Twisted batch candy packaging machine

A packaging machine and candy technology, applied in packaging, food packaging, lollipop packaging, etc., can solve problems such as stretching, deformation and fracture of the front end, and achieve the effect of preventing twisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

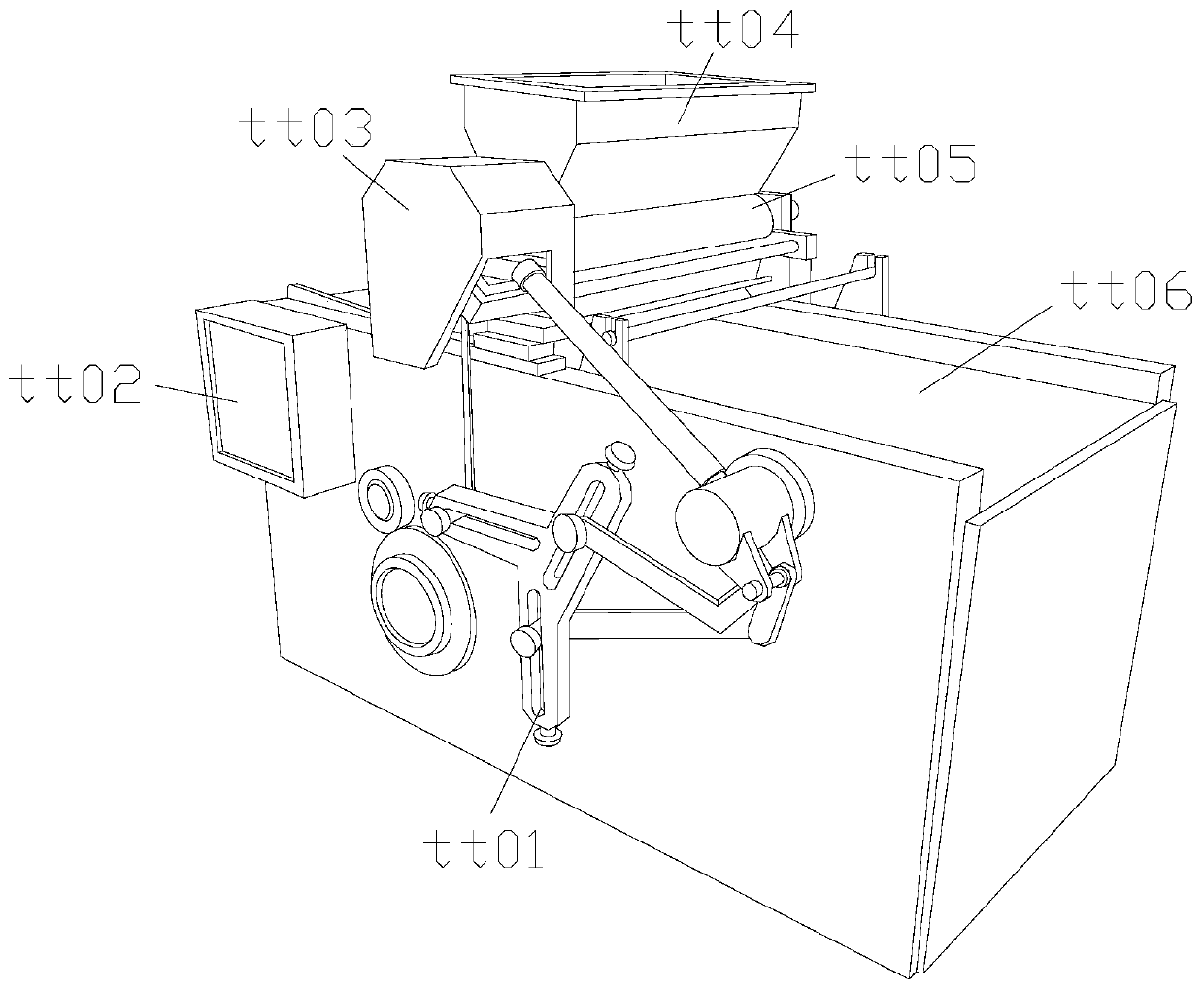

[0032] as attached figure 1 to attach Figure 5 Shown:

[0033] The invention provides a twist-type batch candy packaging machine, the structure of which includes a transfer rod tt01, a control box tt02, a side control body tt03, an introduction box tt04, an even lane tt05, and a conveying table tt06.

[0034] The transfer rod tt01 is installed on the outer surface of the conveying table tt06, the control box tt02 and the transfer rod tt01 are installed on the same vertical plane, the transfer rod tt01 touches the inside of the side control body tt03, and the evenly divided lane tt05 is set at the introduction The boxes tt04 are below and connected to each other, and the end of the evenly dividing lane tt05 away from the introduction box tt04 is provided with a delivery table tt06.

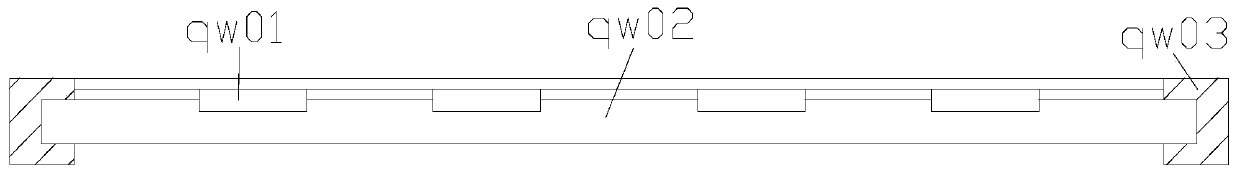

[0035] Wherein, the evenly dividing lane tt05 includes a block qw01, a placement lane qw02, and a side rotation body qw03, the left and right ends of the placement lane qw02 are embedded in the ...

Embodiment 2

[0042] as attached Image 6 to attach Figure 8 Shown:

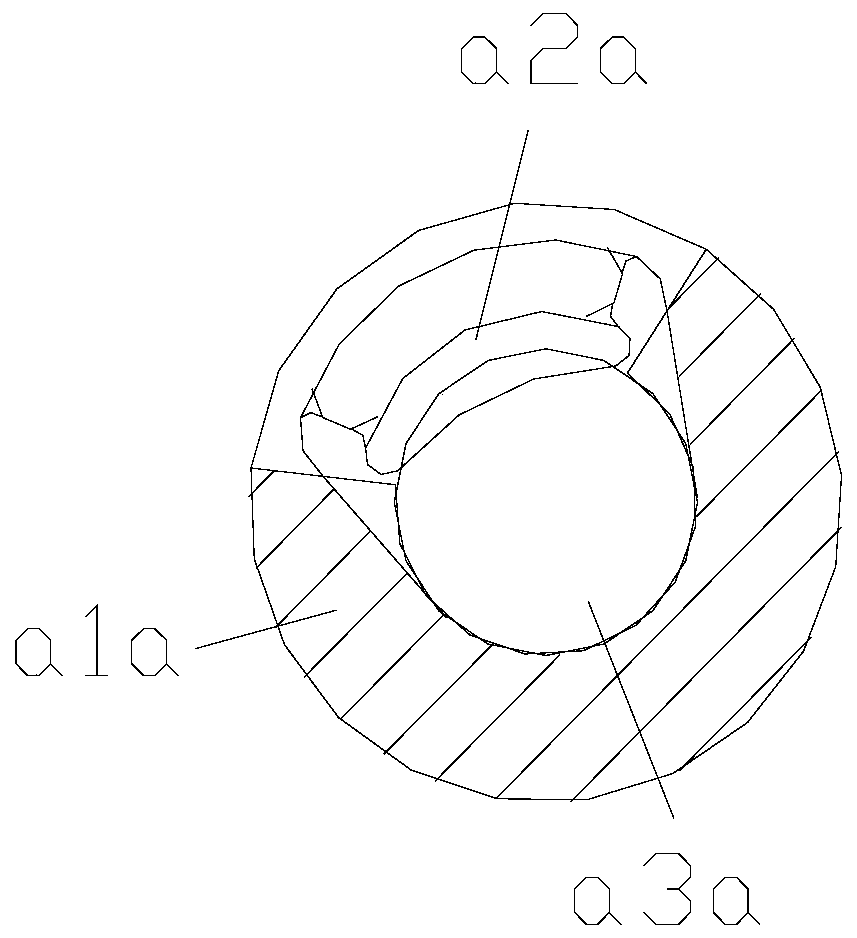

[0043] Wherein, the induration arc zx11 includes an arc m1m, an angle m2m, an expansion layer m3m, and an arc m4m, the arc m1m is connected with the expansion layer m3m, and the angle m2m is installed inside the expansion layer m3m, The expansion layer m3m and the clamping arc m4m are an integrated structure, the said arc m1m is a hemispherical structure, the said arc m1m is placed at the rear of the whole to have a certain resistance to resistance, and the contraction m2m allows the outer layer to have a certain fixing force Under normal circumstances, clamp to one side, and the clamping arc m4m buckles the conflicting wrapping paper.

[0044] Wherein, the clipping arc m4m includes the fold angle hh1, the support layer hh2, the bayonet hh3, and the side bending edge hh4, the fold angle hh1 is connected with the support layer hh2, and the fold angle hh1 is far away from the end and side Bends hh4 are connected to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com