Exhaust type acid and flame resistant lead acid storage battery used for electric road vehicles

A technology for lead-acid batteries and road vehicles, applied in the field of deep cycle, high specific energy, can solve the problems of poor high-rate discharge performance, complicated manufacturing process, lead poisoning of workers, etc., and achieve excellent sealing performance, convenient and fast processing, The effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

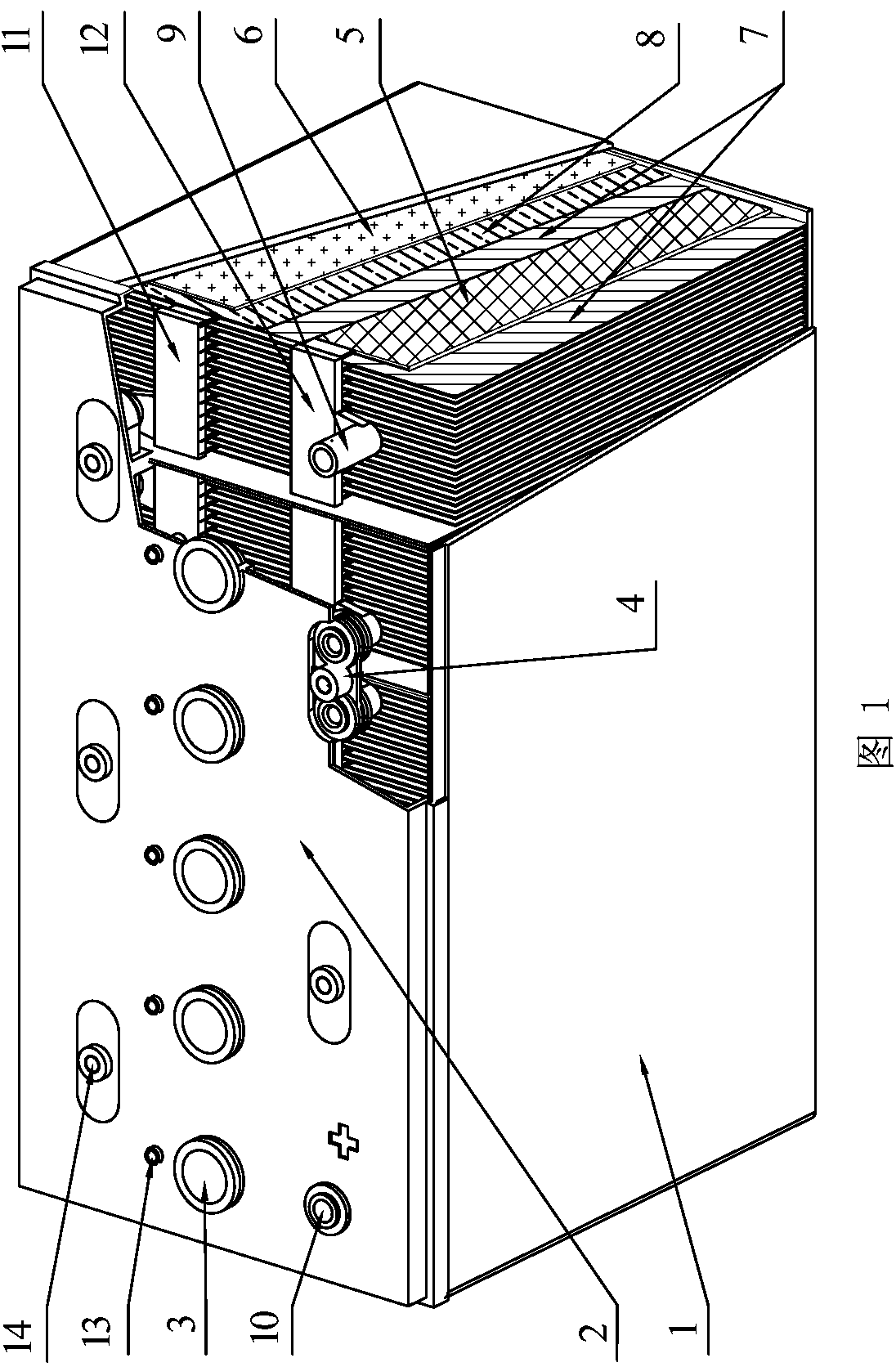

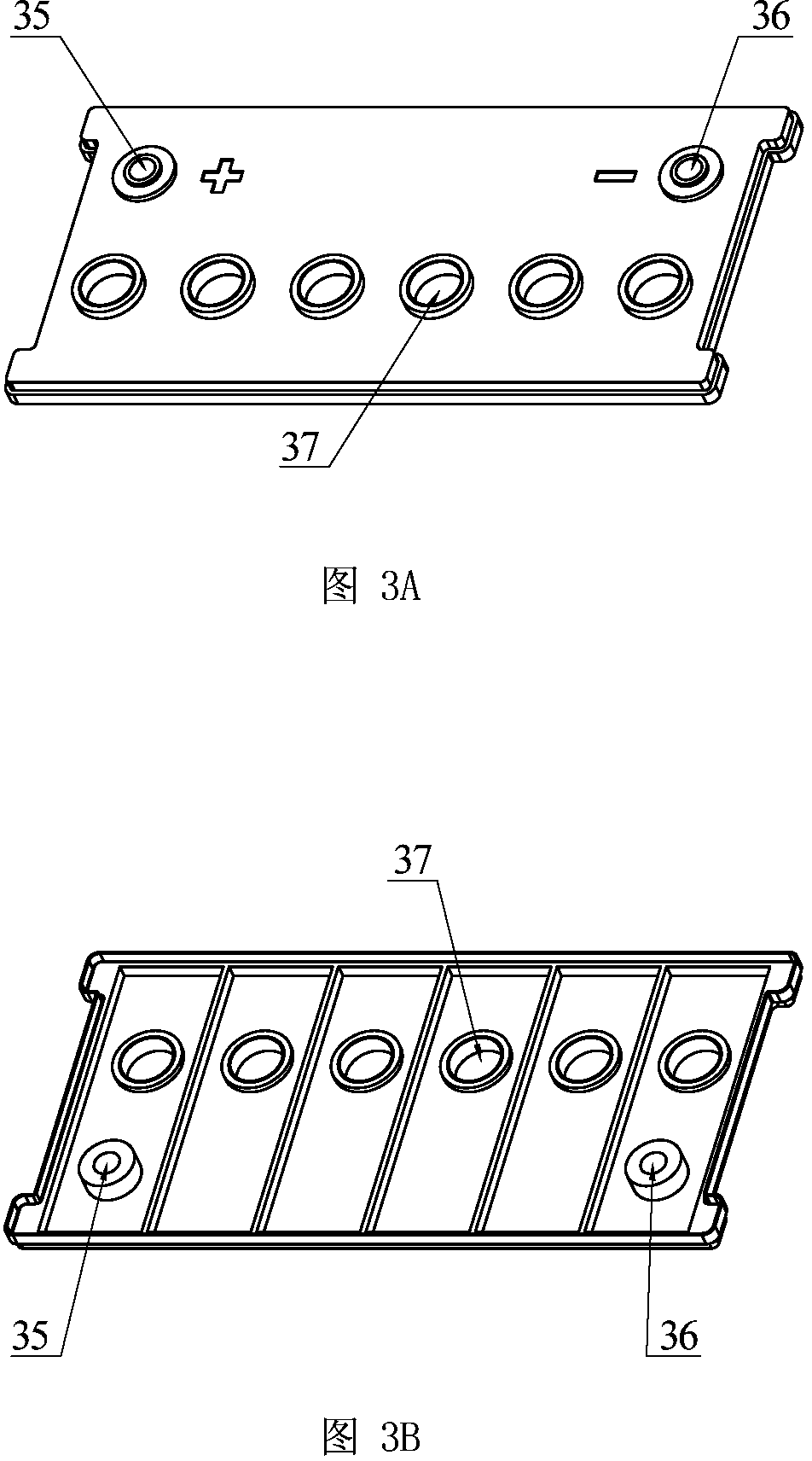

[0040] Embodiment 1 of the present invention takes a 12V100Ah storage battery as an example, and its structure is as follows figure 1 As shown, the maximum design dimensions of the battery are 336mm in length, 172mm in width, and 223mm in height. This vented acid-proof explosion-proof lead-acid battery is mainly composed of battery tank 1, battery cover 2, acid-proof explosion-proof plug 3, metal connection lead sleeve 4, voltage monitoring screw post 14, temperature sensor jack 13, positive plate 5. It consists of negative plate 6, positive separator 7, negative separator 8, negative pole 9, positive pole 10, positive bus 11, negative bus 12 and sulfuric acid colloidal electrolyte.

[0041] The design height of the battery tank is 209mm, which is divided into 6 cells. The wall thickness between the cells of the battery tank is 1.2mm. The thickness of the outer wall and bottom of the battery tank is 3mm. The bottom of the battery tank is designed as a flat bottom. The degree...

Embodiment 2

[0056] Embodiment 2 of the present invention takes a 2V150Ah storage battery as an example, and its structure is as follows Figure 10 As shown, the maximum design dimensions of the battery are 62mm in length, 172mm in width, and 274mm in height. This exhaust-type acid-proof explosion-proof lead-acid battery is mainly composed of a battery tank 101, a battery cover 102, an acid-proof explosion-proof plug 103, a temperature sensor jack 104, a positive plate 105, a negative plate 106, a positive separator 107, and a negative plate. Separator 108, positive pole 109, negative pole 110, positive bus 111, negative bus 112 and sulfuric acid colloidal electrolyte.

[0057] The design height of the battery tank is 260mm, the width is 172mm, and the length is 62mm. The thickness of the outer wall and bottom of the battery tank is 3mm. The bottom of the battery tank is designed as a flat bottom, and the demoulding slope is less than 0.3%.

[0058] The design height of the battery cover ...

Embodiment 312V10

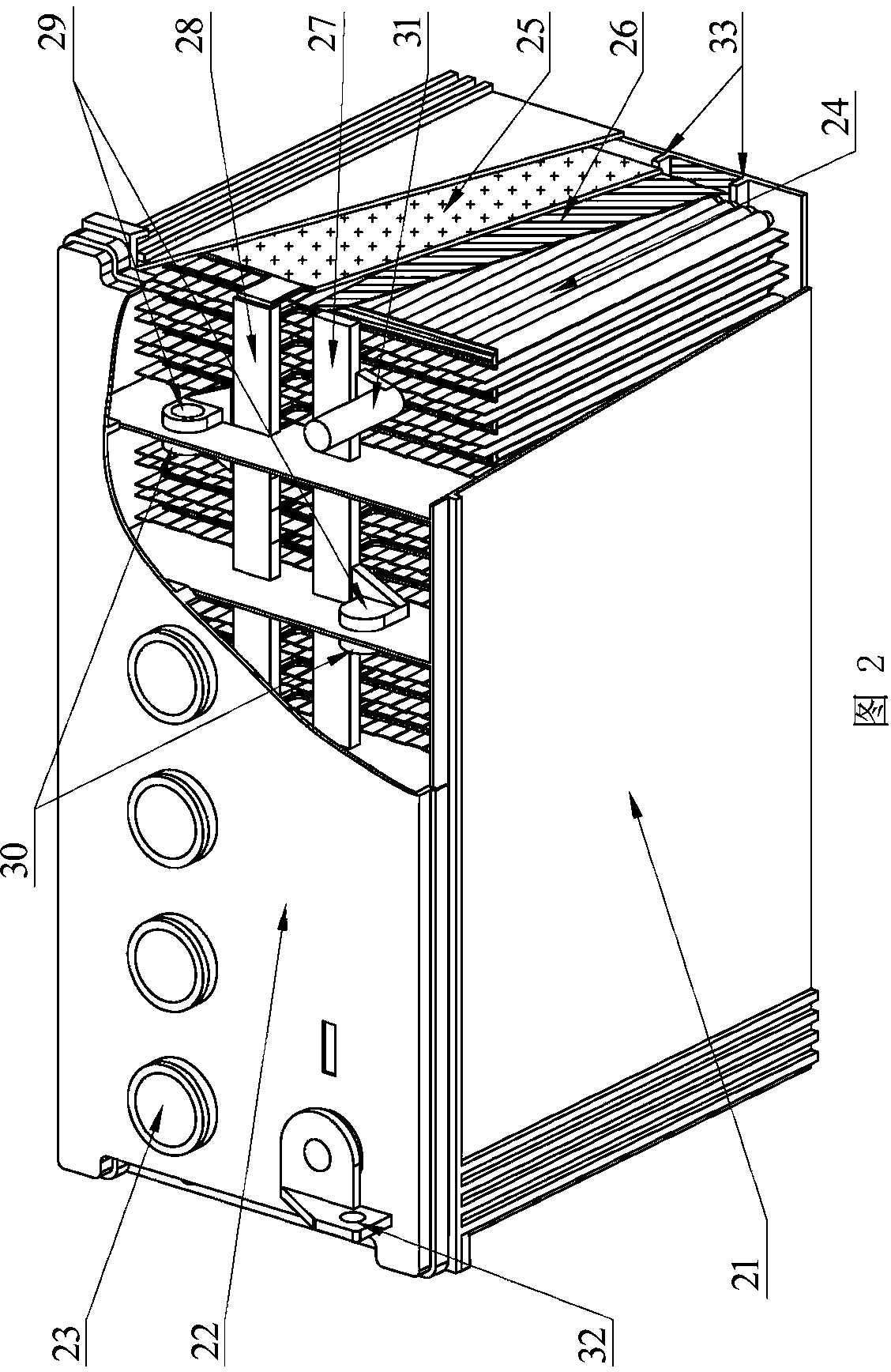

[0074] Embodiment 3 of the present invention takes 12V100Ah storage battery as an example of another type of storage battery, but not limited to 12V storage battery, its structure is as follows Figure 11 As shown, the maximum design dimensions of the battery are 336mm in length, 172mm in width, and 238mm in height. This exhaust-type acid-proof explosion-proof lead-acid battery is mainly composed of a battery tank 121, a battery cover 122, an acid-proof explosion-proof plug 123, a positive plate 125, a negative plate 126, a positive separator 127, a negative separator 128, and a negative pole 129. , positive pole 130, positive bus bar 132, negative bus bar 131, right bias pole 133, left bias pole 134 and sulfuric acid colloidal electrolyte.

[0075] The design height of the battery tank is 224mm, which is divided into 6 cells. The wall thickness between the cells of the battery tank is 1.2mm. The thickness of the outer wall and bottom of the battery tank is 3mm. The bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com