Minitype diamond-tooth milling cutter and processing technology thereof

A processing technology and milling cutter technology, applied in the field of diamond-tooth milling cutter and its processing technology, can solve the problems that the milling cutter is not suitable for processing multi-layer printed circuit boards, and is not suitable for processing milling cutters with extremely small outer diameters, etc. The effect of good quality, guaranteed milling strength and high surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

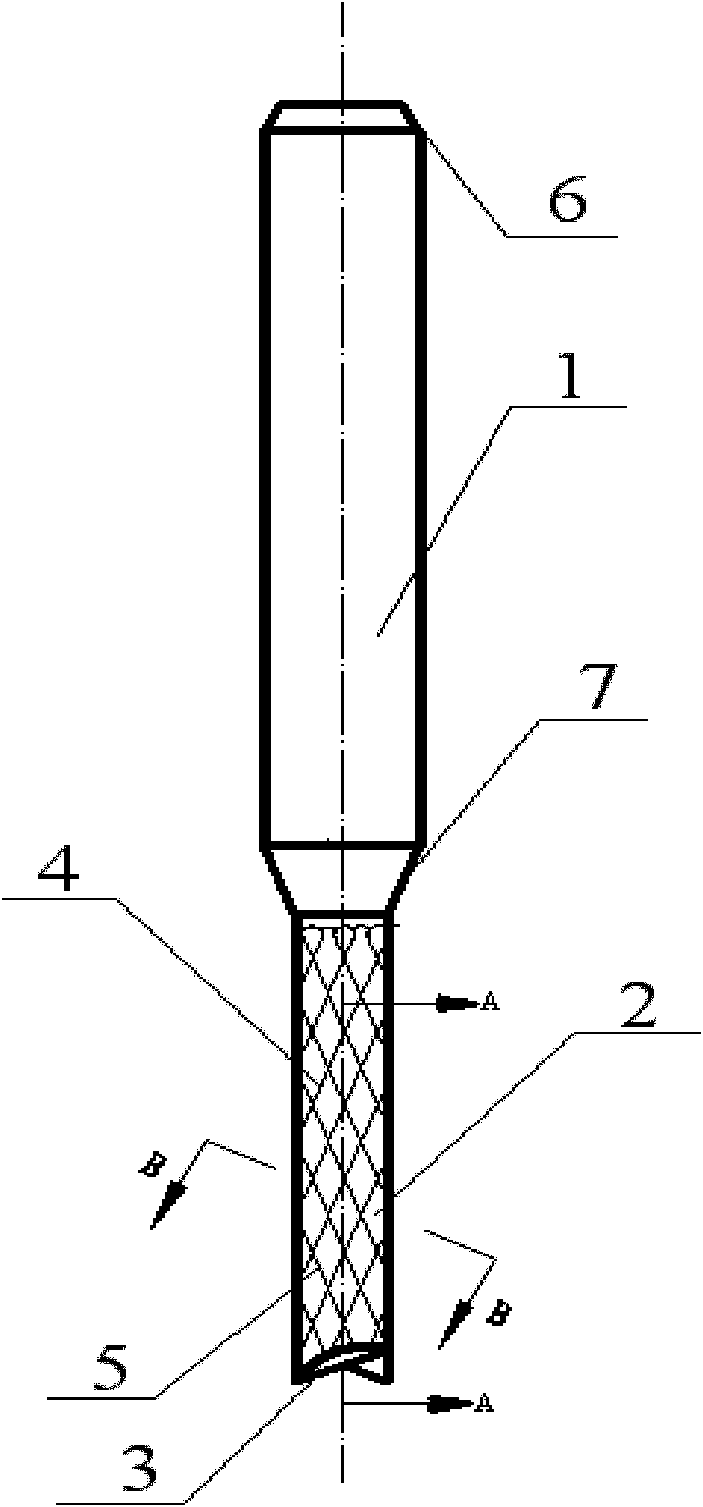

[0032] The invention provides a kind of processing technique of processing miniature rhomboid milling cutter, comprises the following steps:

[0033] (1) Grinding of the shank of the milling cutter: the bar of the selected material is roughly ground to After semi-finishing Finally, through fine grinding, the outer diameter of the end of the rod is ground to and polished smooth;

[0034] (2) Determine the length and end chamfer of the milling cutter head;

[0035] (3) Rough grinding of the milling cutter head: grind the outer diameter of the milling cutter head at the determined position to

[0036] (4) Semi-finishing of the spiral groove: cutting the spiral groove of the milling cutter head to Through the semi-finishing step, the consistency of the blade size can be accurately guaranteed, laying the foundation for the accuracy of the blade size after processing in the subsequent process;

[0037] (5) Grinding of the spiral groove: According to the designed angle, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com