Whistling lollipop packaging machine

A technology of lollipop and packaging machine, which is applied in the direction of packaging lollipop, packaging, transportation packaging, etc., and can solve the problems of large volume, complex structure of the whole machine, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

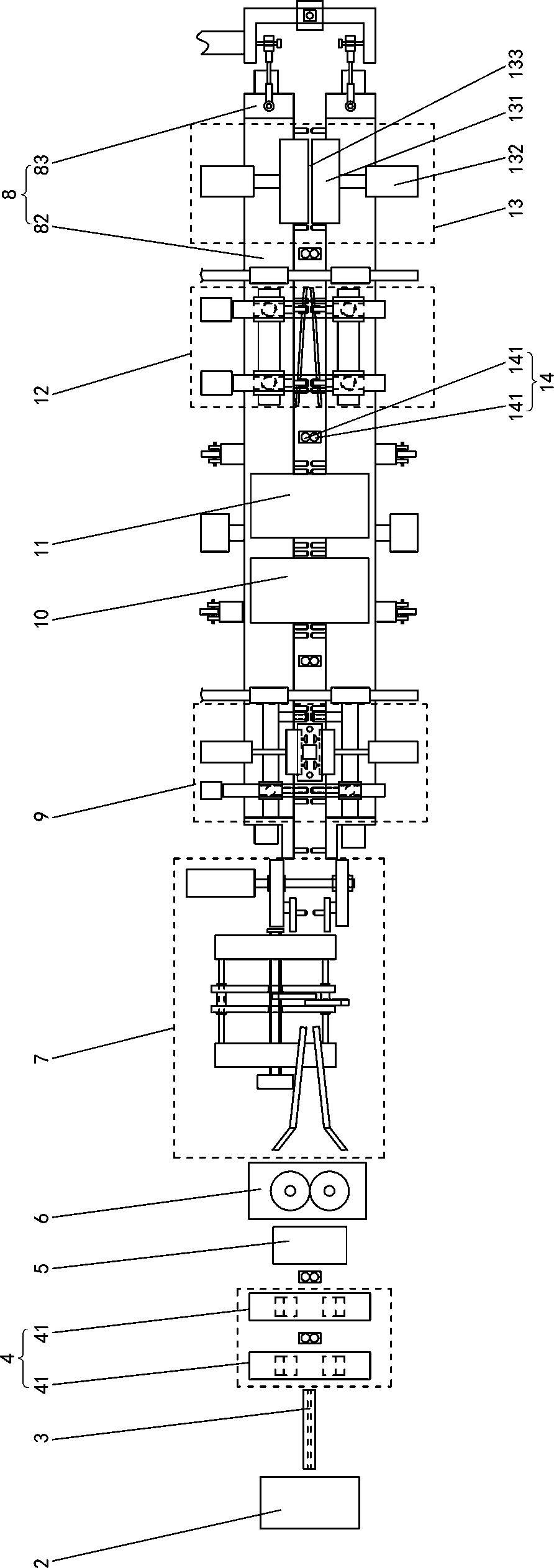

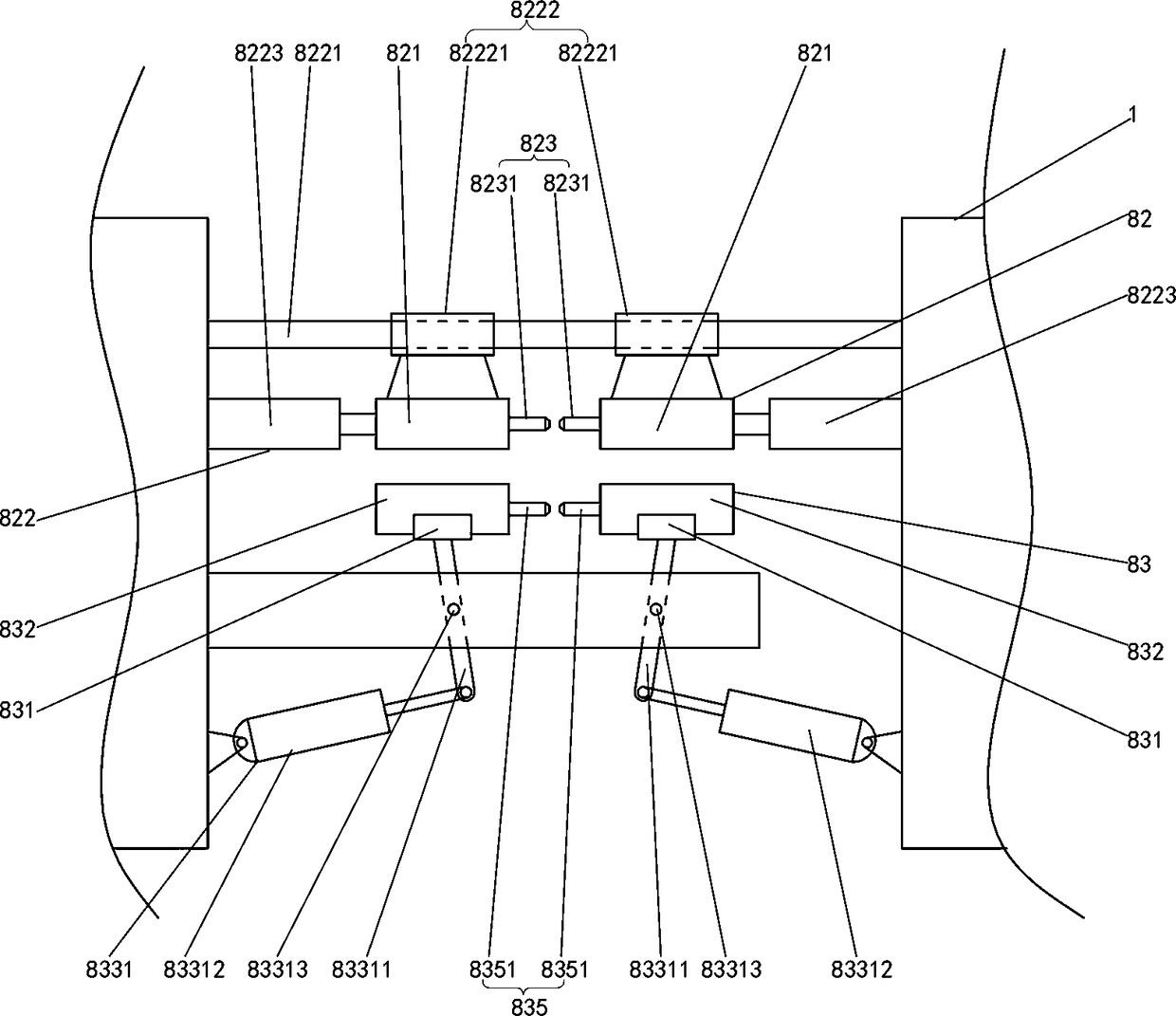

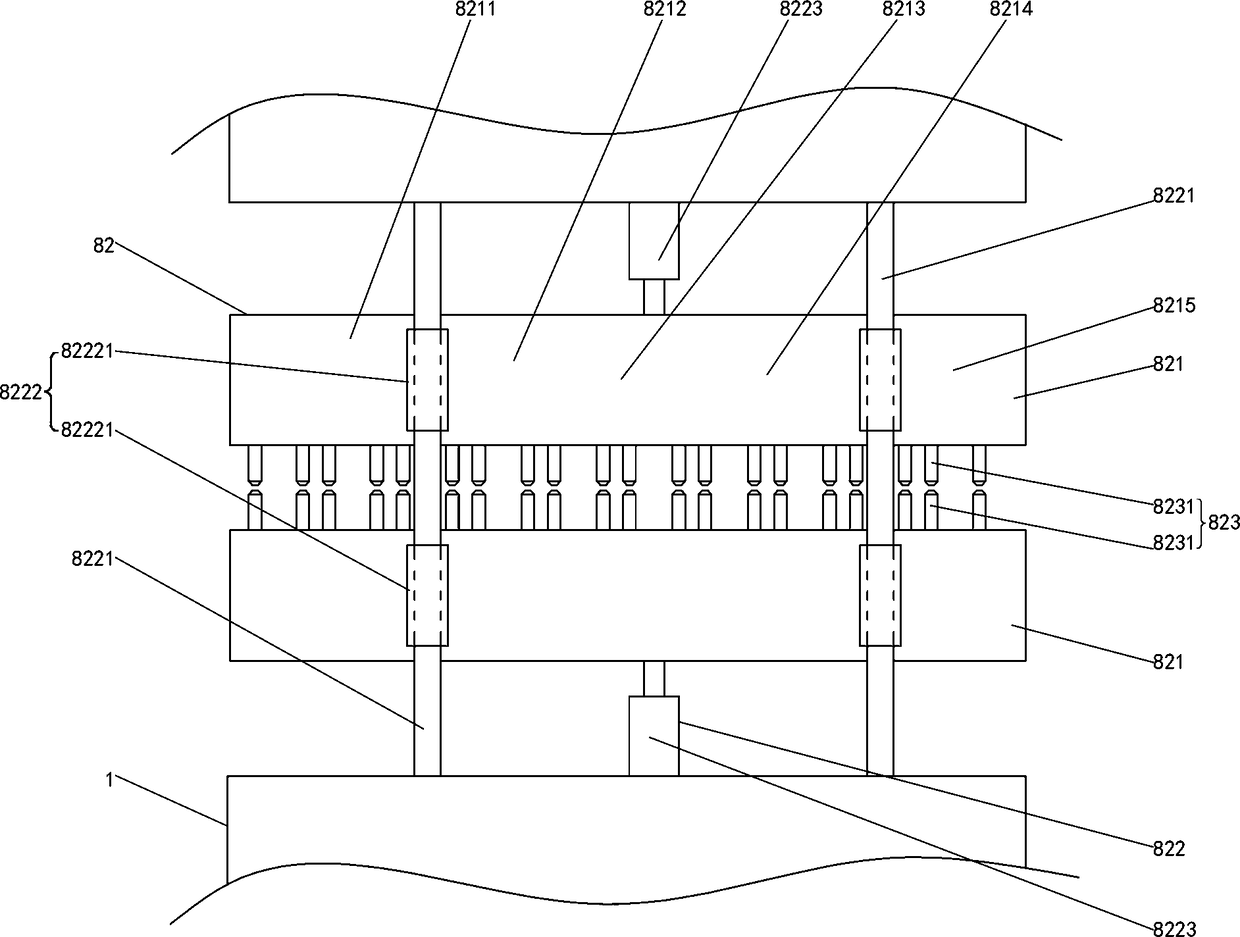

[0046] like figure 1 As shown, this whistling lollipop packaging machine includes a frame 1, a packaging film unwinding device 2, a packaging film folding device 3, an edge sealing device 4, an easy-tear cutting device 5, a pinching device 6, and a bag body divider. Cutting device 7, horizontal bag feeding mechanism 8, bag opening opening device 9, powdered sugar filling device 10, lollipop filling device 11, bag opening straightening device 12, sealing device 13 and bag returning device (not shown in the figure ), packaging film unwinding device 2, packaging film folding device 3, edge sealing device 4, easy-tear cutting device 5, pinch device 6, bag body cutting device 7, bag opening device 9, powdered sugar filling The device 10, the lollipop filling device 11, the sealing device 13 and the bag return device are all installed on the frame, the packaging film unwinding device 2, the packaging film folding device 3, the edge sealing device 4, the easy-tear cutting device 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com