Submerged dredging machine

A dredger and motor technology, which is applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of large investment, high labor intensity of operators, inconvenient movement, etc. Wide range, good dredging effect and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

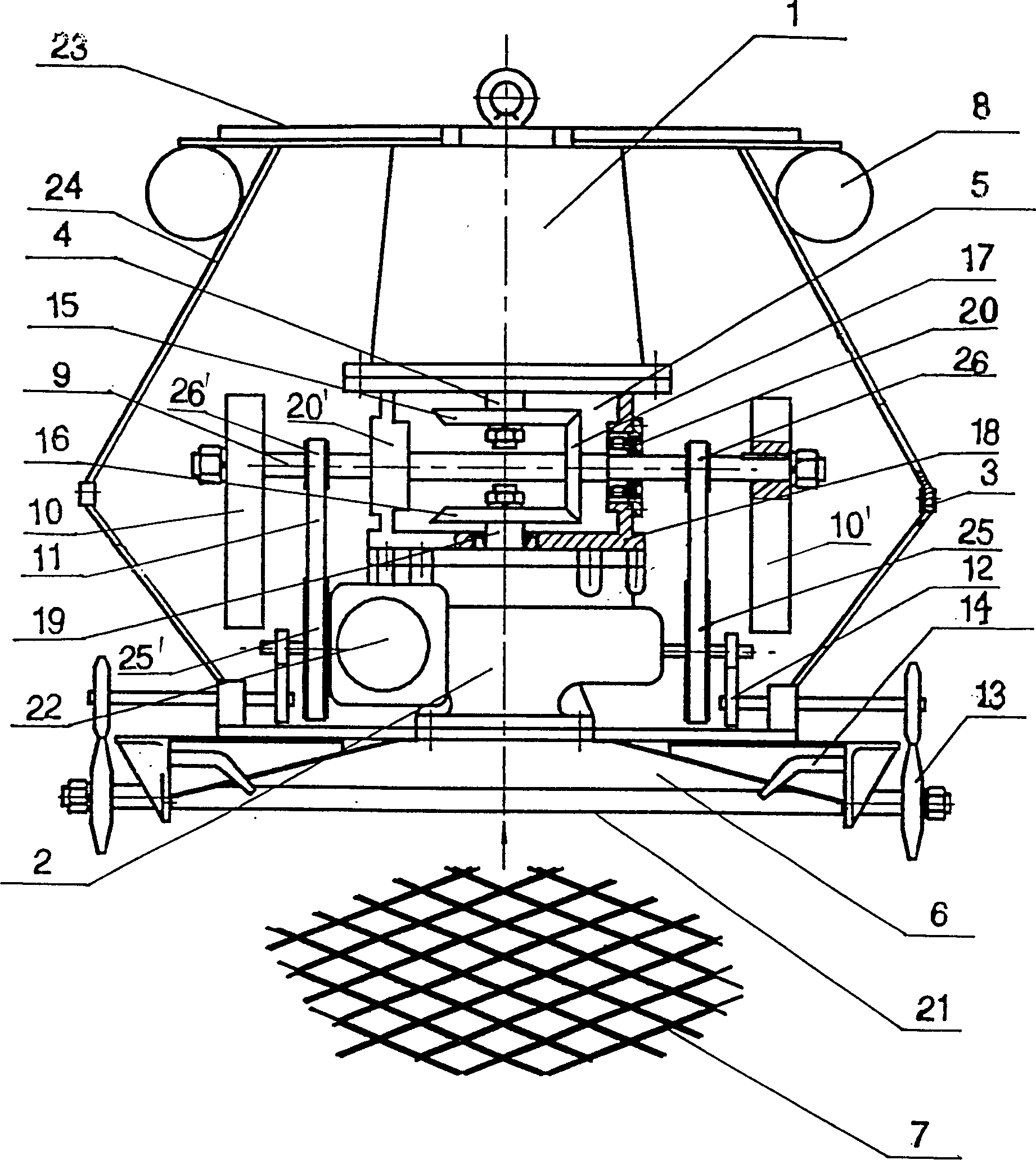

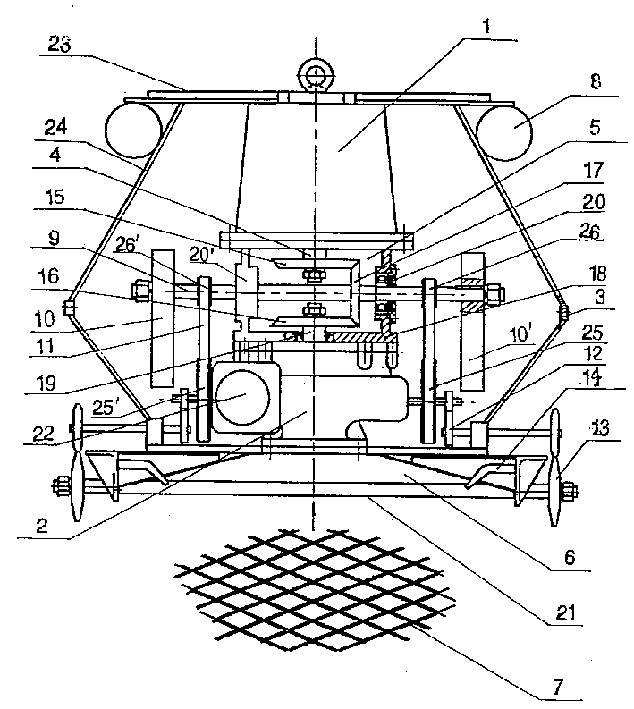

[0013] Such as figure 1 The shown submersible dredger includes an electric motor 1 , a mud pump 2 and a sealed housing 3 . The sealed housing 3 is tightly formed by the housing cover plate 23 , the housing wall 24 and the housing chassis 6 to provide a sealed space preventing water from entering. The electric motor 1 is fixed on the inner side of the housing cover plate 23, and its output shaft 4 passes through a speed change gearbox 5, and then outputs the power to the impeller shaft 19 of the mud pump 2 and the power shaft 9 perpendicular to the impeller shaft, and passes through The change of the gear ratio between the gears in the transmission gearbox 5 controls the rotating speed of the impeller shaft 19 and the power shaft 9 . The mud pump 2 is fixed on the housing chassis 6 , and the working surface 21 of the housing chassis is connected to the mud suction port of the mud pump 2 . The outside of the chassis working surface 21 is covered with a cutting screen 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com