Twisting packing machine for special-shaped candy sticks

A packaging machine and lollipop technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of consumers who are difficult to consume, easy to generate mechanical vibration, and slow machine operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

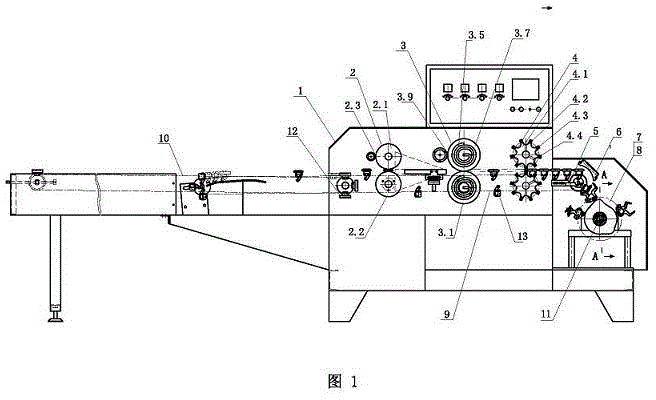

[0024] exist figure 1 In the special-shaped lollipop kink packaging machine shown, a transport chain 10, a clamping chain 9, a sugar feeding position correction device 2, a stick sealing device 3, a transverse sealing and cutting device 4, a heat clamping device are sequentially arranged on the main body 1. The device 7 and the kinking device 8, the thermal clamping device 7 and the kinking device 8 are arranged on the main shaft 11 opposite to each other, and a plurality of material trays 12 are evenly arranged on the material transport chain 10. Loading and conveying, a plurality of clamping claws 13 are evenly arranged on the clamping chain 9, and the number of the material trays 12 and clamping claws 13 set on the machine is determined according to the specifications of the sugar and the actual work needs.

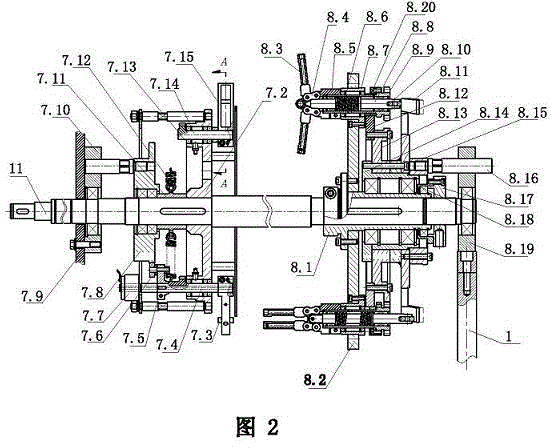

[0025] in as figure 2 In the shown heat clamping device 7 and kinking device 8, one end of the main shaft 11 passes through the fuselage 1 and is rotatably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com