Full-automatic single-twist air-blowing packaging machine

A fully automatic and packaging machine technology, applied in the field of lollipop packaging, can solve the problems of lack of special production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

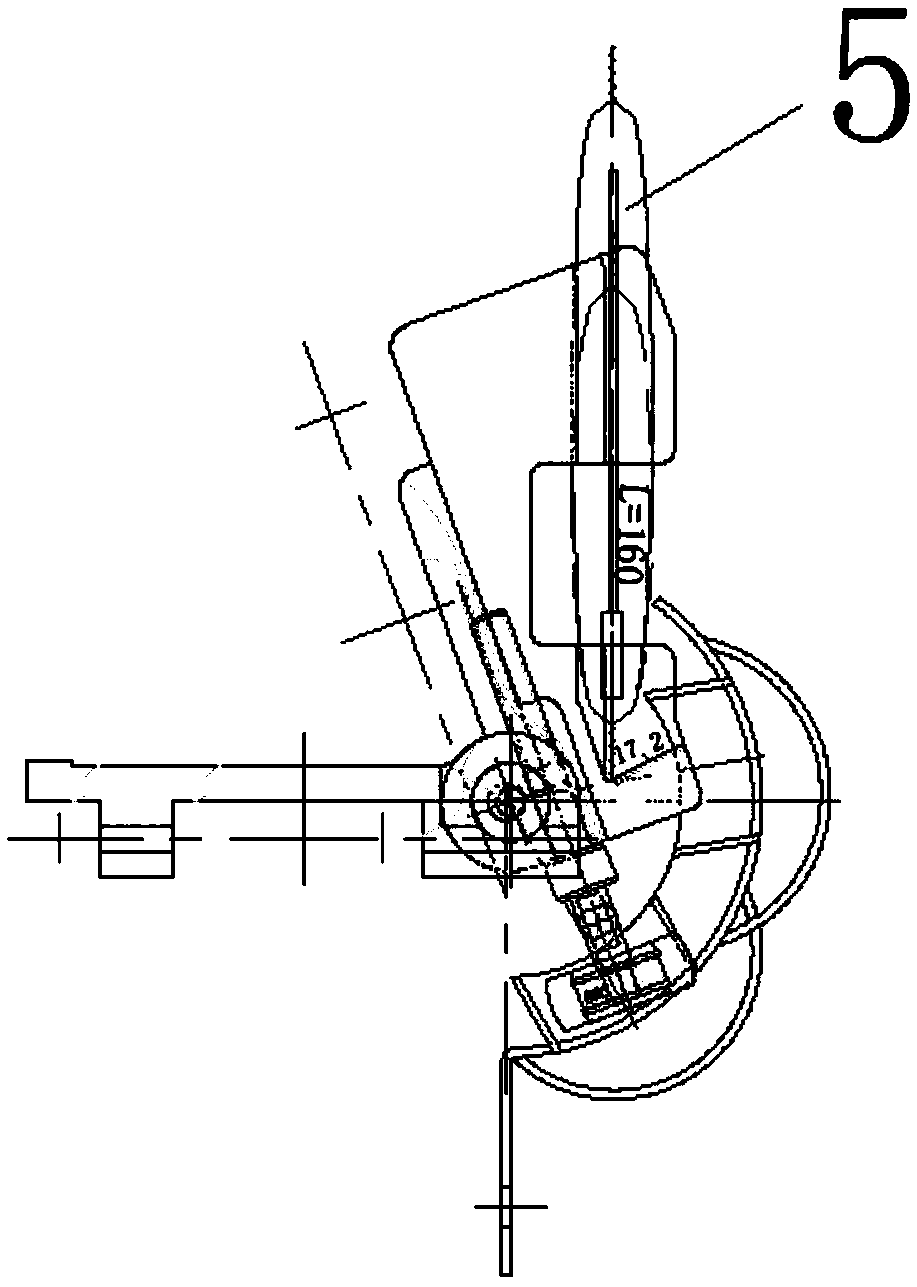

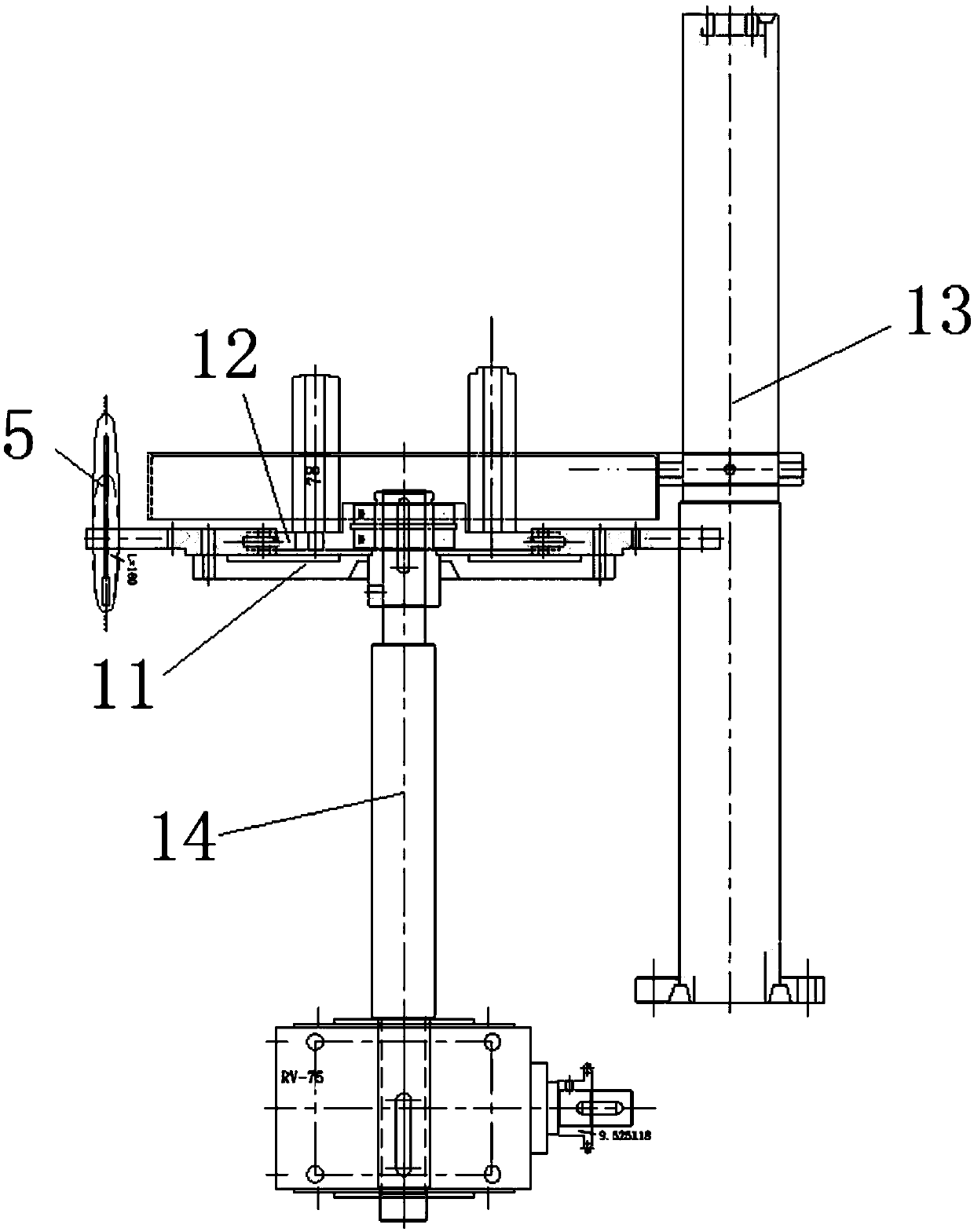

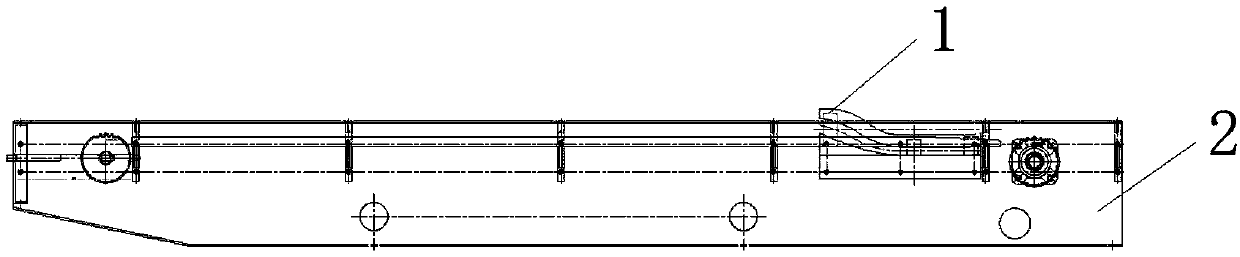

[0058] Example 1: See Figure 1-26 , the present invention provides a technical solution: a fully automatic single-twisting air-blowing packaging machine, including a lollipop conveyor, a sugar-feeding gripper assembly, a heat-sealing tongs assembly, a candy head tongs assembly, a sugar-discharging gripper assembly, Mounting frame 6 and positioning shaft 13;

[0059] The lollipop conveyor includes a conveyor 2 installed on a mounting frame 6, several holders 4, several lollipop placers 3 and a lollipop turner 1;

[0060] Wherein, the conveyor belt in the conveyor 2 does rotary motion; the holder 4 is a strip structure, and several holders 4 are evenly installed on the outer ring of the conveyor belt, and the length direction of the holder 4 is in line with the conveyor belt. The central axis of rotation is parallel; the lollipop placer 3 is a bar-shaped structure, and the upper surface of the lollipop placer 3 is provided with a concave bar-shaped lollipop placement nest, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com