Tooth-inlaid special high-speed rubber tapping tool with two sections of edges and design method

A cutting tool design and rubber tapping technology, which is applied in application, agriculture, forestry, etc., can solve the problems of not smooth cutting surface, low coaxiality, and difficult processing, so as to improve the quality and efficiency of rubber tapping, improve the removal efficiency, and avoid Difficult to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

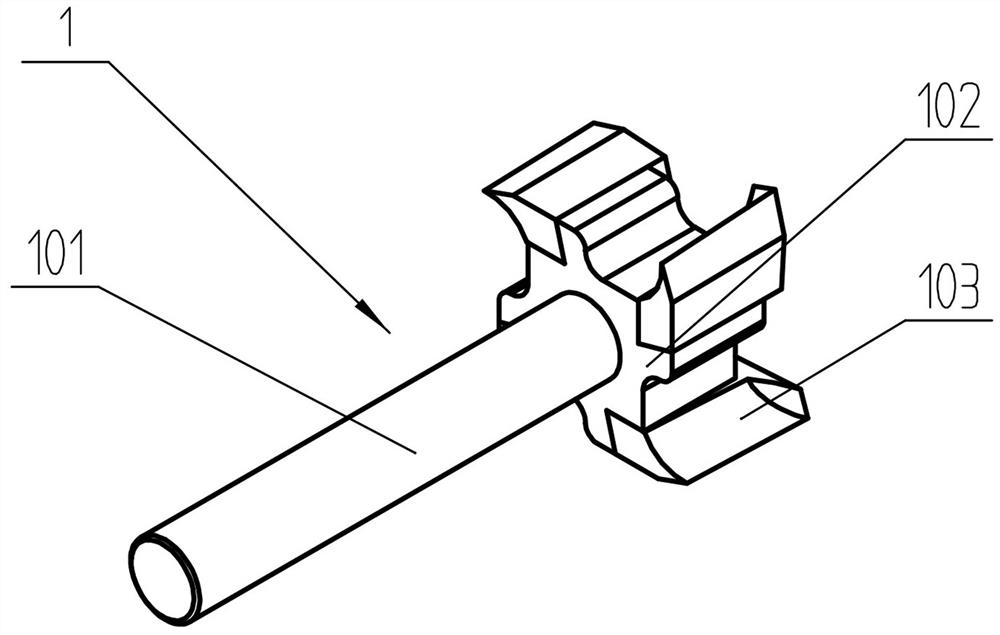

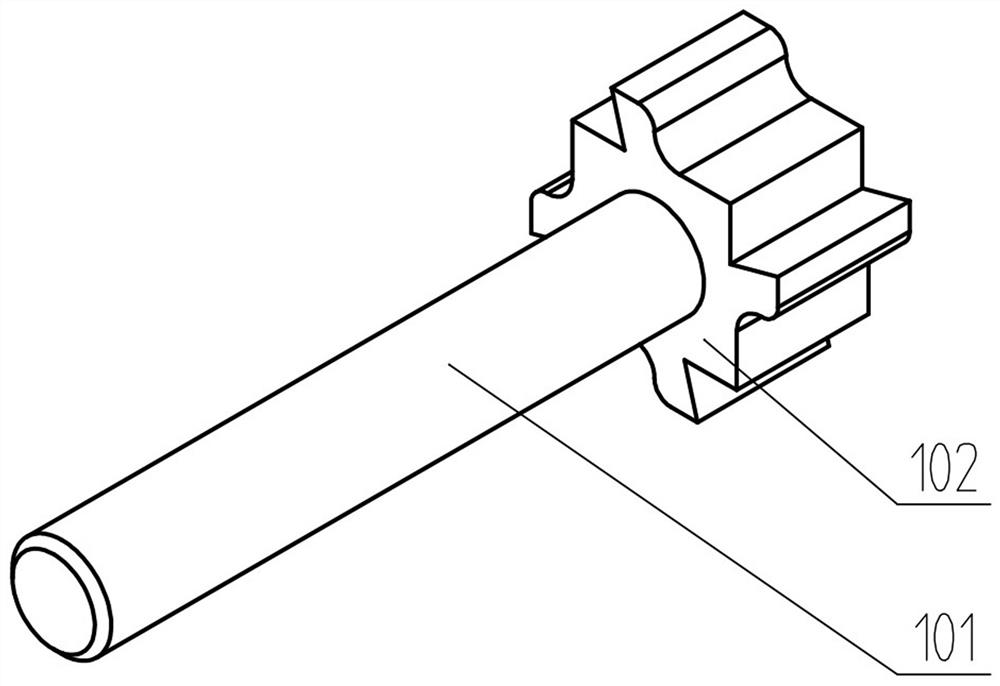

[0047] Specific embodiment 1 (two-stage blade insert type special high-speed rubber tapping tool 1)

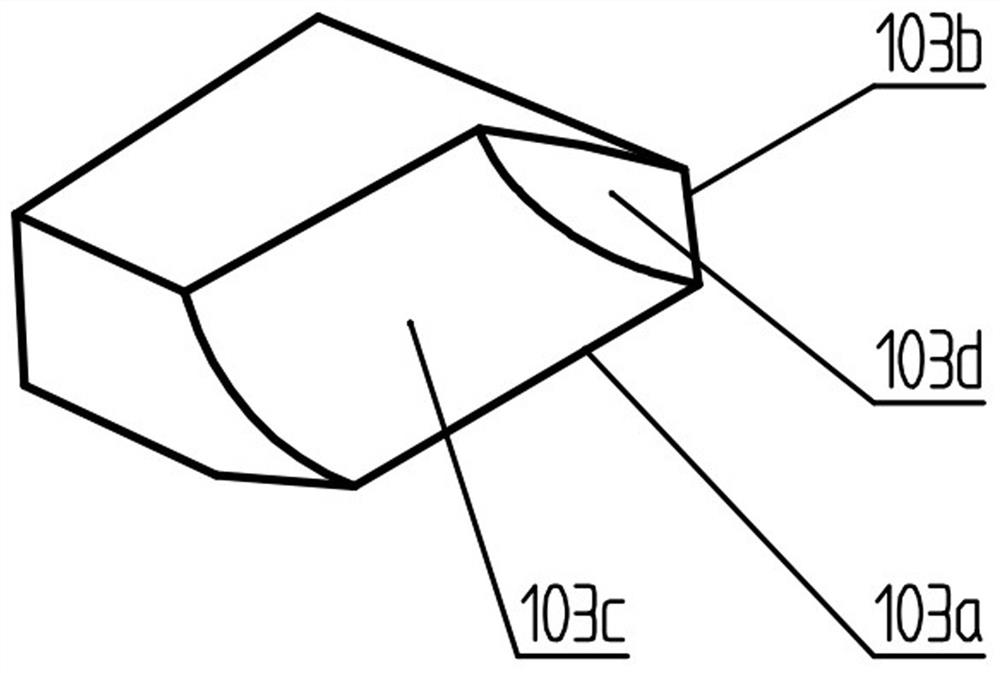

[0048] The calculation process of the tapping removal efficiency is established, and the ratio of the cutting amount of the first cutting edge 103a and the second cutting edge 103b is determined, which is used to guide the design of the relevant parameters of the first cutting edge 103a and the second cutting edge 103b.

[0049] The overall removal efficiency of the special high-speed rubber tapping tool 1 for the two-stage blade insert type is determined by the formula (1):

[0050]

[0051] In formula (1), P is the overall removal efficiency of the special high-speed rubber tapping tool with two-stage inserts (mm) 3 / min)α p is the depth of cut (mm), α e is the cutting width (mm), α f is the feed rate (mm / z), V f is the cutting speed (z / min), h is the actual depth of cut (mm), α 2 is the second relief angle, d is the actual cutting width (mm), and λ is the first edge...

specific Embodiment 2

[0075] Specific embodiment 2 (two-stage integral type special high-speed rubber tapping tool 2)

[0076] like Image 6 As shown, the geometric features of the two-section integral type high-speed rubber tapping tool 2 are the same as those of the two-section blade insert type special high-speed rubber tapping tool 1. The rubber tapping blade is driven to rotate by the motor, and the two cutting edges are in contact with the rubber skin and flow out from the rake face. . Using the integral design, in the manufacturing process, the blank is blanked, and the turning and grinding processes are directly formed, which avoids the cumbersome inlaying process; the material casting or powder metallurgy process makes there is no gap between the blade and the cutter head. It ensures the overall strength and stability of the tool, and avoids wood chips flowing into the gap to contaminate or affect the assembly process.

[0077] The material of the rubber tapping tool is high-speed steel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com