Preparation process of high-strength durable stainless steel slicing knife

A preparation process and a technology for slicing knives, which are used in manufacturing tools, metal material coating processes, heat treatment equipment, etc., can solve the problems of slicing knives that cannot be sharp, low hardness, dullness, etc. The effect of excellent grinding performance and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation process of a high-strength durable stainless slicing knife of the present embodiment comprises the following steps:

[0027] (1) Melt the stainless steel material into a raw material liquid, and pour the liquid into the blade mold for molding;

[0028] (2) Heat the formed blade to 780°C and keep it warm for 4 hours;

[0029] (3) Put the heat-treated blade in step (2) into quenching oil to cool;

[0030] (4) Place the nano-scale crystalline silica powder in a high-temperature furnace and heat it to 1600°C;

[0031] (5) Evenly spray high-temperature silicon dioxide powder onto the outer surface of the blade, and immediately cool it with liquid nitrogen for 1 second;

[0032] (6) Place the blade coated with silicon dioxide on the outer surface in the mold and heat it to 1300°C, and keep it warm for 1.2 hours;

[0033] (7) Cool the blade obtained in step (6) to 700°C naturally, and then send it into a closed cooling room and use liquid nitrogen spray to coo...

Embodiment 2

[0036] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this example,

[0037] Step (2) heating to 830°C and keeping it warm for 5 hours;

[0038] Step (4) heating to 1700°C;

[0039] Step (5) cooling with liquid nitrogen for 2 seconds;

[0040] Step (6) heating to 1400°C and keeping it warm for 1.5 hours;

[0041] Step (7) Cool to 800°C and spray with liquid nitrogen for 30 seconds.

Embodiment 3

[0043] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this example,

[0044] Step (2) heating to 800°C, heat preservation treatment for 4.5 hours;

[0045] Step (4) heating to 1650°C;

[0046] Step (5) cooling with liquid nitrogen for 1.5 seconds;

[0047] Step (6) heating to 1350°C, and heat preservation treatment for 1.3 hours;

[0048] Step (7) Cool to 750°C with liquid nitrogen spray cooling for 25 seconds.

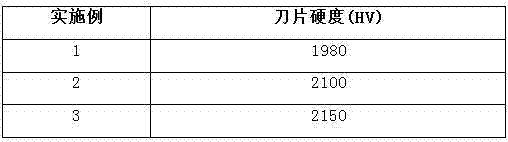

[0049] The blade hardness test table that embodiment 1 to embodiment 3 make

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com