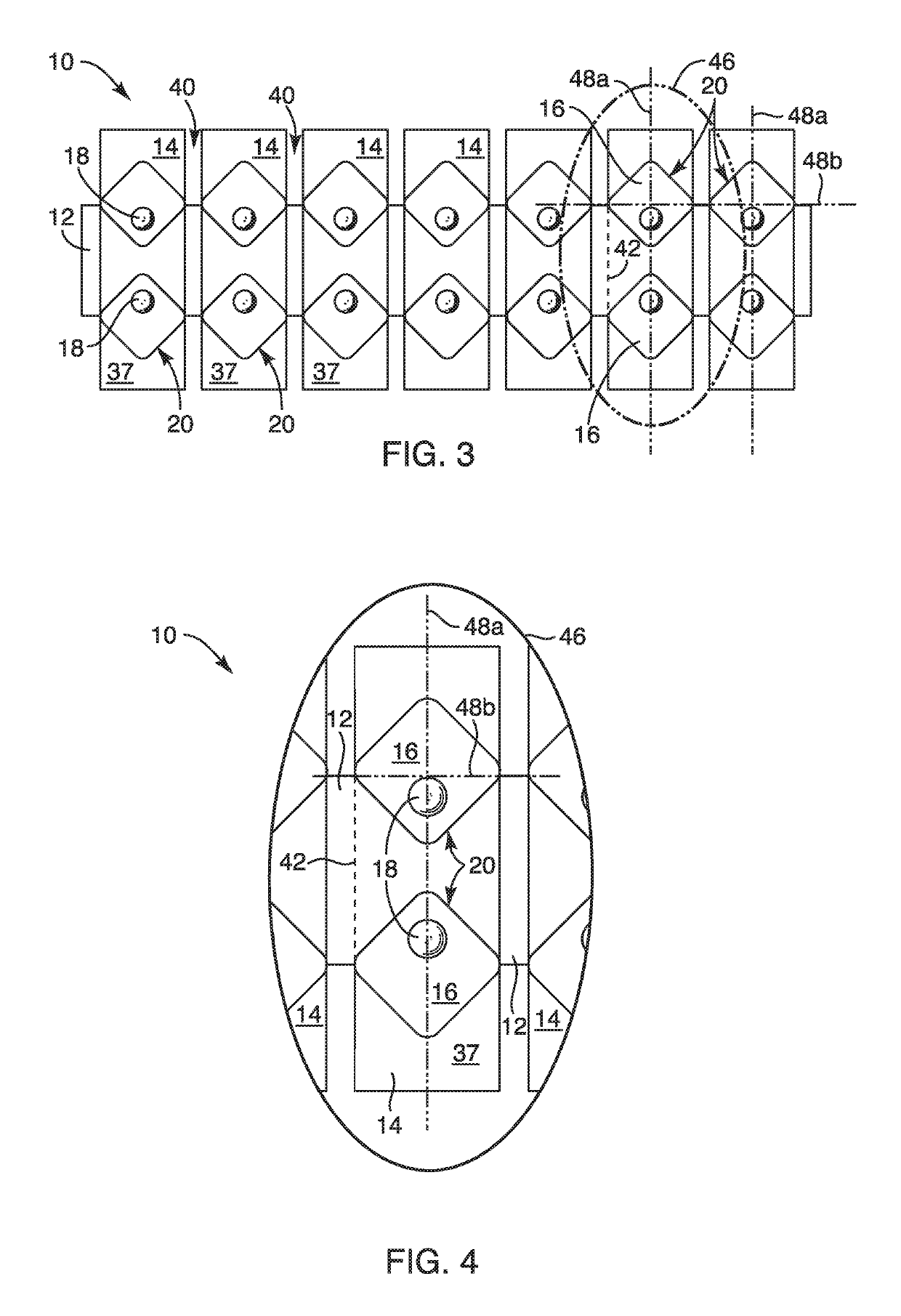

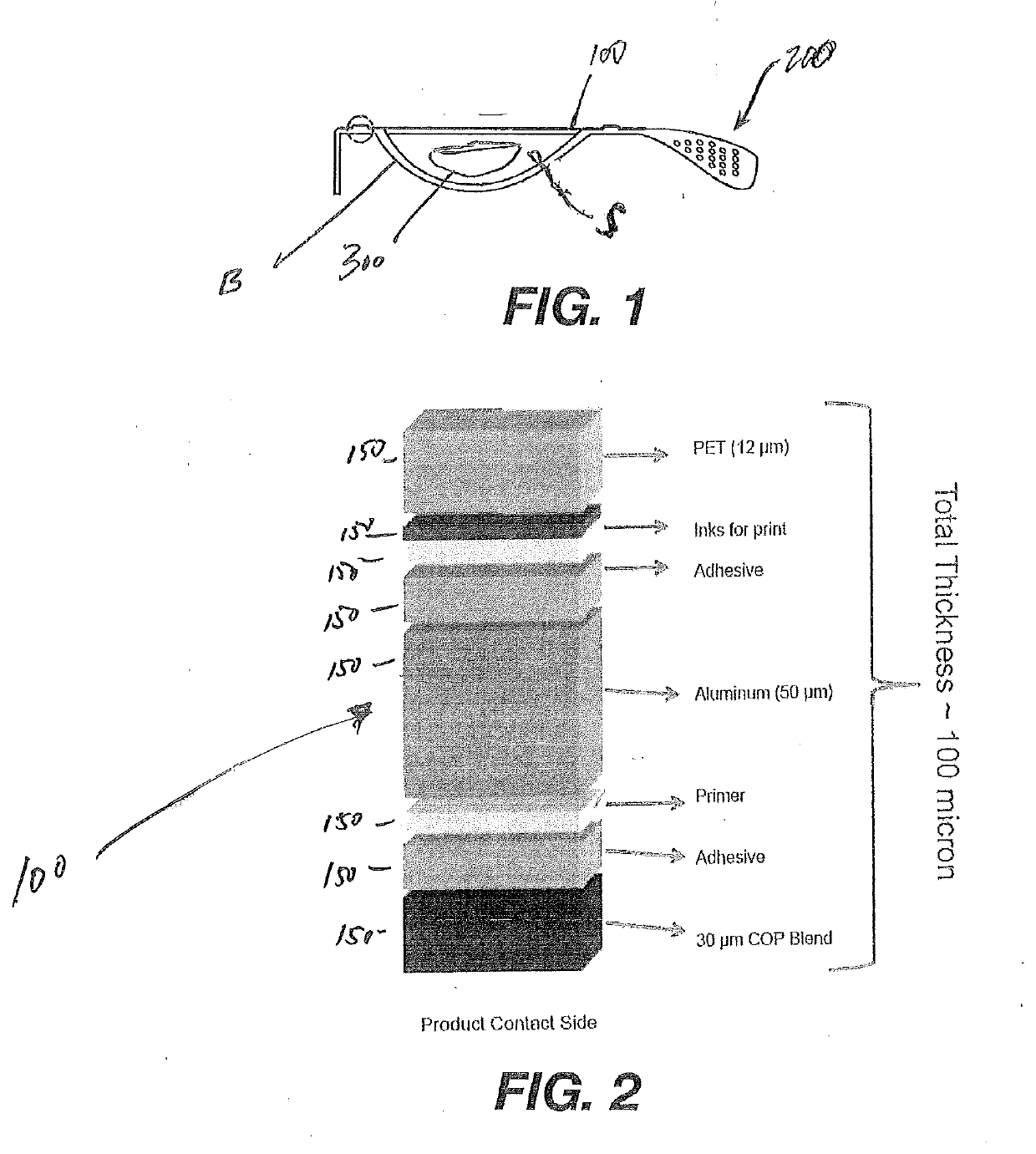

Package for an ophthalmic device having a multilayer lidstock containing a cyclic olefin seal layer

The present invention is related to a contact lens package with a heat sealable multilayer packaging lidstock formed from:a support layer anda peelable seal layer made from a polymer blend, such polymer blend formed from a material:from 40 to 85% by weight of one or more first amorphous cyclic olefin polymer(s) characterized by a glass transition temperature of at least 120° C.from 10 to 55% by weight of one or more second amorphous cyclic olefin polymer(s) characterized by a glass transition temperature of less than 120° C., andfrom 0.5 to 15% by weight, preferably 0.5 to 10% by weight of at least one elastomeric copolymer comprising at least one polymerized monovinylarene and at least one polymerized acyclic olefin.

Owner:JOHNSON & JOHNSON VISION CARE INC

Pet-medicine-capsule wrapper apparatus and method

ActiveUS10299496B2Maintain the shape of the treat wrapAccessory food factorsWrappingBiomedical engineeringPutty

Methods and compositions for obscuring medicines formed as tablets, capsules, pills, and so forth may be presented in clean packaging, with built-in work space on a substrate, film layer. A flexible paste, gum, putty, or malleable and formable treat material may be folded without touching the actual treat composition on its outermost surface. A medicament set onto a location on a surface of the composition may then be folded inside by folding, molding, or otherwise manipulating the composition, thus forming a sealed morsel, leaving no residue (e.g., powder, scent, taste, etc.) of the medicament on the outer surface of the composition when administered to a pet.

Owner:GOLDBERG MARY ELIZABETH

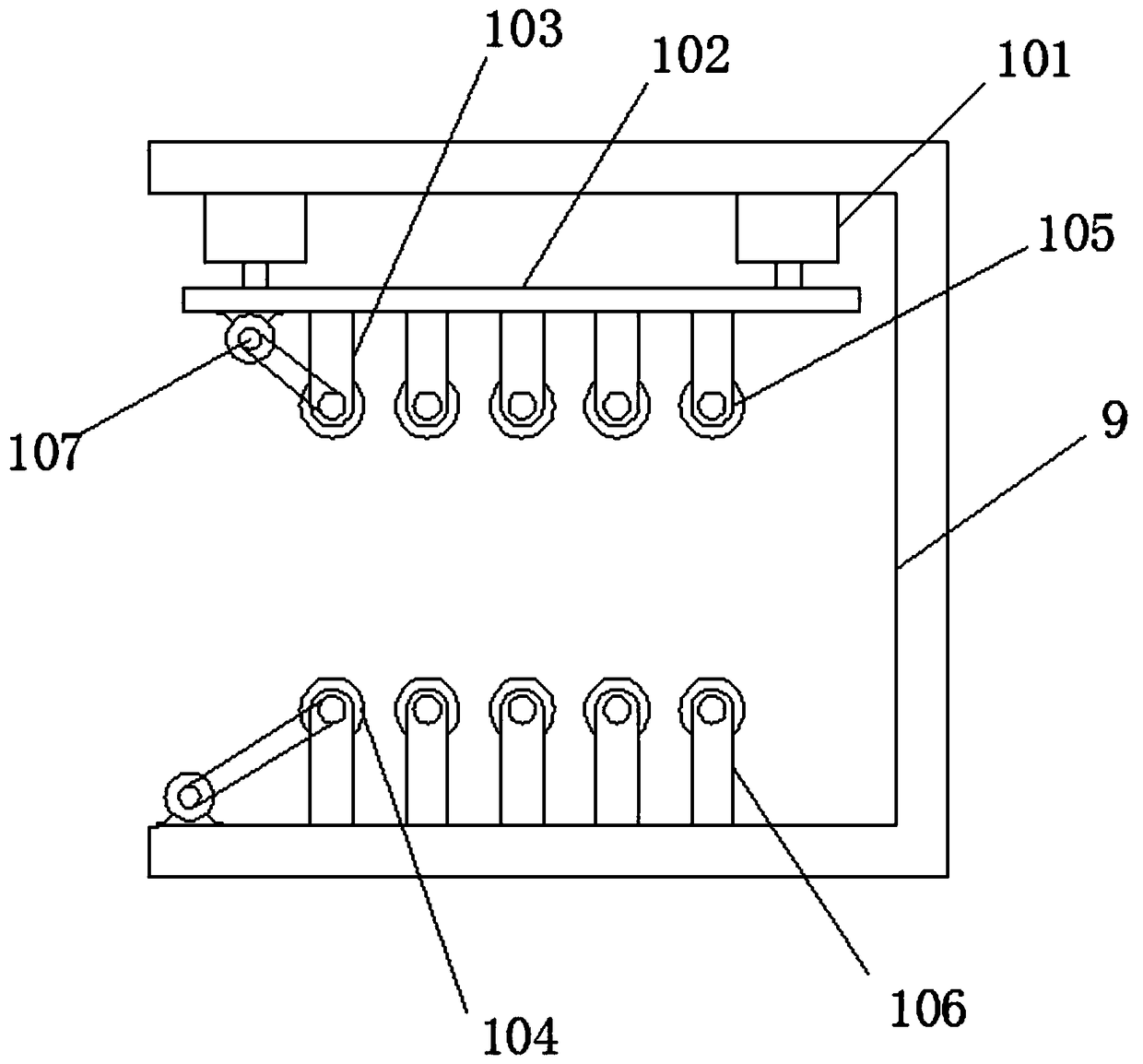

Production equipment and method for rod insertion food

PendingCN112623331AShorten the timeIncrease productivityWrapping material feeding apparatusFrozen sweetsMechanical engineeringIndustrial engineering

The invention discloses production equipment for rod insertion food, belongs to the field of food production equipment. The production efficiency can be improved, and the production equipment comprises a rack, an upper end preheating part arranged on the rack, a lower end preheating part arranged on the rack, a sealing component arranged on the rack, a molding component arranged on the rack, a rod inserting device arranged on the rack, a pouring device arranged on the rack, a sealing device arranged on the rack, a cutting device arranged on the rack, and a horizontal dragging component arranged on the rack.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

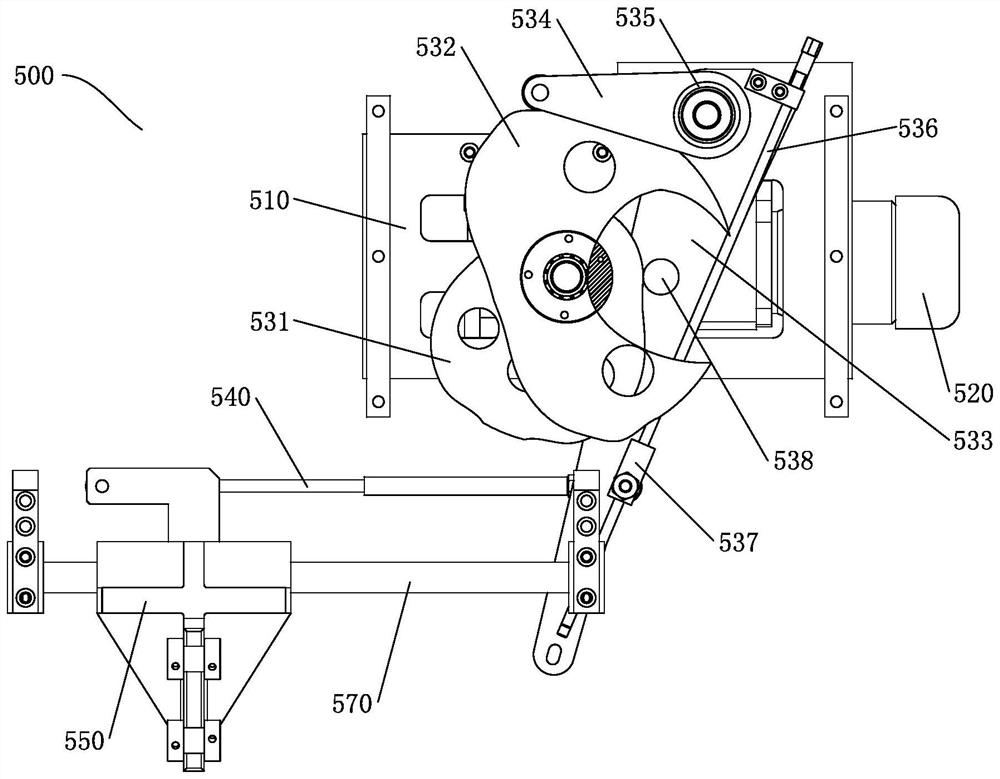

Lollipop self-rotatingmachine for lollipop packaging

ActiveCN109573148AGuaranteed tightnessWrapper twisting/gatheringPackaging lollipopsEngineeringMechanical engineering

The invention discloses a lollipop self-rotatingmachine for lollipop packaging. The lollipop self-rotatingmachine comprises an installation frame, a second center shaft, a candy head clamp assembly and a hot sealing clamp assembly, the hot sealing clamp assembly is used for heat-sealing packaging bags to lollipop sticks, and the candy head clamp assembly is used for driving lollipops to do self-rotatingtype movement. According to the lollipop self-rotatingmachine for lollipop packaging, the packaging bags are heated while rotating is conducted, and when the cylinder-shaped packaging bags are sealed and tightly fixed to plastic rods in a heating mode, the tightness of the packaging bags being heat-sealed to the plastic rods can be ensured.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

Package for an Ophthalmic Device Having a Multilayer Lidstock Containing a Cyclic Olefin Seal Layer

The present invention is related to a contact lens package with a heat sealable multilayer packaging lidstock formed from:a support layer anda peelable seal layer made from a polymer blend, such polymer blend formed from a material:from 40 to 85% by weight of one or more first amorphous cyclic olefin polymer(s) characterized by a glass transition temperature of at least 120° C.from 10 to 55% by weight of one or more second amorphous cyclic olefin polymer(s) characterized by a glass transition temperature of less than 120° C., andfrom 0.5 to 15% by weight, preferably 0.5 to 10% by weight of at least one elastomeric copolymer comprising at least one polymerized monovinylarene and at least one polymerized acyclic olefin

Owner:JOHNSON & JOHNSON VISION CARE INC

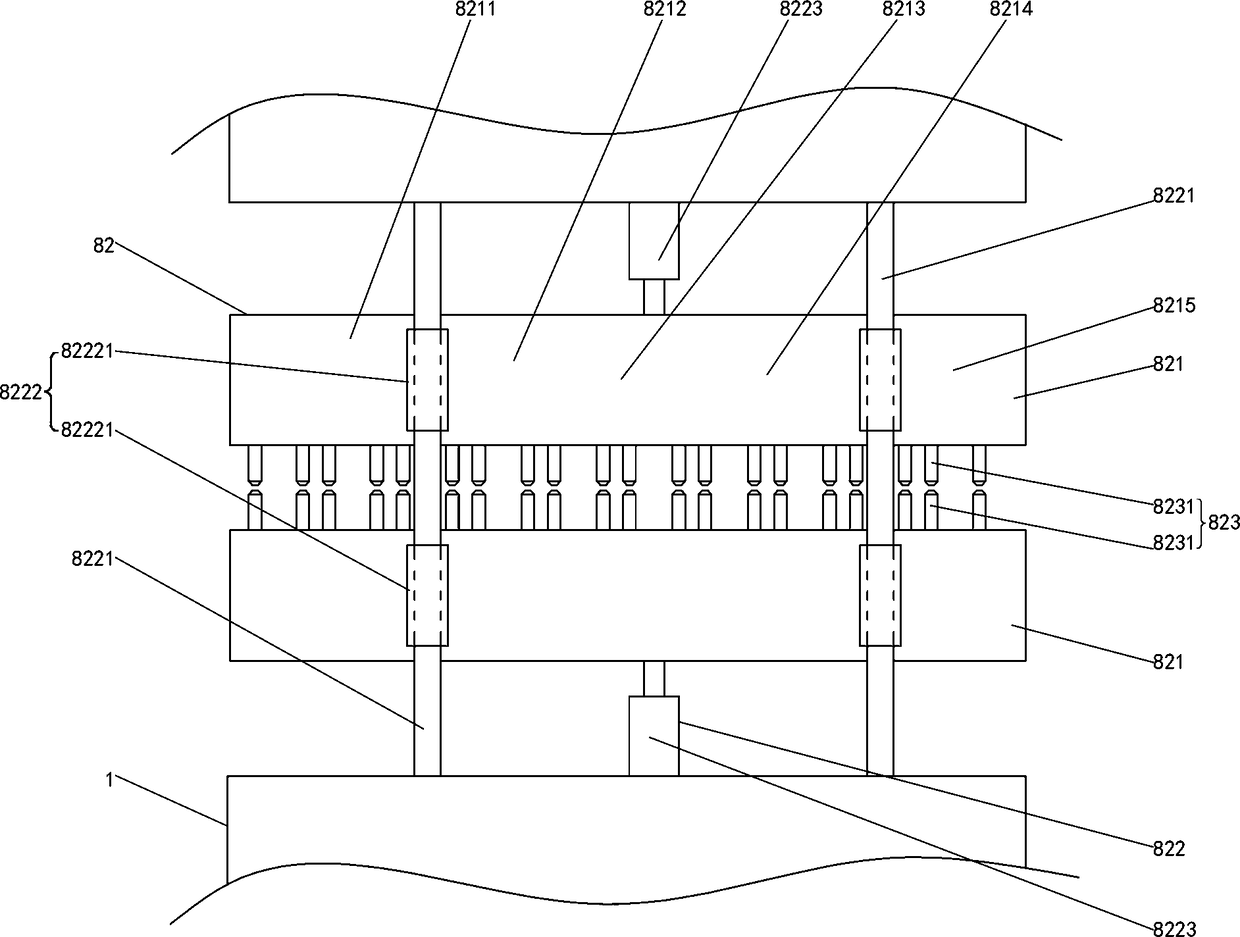

Folded sheet upper-end preheating part and plunger food production equipment

PendingCN112607098ASoft textureFacilitates the sealing stepWrapping material feeding apparatusPackaging lollipopsEngineeringMechanical engineering

The invention discloses a folded sheet upper-end preheating part and plunger food production equipment, which belong to the field of food processing equipment and can improve production efficiency. The folded sheet upper-end preheating part comprises a preheating base, and further comprises a drive part, wherein a supporting partition plate is arranged on the preheating base; a metal plate fixing frame is arranged at the upper end of the supporting partition plate; the bottom of the metal plate fixing frame is fixedly equipped with a metal baffle plate; during transfer, two folded parts of the folded sheet are separately positioned at the two sides of the metal baffle plate; the two sides of the metal baffle plate are further separately equipped with a first heating clamping plate and a second heating clamping plate for heating the upper part of the folded sheet; and the drive part is in transmission connection to the first heating clamping plate and the second heating clamping plate, and drives the first heating clamping plate and the second heating clamping plate to get close to or get away from the metal baffle plate.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

A candy pushing device for lollipop packaging machine

ActiveCN105346765BChanging the length of the chute trackChange stretch pointPackaging lollipopsEngineeringSugar

The invention discloses a lollipop pushing device for a lollipop packing machine. The device comprises a cam, a pushing rod, a pushing rod fixing plate, and a lollipop pushing clamp which is arranged at one end of the pushing rod, wherein the cam and the pushing rod fixing plate are coaxially arranged through a rotating shaft; the cam is fixedly mounted on the rotating shaft, and the pushing rod fixing plate can rotate on own axis on the rotating shaft; the pushing rod is movably mounted along the circumference of the pushing rod fixing plate; a slide block which is positioned in a chute of the cylindrical cam is fixed in the middle part of the pushing rod; the pushing rod fixing plate can rotate on own axis to drive the pushing rod to move along the circumference of the cam, and the slide block can move along a track of the chute of the cylindrical cam. The device has the beneficial effects that the cam is formed by combining an 100-degree sector block and a 260-degree sector block; the 100-degree sector block can rotate in 0 to 5 degrees by using the rotating shaft 3.3.5 as a center, so as to change the length of the track of the chute of the cylindrical cam, and as a result, a telescoping point of the pushing rod can be changed.

Owner:成都三可实业有限公司

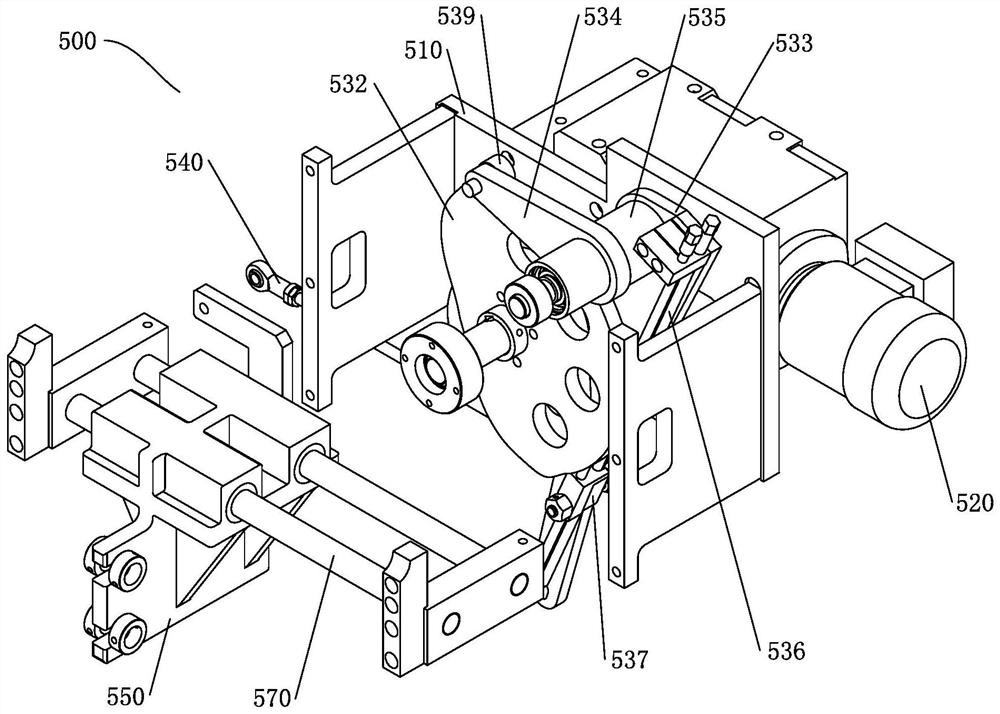

Single-twist inflating packing machine

ActiveCN109573146AIncrease productivityWrapper twisting/gatheringPackaging lollipopsEngineeringRotating disc

The invention discloses a single-twist inflating packing machine. The single-twist inflating packing machine comprises an installation frame and a hot sealing clamp assembly; the hot sealing clamp assembly is installed on the installation frame; the hot sealing clamp assembly comprises a second center shaft, a second guiding wheel, a plurality of groups of heat sealing clamps and a second rotatingdisc; the second center shaft is vertically installed on the installation frame; the outer wall of the second guiding wheel is in a continuous and irregular curved surface shape; the second guiding wheel rotatably sleeves the shaft section of the second center shaft; the second guiding wheel is fixedly connected with the installation frame; the second rotating disc is fixed to the second center shaft in a sleeving mode, and located on the lower part of the second guiding wheel; each group of heat sealing clamps comprises a first heat sealing clamp, a second heat sealing clamp and an elastic repositor; and the multiple groups of heat sealing clamps are uniformly distributed around the central axis of the second rotating disc. Lollipops are clamped by the heat sealing clamps, meanwhile, packing bags are heat-sealed to lollipop sticks, and the production efficiency is high.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

Canning equipment

PendingCN112758389AEffective croppingImprove croppingWrapping material feeding apparatusFrozen sweetsElectric machineryEngineering

The invention discloses canning equipment, and belongs to the technical field of food production equipment. The canning equipment comprises a horizontal dragging device and a cutting device; the horizontal dragging device comprises a dragging support, a dragging motor, a dragging transmission mechanism and a clamping mechanism; the cutting device comprises a cutting motor, a cutting transmission mechanism, a cutting die cutter, a front pressing plate, a rear pressing plate, a front seat plate and a rear seat plate; the front pressing plate is arranged on the rear side of the front seat plate, the cutting die cutter and the rear pressing plate are arranged on the front side of the rear seat plate, the cutting motor drives the front seat plate and the rear seat plate to synchronously move in the opposite directions or move synchronously in the front-back direction, and waste edge outlets cooperating with the cutting die cutter are formed in the rear pressing plate, the front pressing plate and the front seat plate; and the front pressing plate and the rear pressing plate make contact with a sheet and clamp the sheet, the rear pressing plate floats backwards relative to the rear seat plate under the abutting action, the cutting die cutter can cut the portion, needing to be cut, of the sheet, and cut waste is separated from the cutting device through the waste edge outlet.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

A lollipop automatic stringing machine

ActiveCN110921004BContinuous threading taskWrapper twisting/gatheringPackaging lollipopsEngineeringWire wrap

The present invention relates to the technical field of food machinery, in particular to an automatic lollipop stringing machine, which includes a mounting seat, a winding wheel, a threading mechanism, a feeding mechanism and a ribbon, and the mounting seat is provided with a drop hole. The wire tie mechanism is set above the blanking hole, the feeding port of the feeding mechanism is set between the wire tie mechanism and the blanking hole, the winding wheel and the traction mechanism are both set on the mounting seat, and one end of the tie wire belt is wound on the winding wheel , the other end of the tie ribbon is set on the working end of the tie mechanism through the traction mechanism. This equipment is simple and efficient, and can continuously carry out the tie task.

Owner:郑晓华

Full-automatic single-twist air-blowing packaging machine

PendingCN109573147AIncrease productivityWrapper twisting/gatheringPackaging lollipopsEngineeringAutomatic testing

The invention discloses a full-automatic single-twist air-blowing packaging machine. The full-automatic single-twist air-blowing packaging machine comprises a lollipop conveyor, a sugar feeding gripper assembly, a heat sealing clamp assembly, a candy head clamp assembly, a sugar discharge gripper assembly, a mounting frame and a positioning shaft; and the heat sealing clamp assembly is used for heat sealing a packaging bag on a lollipop stick, and the candy head clamp assembly is used for driving lollipops to perform the rotary motion. When the lollipops are placed in cylindrical packaging bags with one ends pressed and sealed, an operator sequentially puts the packaged lollipops into the heat sealing clamp assembly, the opening ends of the packaging bags can be heat sealed on the lollipopsticks as the heat sealing clamp assembly operates, and thus the production efficiency is remarkably improved.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

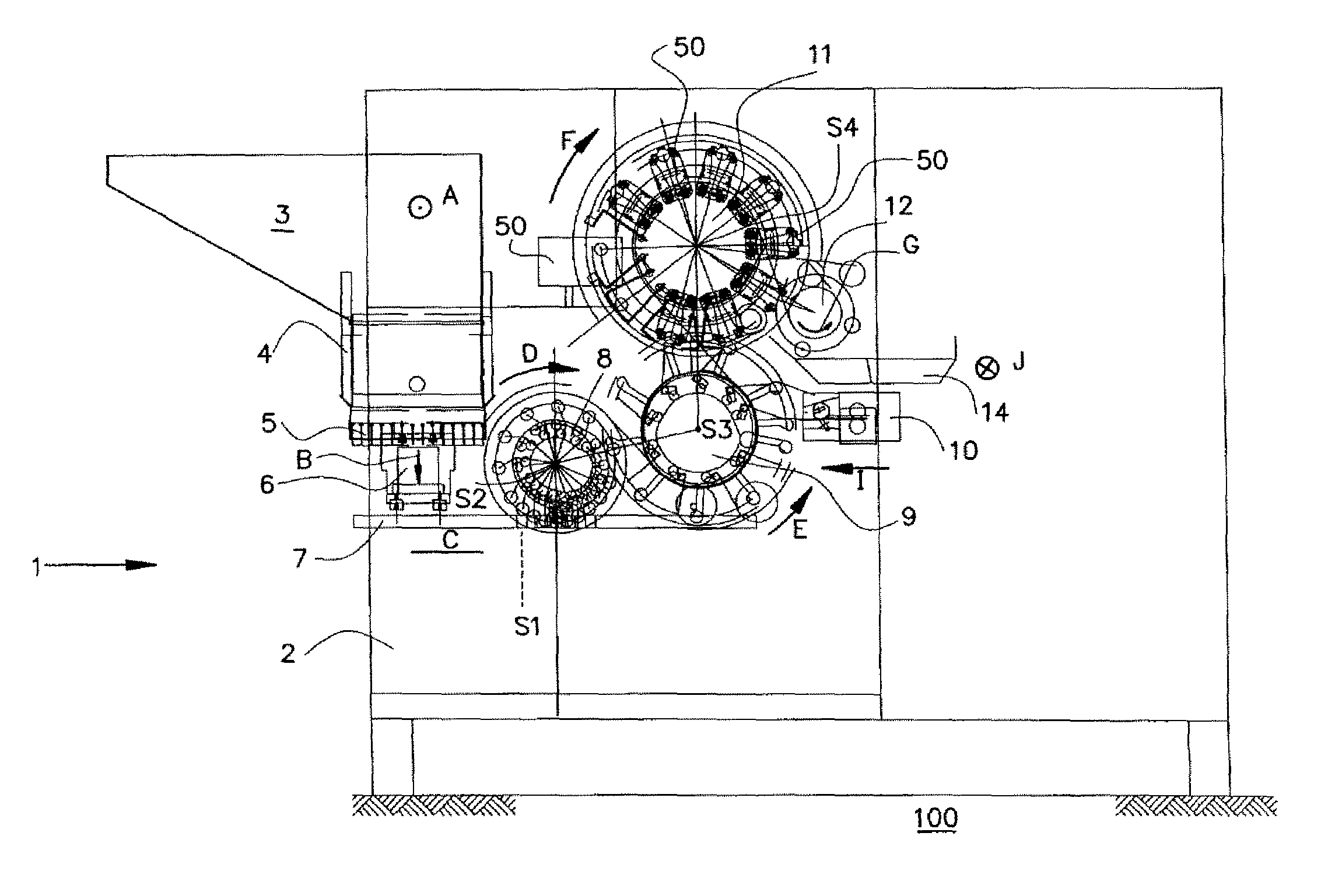

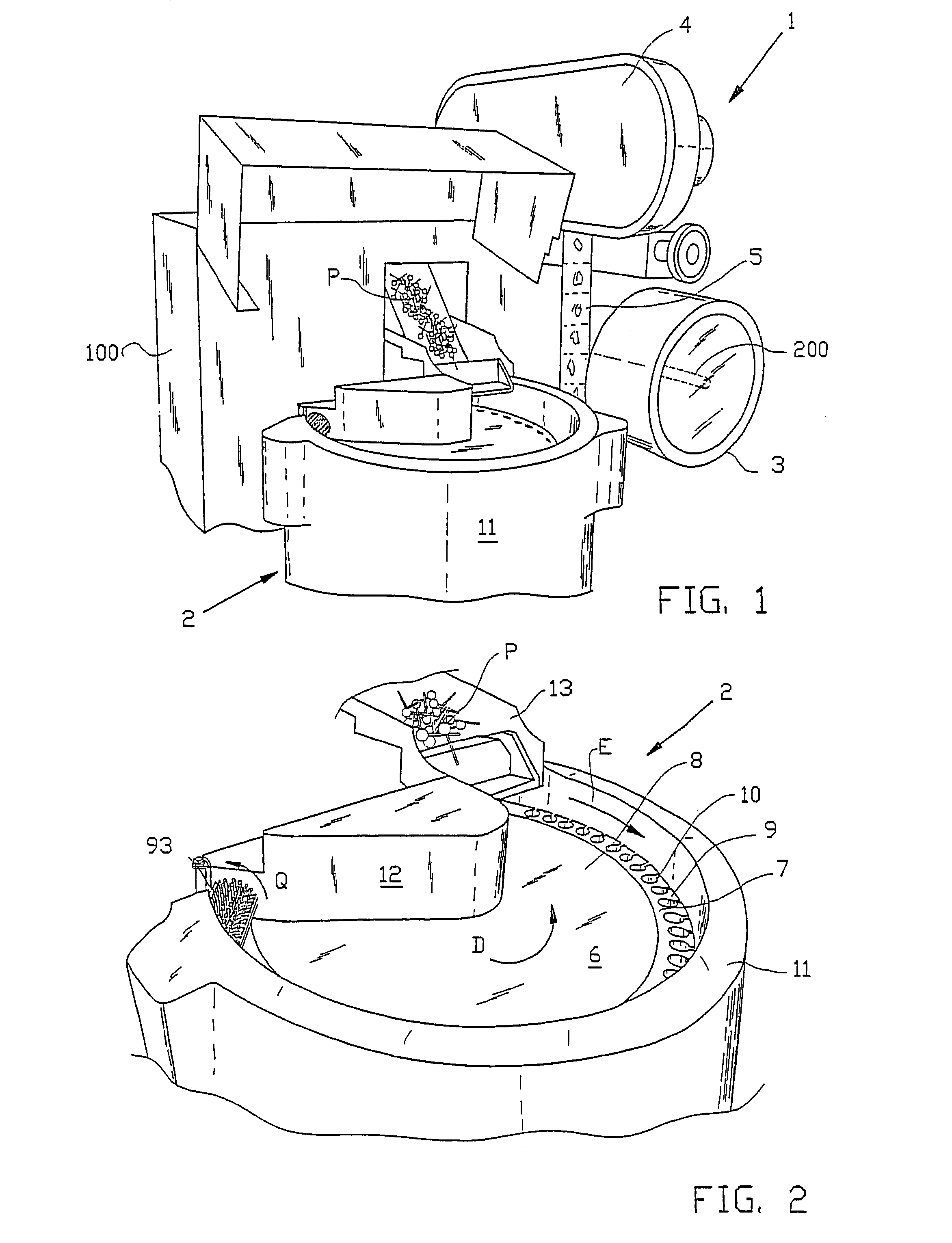

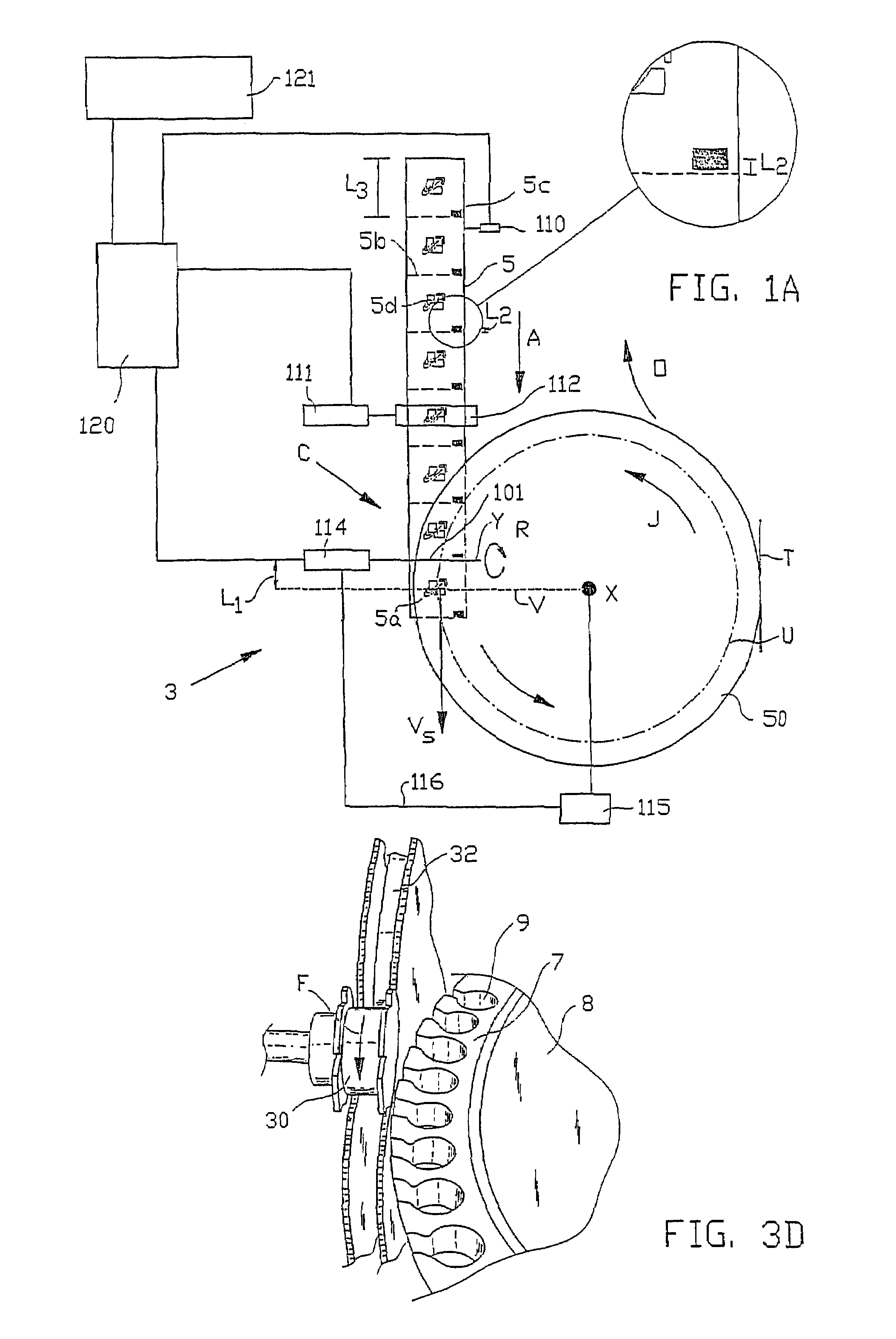

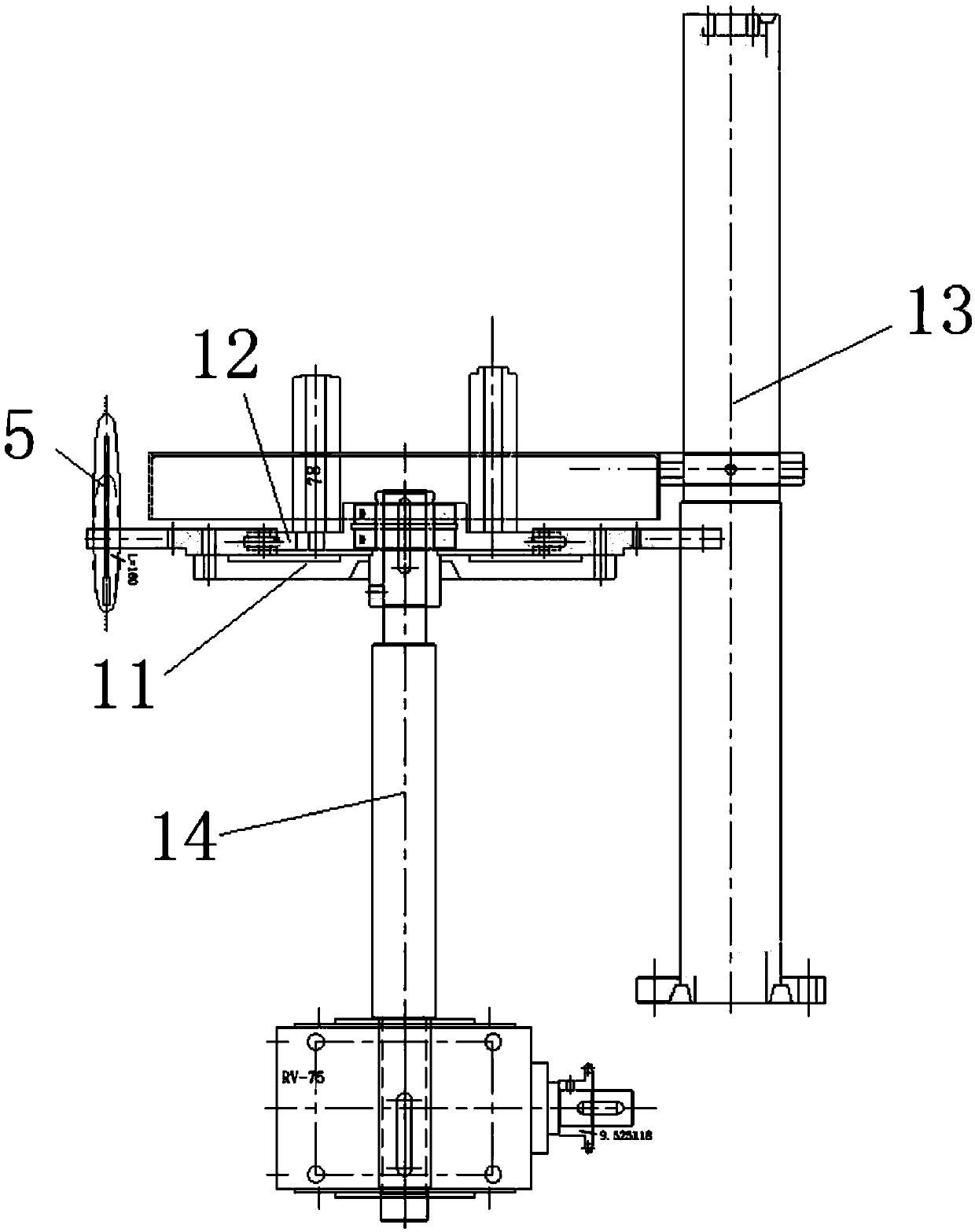

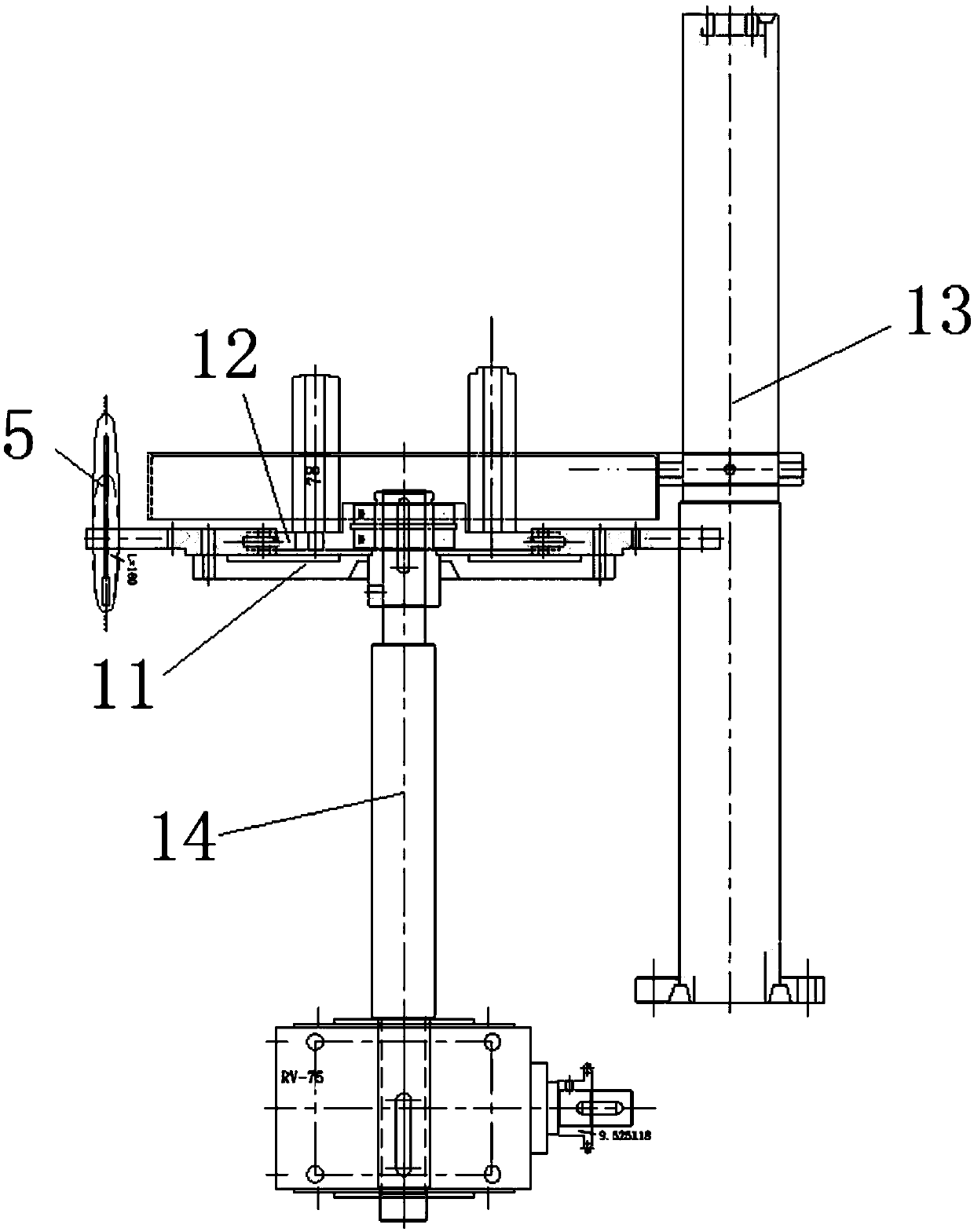

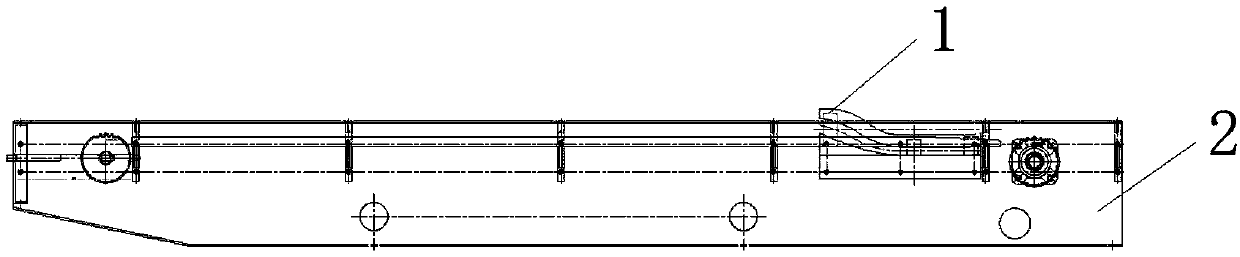

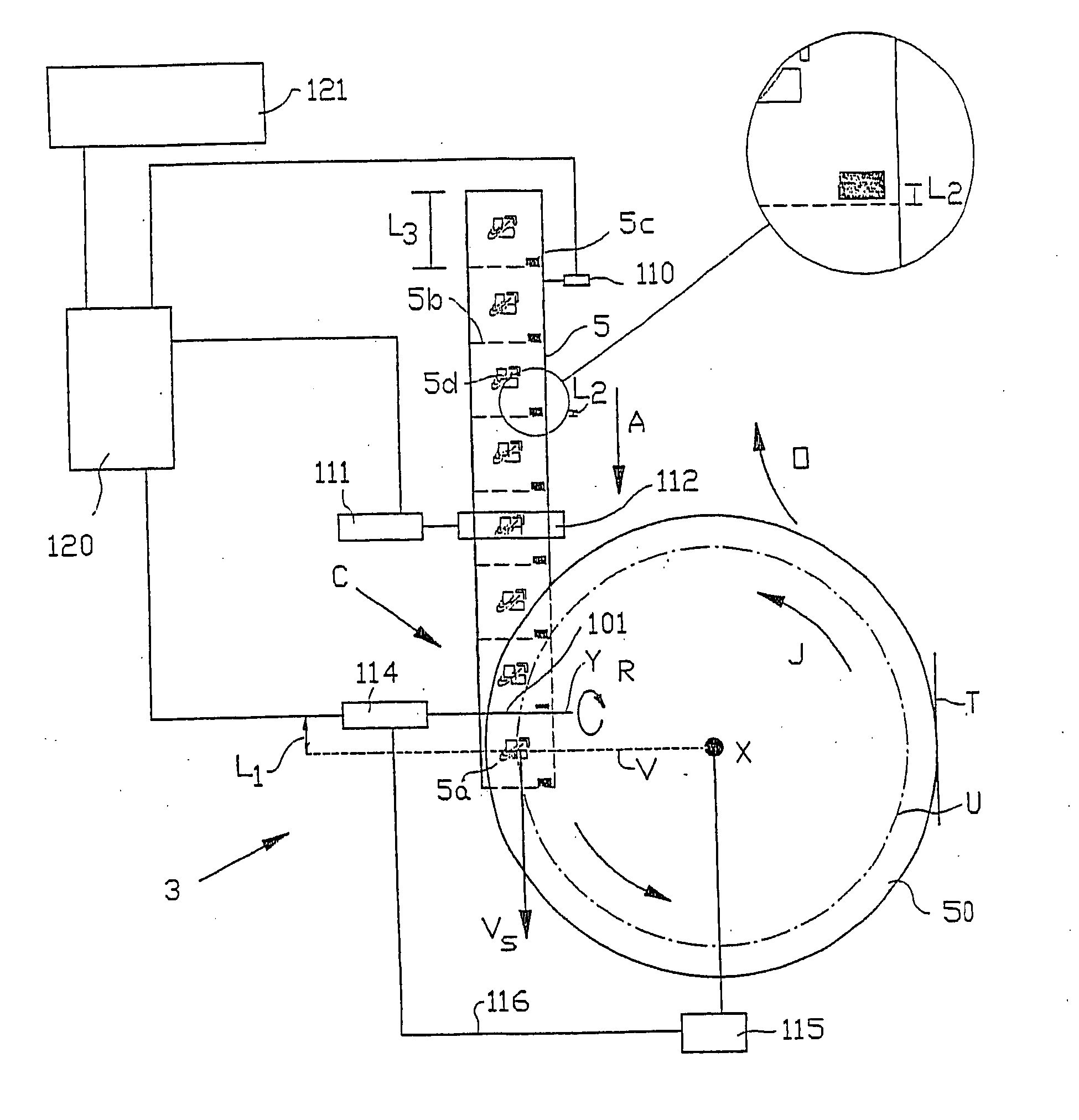

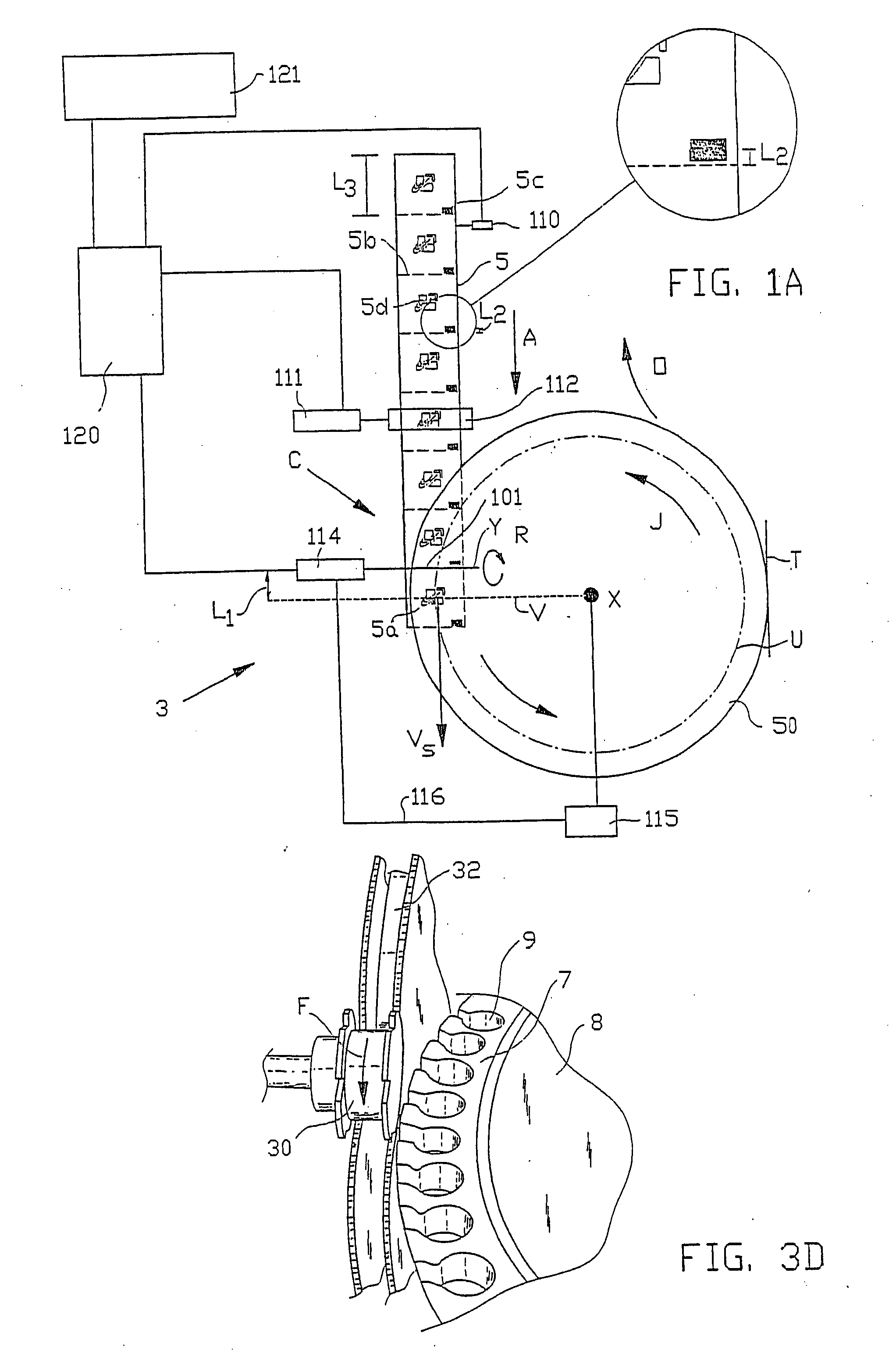

Machine for packaging products

InactiveUS20080034715A1Easy to moveSpaceWrapper folding/bending apparatusConveyor wrappingEngineeringMechanical engineering

Device for packaging products having a head and a stick, such as lollipops (P), in wraps, includes a frame having first supply elements (2) for supplying the products, second elements (4) for supplying a web (5) of wrapping material, elements (101) for cutting a wrap from the web, a wrapping station having a driven series of elements for retaining the products and circulating in a first direction about a horizontal shaft, and a drum (50) driven in the same direction having elements for enveloping the product heads with a wrap and elements for securing the wrap on the products, the wrapping station including a supply station and a discharge station, the second supply elements being positioned for supplying the web of wrapping material according to a path that is tangential to the drum, in a direction running along with the drum rotation.

Owner:CFS WEERT BV

Twisted batch candy packaging machine

InactiveCN111332525APrevent twistingEfficiency of control rotationConveyor wrappingPackaging lollipopsEngineeringPackaging machine

The invention discloses a twisted batch candy packaging machine. The twisted batch candy packaging machine structurally comprises a transfer rod, a control box, a side control body, an introduction box, a uniform distribution channel and a conveying table, wherein the transfer rod is arranged on the outer surface of the conveying table, the control box and the transfer rod are arranged on the samevertical plane, candies are arranged on a placing channel along abutting blocks, the abutting blocks are used for evenly arranging the candies, packaging paper of the abutting blocks is continuouslywrapped on the outer surfaces of the candies, one end is used for fixing a stress point, the other end is in a propped state, when an outer layer loses resistance, the packaging paper can be pushed intime, when the candy packaging paper is continuously wrapped, tight packing sections can be subjected to distance interference to control the rotating efficiency and prevent the packaging paper frombeing twisted off, the force of the last end can be fixed towards directed arcs, when folding angles drive side bending edges to be continuously bent, the force of stacking the middle end is assisted,partition openings control the protruding force of clamping layers, the grain of the packaging paper is consolidated, and after packaging paper joints are twisted, the packaging paper joints are pressed and do not loosen.

Owner:张新旺

Quantitative feeding mechanism for spherical food

InactiveCN104477424ARealization of quantitative feedingPrevent crashSolid materialPackaging lollipopsEngineeringMechanical engineering

The invention relates to a quantitative feeding mechanism for food, in particular to a quantitative feeding mechanism for spherical food. The quantitative feeding mechanism for spherical food comprises a fixed plate, an air cylinder used as a driving device and an inclined feeding chute, wherein a piston rod of the air cylinder is hinged with a rocker plate, the rocker plate is hinged onto the fixed plate, a front sliding groove in a vertical direction is formed in one side of a hinging point of the rocker plate and the fixed plate, a rear sliding groove in the vertical direction is formed in the other side of the rocker plate and the fixed plate, a front stop claw and a rear stop claw are arranged below the rocker plate, the front stop claw and the rear stop claw are hinged on the fixed plate, the front stop claw is hinged with a front connecting rod, the rear stop claw is hinged with a rear connecting rod, pins are arranged on the front connecting rod and the rear connecting rod, the front connecting rod is slideably connected with the rocker plate through a pin which is fit with the front sliding groove in the rocker plate, and the rear connecting rod is slideably connected with the rocker plate through a pin which is fit with the rear sliding groove in the rocker plate. The purpose of the invention is to provide a quantitative feeding mechanism for spherical food which is simple in structure and is purely mechanical.

Owner:CHONGQING DAJIAFU FOOD

A double-head twist type lollipop packaging equipment

ActiveCN111330923BConvenience to workImprove work efficiencyHollow article cleaningPackaging lollipopsStructural engineeringSugar

The invention discloses a double-head twisted lollipop packaging equipment, the structure of which comprises a frame, a motor, a sugar tray, a kink, a controller, and a paper feeding device. A controller is arranged on the top of the frame, and the paper feeding device is installed on On the frame, the sugar sorting tray is set on the side of the paper feeding device, a kink is installed above the sugar sorting tray, and a motor is installed at the bottom of the sugar sorting tray. The sugar sorting tray includes a tray body, a main gear, a sugar ring, a rotating shaft, and a secondary gear. There is a main gear in the middle of the inside of the disc body, a sugar ring is evenly distributed on the outer edge of the disc, and a secondary gear is installed on the outer bottom of the sugar ring, and the secondary gear meshes with the main gear. The beneficial effect of the present invention is: The cooperation can clean the sugar ring in a cycle without stopping the machine for cleaning, which improves the work efficiency, and the cleaning block can be reset by driving the unwinding wheel to rotate a few times through the rotation of the screw, which is convenient for repeated work.

Owner:新昌县兴欧智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com