Lollipop ribbon kinking and packing machine

A lollipop and packaging machine technology, which is applied to the packaging of lollipops, packaging, and food packaging, can solve the problems of low processing efficiency and excessive labor costs, and achieve the goal of improving work efficiency, improving aesthetics, and facilitating maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

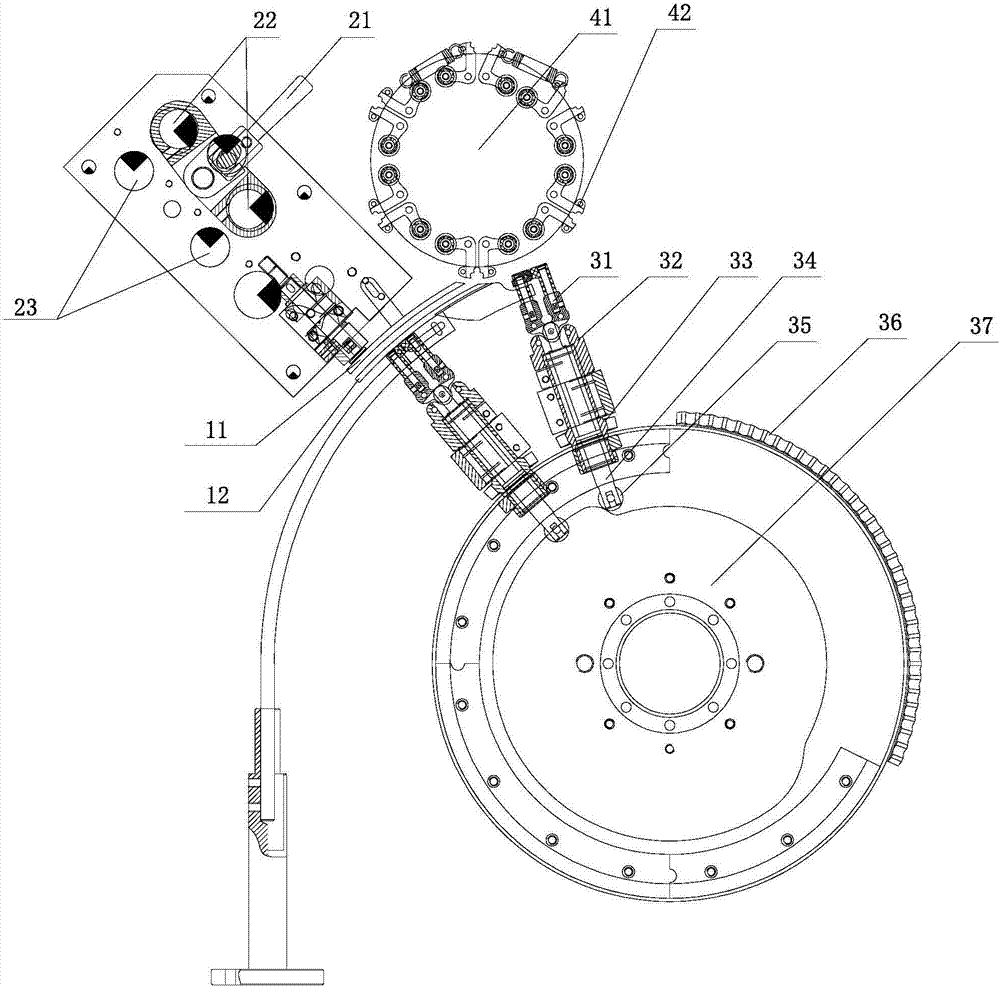

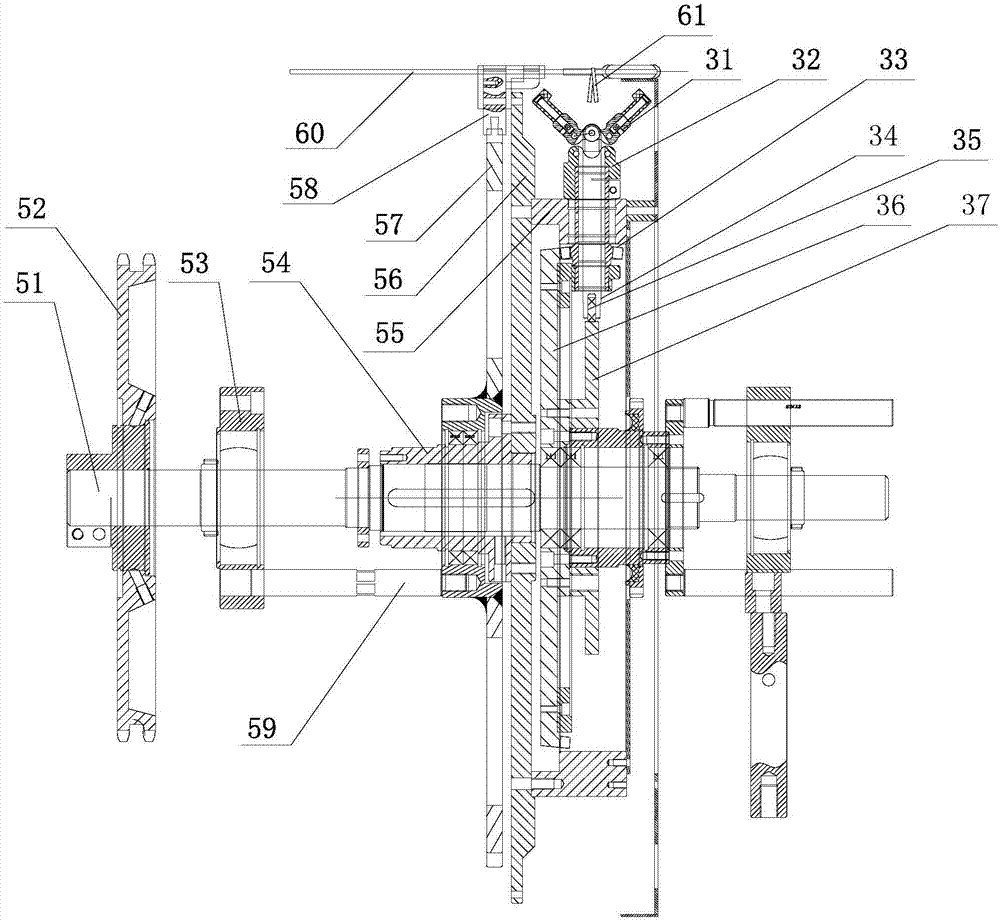

[0016] Embodiment 1: as Figure 1 to Figure 3 The lollipop binding and twisting packaging machine shown includes a binding conveying device, a binding straightening device, a binding and twisting device, a candy stick fixing device, and an arc bend;

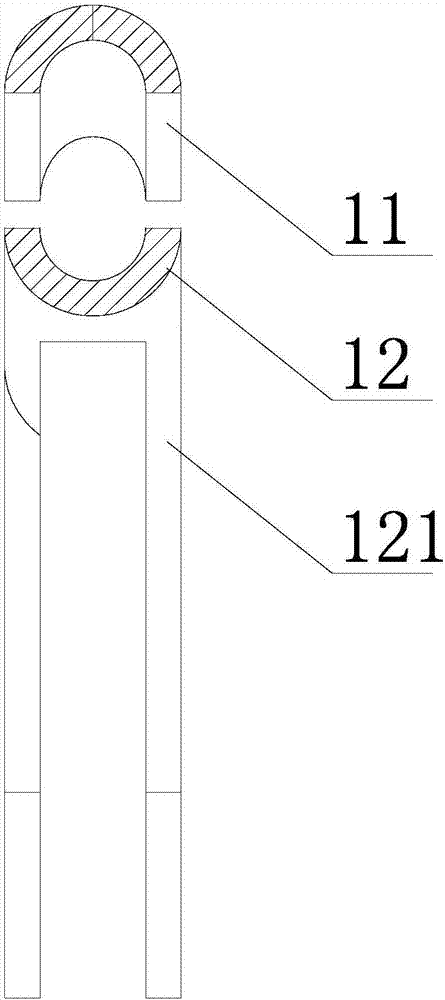

[0017] The candy stick fixing device includes a rotating disk 57 and a candy stick fixing seat evenly arranged along the circumference of the rotating disk 57, which is used to fix the lollipops that have been packaged in bags delivered from the twisting machine. The curved pipe includes an arc-shaped channel for the sugar stick 60 to pass through the upper silk groove 11 and the lower silk groove 12. The upper silk groove 11 and the lower silk groove 12 are provided with corresponding upper and lower silk through holes Holes, the upper thread through hole and the lower thread through hole are oval and the major semiaxis of the lower thread through hole is greater than the major semiaxis of the upper thread through hole, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com