Lollipop packaging device for lollipop packaging machine

A packaging machine and lollipop technology, which is applied to the packaging of lollipops, packaging, transportation packaging, etc., can solve the problems of low automation level and difficulty in improving production efficiency, and achieve the effect of improving the automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

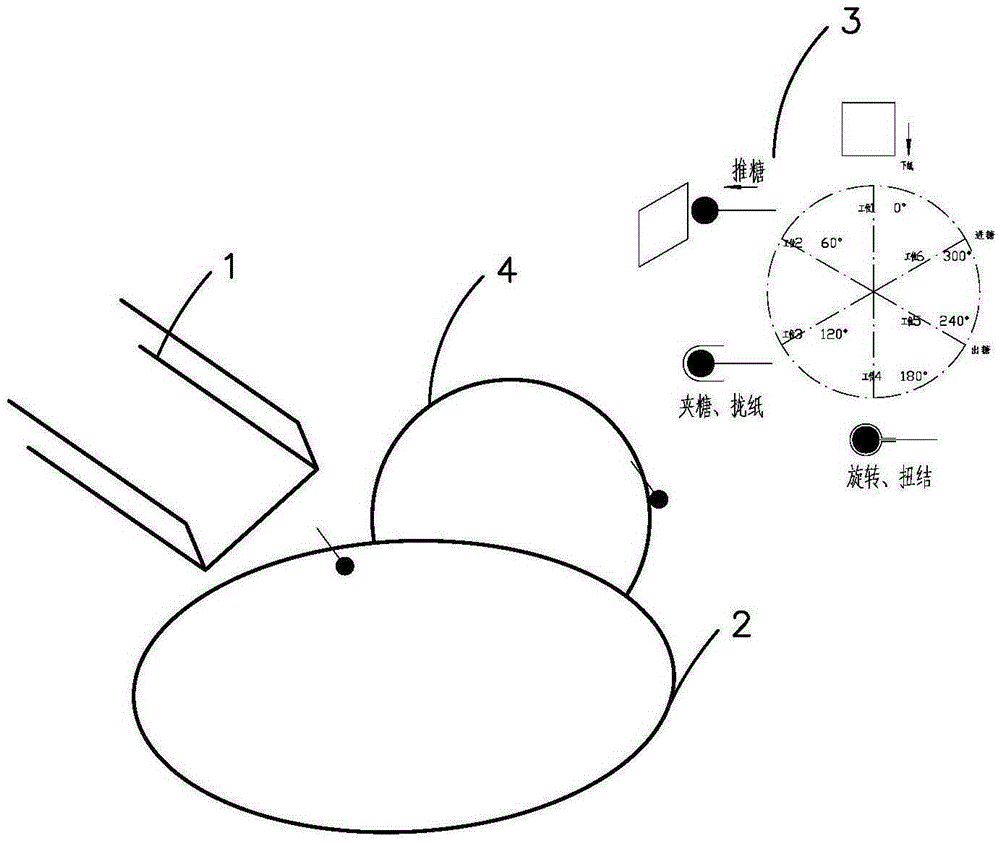

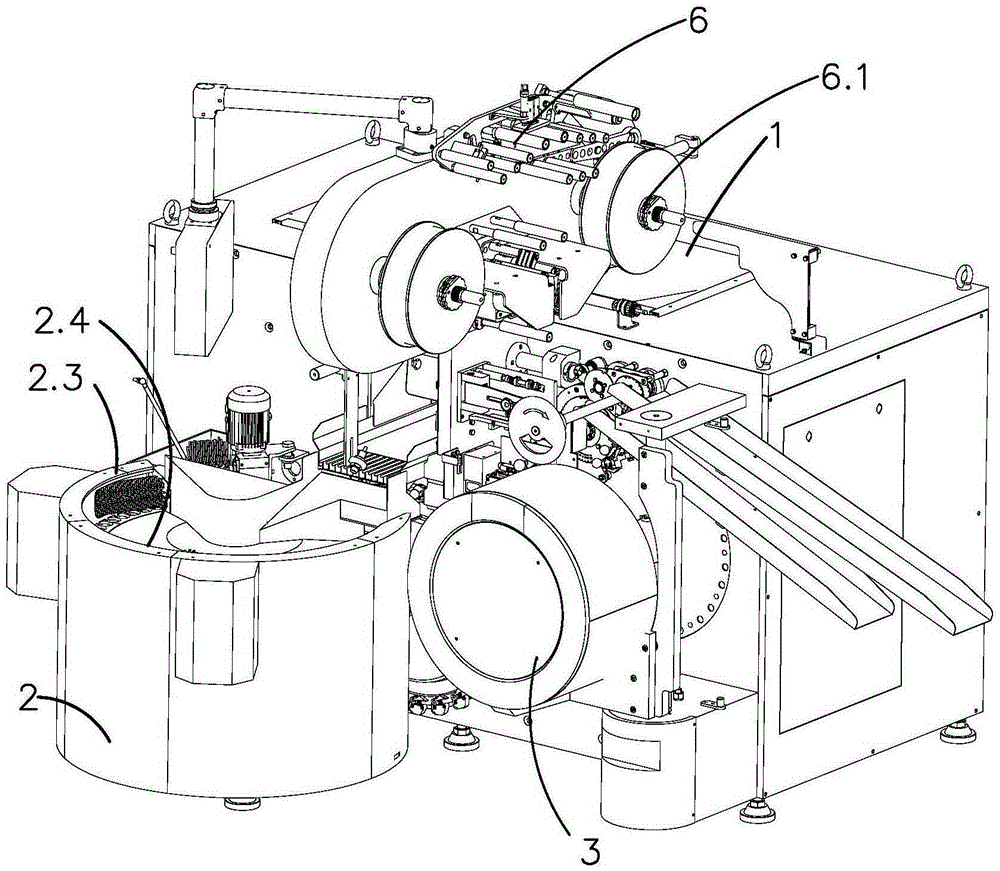

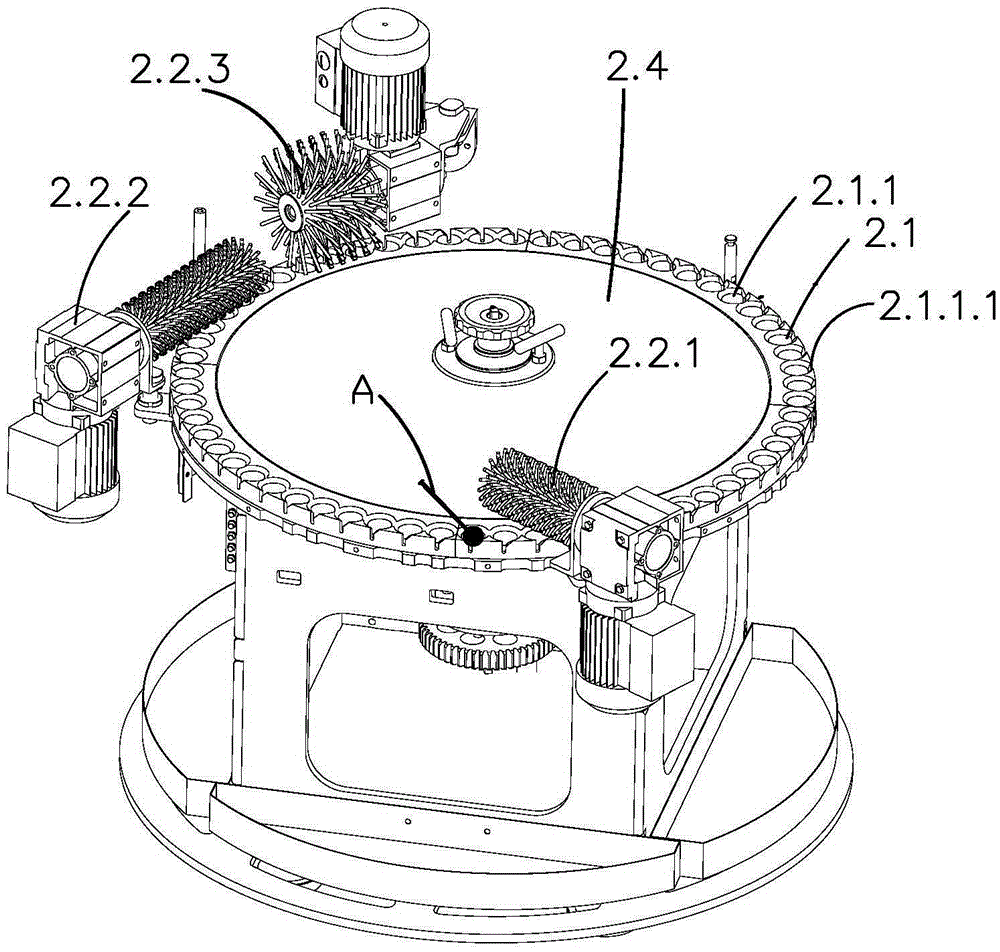

[0050] When the lollipop packaging machine is working, the lollipop material A to be packaged enters the feeding box 1.2 of the unloading device 1 through the conveyor belt of the production workshop, and slides into the feeding box 1.2 through the "V"-shaped section of the feeding box 1.2. Installed on the guide plate 1.4 between the discharge port 1.3 and the feed box 1.2. The guide plate 1.4 can be cyclically vibrated back and forth, left and right, and the sugar A that slides into the guide plate 1.4 is sifted out from the discharge port 1.3 and dropped into the sugar sorting tray 2.1. The upper part of the extension part of the guide plate 1.4 is equipped with a sugar inlet speed control device 1.1. The sugar inlet speed control device 1.1 is mainly composed of an infrared measuring instrument 1.1.1. The infrared measuring meter 1.1.1 passes the detection of falling into the sugar tray 2.1 The accumulation height of sugar A is used to judge the speed of sugar intake. If t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com