Patents

Literature

86results about How to "Guaranteed to be smooth and flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infrared ray welding device for welding bar-shaped zone

InactiveCN101767235AWelding is suitable forGuaranteed to be smooth and flatFinal product manufactureSoldering apparatusInfraredEngineering

The invention relates to an infrared ray welding device for welding bar-shaped zone, comprising one or more welding unit mechanisms, wherein the welding unit mechanism comprises a reflecting shade the two ends of which are provided with lampshade fixing end plates; the surface of the inner cavity of the reflecting shade is of a smooth concave mirror, and the inner cavity is a semielliptic columnar cavity body; the two ends of the inner cavity of the reflecting shade are provided with infrared tubes through a tube installation frame; the infrared tube is positioned on one focal line of the semielliptic columnar cavity body, and the other focal line of the semielliptic columnar cavity body is used for arranging the object to be welded; and when more than one welding unit mechanism is arranged, the welding unit mechanisms are connected by a connecting mechanism. The invention is suitable for fast and uniformly welding the object which is fragile and not easy to contact, the device can make infrared ray form a bar-shaped heating zone with consistent temperature, can realize synchronous welding of multiple groups of zones, and has the characteristic that the interval of the welding zone can be adjusted, thus effectively improving the welding quality and welding efficiency, having non-pollution and saving energy.

Owner:天津必利优科技发展有限公司

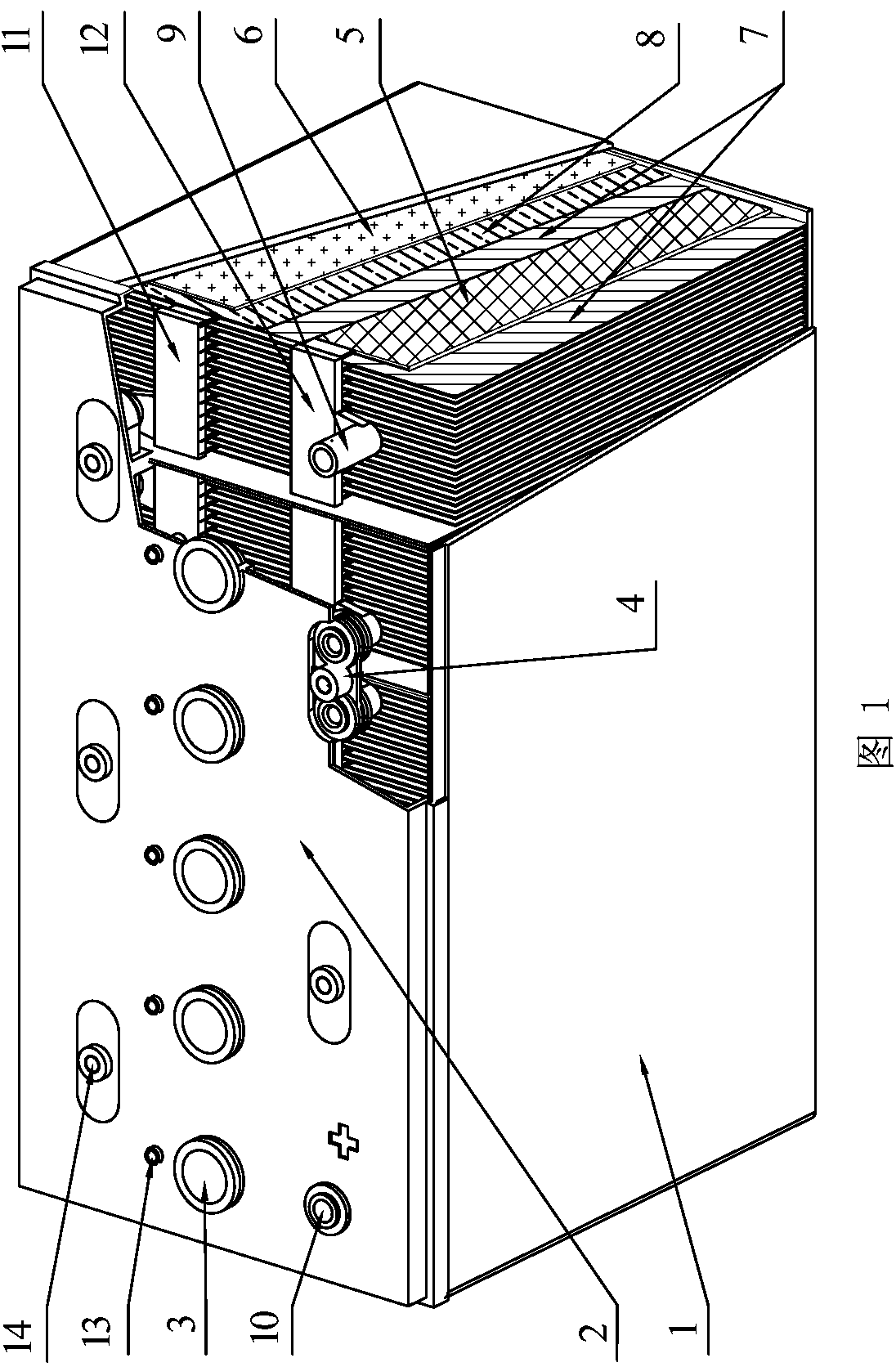

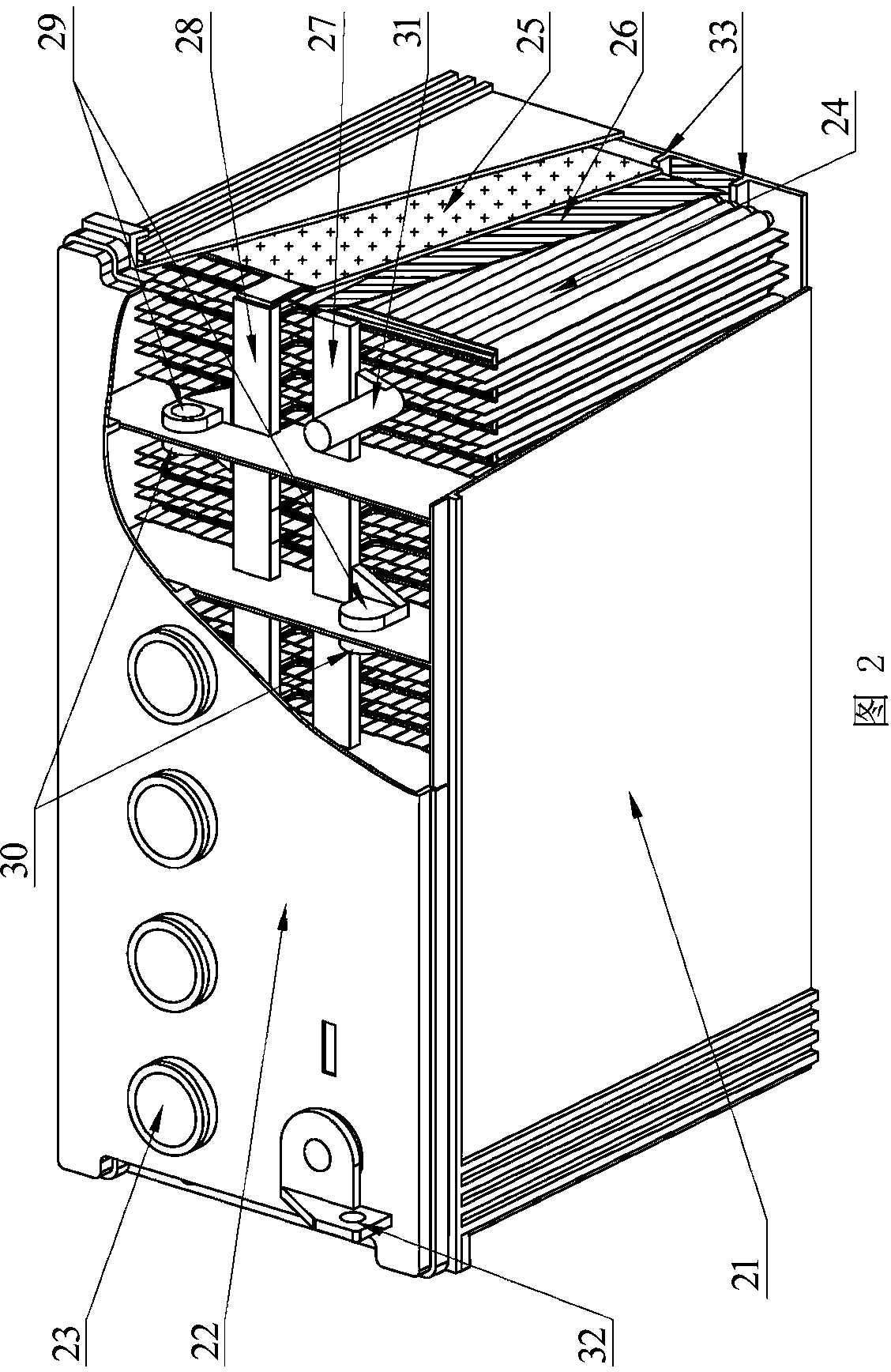

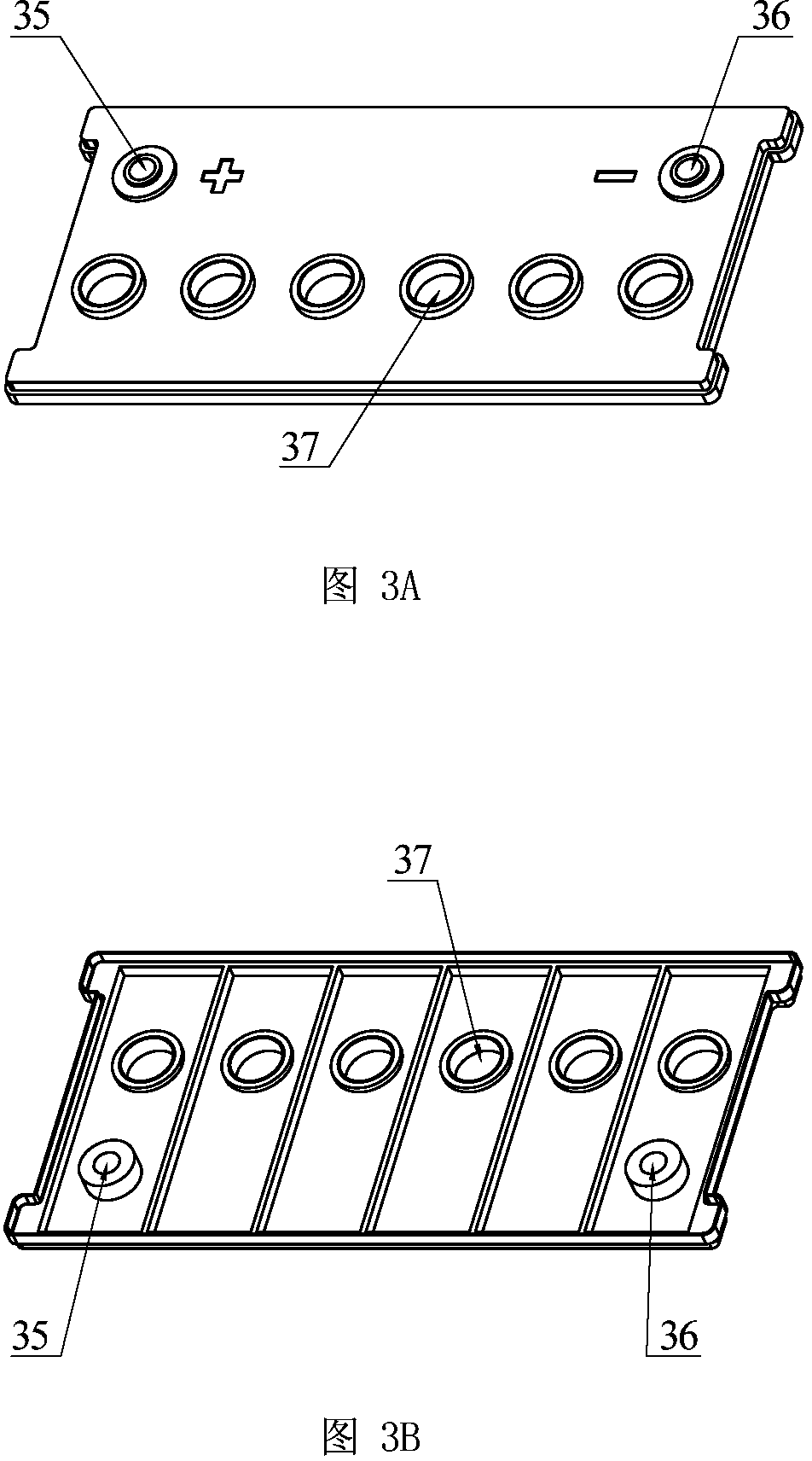

Exhaust type acid and flame resistant lead acid storage battery used for electric road vehicles

InactiveCN103000830AAvoid corrosionTimely and accurate detectionLead-acid accumulatorsLead-acid accumulator electrodesElectrolytic agentElectrical battery

The invention relates to a designing and manufacturing method of an exhaust type acid and flame resistant lead acid storage battery having the advantages of high specific energy, long life, fast charging and no corrosion and used for electric road vehicles. The charging and discharging states and the temperature changes of all 2V single batteries of a 2-48V storage battery are timely monitored through improving the design of the case-lid structure of the lead acid storage battery, the single batteries are connected through adopting whole metallic lead sleeve inserts pre-injected into a battery lid, the bottom of the battery is not provided with a saddle, exhaust plugs are provided with acid and explosive resistant devices, positive and negative electrode plates are designed to be paste type thin electrode plates to substitute thick tubular positive electrode plates, a separation plate can individually adopt an ultrathin glass fiber separation plate or a PE separation plate or combines the ultrathin glass fiber separation plate with the PE separation plate, and an electrolyte adopts a colloidal electrolyte. The above designing and manufacturing method can ensure a case that the storage battery is not detonated by an open fire in the use process, equipment corrosion of acid mist and caused environmental pollution to be eliminated, a rated capacity C3 value to be reached after 1h rapid charging, charging of the battery to be completed within 3h, and the storage battery to have the characteristics of high specific energy, deep cycle and long life.

Owner:崔荣龙

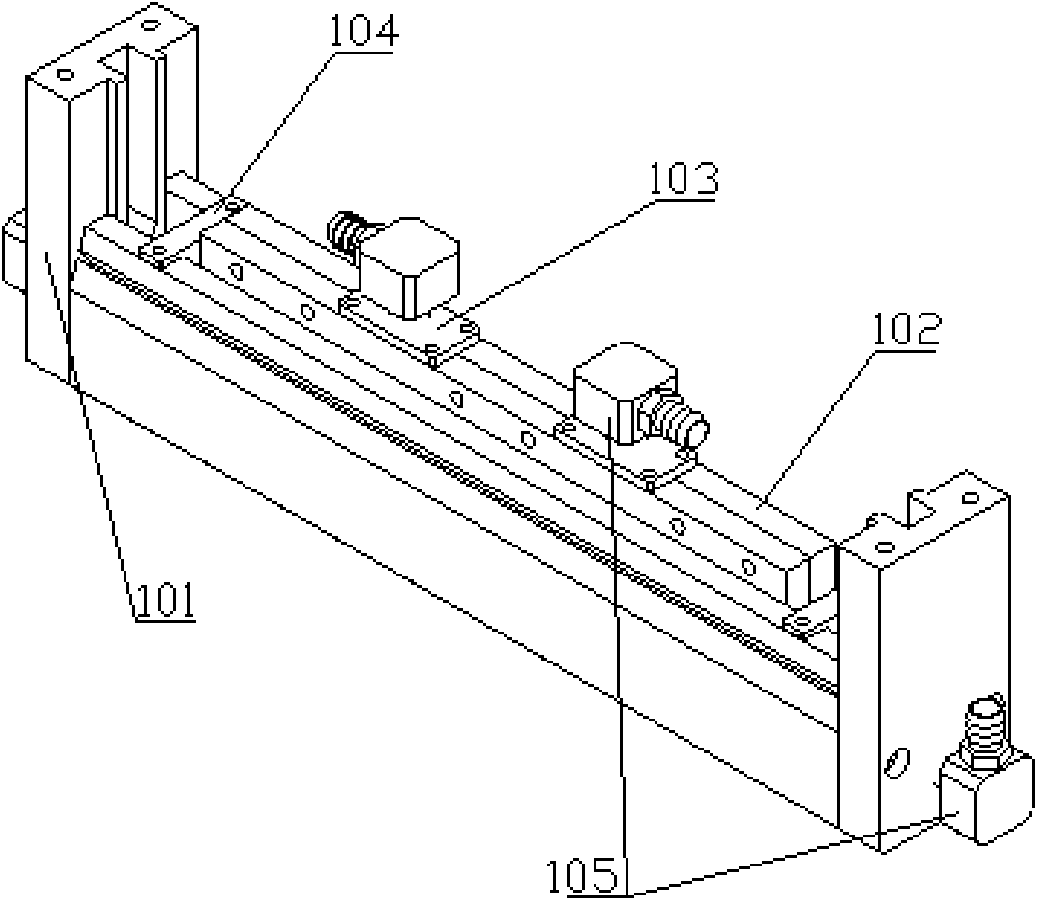

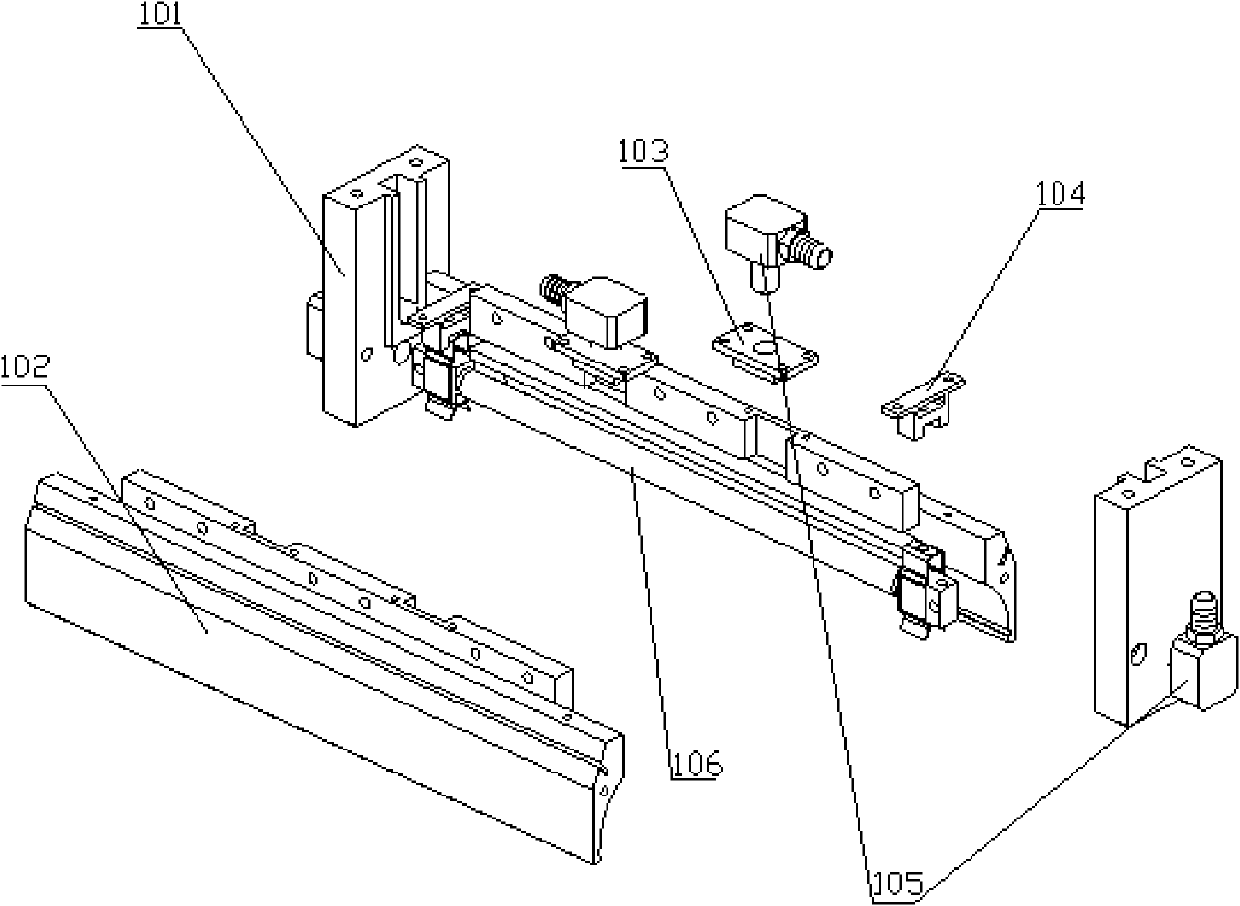

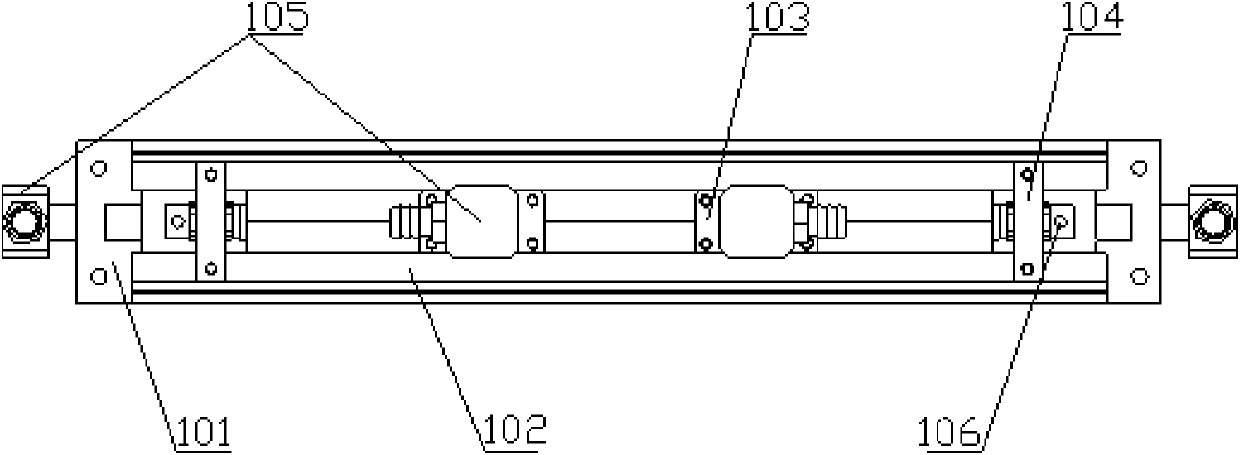

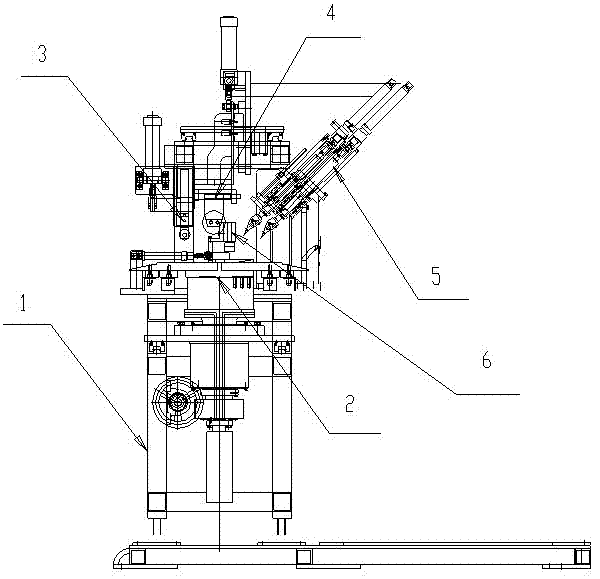

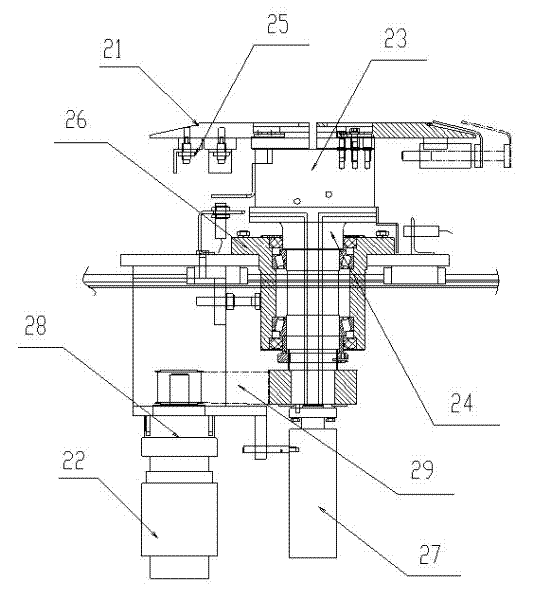

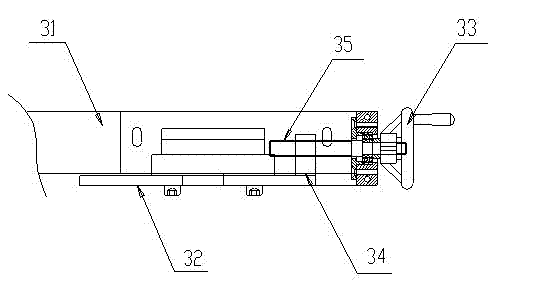

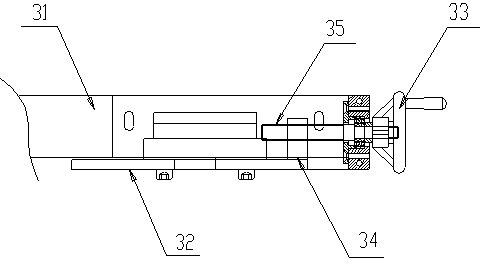

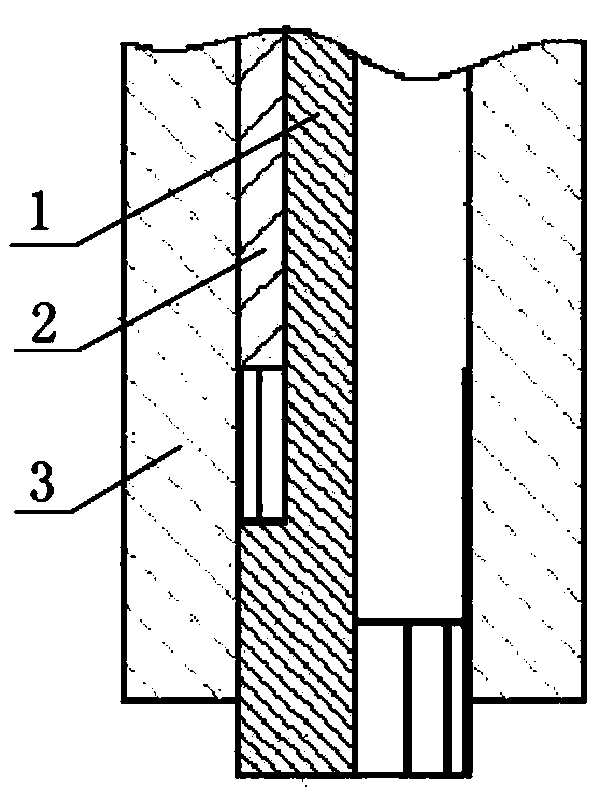

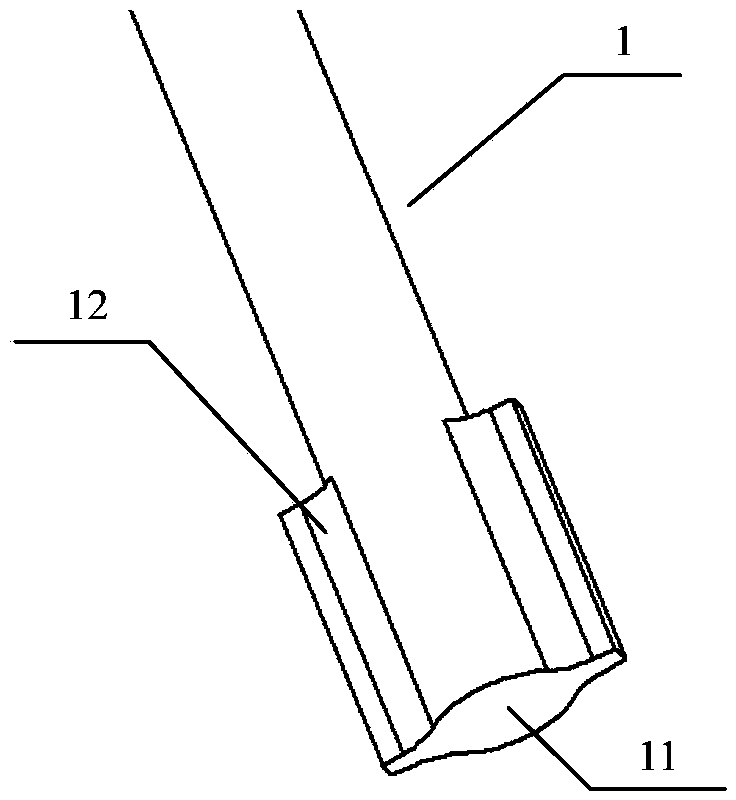

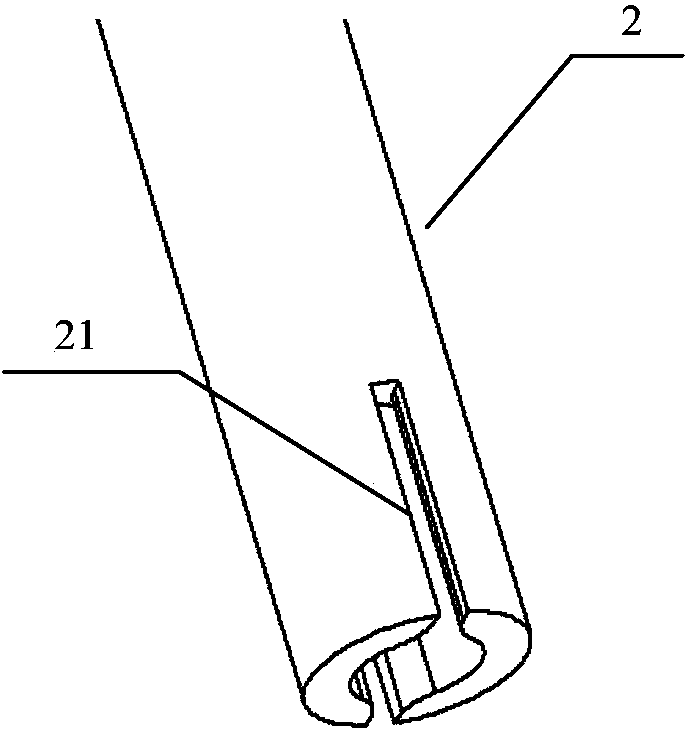

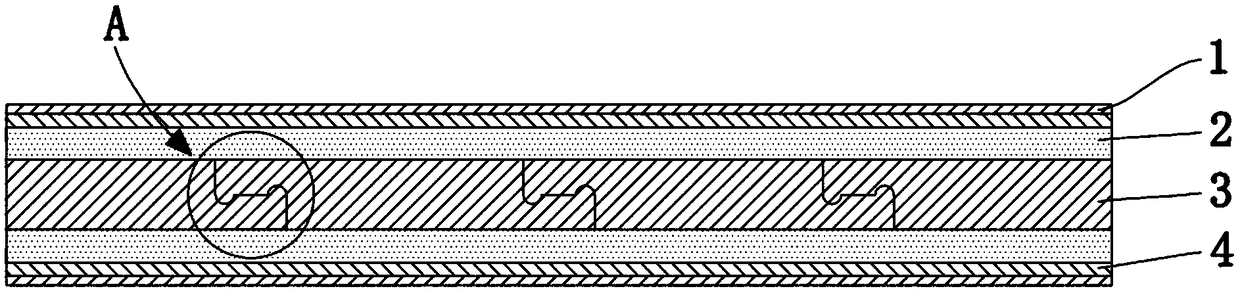

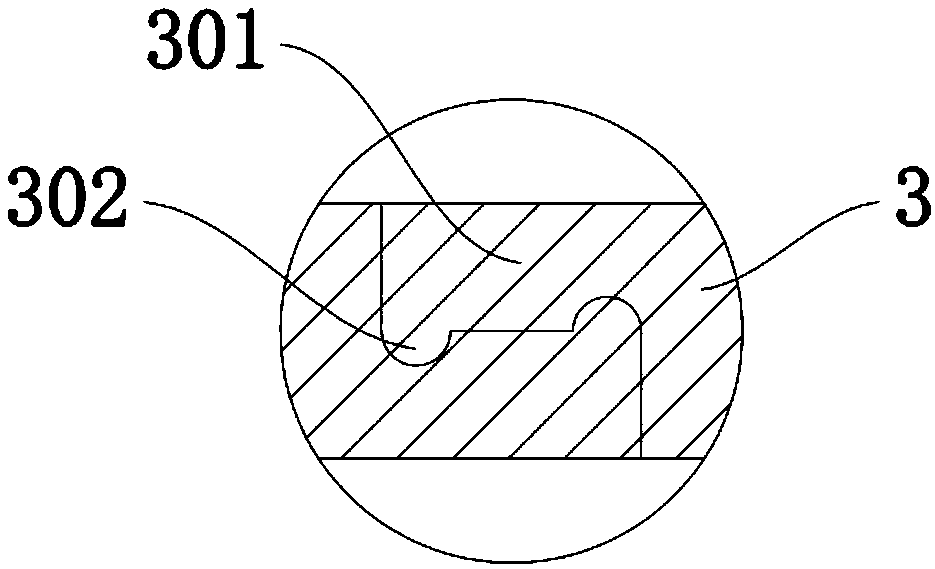

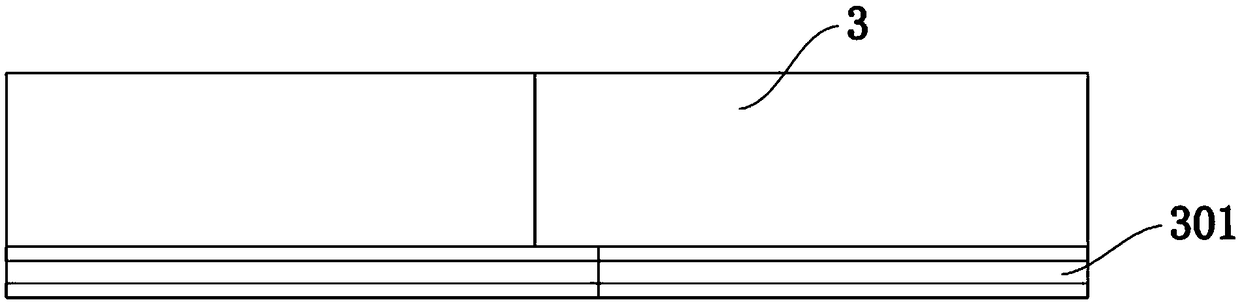

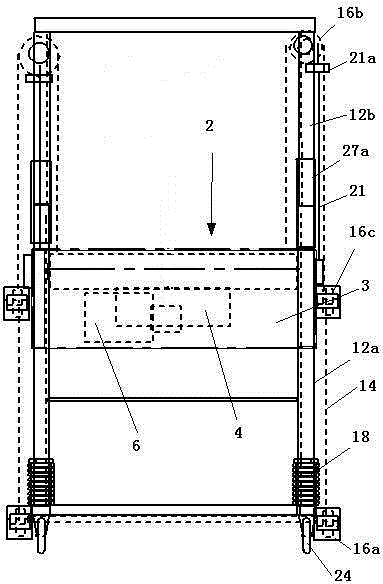

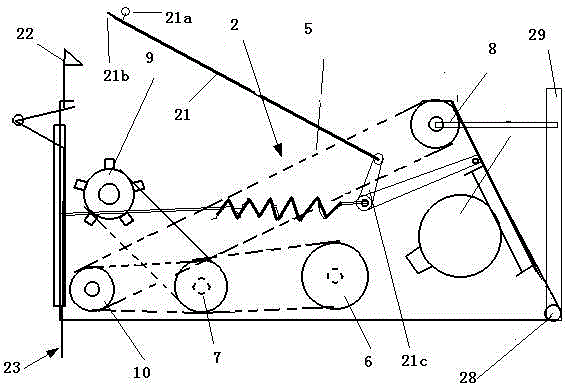

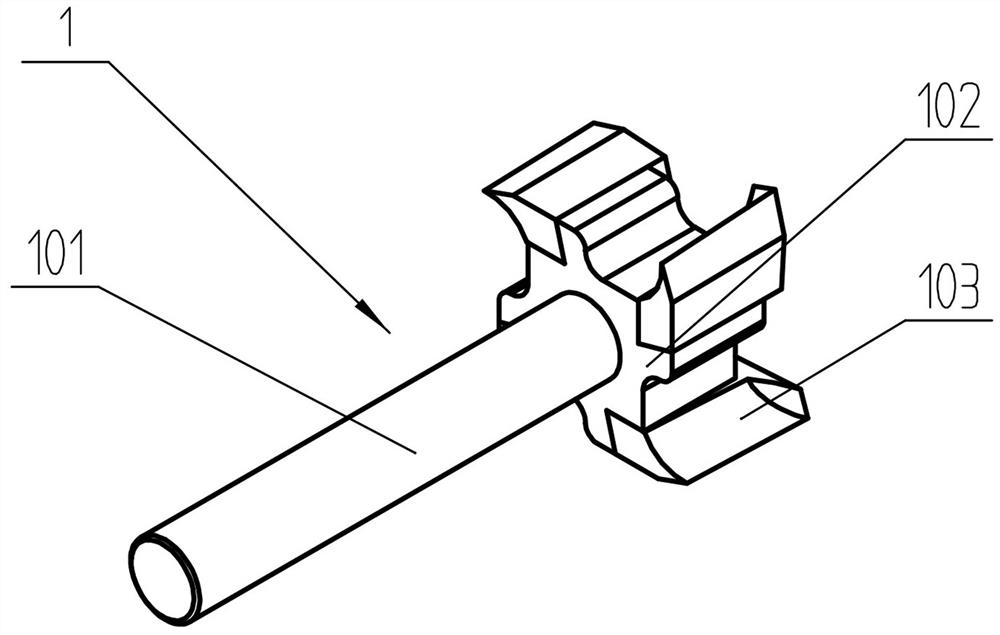

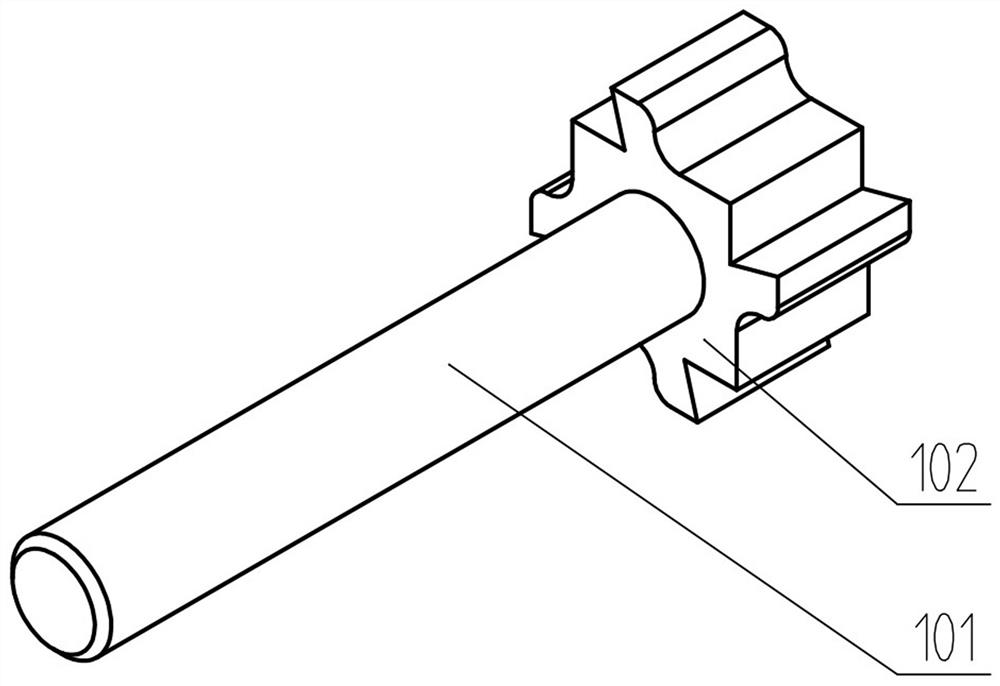

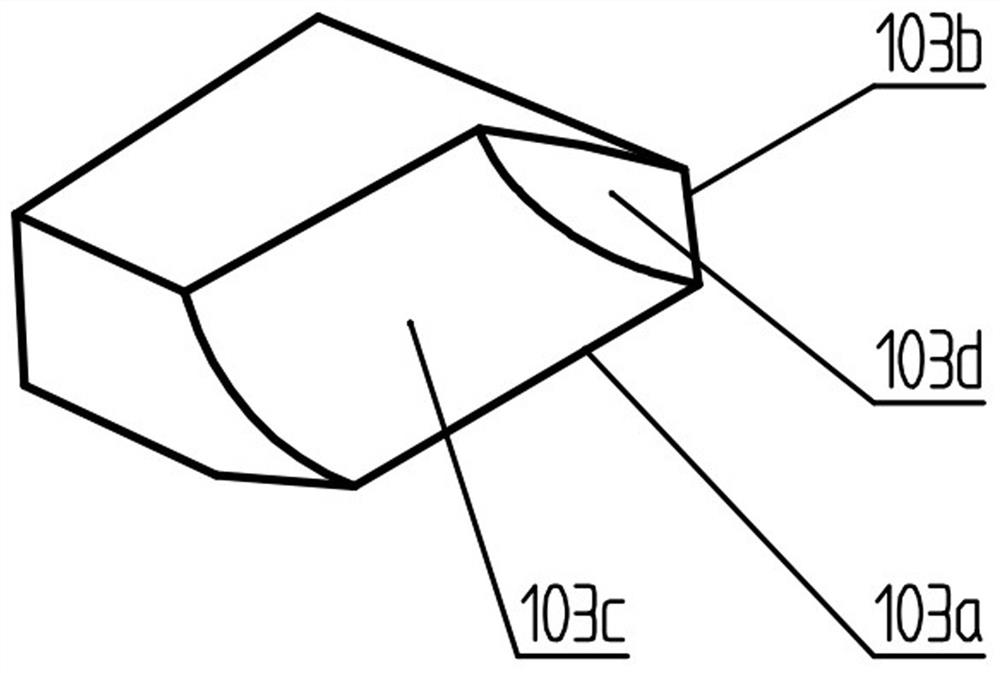

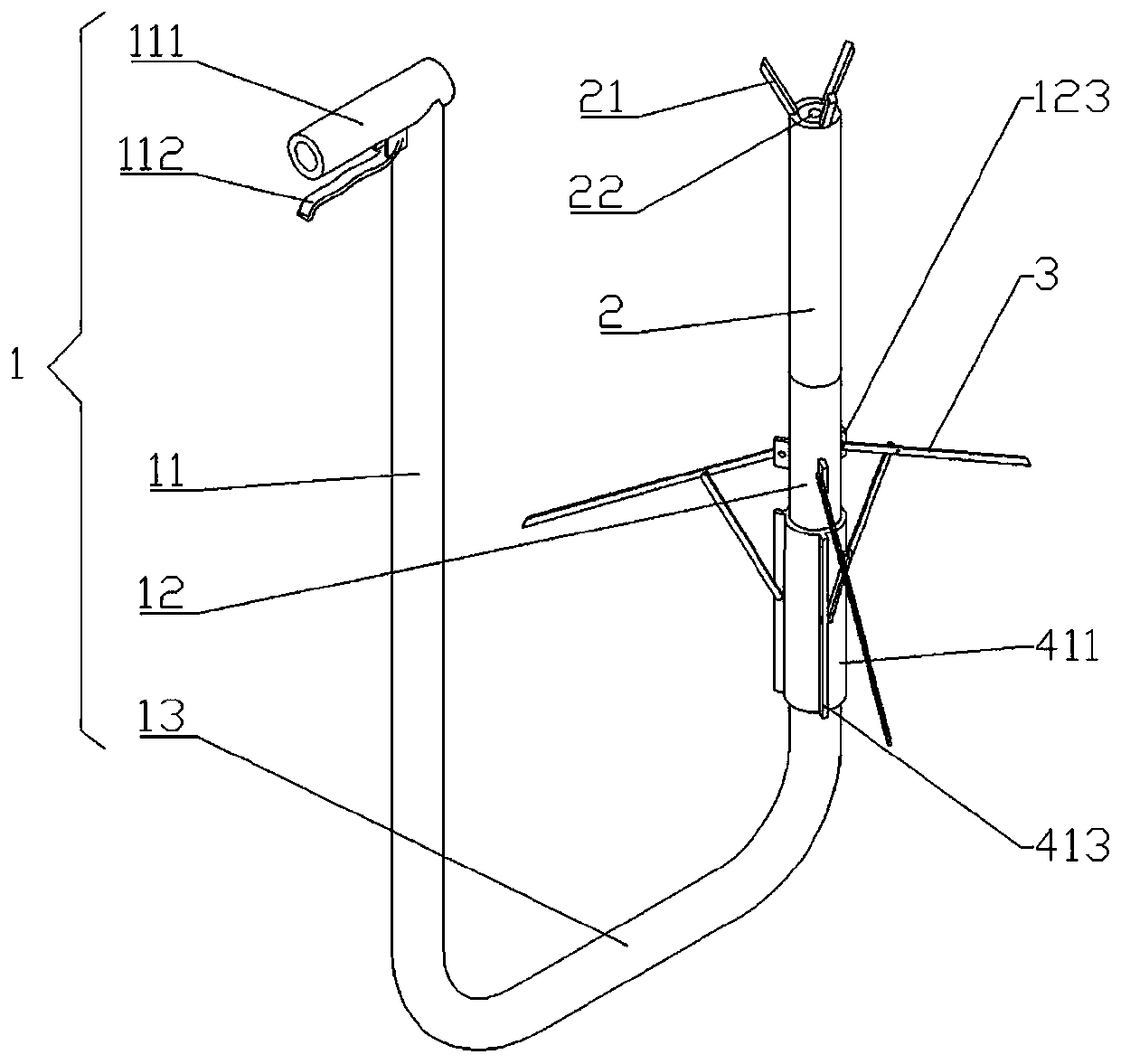

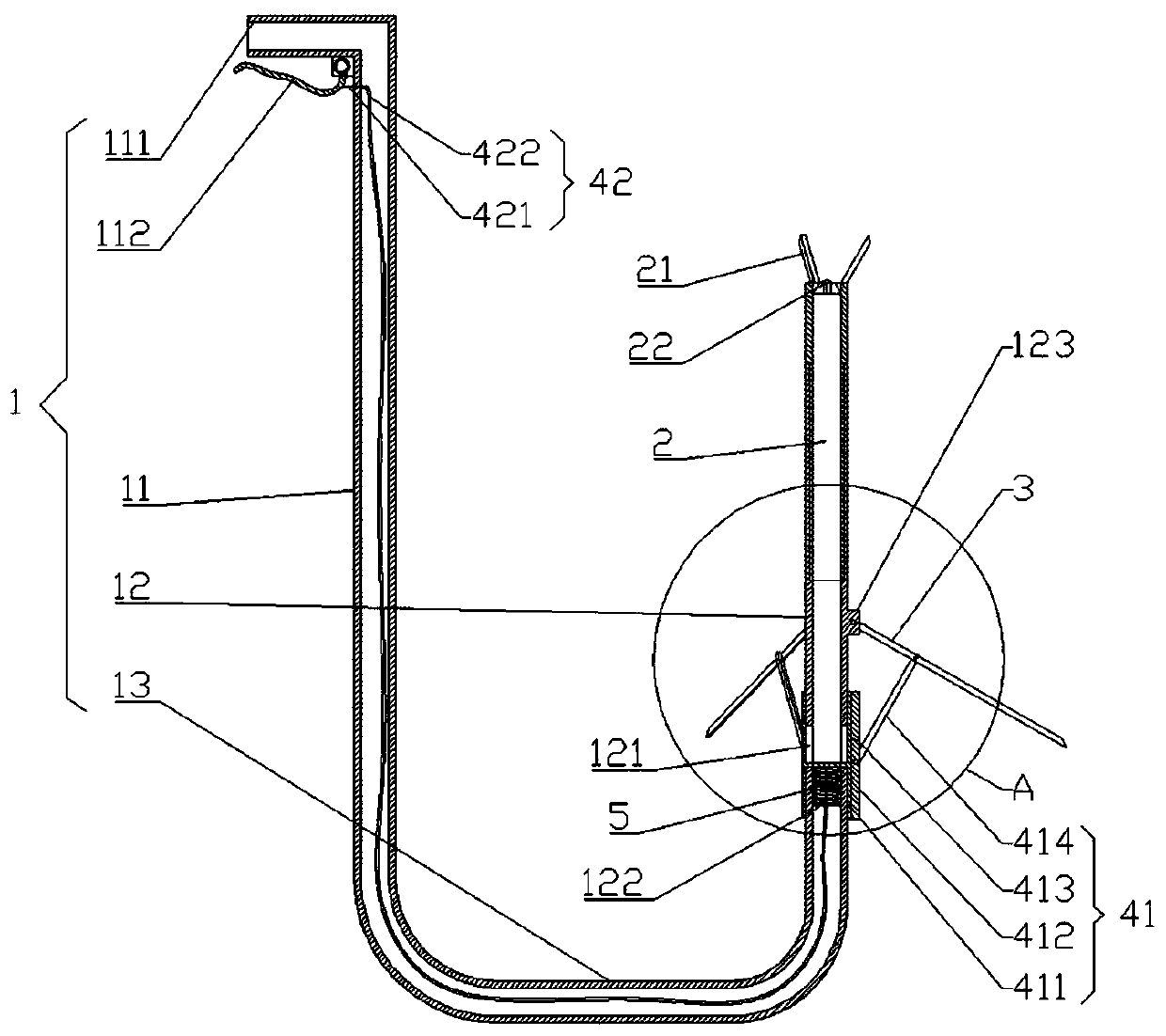

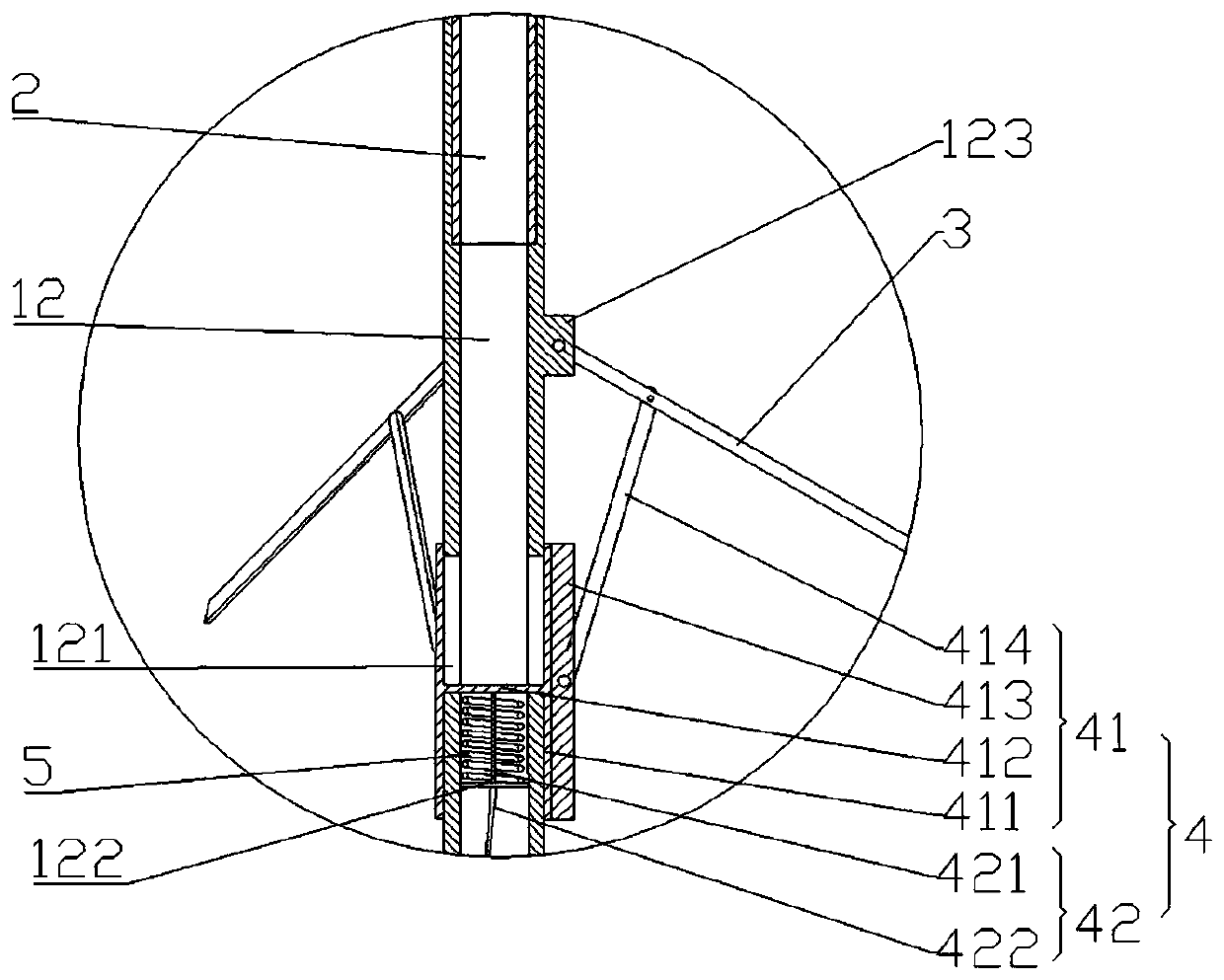

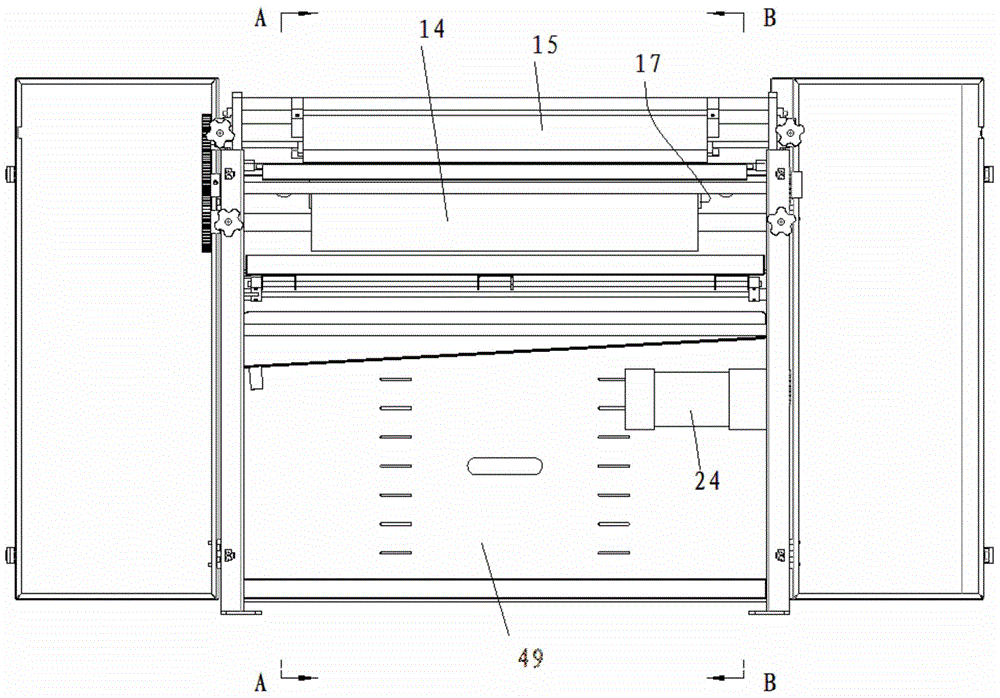

Horizontal triangle adhesive tape sticking device

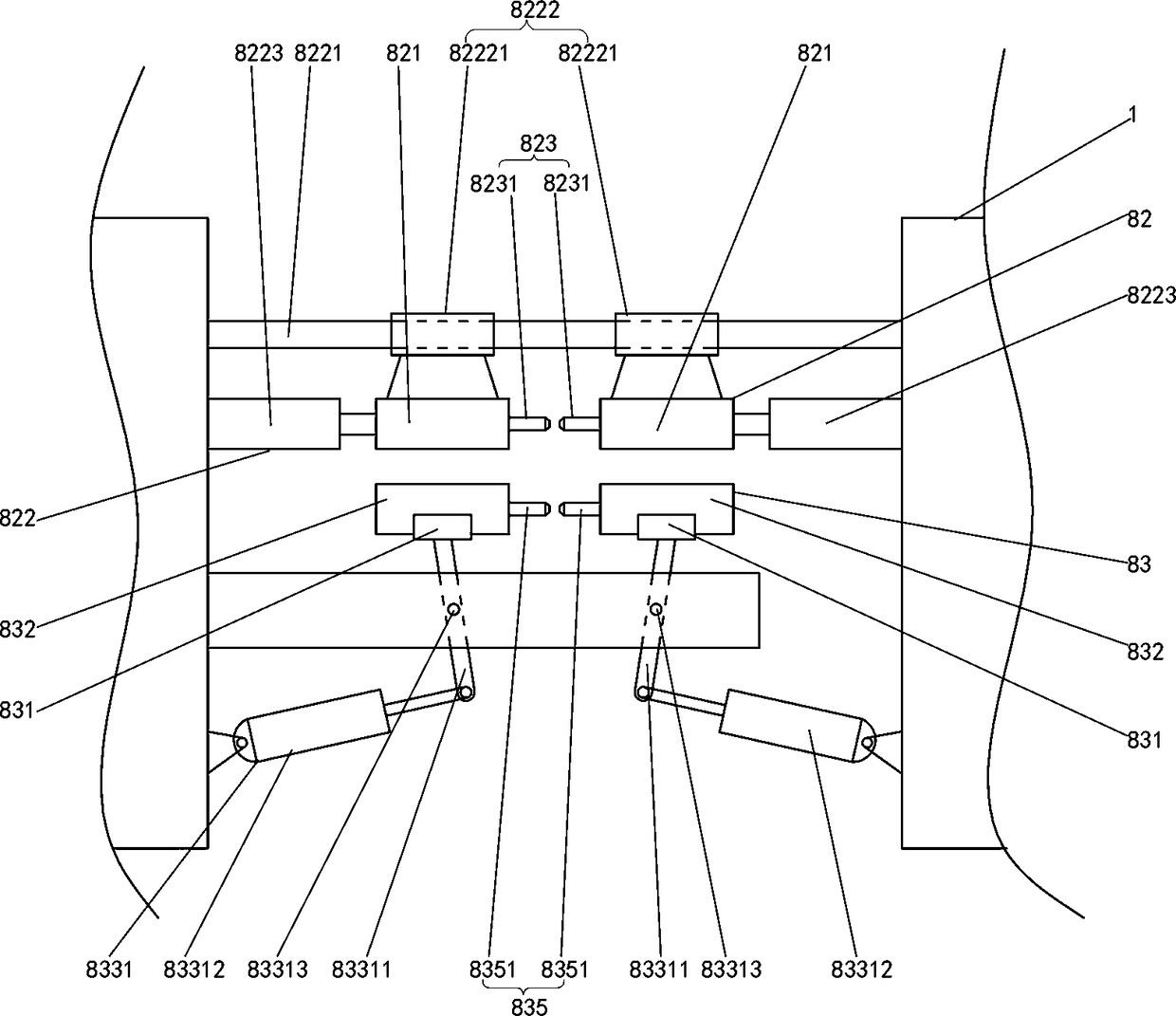

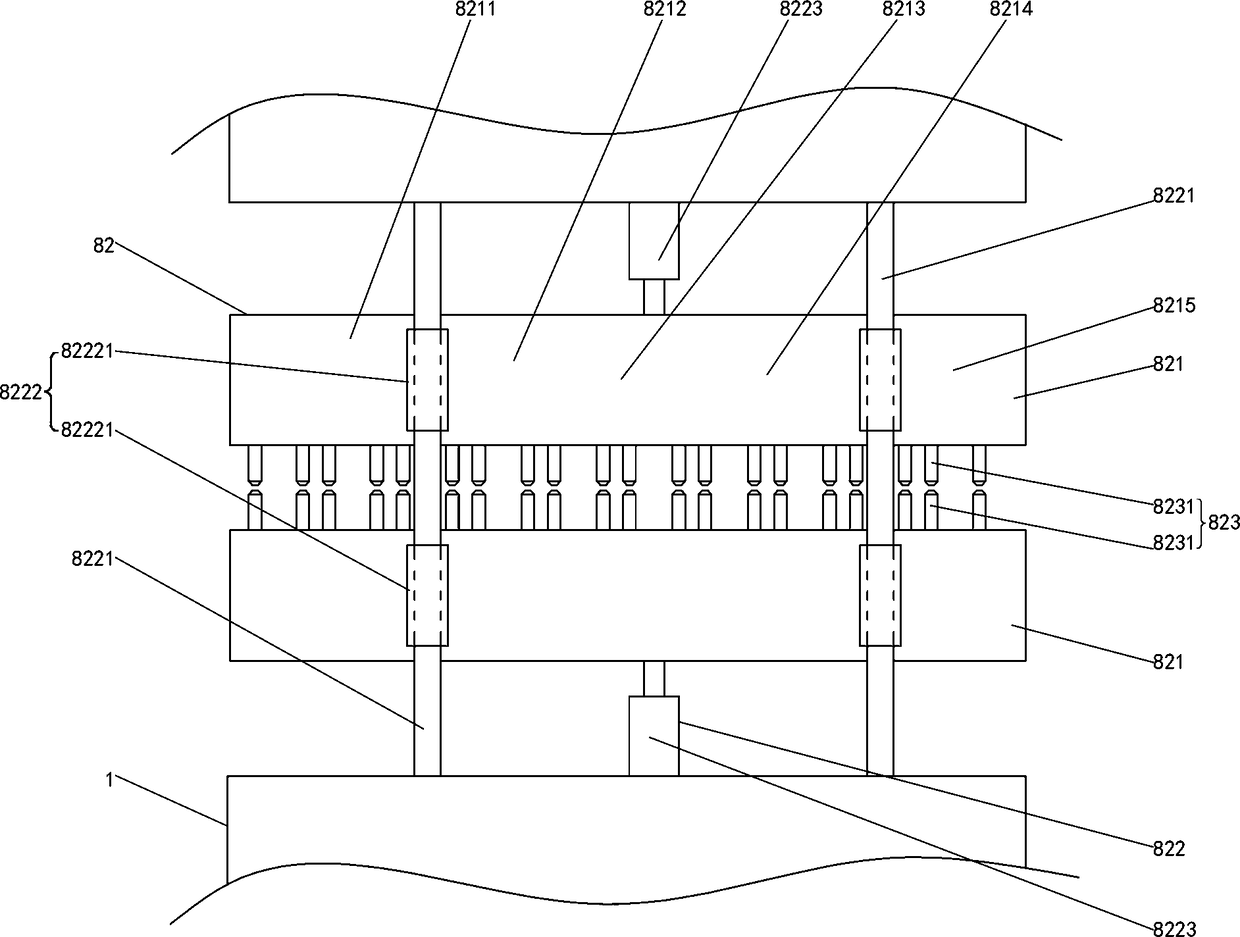

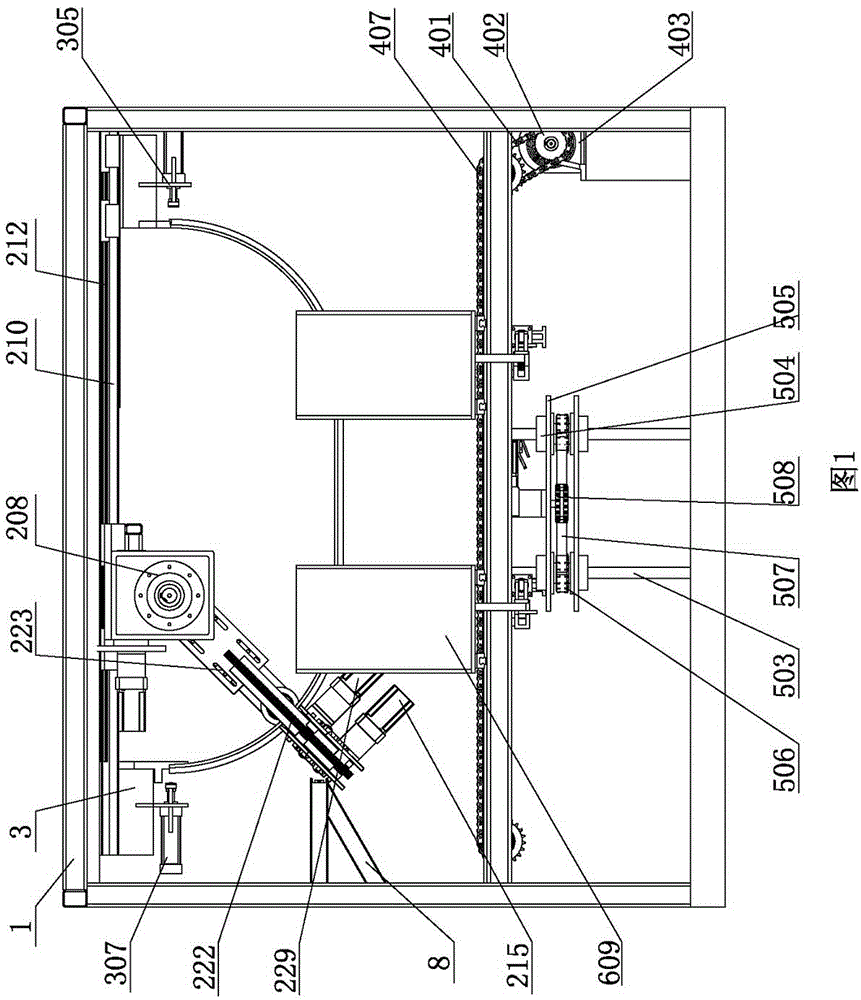

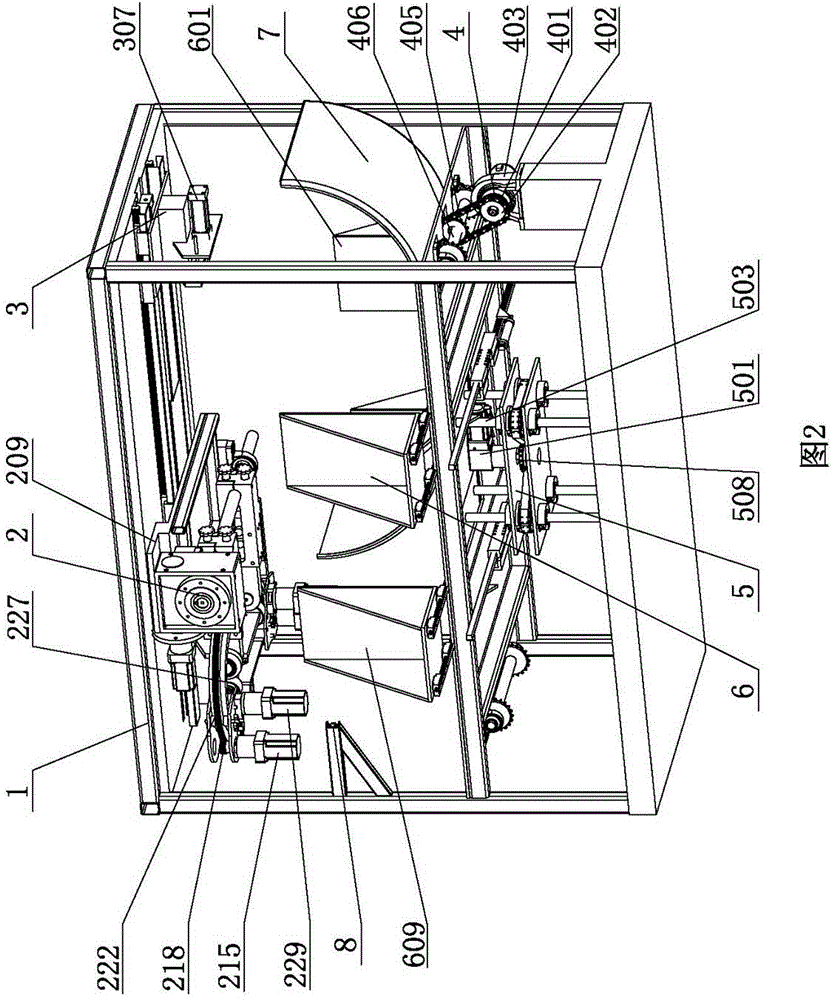

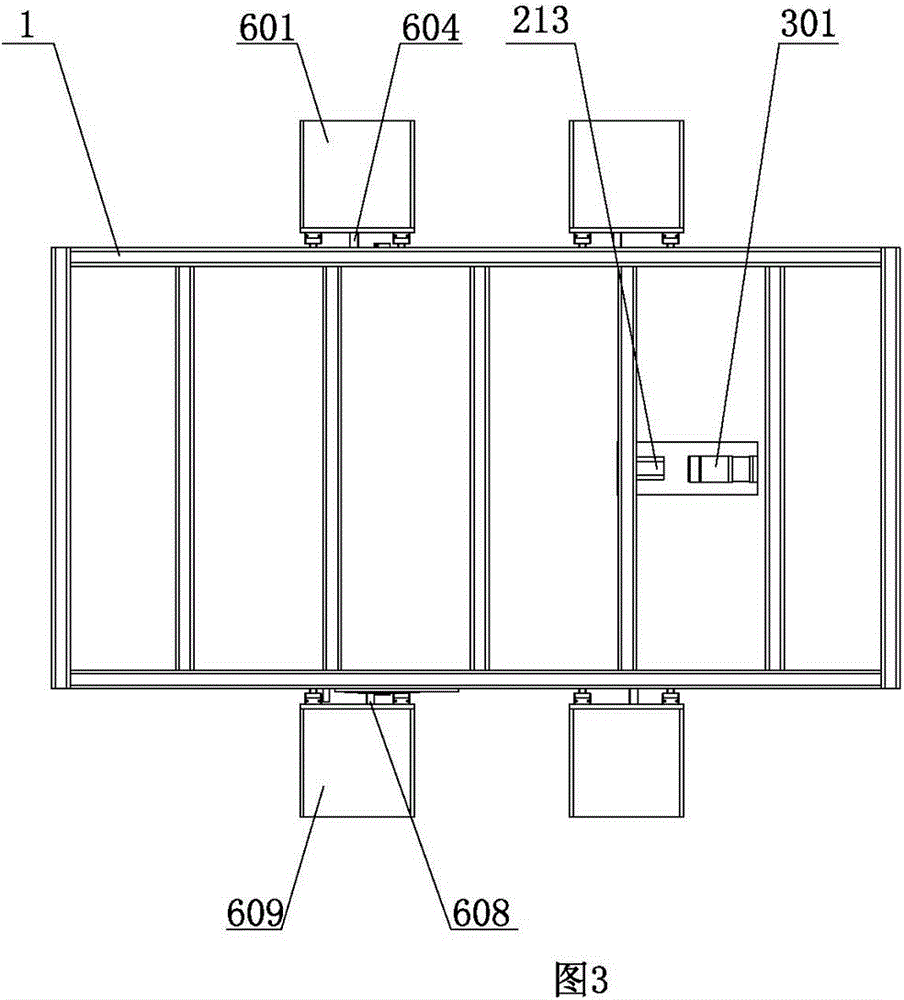

ActiveCN102363366AGuaranteed to be smooth and flatFully automatic laminating operationTyresMetal working apparatusAdhesiveEngineering

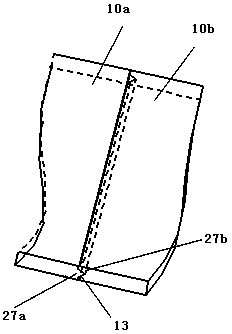

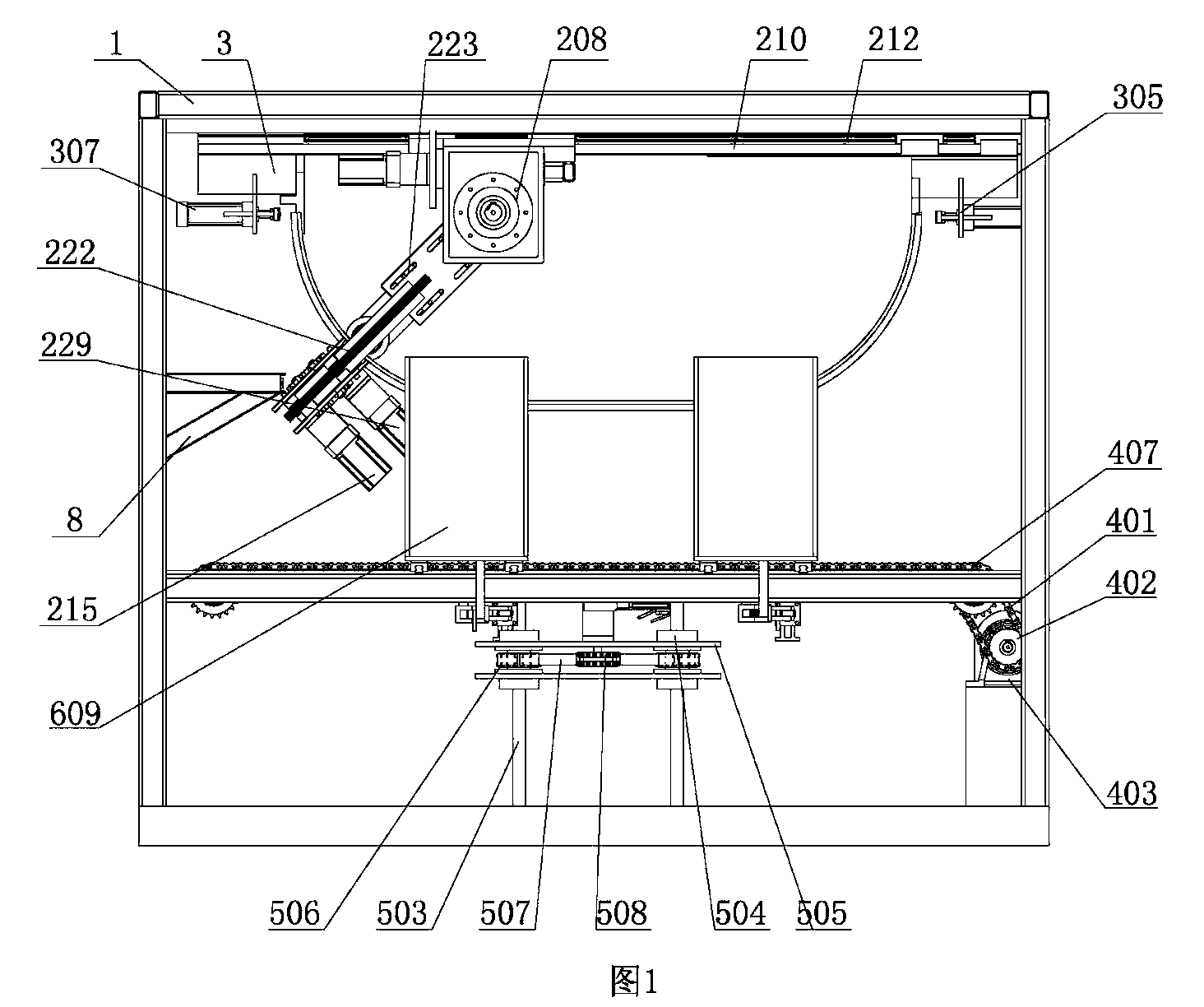

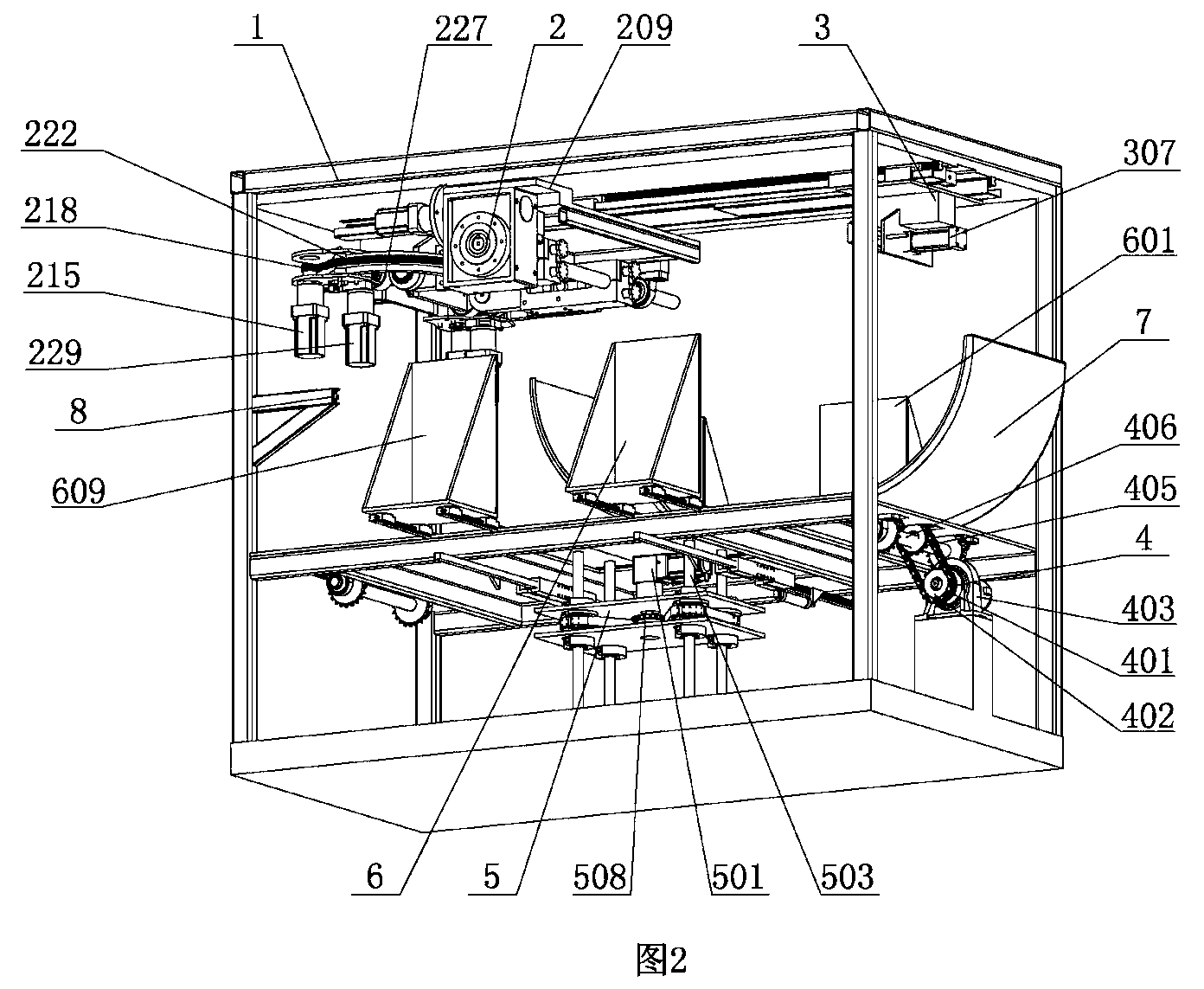

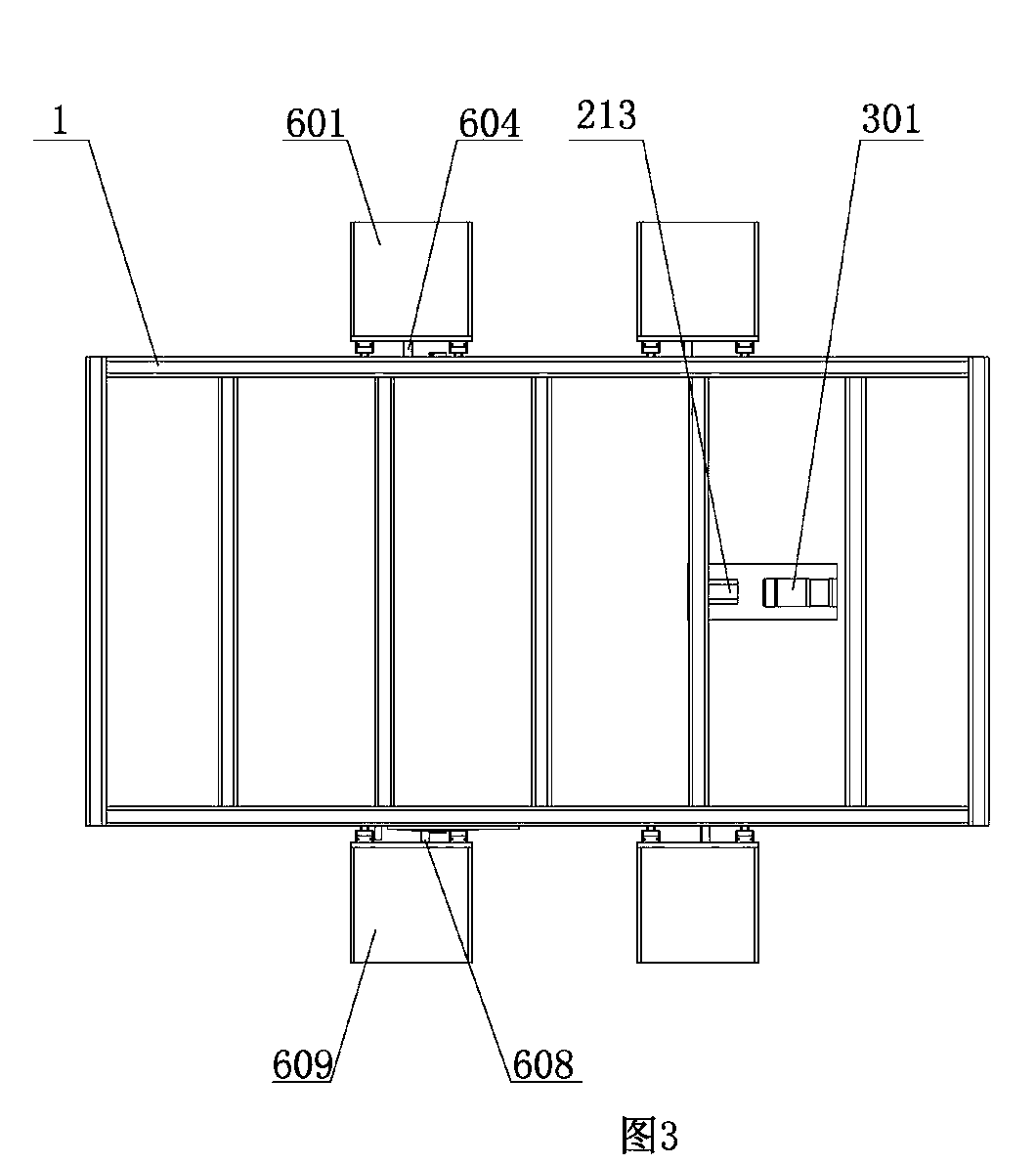

The invention relates to a horizontal triangle adhesive tape sticking device. The device is characterized by comprising a frame (1) and a winding device (2) and two heating cutter devices (3) horizontally arranged on the frame (1); and a small pressure wheel device (4) and a big pressure wheel device (5) are arranged on the frame (1) above the winding device (2). By adopting the horizontal triangle adhesive tape sticking device, full-automatic sticking operation is realized, the production efficiency and the success rate are improved, and smoothness of the stuck position is ensured.

Owner:合威智能装备(江苏)有限公司

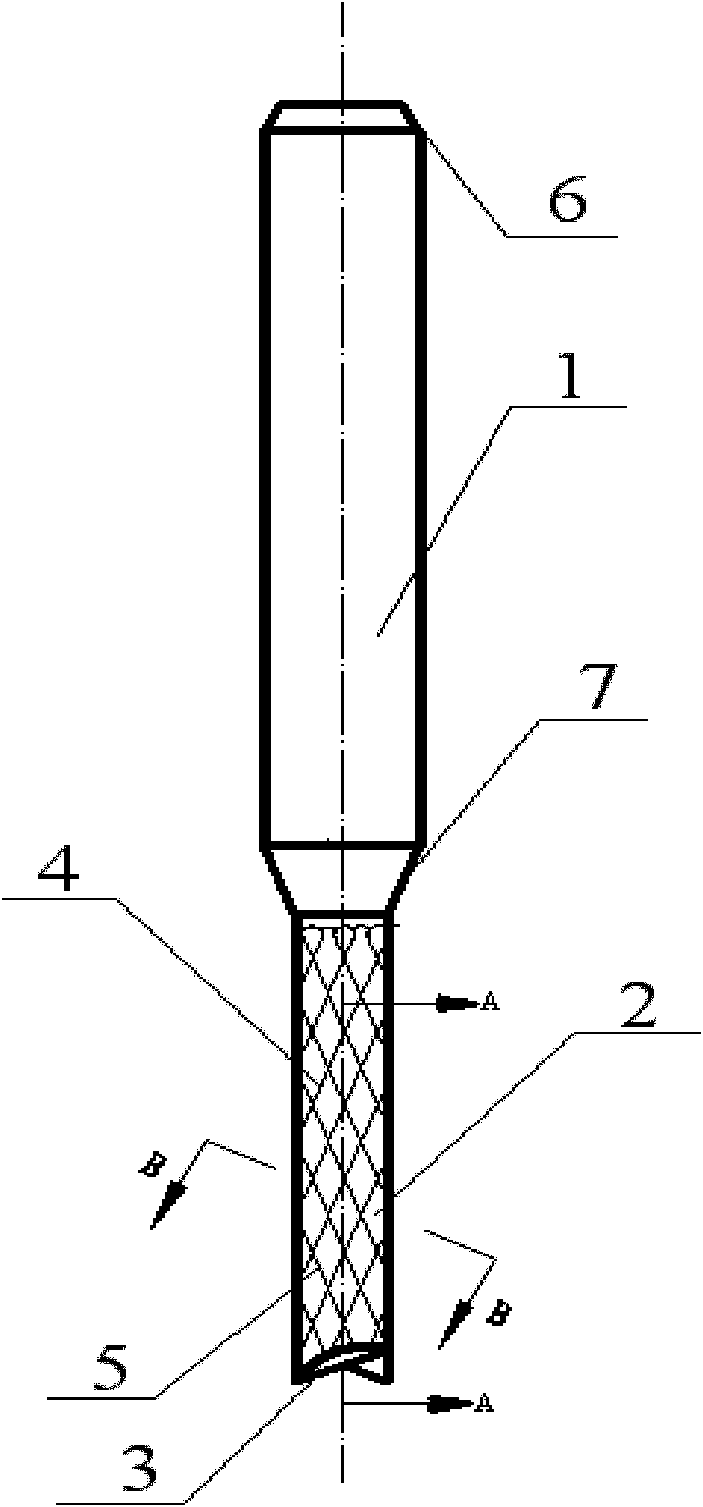

Minitype diamond-tooth milling cutter and processing technology thereof

InactiveCN102120275AGuaranteed milling strengthImprove sharpnessMilling cuttersEngineeringMilling cutter

The invention belongs to the field of milling cutters, in particular to a minitype diamond-tooth milling cutter which is used for processing the minitype slotted hole of a multilayer printed wiring board, and a processing technology thereof. On the basis of the prior art, a step of semi-accurately cutting a spiral groove is added in the processing technology, and thus the cutting mill with the minimum external diameter can be favorably processed. The invention also provides a minitype diamond-tooth milling cutter which is suitable for processing the minitype slotted hole of the multilayer printed wiring board; the helical angles of the left spiral groove and the left spiral groove are respectively 18-22 degrees; and the external diameter phi d of the head of the milling cutter is 0.4-0.7mm. Under the condition that the external diameter of the milling cutter is smaller, a proper spiral angle is chosen; force borne by the head of the milling cutter is reduced while chip removal space is reasonably designed; the phenomenon of excessive wearing or'snapping' because force borne by the head of the milling cutter is too big is avoided; and the milling cutter still has bigger milling strength. The minitype diamond-tooth milling cutter and the processing technology thereof can be used for processing minitype slotted holes.

Owner:ZHEJIANG RICHVERTEX PRECISION TOOLS

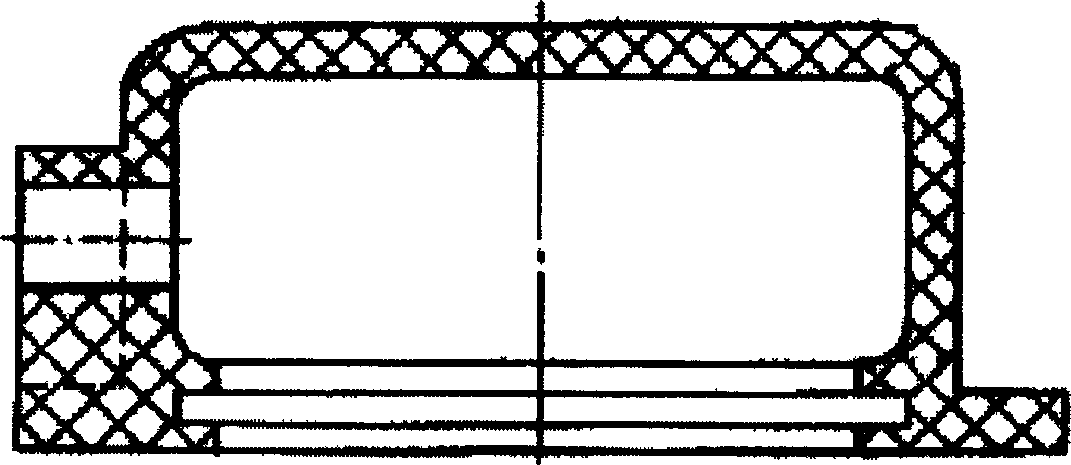

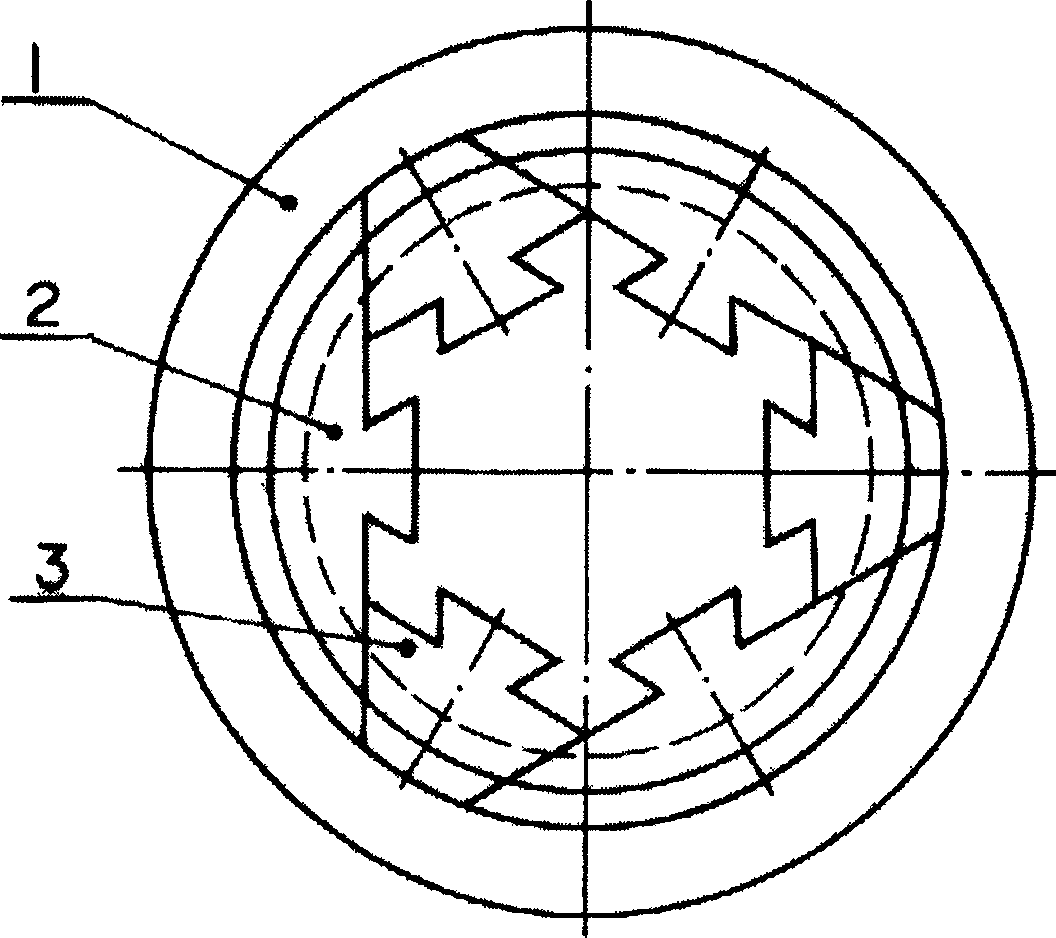

Contracting internal core withdrawing device used for plastic mould and its use method

A contractible core unit for plastic mould is composed of moulding core and its fixing plate, primary and secondary slide blocks arranged along circumference at intervals, oblique push rods and its fixing plate, push plate, movable mould seat, and fixing part. When the mould is used for injection moulding, the inner surface of moulding cavity is smooth. After said injection moulding, the primary and secondary slide blocks are contracted inward under the action of push mechanism, so the bottle neck-shaped plastic product can be easily taken out of the mould.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

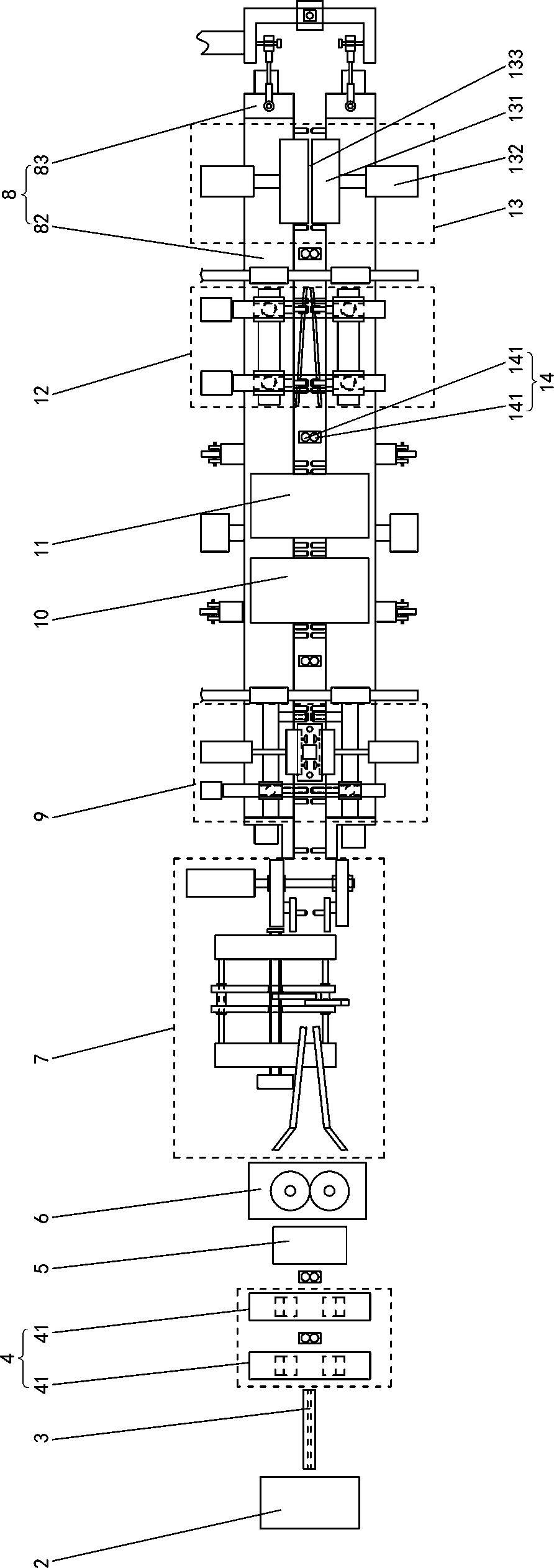

Whistling lollipop packaging machine

PendingCN108639422ARealize stepping movementNeatly combinedWrapper twisting/gatheringPackaging lollipopsPackaging machine

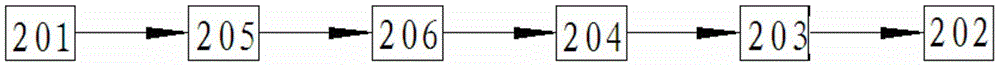

The invention disclose a whistling lollipop packaging machine which comprises a machine frame, a packaging film unrolling device, a packaging film folding device, a sealing device, an easy-to-tear opening shear device, a clamping conveying device, a bag body cutting device, a horizontal bag conveying mechanism, a bag opening device, a lollipop powder filling device, a lollipop filling device, a bag opening straightening device, a sealing device and a bag return device. The packaging film unrolling device, the packaging film folding device, the sealing device, the easy-to-tear opening shear device, the clamping conveying device and the bag body cutting device are sequentially arranged in the conveying direction of packaging films, the bag opening device, the lollipop powder filling device,the lollipop filling device, the bag opening straightening device, the sealing device and the bag return device are sequentially arranged in the bag conveying direction of the horizontal bag conveyingmechanism, and the horizontal bag conveying mechanism is arranged between the bag body cutting device and the sealing device. The horizontal bag conveying mechanism organically integrates bag makingand lollipop filling into a whole, the whole machine is compact in structure, low in overall manufacturing cost and small in occupied space, and it is ensured that bag openings of packaging bags are sealed in order.

Owner:汕头市茂发食品有限公司 +1

Horizontal triangle adhesive tape sticking device

ActiveCN102363366BGuaranteed to be smooth and flatFully automatic laminating operationTyresMetal working apparatusAdhesiveEngineering

The invention relates to a horizontal triangle adhesive tape sticking device. The device is characterized by comprising a frame (1) and a winding device (2) and two heating cutter devices (3) horizontally arranged on the frame (1); and a small pressure wheel device (4) and a big pressure wheel device (5) are arranged on the frame (1) above the winding device (2). By adopting the horizontal triangle adhesive tape sticking device, full-automatic sticking operation is realized, the production efficiency and the success rate are improved, and smoothness of the stuck position is ensured.

Owner:合威智能装备(江苏)有限公司

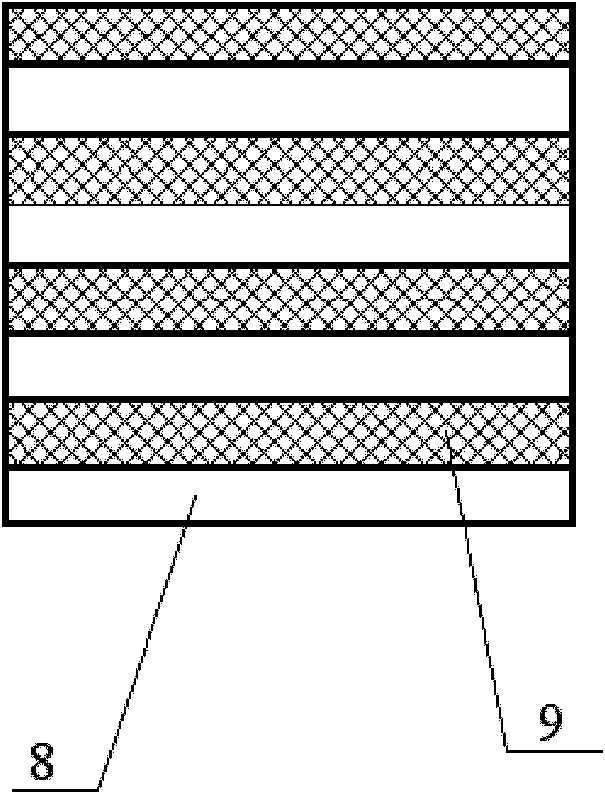

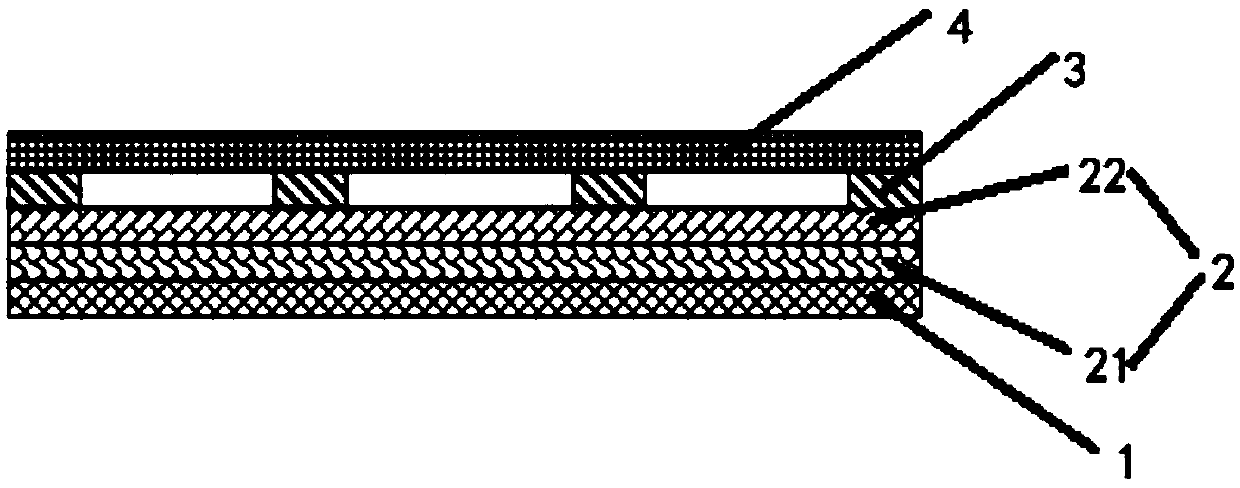

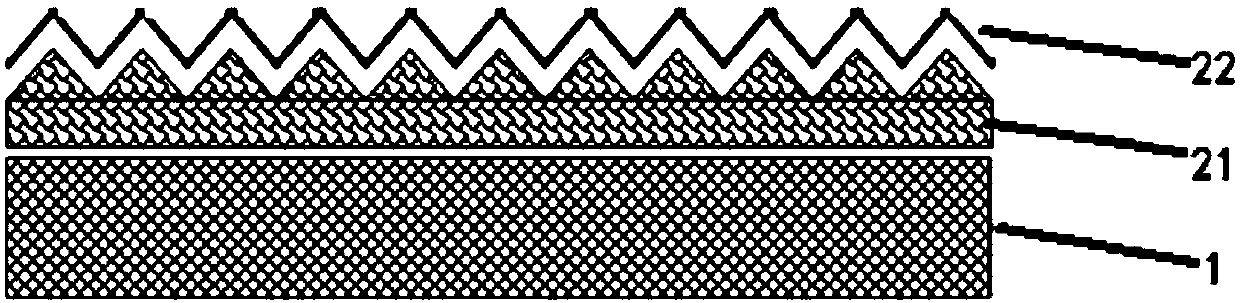

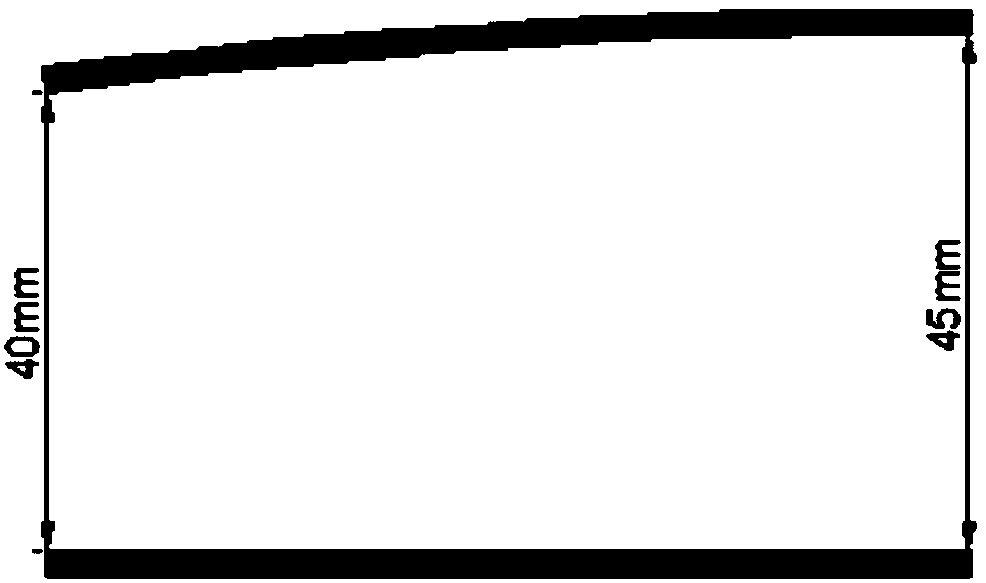

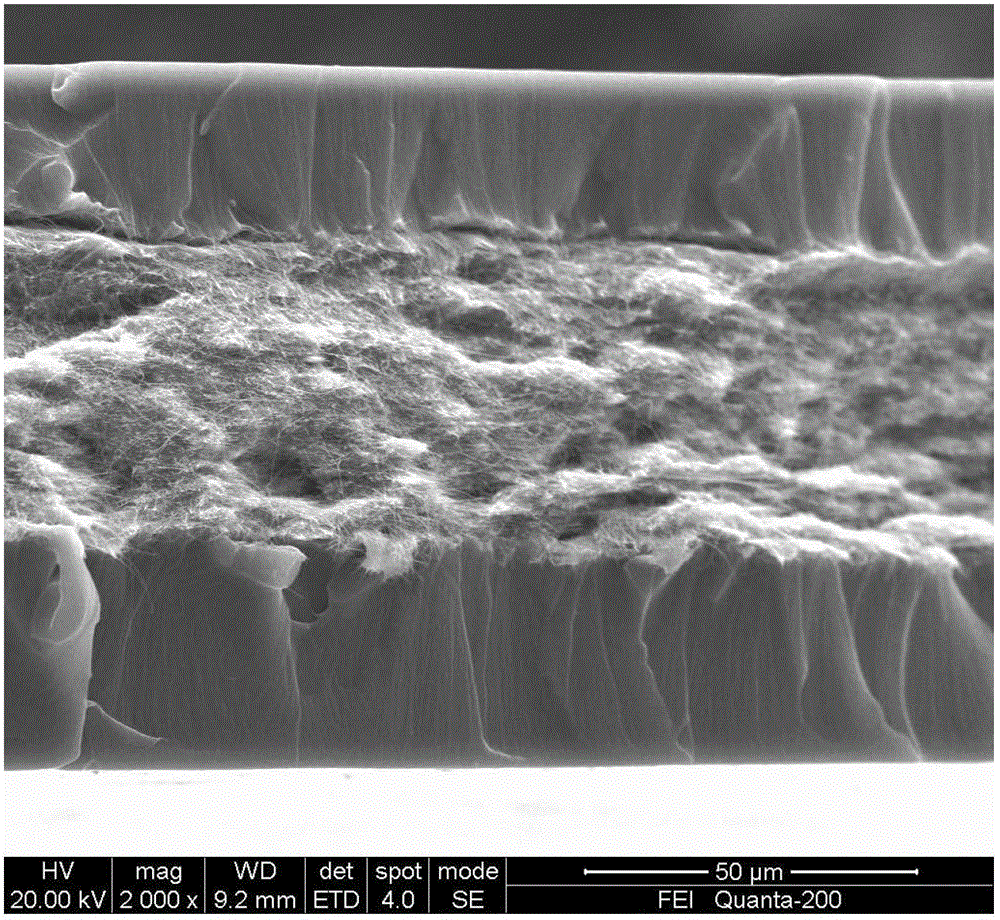

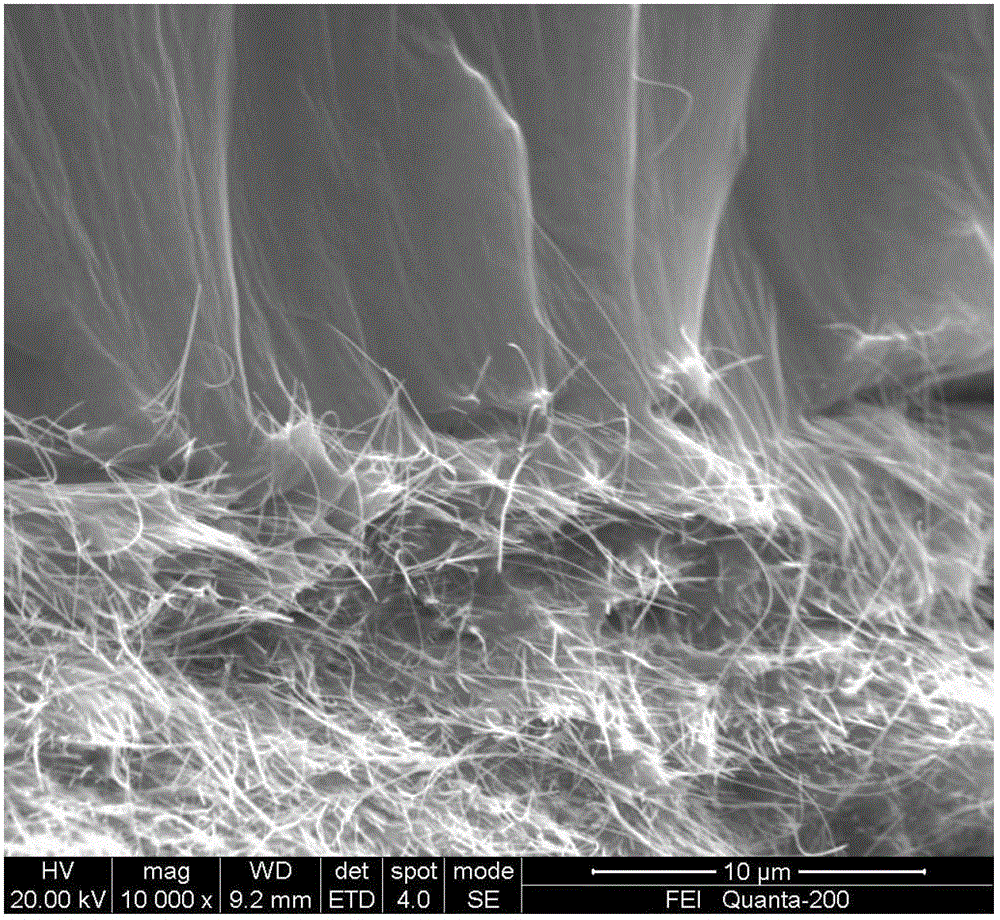

Graphene-based high-emissivity infrared emission film and preparation method thereof

ActiveCN109618428AHigh emissivityIncrease the areaOhmic-resistance electrodesGrapheneEmissivityAdhesive

The invention discloses a graphene-based high-emissivity infrared emission film and a preparation method thereof. The graphene-based high-emissivity infrared emission film comprises a transparent substrate, a roughened graphene composite layer, an electrode layer and a packaging layer which are sequentially stacked from bottom to top, wherein the graphene composite layer is a composite layer formed by an adhesive layer formed by curing a liquid adhesive and a graphene thin film when the graphene thin film which grows on a rough processed catalytic substrate is transferred to the transparent substrate through the liquid adhesive; the adhesive layer completely copies rough lines on the catalytic substrate; and the roughness of the graphene composite layer is 0.5-40 [mu]m. The graphene composite layer is formed when the graphene thin film which grows on the rough processed catalytic substrate is transferred to the transparent substrate by the liquid adhesive, so that the specific surfacearea and the surface roughness of the graphene composite layer are obviously improved, thereby improving the emissivity of the infrared emission film.

Owner:CHONGQING GRAPHENE TECH

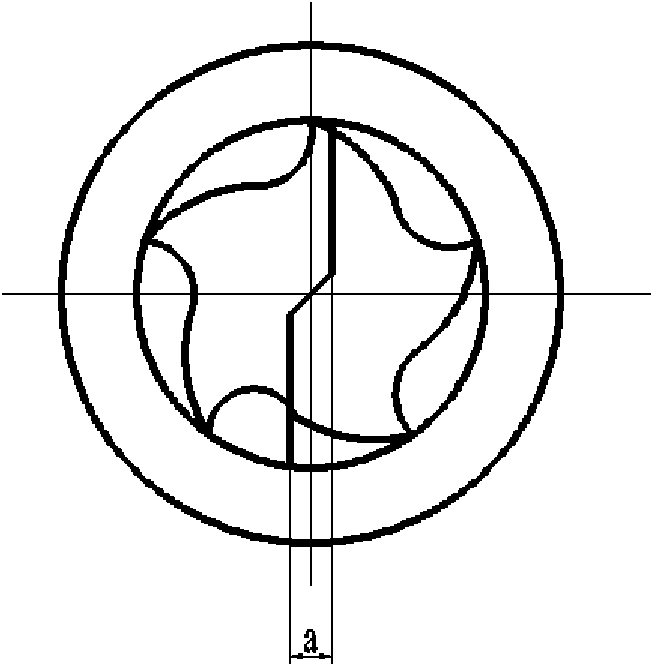

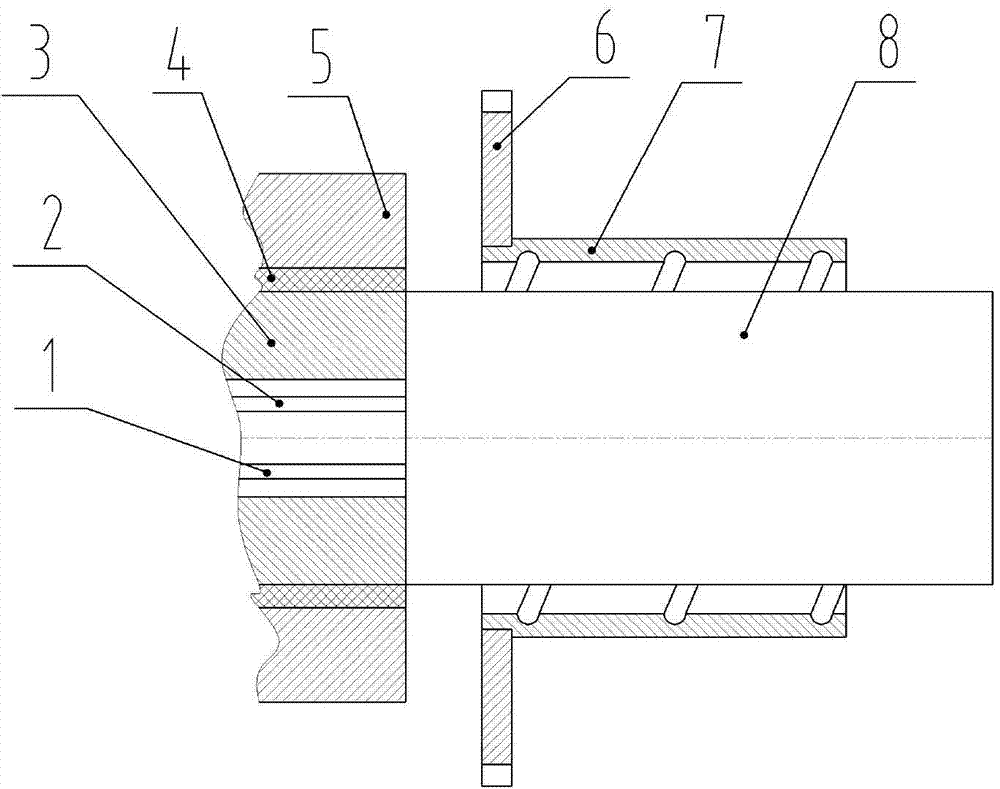

Welding spot area fully stirred key-hole-free friction stir spot welding method and tool

ActiveCN103801819AStir wellGuaranteed to be smooth and flatNon-electric welding apparatusSpot weldingBiomedical engineering

The invention discloses a welding spot area fully stirred key-hole-free friction stir spot welding method and tool. The tool comprises a stirring needle, a shaft shoulder, and a clamp sleeve which are sequentially sleeved from inside to outside and are arranged in a relatively sliding manner, at least two stirring raised ribs are uniformly distributed peripherally on the outer wall of a stirring end of the stirring needle, a holding notch matched with the stirring raised rib is formed in the end face of the shaft shoulder, the stirring raised rib can stretch along the holding notch, and the end face of the stirring end of the stirring needle and the end face of the shaft shoulder and the clamp sleeve are on the same horizontal plane. According to the method and the tool provided by the invention, the defect of complicated distribution of a backfill friction stir spot welding joint is effectively eliminated, and meanwhile, the advantage that no key hole is left in the surface of the backfill friction stir spot welding joint is also kept.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

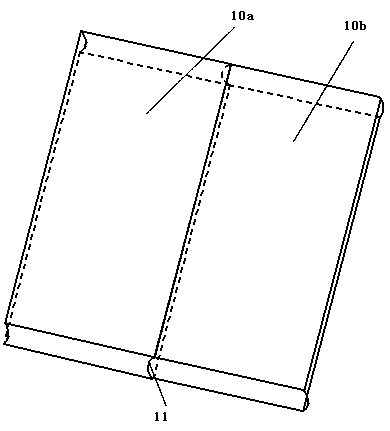

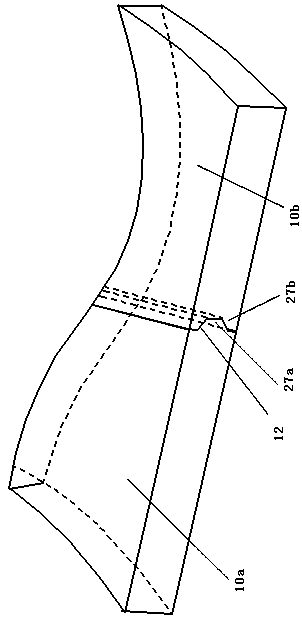

Solid wood veneer and manufacturing process thereof

InactiveCN108789677AIncrease the degree of fixationImprove bending resistanceLaminationLamination apparatusSolid woodSurface layer

The invention discloses a solid wood veneer and a manufacturing process thereof. A cabinet body board comprises a surface layer solid wood veneer and a solid wood board core, wherein the side edges ofthe solid wood board cores are meshed with each other through side extending parts, the end parts of the solid wood board cores are meshed with each other through the meshing grooves, the solid woodreinforcing plates are bonded and fixed on the two sides of the solid wood board core, a wood chip leveling layer is arranged on the outer surface of the solid wood reinforcing plate, the surface of the wood chip leveling layer is bonded and fixed with a surface layer solid wood veneer. According to the solid wood veneer, the solid wood board core is adopted as the base material to manufacture thecabinet body board, the solid wood board core is fixed through the solid wood reinforcing board, the fixed degree between the solid wood board cores is high, the bending resistance of the cabinet body plate is effectively improved, the structural strength of the cabinet body plate is guaranteed, and the structure strength of the cabinet body plate is matched with the wood chip leveling layer, itis guaranteed that the surface layer solid wood veneer is smooth and flat after being attached to the surface layer solid wood veneer, and the manufacturing quality of the cabinet body panel is high.The manufacturing process has the beneficial effects of being simple in operate, the saw dust can be recycled, the use amount of precious wood is reduced by taking the solid wood board core as the base material, and resources are saved.

Owner:安徽附利整体家居有限公司

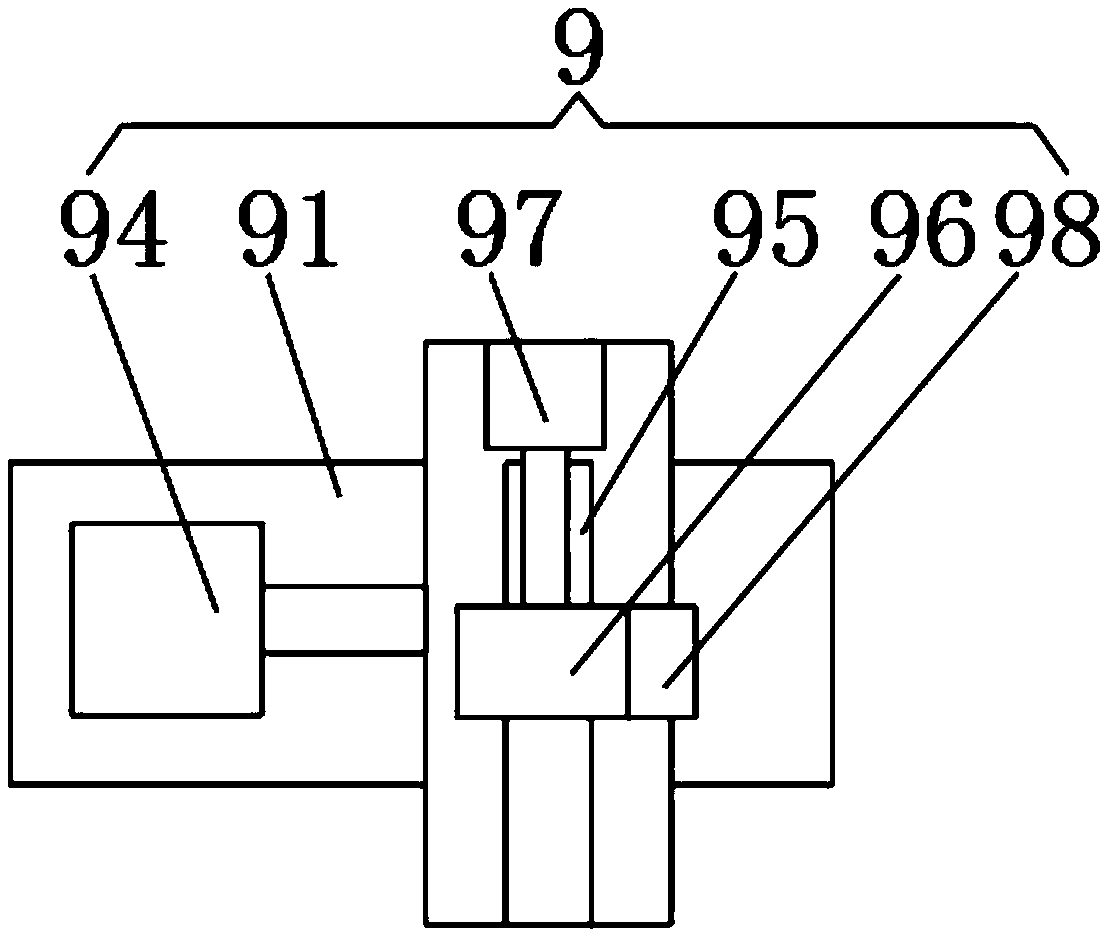

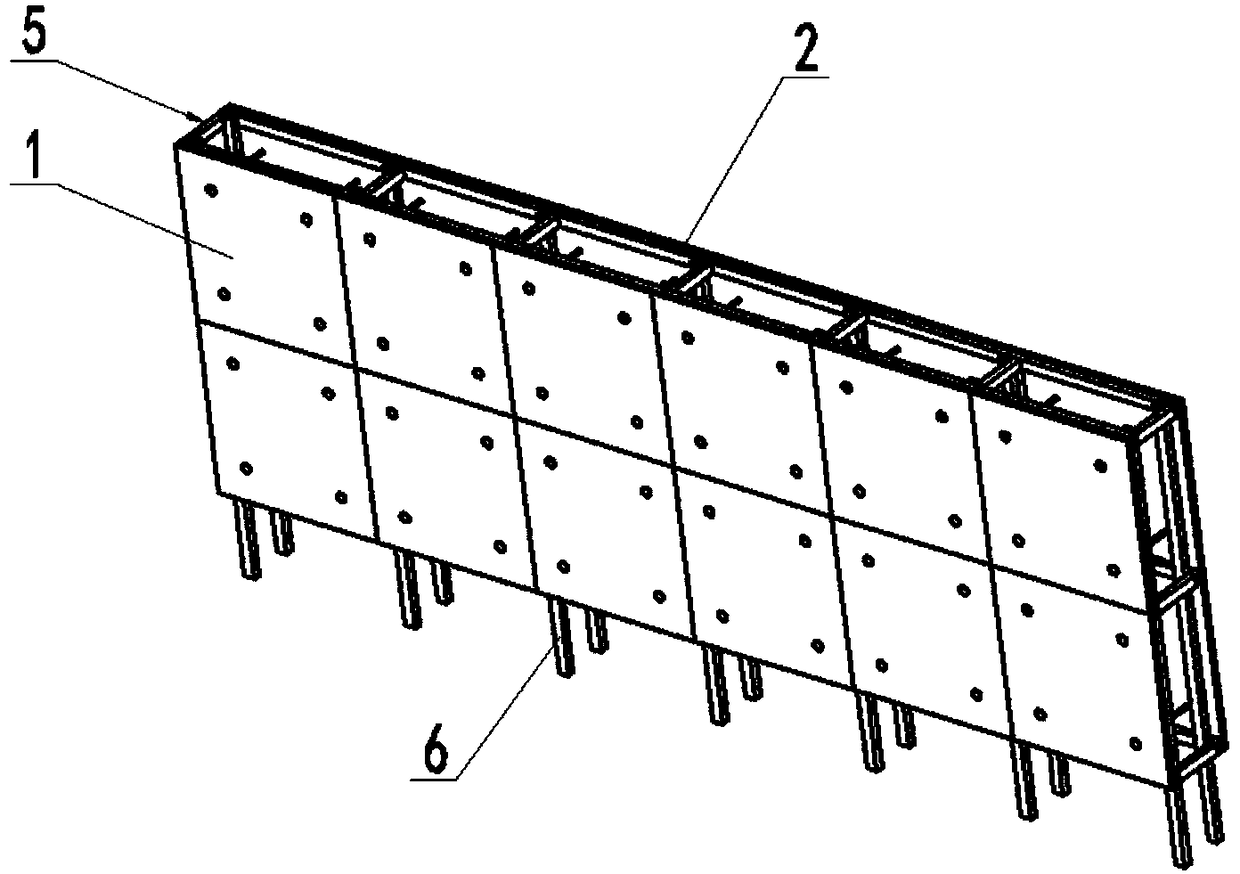

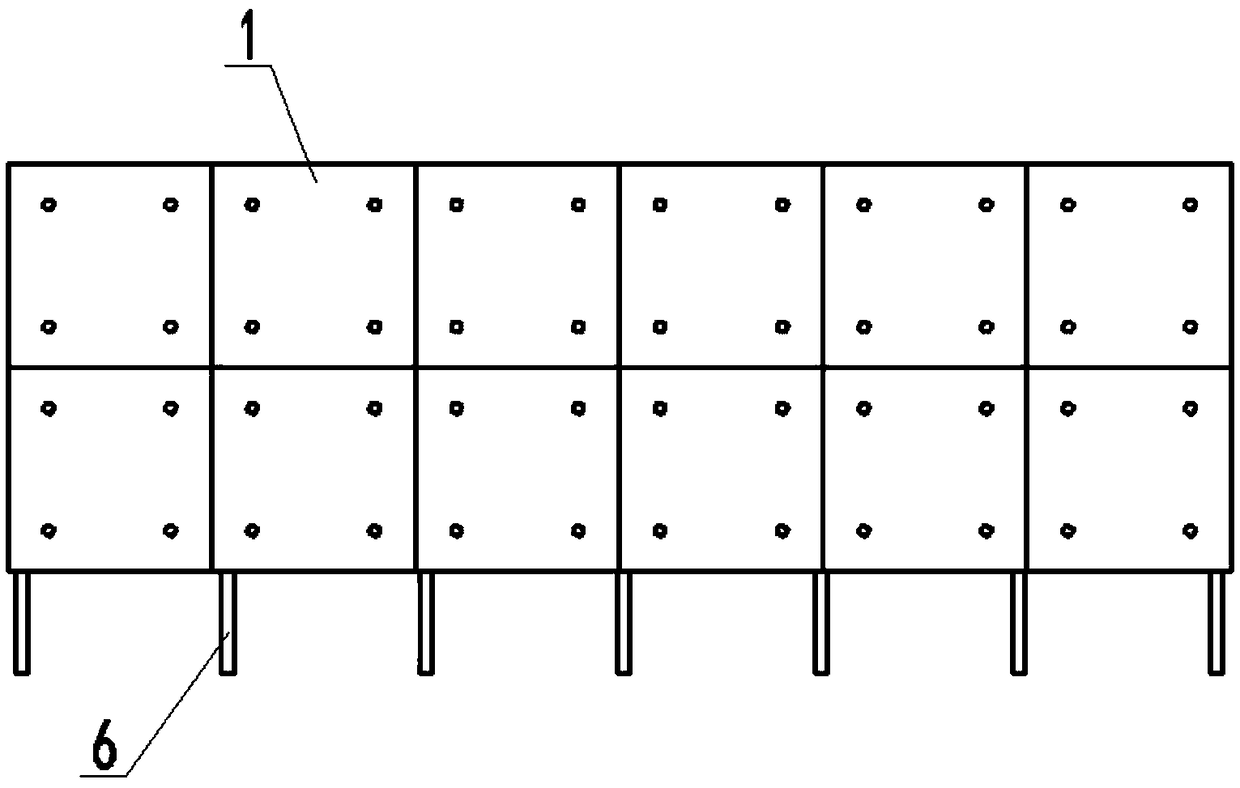

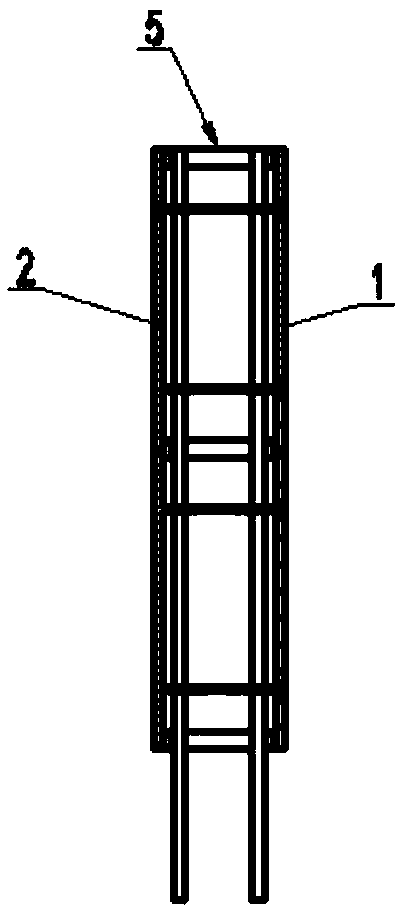

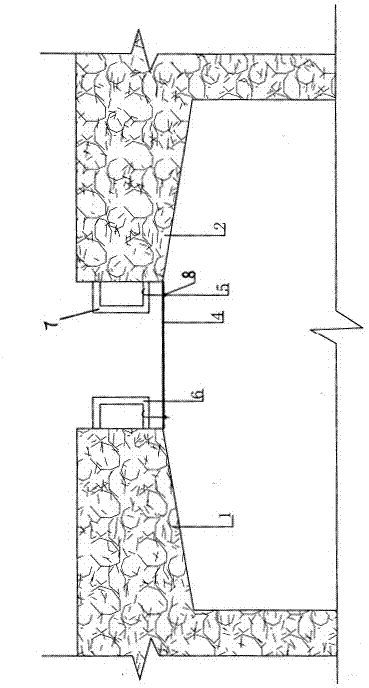

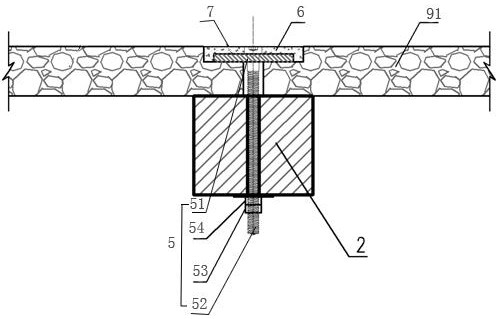

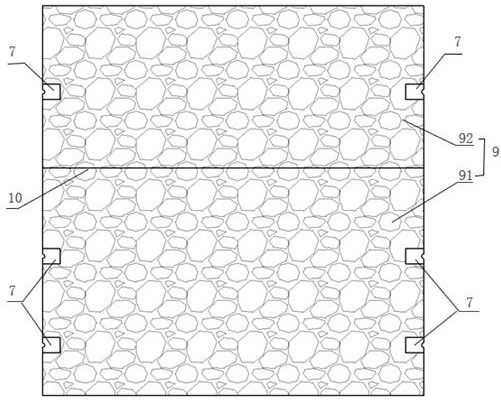

Concrete formwork combining and flatness adjusting structure

PendingCN110593563AGuaranteed flatnessGuaranteed stabilityAuxillary members of forms/shuttering/falseworksButt jointSlurry

The invention discloses a concrete formwork combining and flatness adjusting structure and belongs to the field of buildings. Fixing mechanisms are arranged at backs of formworks, grooves and / or bulges are arranged on end surfaces of the formworks, opposite adjusting bolts are arranged in formworks perpendicular to end surfaces of butt-jointed formworks, adjusting bolt combining parts are connected between the adjusting bolts, notches with thickness smaller than that of formworks are arranged near butt-jointed edges at backs of the formworks, a mixed formwork comprises a wooden formwork arranged between a pair of steel formworks, steps are arranged on end surfaces of opposite steel formworks, the two ends of the wooden formwork are arranged on the steps, and lower end surfaces of the stepsare in threaded connection with long adjusting bolts and adjusting bolt combining parts. The structure can guarantee smoothness and flatness of concrete surfaces, prevent loss of concrete slurry, improve formwork combination speed and combination quality, guarantee concrete casting quality and improve construction quality.

Owner:ANYANG NORMAL UNIV

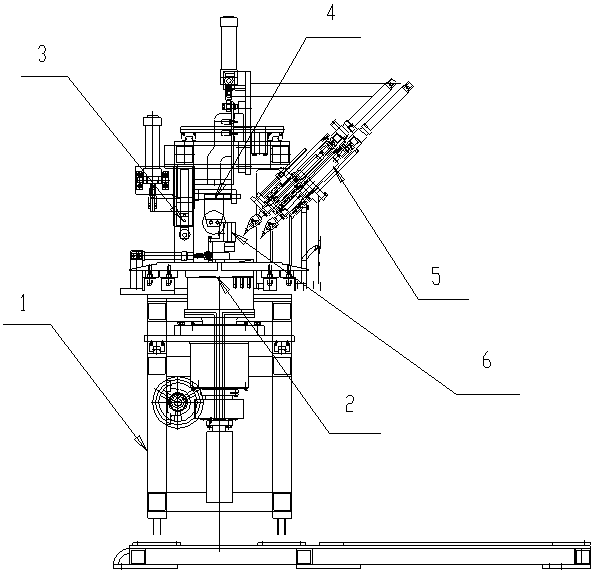

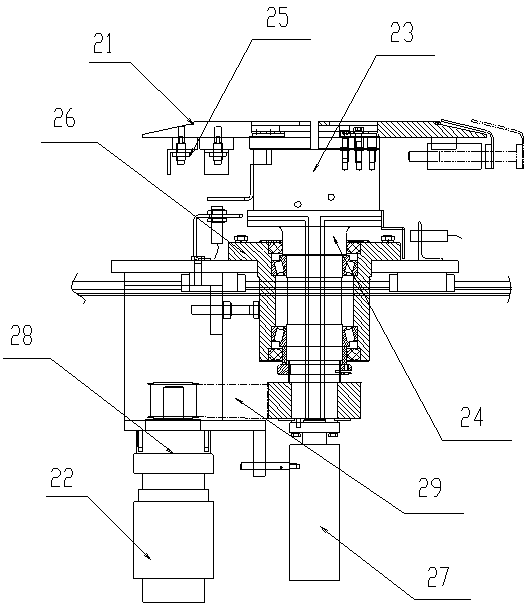

Tire protection cover spin-edge machine

The invention discloses a tire protection cover spin-edge machine which comprises a rack, wherein a spin-edge moving mechanism is arranged on the rack. A sliding fixing block is arranged on an execution part of the spin-edge moving mechanism, and a rotating shaft and a swing-arm drive motor are arranged on the sliding fixing block. An output shaft of the swing-arm drive motor is connected with the rotating shaft, and a spin-edge mechanism is arranged on the rotating shaft. The spin-edge mechanism is provided with a swing arm, and an internal pressure wheel and a spin-edge gear ring are arranged on the swing arm. A moving seat is arranged on the outer periphery of the spin-edge gear ring in movable mode, and the moving seat can move along the spin-edge gear ring. A drive motor is arranged on the moving seat, and a rotating gear wheel is arranged on an output shaft of the drive motor. The rotating gear wheel is in mesh connection with the spin-edge gear ring, and a spin-edge actuator is arranged on the moving seat. An external pressure wheel is arranged on an output shaft of the spin-edge actuator, and the external pressure wheel and the internal pressure wheel are arranged side by side. The tire protection cover spin-edge machine can replace the manpower to proceed with edgefold handling. The tire protection cover spin-edge machine has the advantages of greatly improving the production efficiency, guaranteeing the processing quality, lowering the rejection rate, and finally achieving the aim of greatly reducing cost.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

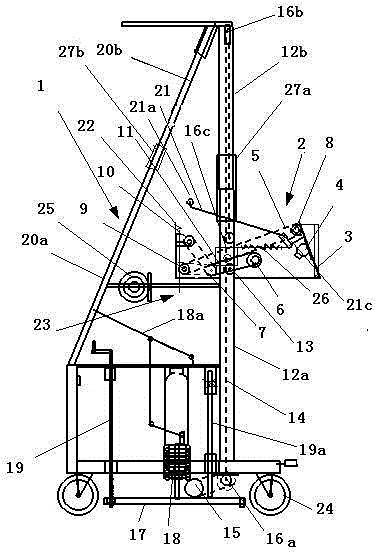

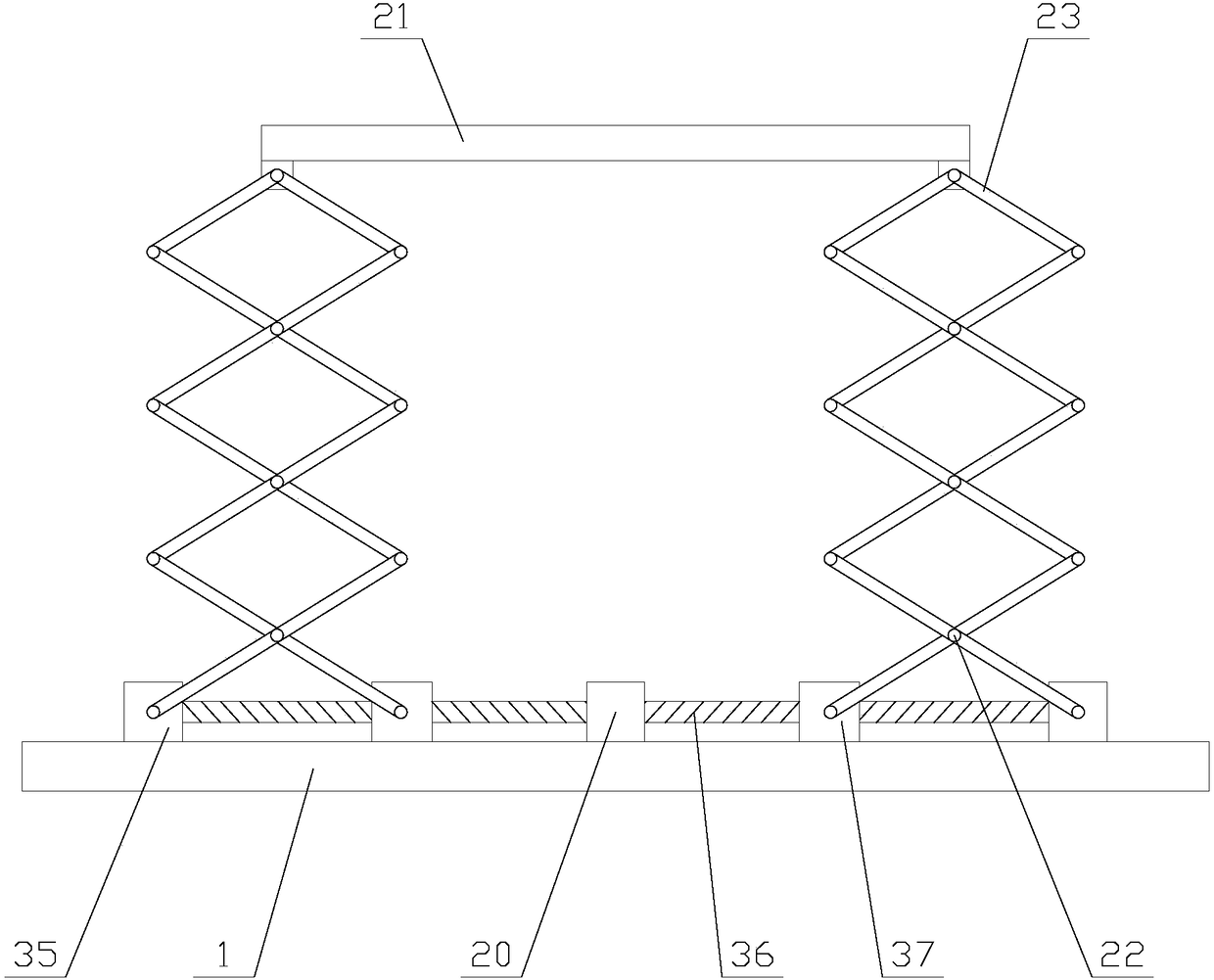

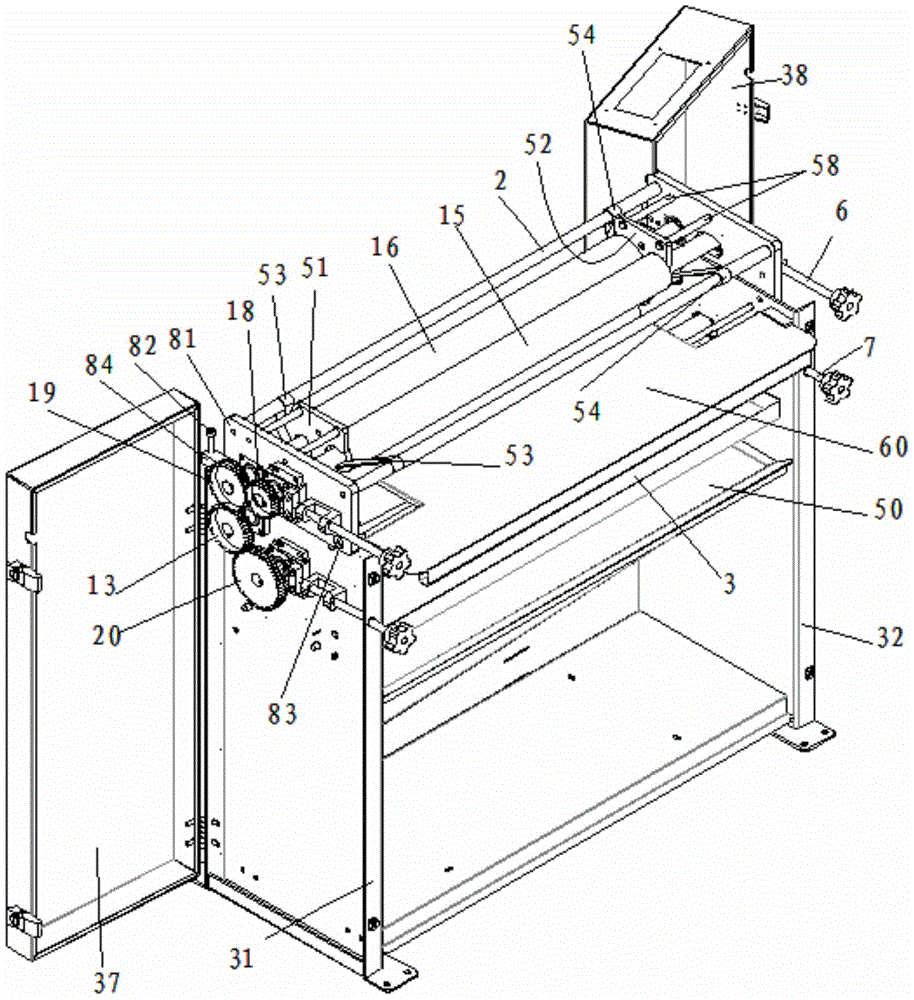

Multi-functional automatic wall painting machine

InactiveCN105604304AGuaranteed to be smooth and flatSufficient supplyBuilding constructionsStructural engineeringMultiple function

A multi-functional automatic wall painting machine belongs to the field of constructions, wherein a wall painting main machine is disposed on a perpendicular frame which is located on the side of a virtual frame close to a wall body; a lifting drive device is connected to the wall painting main machine; a cement mortar hopper is disposed on the wall painting main machine; a wall painting plate is disposed on the side of the wall painting main machine close to the wall body; a conveying belt of which the end part is located on the upper end of the wall painting plate is disposed in the cement mortar hopper; and a vibrator is disposed on the inner side of the wall painting plate. By use of the wall painting machine, wall painting can be implemented automatically, and wall painting efficiency is increased. The working efficiency of the wall painting machine is equal to the working efficiency of at least eight wall painting technicians, so that the wall painting efficiency is increased greatly; manual expenses are reduced; company benefits are increased; construction can be completed on time within a contract term; competiveness among peers in the same industry is enhanced; and users' time requirements are satisfied.

Owner:袁国堂

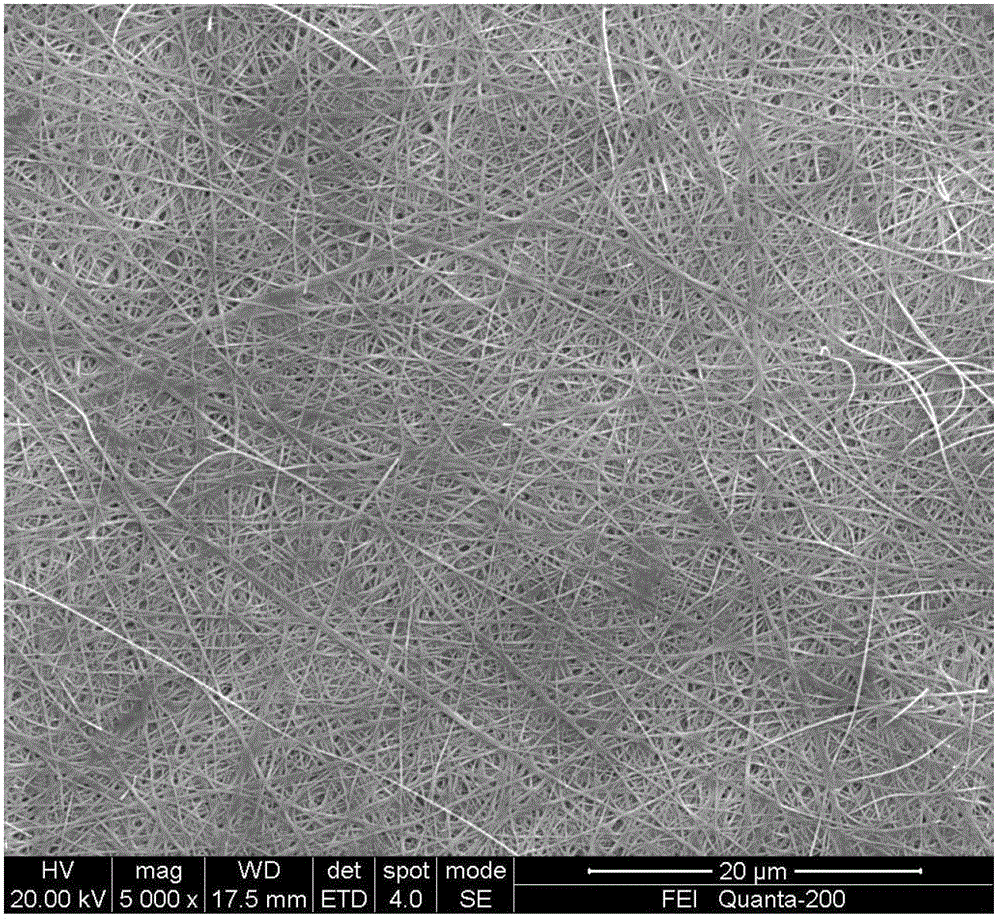

Chrysotile nanofiber and resin composite transparent film, and preparation method and application thereof

InactiveCN103331967ARefractive index adjustmentLow viscositySynthetic resin layered productsSolid-state devicesComposite filmUV curing

A chrysotile nanofiber and resin composite transparent film, and a preparation method and application thereof. The film includes a layer of chrysotile nanofiber layer with pores; the nanofiber layer is wrapped between an upper resin layer and a lower resin layer; and the resin is infiltrated into the pores of the fiber layer. The content of chrysotile nanofiber is 20wt%-75wt%, and the thickness of the transparent composite film is 70-150 mum. The method is as below: adding chrysotile nanofiber into water, adding a polymer binder, and forming a uniform colloidal solution through mechanical stirring and ultrasonic; filtering the colloidal solution with a microfiltration membrane, and drying the obtained filter membrane to form a white chrysotile nanofiber film; and impregnating the chrysotile nanofiber film in vacuum in a UV curing resin, taking out the film, leveling and forming, curing with the UV to obtain the chrysotile nanofiber and resin composite film. The composite transparent film can be applied to substrate materials of organic electroluminescent devices.

Owner:CENT SOUTH UNIV

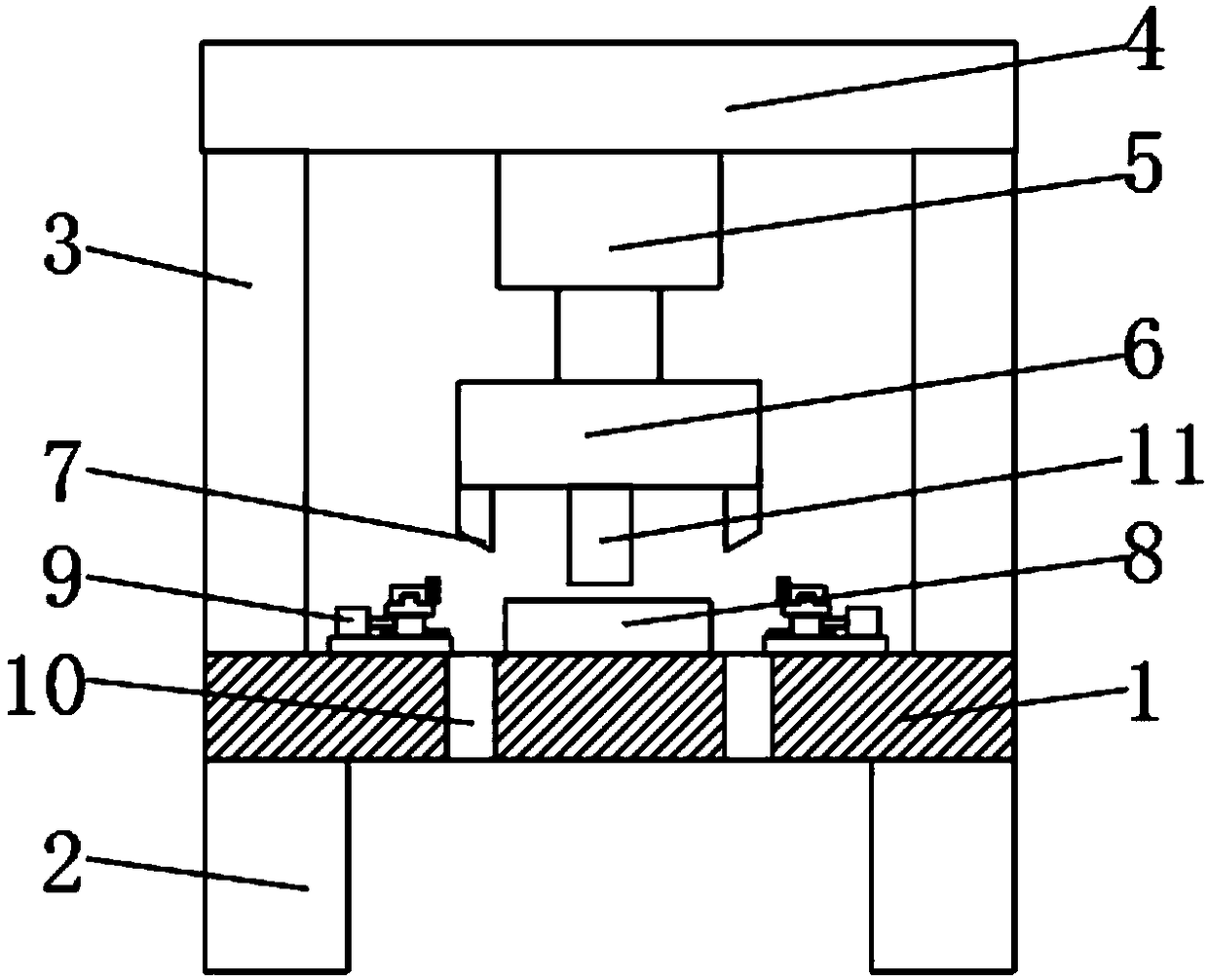

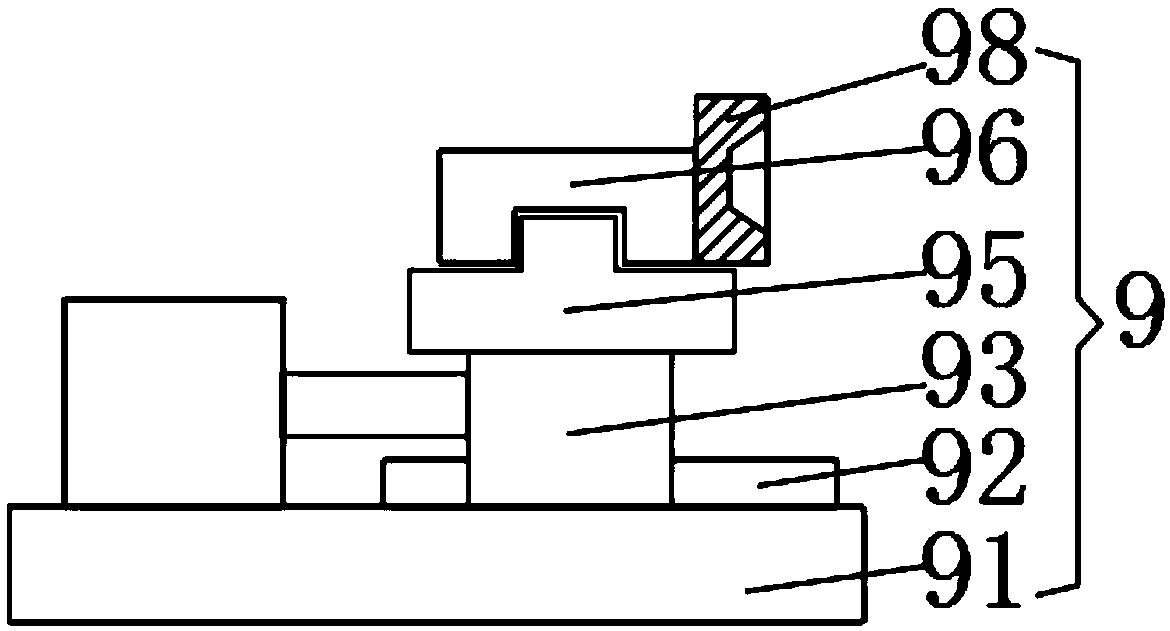

Stamping mechanical equipment for processing optical instrument component

InactiveCN108890312AReasonable structural designAvoid misalignmentOther manufacturing equipments/toolsOptical instrumentWorkbench

The invention belongs to the technical field of processing optical instrument components and discloses stamping mechanical equipment for processing the optical instrument components. The stamping mechanical equipment for processing the optical instrument components is characterized in that a top plate is fixed on top of two sets of support columns; a first electric telescopic rod is fixed in the middle of the bottom of the top plate; a cutter head is connected to the bottom of the first electric telescopic rod; both sides of the left and right of the bottom of the cutter head are fixedly provided with cutting tools; a pressing device is fixed in the middle of the bottom of the cutter head; a workbench is fixed in the middle of the top of a base; the top of the base is opened with two setsof cutter grooves which are of the same structure and cooperate with the cutting tools; the two sets of the cutter grooves are distributed on both sides of the workbench; an edge grinding device fixedon top of the base is disposed on one side, near the workbench, of the support columns; the edge grinding device is capable of grinding edges and corners and cutting surfaces of the components, eliminating burrs on the cutting surfaces and corners and thus ensuring that corners of finished components are smooth and flat.

Owner:江苏鸿鹄激光科技有限公司

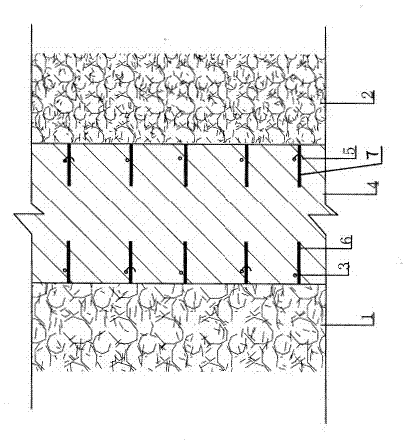

Assembled steel structural integrated house wall

The invention provides an assembled steel structural integrated house wall comprising external wall boards, internal wall boards, connecting screws, nuts and a steel structural wall skeleton. The external wall boards and the internal wall boards cover two sides of the wall skeleton respectively; one ends of the connecting screws are embedded in the internal wall boards; the external wall boards are provided with connecting holes corresponding to the connecting screws; the other ends of the connecting screws run through the connecting holes to be screwed with the nuts; thus, the external wall boards, the internal wall boards and the wall skeleton are connected integrally. According to the technical scheme, structural strength of the integral wall is improved through the connecting screws, the external wall board and the internal wall board are assembled more conveniently, operating space is enlarged, the outer surface of the wall keeps flat and tidy, vertical keels can be inserted intothe ground to be connected with the same so that the capacity of resisting severe environment is improved; besides, as the wall is filled with a thermal insulating material, the wall is suitable to beused in hot summer, people's living environment is improved, and service life of the wall is prolonged.

Owner:NANNING UNIV

Tooth-inlaid special high-speed rubber tapping tool with two sections of edges and design method

ActiveCN113100013AImprove tapping quality and efficiencyImprove removal efficiencyForestryElectric machineryKnife blades

The invention relates to the field of rubber cutting production, in particular to a rubber tapping tool with two sections of cutting edges, which is controlled by a motor to automatically perform high-quality, efficient and protective cutting on rubber trees. The invention provides the inlaid rubber tapping tool with two sections of cutting edges, which is matched with a motor. The tool consists of a milling cutter head, a cutter bar and a blade. The inlaid design can adapt to different rubber tapping environments, blades of different structures and angles can be flexibly selected, and the rubber tapping requirement is met; the tool adopts the structural design of a small wedge angle, a large front angle, a large rear angle and an arc chip guide, so that the cutting requirement of wood is met, a smooth and flat cutting plane is obtained, and rubber discharging, heat dissipation and chip removal are facilitated; due to the design of the two sections of cutting edges, smooth and flat cutting planes and side surfaces are guaranteed, and rubber trees are prevented from being damaged; and the inclination angle of the cutting edges prevents a rubber solution from losing from the side surfaces, so that the yield is ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

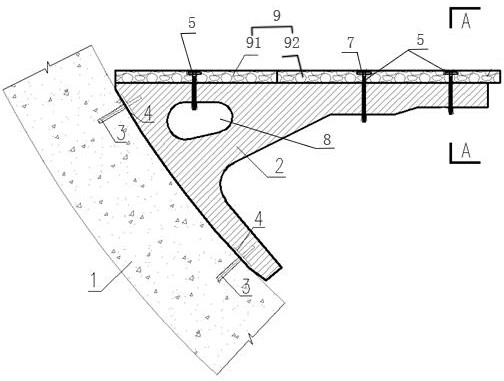

Wet joint construction method of T-shaped beam bridge floor system

ActiveCN103510466BAvoid destructionHigh rate of repeated useBridge structural detailsShaped beamBeam bridge

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

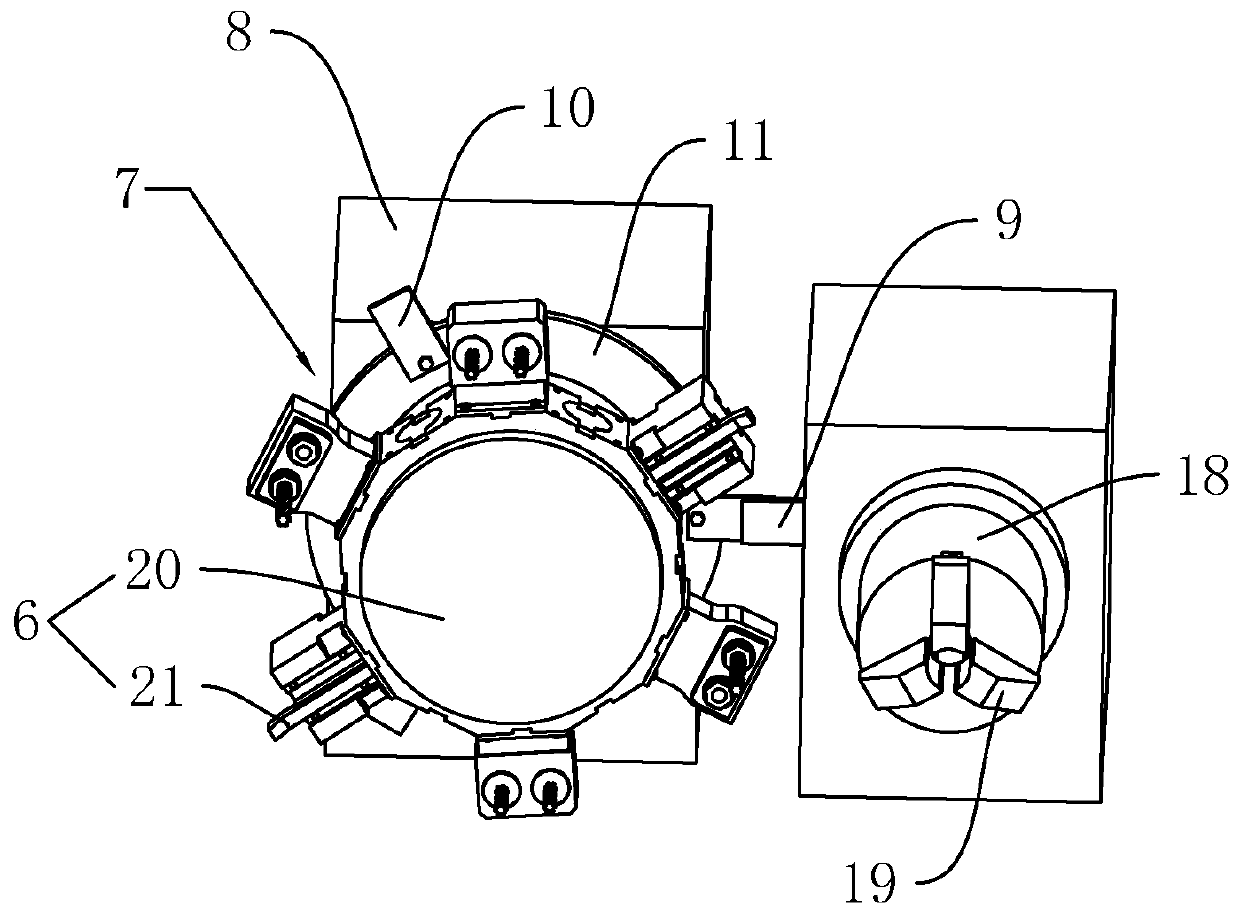

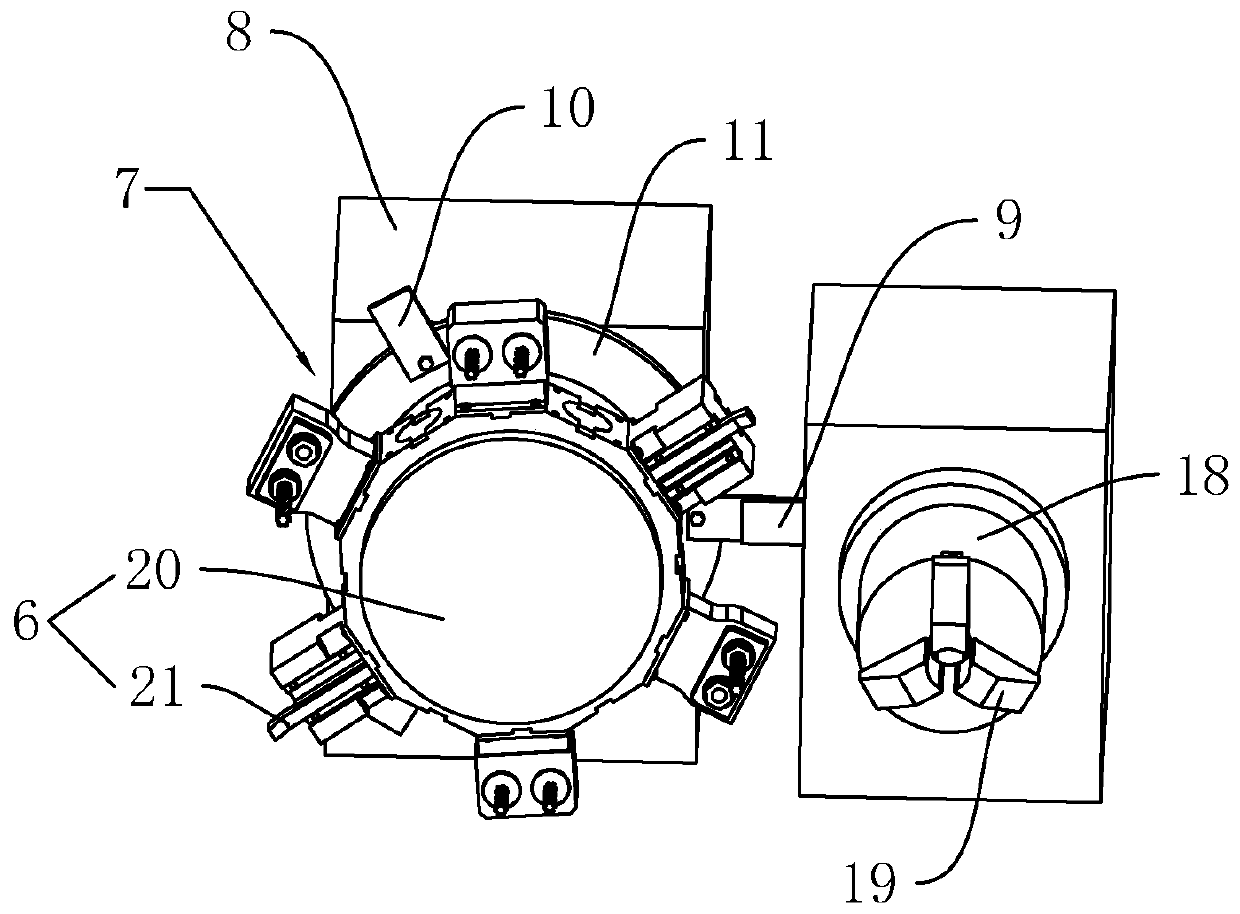

Clamping device for glazing porcelain

ActiveCN111531693AStable and smooth dischargeEasy to reach inCeramic shaping apparatusPhysicsAnnular array

The invention relates to a clamping device for glazing porcelain. The clamping device comprises a clamping rod, a supporting pipe, clamping claws and a controller, wherein a handle is arranged on theclamping rod; a brake handle is hinged to a position below the handle; the supporting pipe is of a pipe body; a plurality of supporting claws inclined outwards are arranged at the top end of the supporting pipe in an annular array; the clamping claws are rod bodies; the controller comprises a control claw and a brake wire; and the control claw comprises a lantern ring and a control rod. The clamping claws approach a second vertical pipe when the brake handle is not stressed, free ends of the clamping laws retract towards the center of the second vertical pipe so as to reach the inside of a blank with a narrow opening; when the supporting claws abut against the bottom of a blank bottle, the brake handle is manually tightened to pull the brake wire so that a connecting rod can drive the lantern ring to slide downwards, when the lantern ring slides downwards, the control rod pulls the clamping claws to expand towards all directions to be stuck on the shoulder of the bottle, and thus the blank with the narrow opening is clamped by the camping claws together with the supporting claws; and the clamping is stable, the glazing on an inner wall and an outer wall is finished at one time, andtime and labor are saved.

Owner:台州市安锋智能科技有限公司

Tire protection cover spin-edge machine

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

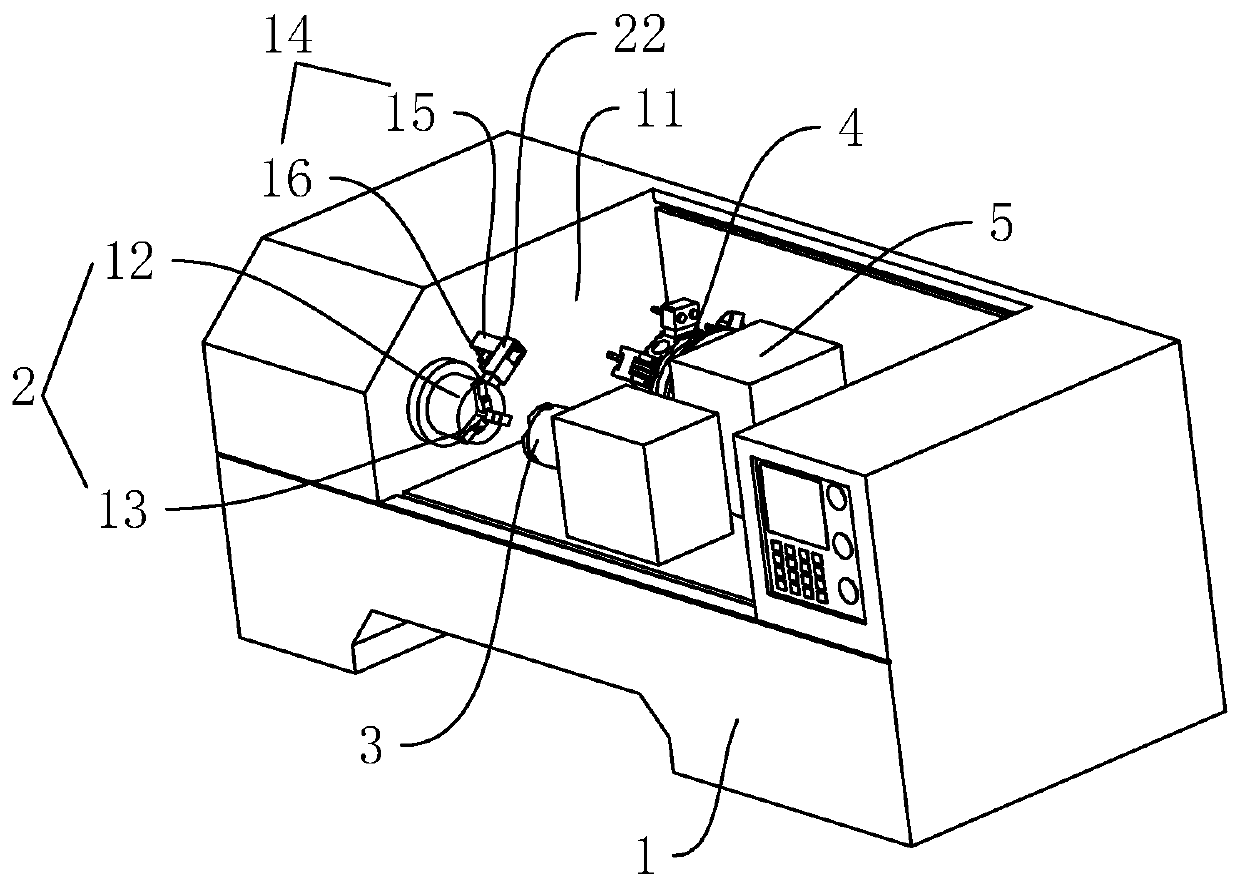

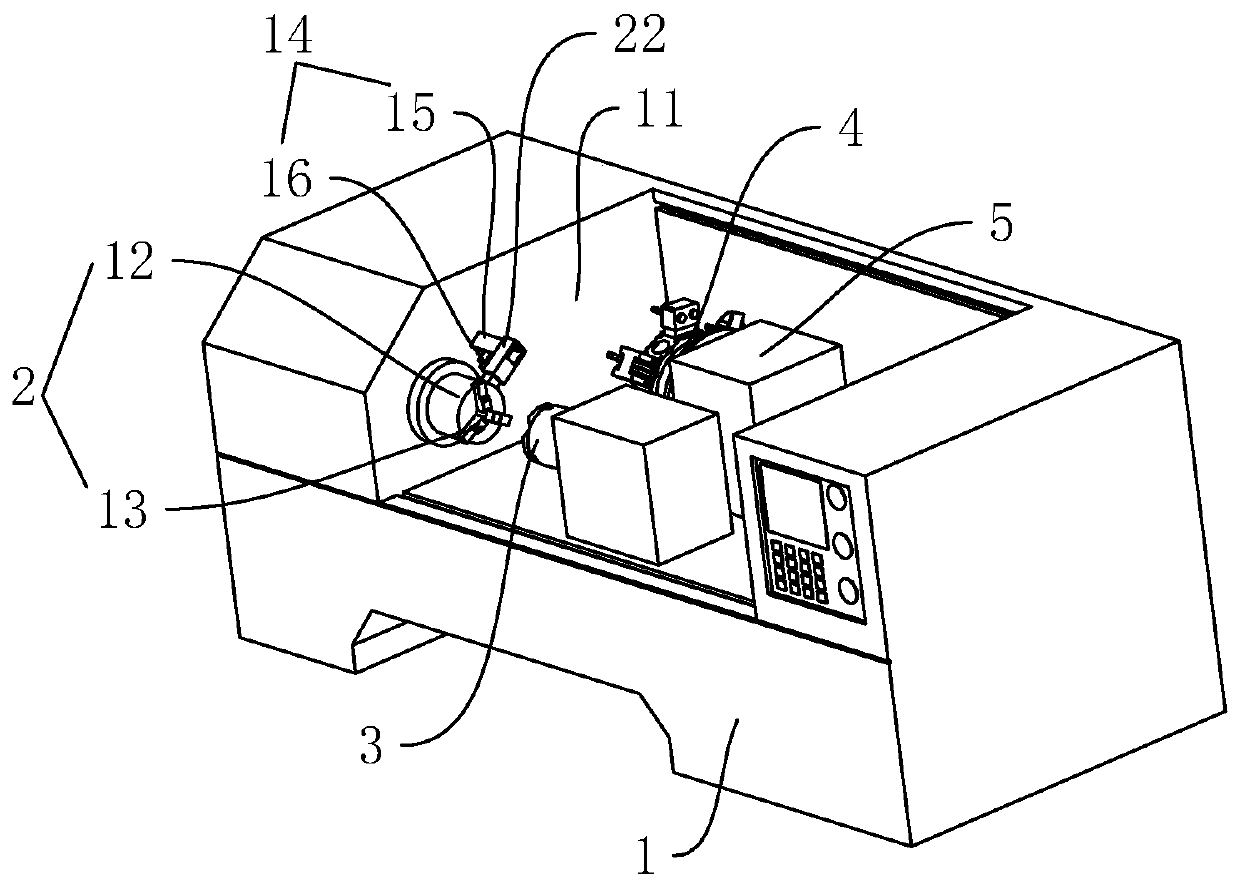

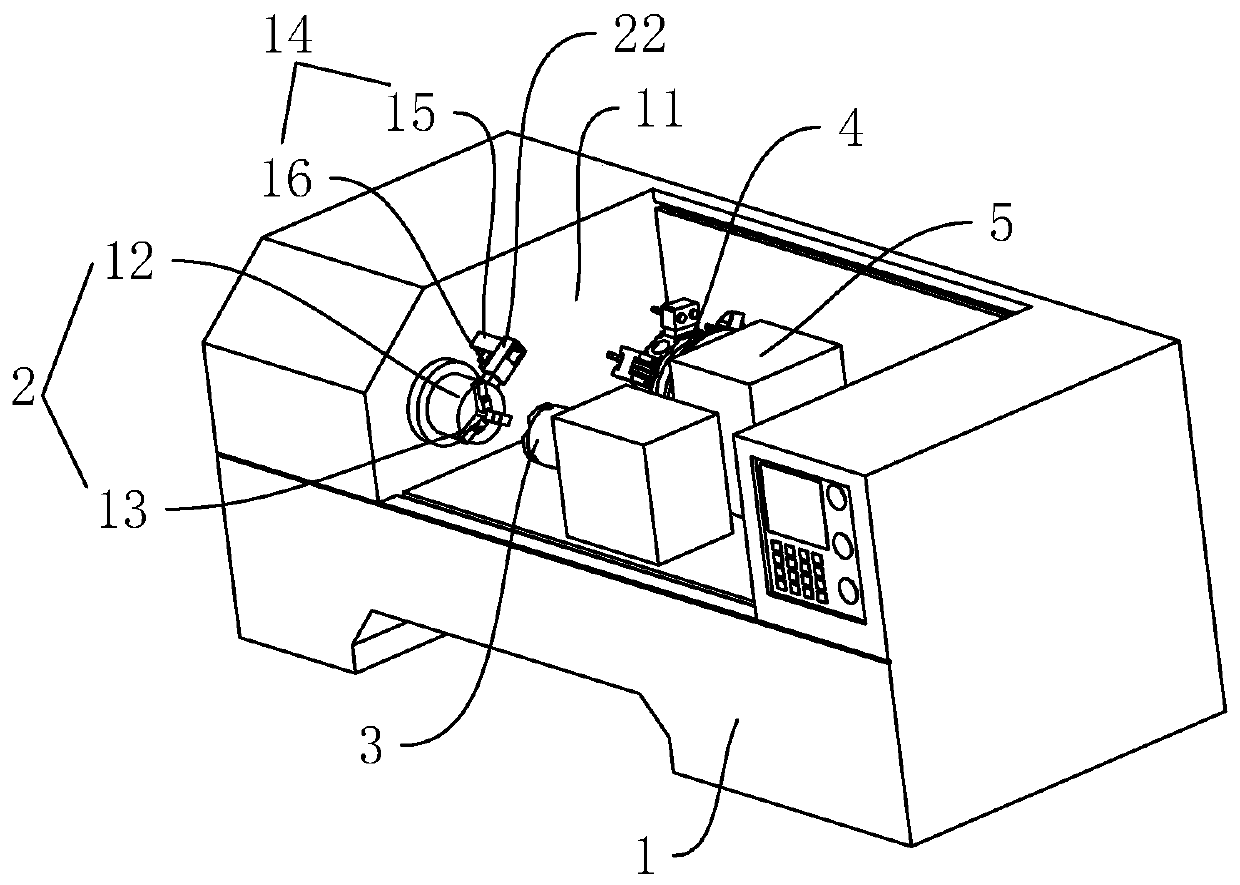

Machine tool and method for performing friction welding by utilizing machine tool

ActiveCN109968037ACircumferential surface is smooth and flatGuaranteed welding effectOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringMachine tool

The invention discloses a method for performing friction welding by utilizing a machine tool, and relates to the field of machine tool equipment. The method aims to solve the problem that the occupiedspace of traditional friction welding is large. According to the technical scheme, the method comprises the following steps that S1, all shafts go back to original points, and two to-be-welded partsare clamped on the main shaft and the auxiliary shaft correspondingly; S2, the main shaft rotates, and meanwhile, the auxiliary shaft is rotated and locked; S3, the auxiliary shaft is moved and positioned, and an auxiliary table drives a pushing block to move to be in contact with the pushing plate; S4, the auxiliary shaft and a tool turret move at the same time and drive the to-be-welded parts tomove to a mutual contact state, and friction heating is achieved; and S5, the rotating speed of the main shaft is reduced to be zero, a first three-jaw chuck loosens the workpiece, and meanwhile, theauxiliary shaft drives the workpiece to return. The method for performing friction welding by utilizing the machine tool has the advantage of less workpiece clamping frequency.

Owner:津上精密机床(浙江)有限公司

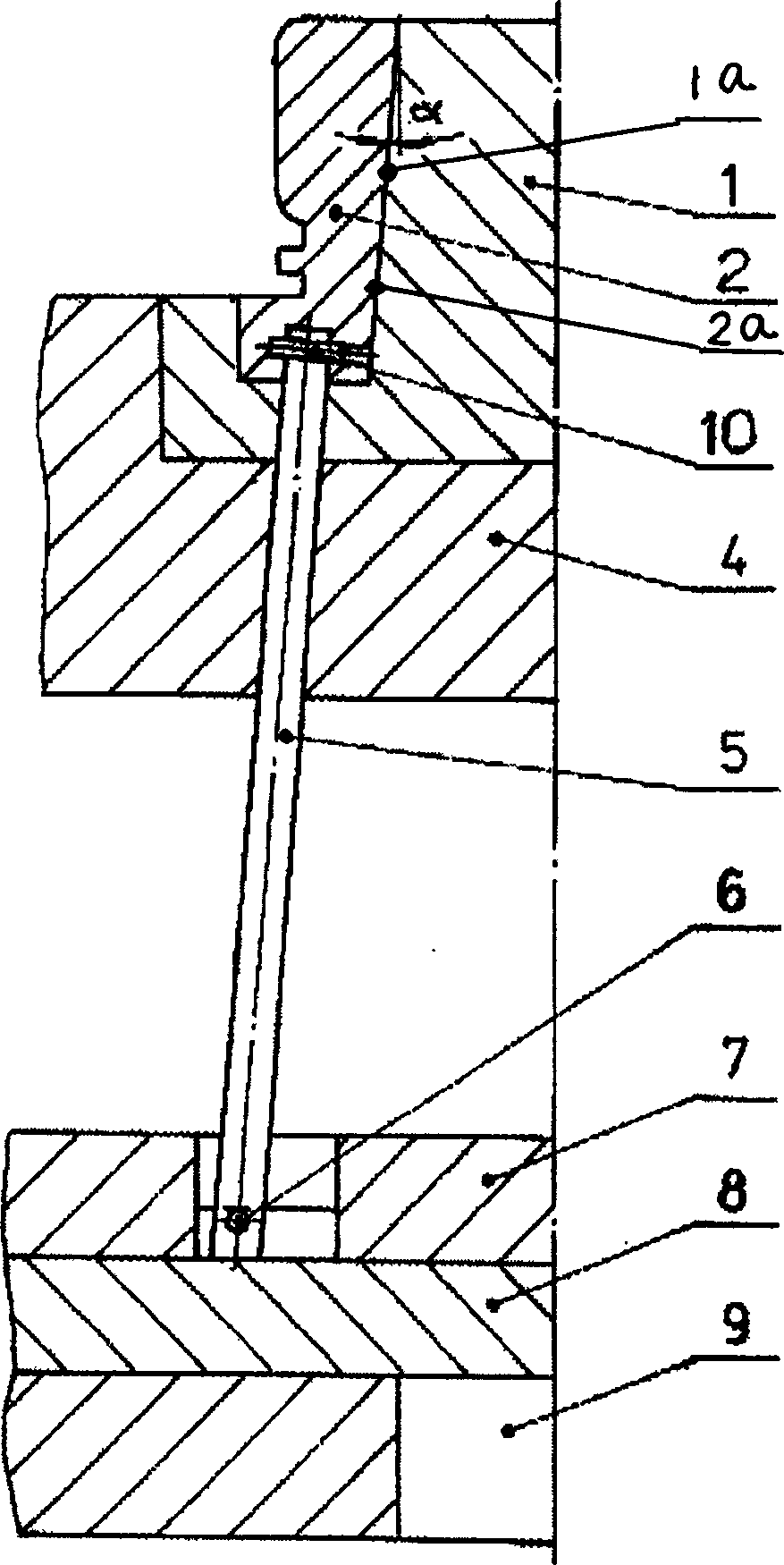

Production device for cable protecting casings with external spiral lines

InactiveCN104494085AWon't fall offUniform wall thicknessTubular articlesSpiral linePetroleum engineering

The invention relates to the machining field, and in particular relates to a production device for cable protecting casings with external spiral lines. The production device for the cable protecting casings with the external spiral lines is mainly formed by combing a perfusion connector and a forming cover die, wherein the perfusion connector is connected with a forming cover die, and the forming cover die comprises an external fixed cover die and an internal fixed cover die. According to the production device for the cable protecting casings with the external spiral lines, an HDPE (high density polyethylene) melting tube blank is extruded from a die, enters a space between the external fixed cover die which rotates and sprays water for cooling and an internal fixed cover die which is communicated with cooling water, and is pulled by a traction machine, so that a protecting casing with an external spiral line is formed, the external spiral line and a tube body are formed at the same time and tightly combined together, the external spiral line is prevented from falling off, an inner wall is formed by the internal fixed cover die, the smooth and flat inner wall is ensured, the inner wall corresponding to the external spiral line is free of dents, and the uniform thickness of the tube body is ensured.

Owner:柳州市桥厦科技发展有限公司

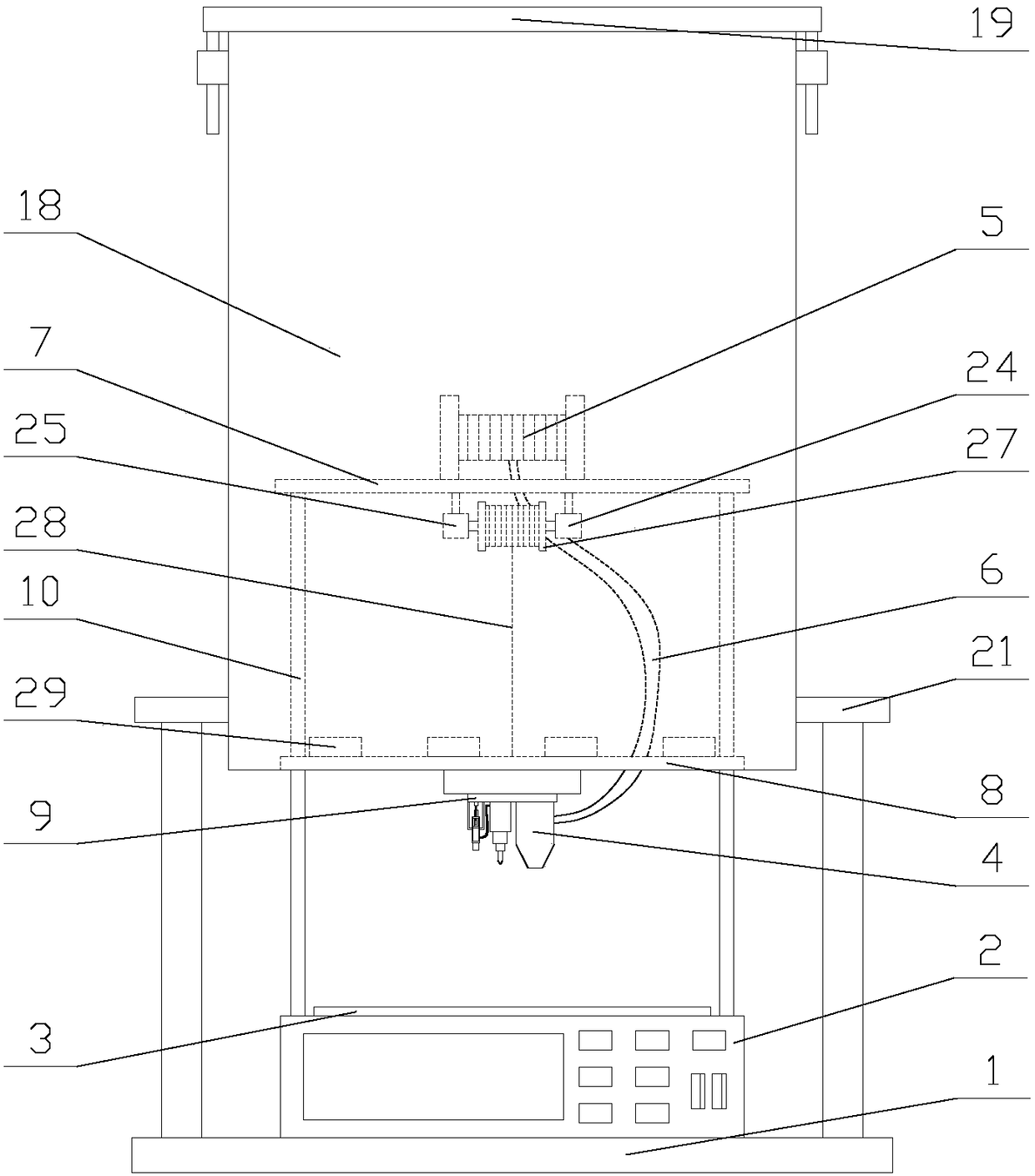

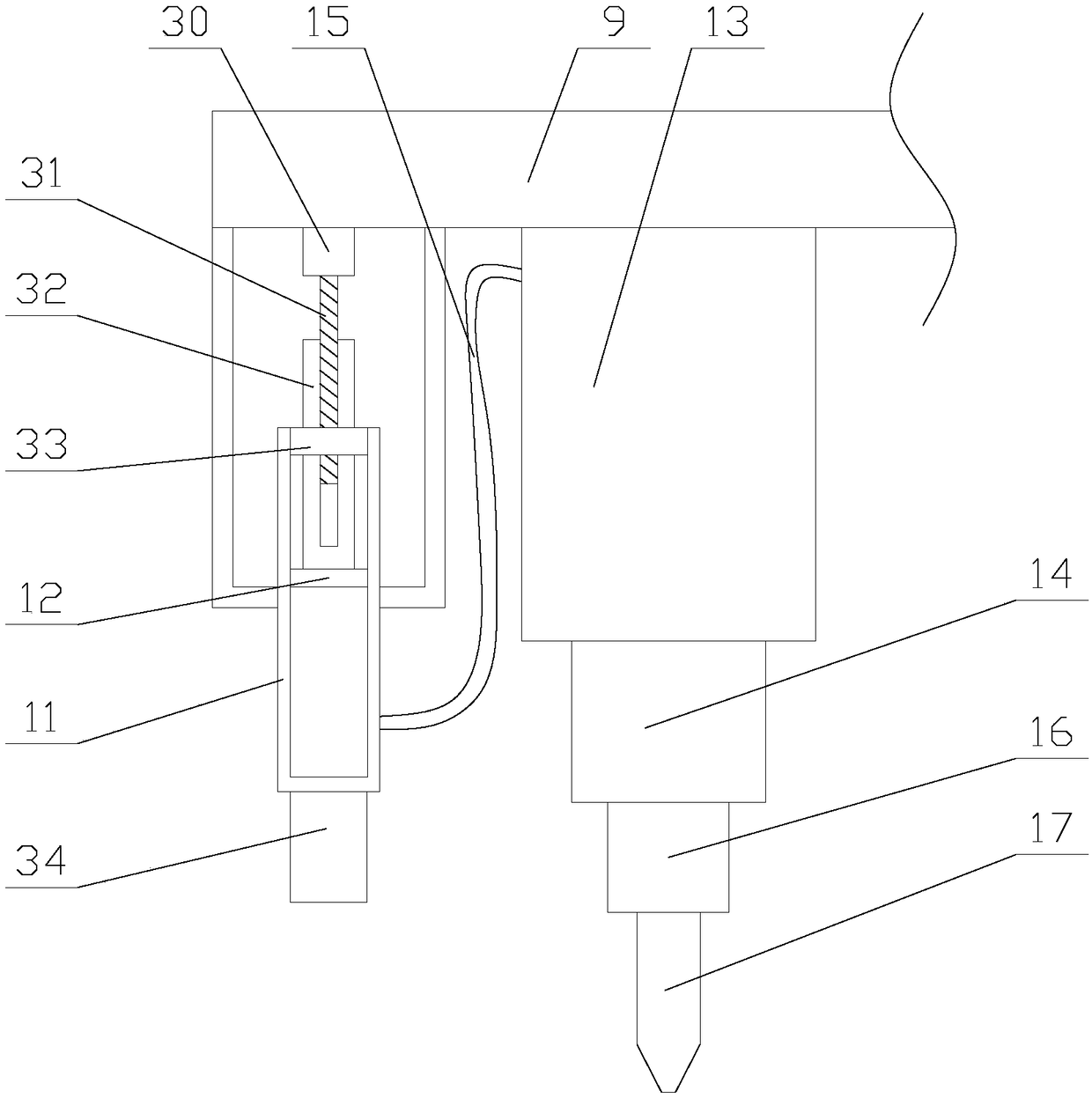

Intelligent 3D printing device with fine processing and protection functions

InactiveCN108262958AHigh running precisionGuaranteed to be smooth and flatAdditive manufacturing apparatusManufacturing data aquisition/processingSputteringProtection mechanism

The invention relates to an intelligent 3D printing device with fine processing and protection functions. The device comprises a protection mechanism, a processing mechanism, a printing table, a sprayhead, an ascending and descending table, a transverse moving table and an ascending and descending mechanism, wherein the processing mechanism comprises a transverse moving assembly, a first oil cylinder, a first piston, a second oil cylinder, a second piston, an oil pipe, a first motor, a milling cutter and two support frames; the protection mechanism comprises a protection ring, a cover plate and two support assemblies; each support assembly comprises a second motor, a side plate and two telescopic assemblies; each telescopic assembly comprises a driving unit, a telescopic frame and two connecting rods. The intelligent 3D printing device with fine processing and production functions has the advantages that projected parts on the spray head single-layer printing surface are cut through the processing mechanism; the smoothness and flatness of the printing surface are ensured; the printing quality is improved; in addition, through the protection mechanism, the protection ring descends;the printing table and the ascending and descending table are shielded; the sputtering of fragments generated during the processing can be prevented; people around the equipment are protected; the practicability of the equipment is improved.

Owner:史彦辉

Bicycle frame welding technology capable of achieving firm welding

ActiveCN113334003AGuaranteed to be smooth and flatGuaranteed StrengthHuman health protectionWelding/cutting auxillary devicesPolishingEngineering

The invention discloses a bicycle frame welding technology capable of achieving firm welding. The welding technology comprises the following steps that A, welding positions are pretreated, specifically, the welding positions of frames are polished through a polishing mechanism; B, primary welding treatment is carried out, specifically, primary welding is carried out through a plasma uniform spot welding technology, so that the capacity of primary fixing between the frames is achieved; and C, first-time post-welding treatment is conducted, specifically, the polishing mechanism is used for conducting first-time polishing treatment on the surfaces obtained after first-time welding. According to the welding technology, the welding positions are firstly polished, so that impurities such as oil stains and the like can be effectively prevented from existing in the welding positions, and the welding positions can be smooth and flat; then primary welding is conducted through the plasma uniform spot welding technology, the two frames can be rapidly fixed, and the strength of the frames cannot be damaged; finally, secondary welding is conducted through the high-frequency welding technology, the overall strength of the frames can be further guaranteed, thus the welding quality of the frames is improved, and the benefits of enterprises are met.

Owner:佛山市顺德区天轴车料有限公司

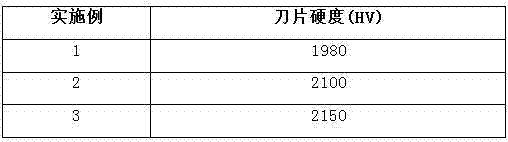

Preparation process of high-strength durable stainless steel slicing knife

InactiveCN107164758AHigh hardnessImprove toughnessFurnace typesMetallic material coating processesWear resistantHardness

The preparation process of a high-strength and durable stainless steel slicing knife of the present invention uses molten stainless steel raw materials to be molded directly, which is quick and easy. Compared with the prior art, the prepared slicing knife not only has the properties of crystalline silica High hardness, but also has the excellent toughness of stainless steel, even if the thickness of the blade is ultra-thin, the hardness is very high, very light and sharp. Due to the silicon dioxide layer on the surface, the wear resistance is excellent, basically no need to sharpen the knife, and the silicon dioxide layer almost isolates the stainless steel material of the blade from contact with the outside world, further eliminating the possibility of rust.

Owner:李燕芹

A rail transit evacuation platform that can resist high wind pressure

ActiveCN111605566BImprove anti-corrosion performanceDurableUnderground chambersRailway componentsButtressArchitectural engineering

The invention discloses the technical field of rail transit facilities, and in particular relates to a rail transit evacuation platform that can resist high wind pressure. The rail transit evacuation platform includes a support pier and a platform plate installed on the support pier. It is a concrete composite material, the platform slab includes a standard block and an adjustment block, and the standard block and the adjustment block are spliced to form a platform slab, and both the standard block and the adjustment block are connected to the pier through a wind pressure resistant bolt assembly The detachable connection, the evacuation platform is made of concrete composite material, which reduces the workload of maintenance, maintenance and replacement in the later operation process, and reduces the maintenance cost. In the technology, the heavy weight of the monolithic platform slab leads to the difficulty of installation. Both the standard block and the adjustment block are detachably connected to the pier through wind-resistant bolt components, which solves the problem that cannot be solved in the prior art. Solve or only rely on increasing the thickness of the platform slab to resist high wind pressure, which will increase the load of the pier and affect the bearing performance.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

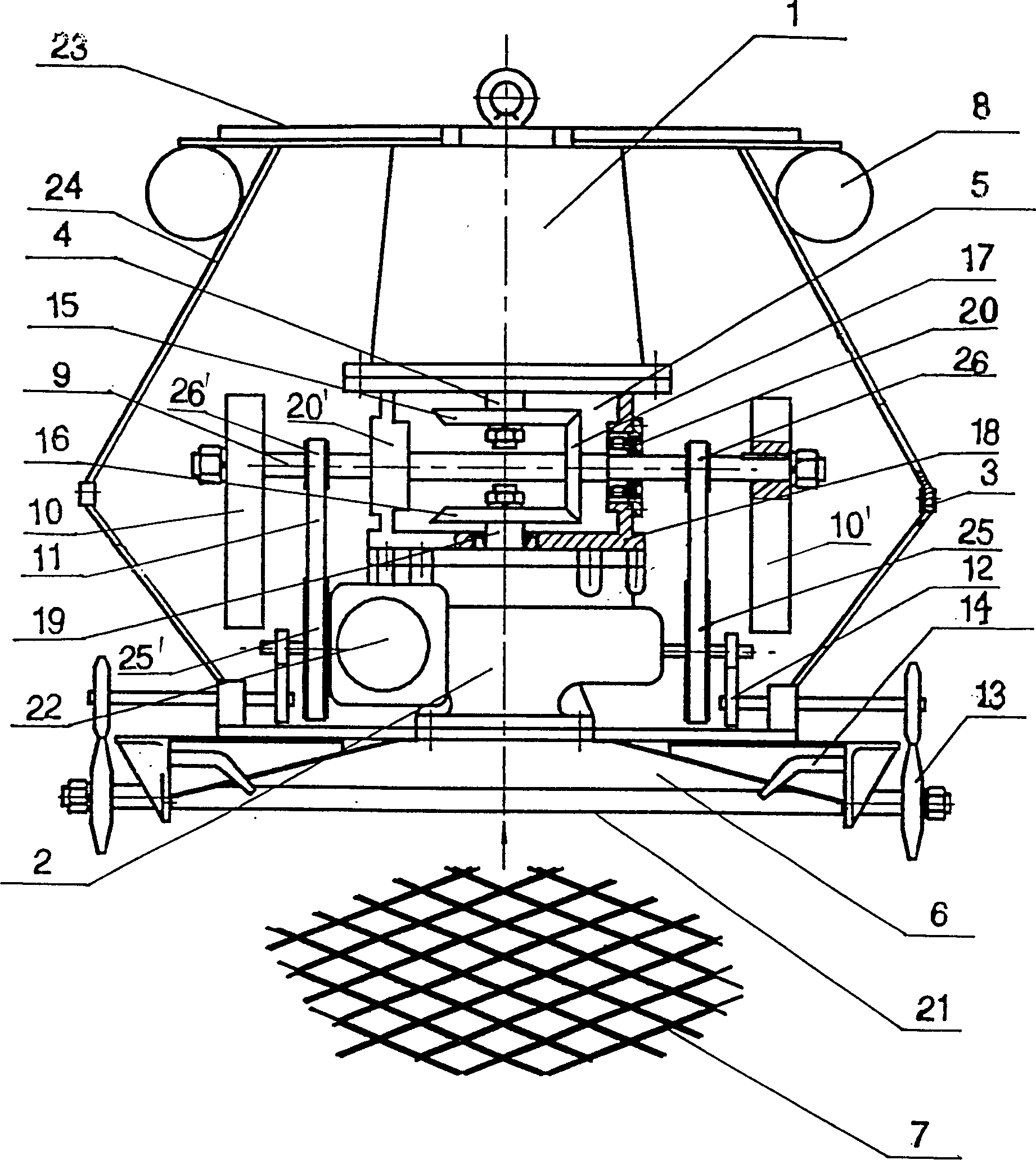

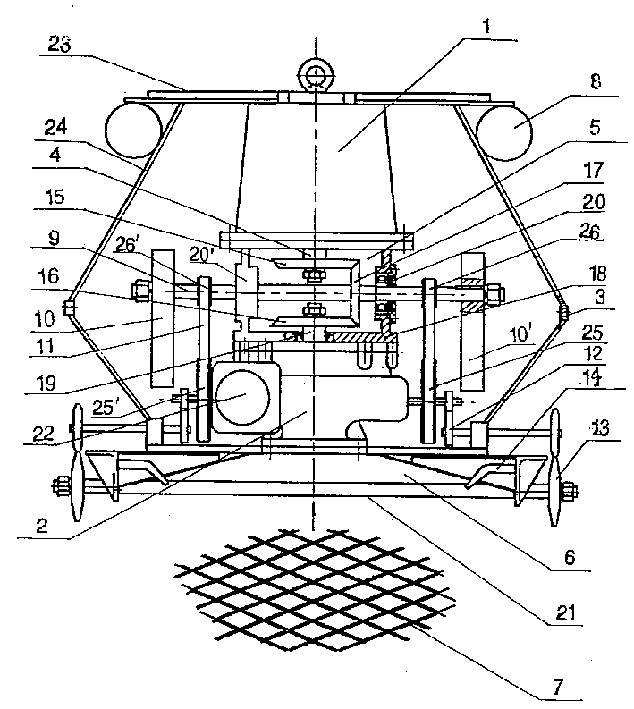

Submerged dredging machine

InactiveCN1175147CImprove ergonomicsIncrease the concentration of the conveying mediumMechanical machines/dredgersControl theoryMud pump

The submersible river-desilting dredging machine is characterized by that its motor and mud pump are placed in a sealed shell body, the output shaft of said motor is connected with the mud pump by means of speed-changing gear box, and a power shaft which is perpendicular to the output shaft of motor is set between the motor and mud pump, the power shaft is matched with speed-changing gear box, and its two ends are equipped with symmetrical eccentric wheels, and the mud pump is placed on the chassis of the shell body, and the outer side of working surface of the chassis is covered with cutting filter screen, and the external end of sealed shell body is equipped with floating body. The invention is applicable to various river dredging engineerings.

Owner:ZHEJIANG JIALI TECH

Spray-coating method of aluminum alloy door and window

InactiveCN110813681AGuaranteed to be smooth and flatGood wear resistance and corrosion resistanceSurface reaction electrolytic coatingPretreated surfacesAnodizingAnodic oxidation

The invention belongs to the technical field of aluminum alloy door and window spray-coating, and particularly discloses a spray-coating method of an aluminum alloy door and window. The method includes the steps of preprocessing, degreasing, deoiling, neutralizing, electrochemical polishing, anodizing, spray-coating and curing. The completeness of the surface of a non-spray-coated aluminum alloy profile can be improved, the smoothness of the surface of a anodized aluminum profile is improved, and therefore the airtightness of a coating is improved, the decoration performance and corrosion resistance of the aluminum alloy profile are enhanced, the spray-coating quality is improved, and the machining quality of the aluminum alloy profile is improved.

Owner:苏州嘉睦碧晟建筑装饰有限公司

Photo album inner core sheet double-faced gluing treatment system and treatment method

InactiveCN104941865AImprove efficiencyAvoid spendingPretreated surfacesCoatingsSocial benefitsBiochemical engineering

The invention discloses a photo album inner core sheet double-faced gluing treatment system and a treatment method. The system comprises photo album inner core sheet double-faced gluing equipment and photo album inner core sheet double-faced gluing drying equipment that are connected; the photo album inner core sheet double-faced gluing equipment is connected with a paper feeding machine; and the photo album inner core sheet double-faced gluing drying equipment is sequentially connected with a finishing machine and a forming machine through transmission equipment. The method comprises the following steps that a photo album inner core sheet is placed at the paper feeding machine, coated by the photo album inner core sheet double-faced gluing equipment, dried on a mesh belt, subjected to photo applying on the finishing machine, and finished and formed on the forming machine. According to the system and method, the coating is performed on the double faces simultaneously, so that coating and drying speeds, and the efficiency are high; the inner core sheet is level and deforms little; the defects existing in a silicon paper technology used that a working field is polluted, the cost is high, waste is caused due to unrecyclable silicon paper, the working efficiency is low due to labor uncovering and applying by hand, and the fluctuation of the product quality by manual operation is large are overcome; and the system and the method have significant economic and social benefits.

Owner:济南今日摄影器材有限公司

Machine tool with friction welding function

PendingCN109794770AGuaranteed to be smooth and flatGuaranteed welding effectOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingEngineering

The invention discloses a machine tool with a friction welding function, and relates to the field of machine tools. The problem that accuracy is decreased due to the fact that number of times of clamping is too many in traditional machine tool machining is solved. According to the key points of the technical scheme, the machine tool comprises that the machine tool with the friction welding function comprises a machine tool body, and further comprises a first clamping device, a second clamping device and an auxiliary device, wherein the first clamping device, the second clamping device and theauxiliary device are arranged on the machine tool body, and the auxiliary device comprises an auxiliary table slidably arranged on the machine tool body, a cutting assembly arranged on the auxiliary table and a pressure compensating assembly arranged on the auxiliary table. The machine tool with the friction welding function has the advantages that the number of times of clamping of the workpieceis reduced, and machining accuracy is improved.

Owner:津上精密机床(浙江)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com