Production device for cable protecting casings with external spiral lines

A production device and sheath tube technology, applied in the field of mechanical processing, can solve problems such as dents on the inner wall, inconsistent wall thickness of the spiral cable protective sleeve, etc., and achieve the effect of ensuring the wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

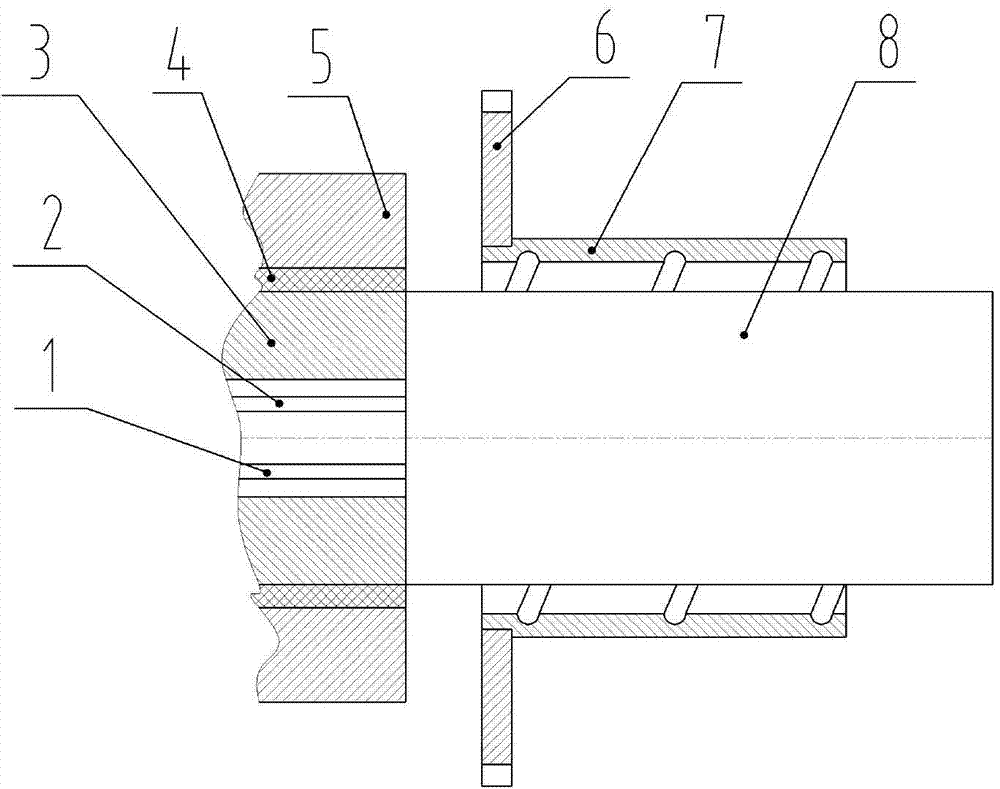

[0014] figure 1 It shows a structural diagram of a production device for an outer helical cable sheath tube provided by the present invention, a production device for an outer helical cable sheath tube, and the production device for an outer helical cable sheath tube It is mainly composed of a pouring joint and a forming sleeve, the pouring joint is connected to the mouth of the forming sleeve, the forming sleeve includes an outer fixed sleeve 7 and an inner fixed sleeve 8, and the internal fixed sleeve 8 is Cylinder, the outer fixed sleeve is 7 cylinders, the inner wall of the outer fixed sleeve 7 is provided with a spiral structure, the inner diameter of the outer fixed sleeve 7 is greater than the outer diameter of the inner fixed sleeve 8, the The inner fixed sleeve 8 is placed in the outer fixed sleeve 7, and the centers of the two cylinders are placed on the center line, so that there is a molding cavity between the inner fixed sleeve 8 and the outer fixed sleeve 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com