Multi-functional automatic wall painting machine

A powder wall machine, multi-functional technology, applied in the direction of construction, building structure, etc., can solve the problems of rising wages, rising wages of technicians, and difficulty in recruiting workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

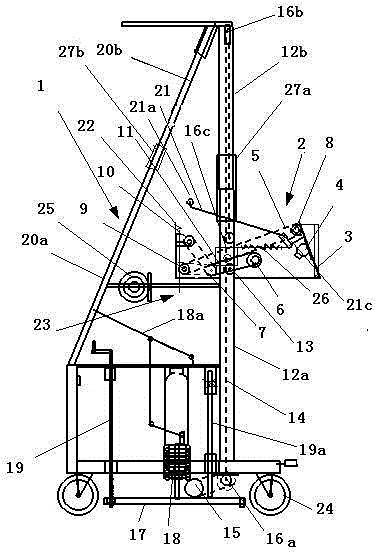

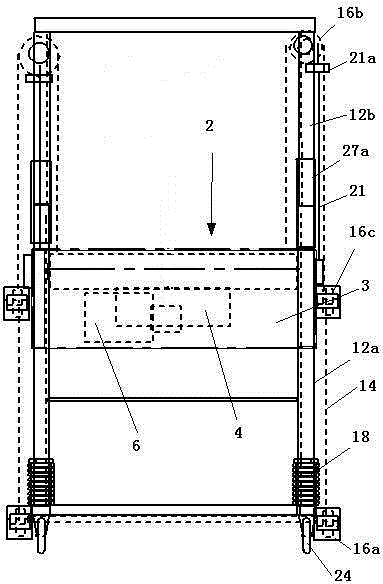

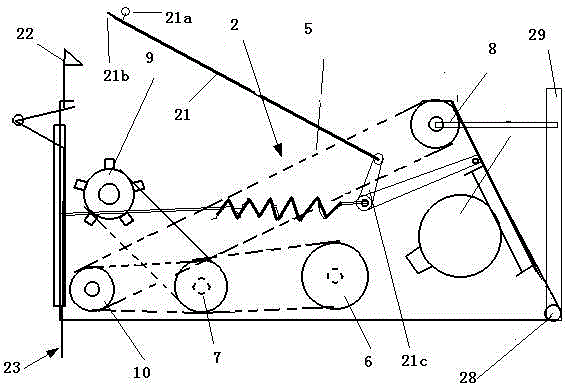

[0011] A multifunctional automatic powder wall machine, figure 1 It is a schematic view of the front structure of the present invention, which includes a vertical frame 1, and a powder wall host 2 is arranged on the vertical frame on the side of the vertical frame 1 close to the wall. The powder wall host 2 is connected with a lifting drive device. A cement mortar hopper 11 is provided, a powder wall panel 3 is provided on one side of the powder wall host 2 close to the wall, baffles 29 are provided on both sides of the powder wall board, and a conveyor belt 5 whose end is located at the top of the powder wall board is arranged in the cement mortar hopper 11, The powder wall board 3 inboards are provided with a vibrator 4, and the powder wall main frame 2 elevating drive devices include vertical frame bottoms that are provided with lifting motors 15, sprockets arranged on the vertical frame, and the sprockets include lower sprockets 16a, upper sprockets 16a, Intermediate sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com