Chrysotile nanofiber and resin composite transparent film, and preparation method and application thereof

A kind of fiber serpentine and nanofiber technology, which is applied in the field of fiber serpentine nanofiber and resin composite film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

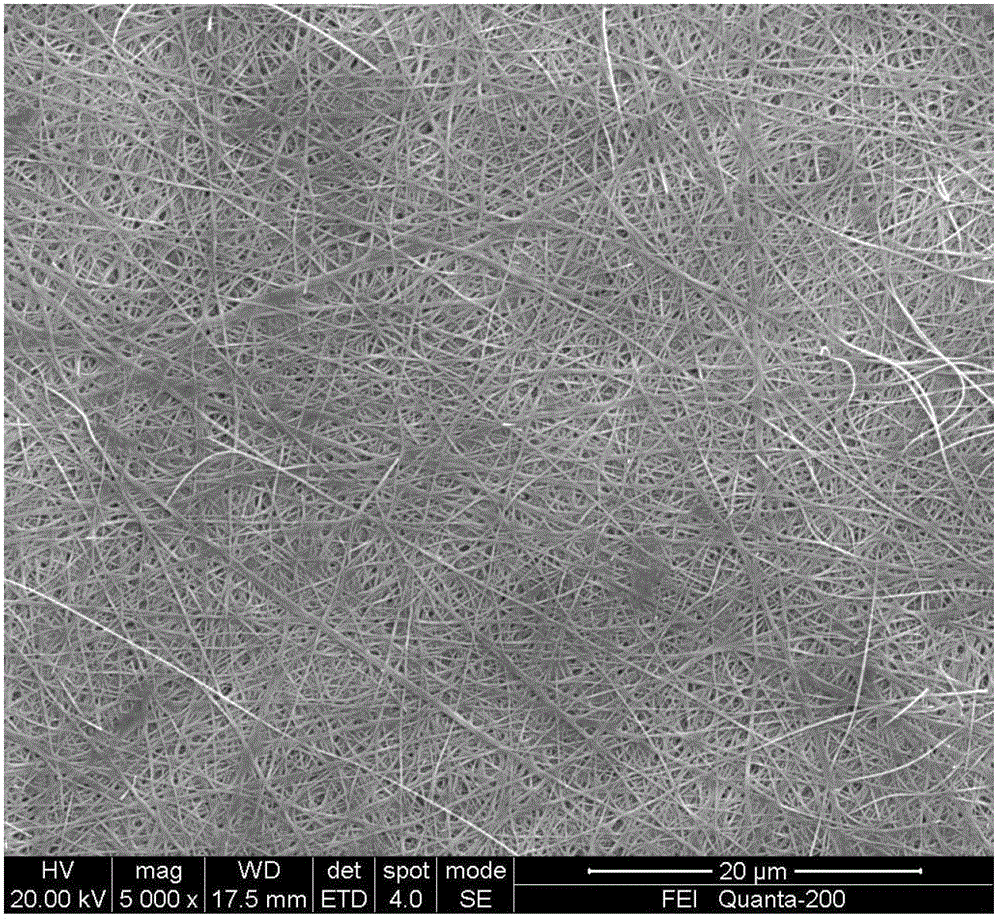

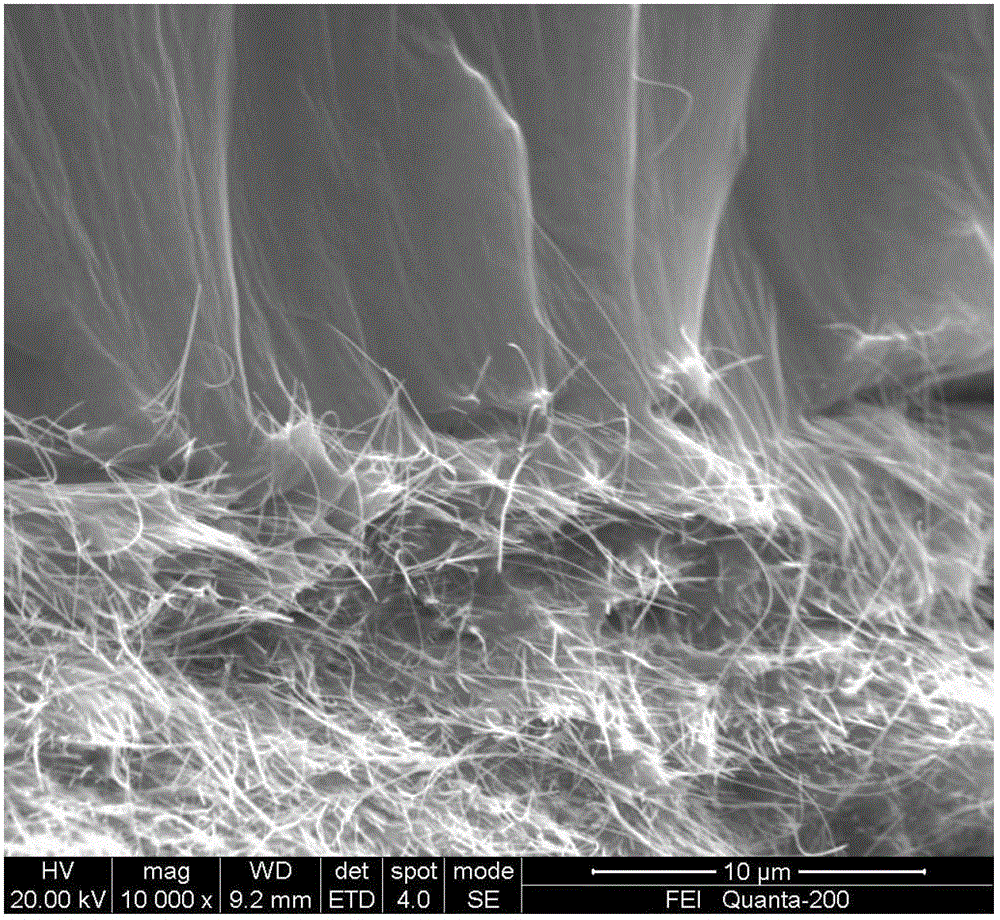

[0023] Example 1: Preparation of chrysotile nanofibers and resin composite transparent film

[0024] Add the chrysotile nanofibers into water, and add sodium polyacrylate with a mass ratio of 20wt% to the chrysotile nanofibers, and form a uniform colloidal solution with a concentration of 0.1% by mechanical stirring and ultrasound. Take 80ml of the colloidal solution and use a microfiltration membrane with a diameter of 50 mm and a pore size of 0.2 μm for vacuum filtration. The obtained filter membrane is vacuum-dried, which is more conducive to the discharge of water and the improvement of film density. white chrysotile nanofiber film. The film is vacuum-immersed in a mixed system cured resin composed of polyurethane acrylate with a refractive index of 1.51, functional monomers and photoinitiators for 24 hours, and then taken out for static pressure molding. The molding pressure is 0.1MPa. Both the light transmittance and mechanical properties of the film are affected. The...

Embodiment 2

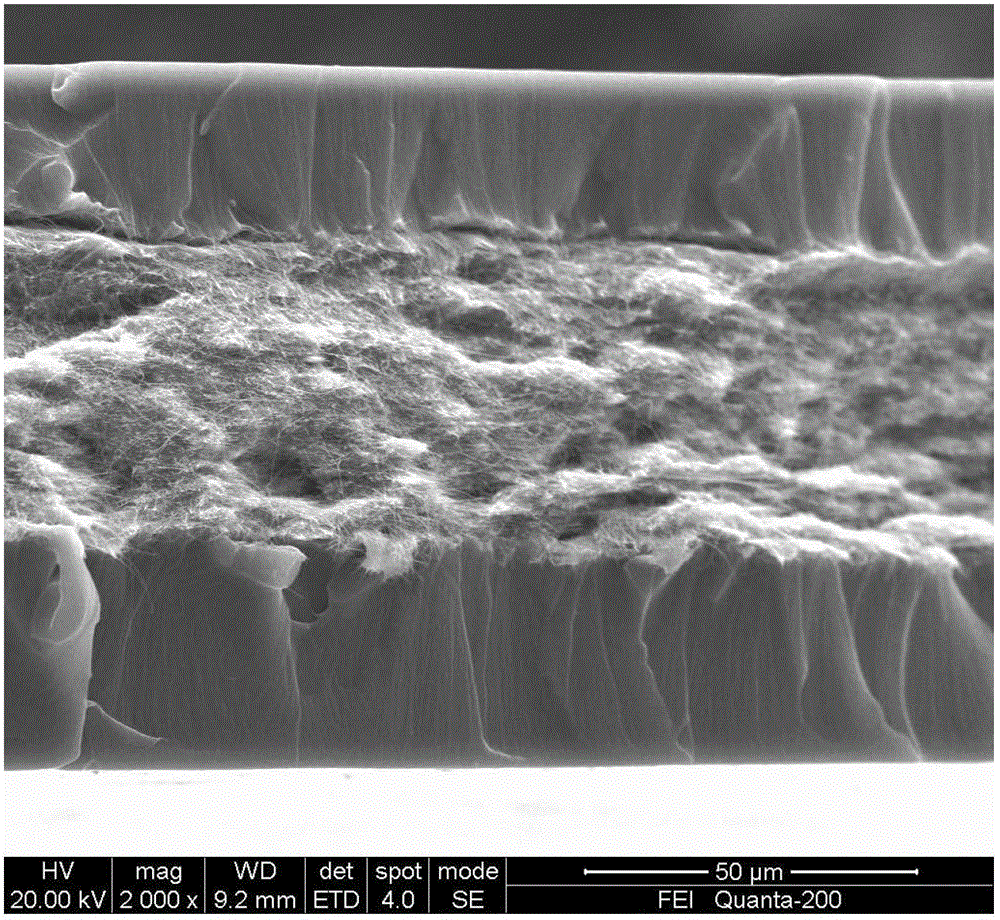

[0025] Example 2: Preparation of chrysotile nanofibers and resin composite transparent film

[0026]Add the chrysotile nanofibers into water, and add polyvinyl alcohol with a mass ratio of 10wt% to the chrysotile nanofibers, and form a uniform colloidal solution with a concentration of 0.2% by mechanical stirring and ultrasound. Take 100ml of the colloidal solution and use a microfiltration membrane with a diameter of 50 mm and a pore size of 0.45 μm to perform pressure filtration at a pressure of 0.5 MPa. The pressure filtration can adjust the filtration pressure to obtain nanofiber films with different densities. The filter membrane obtained after pressure filtration was vacuum-dried to obtain a white chrysotile nanofiber film with a thickness of about 65 μm. The film is vacuum-immersed in a mixed system cured resin composed of acrylic resin with a refractive index of 1.53, functional monomers and photoinitiators for 24 hours, and then taken out for static pressure molding...

Embodiment 3

[0027] Example 3: Preparation of chrysotile nanofibers and resin composite transparent film

[0028] Add the chrysotile nanofibers into water, and add polyacrylamide with a mass ratio of 30wt% to the chrysotile nanofibers, and form a uniform colloidal solution with a concentration of 0.1% by mechanical stirring and ultrasound. Take 100ml of the colloidal solution and use a microfiltration membrane with a diameter of 50mm and a pore size of 0.2μm to carry out pressure filtration, and the applied pressure is 0.3MPa. After the obtained filter membrane is vacuum-dried, a white chrysotile with a thickness of about 50μm is obtained. nanofiber film. The film is vacuum-immersed in a mixed system cured resin composed of epoxy acrylate, functional monomer and photoinitiator with a refractive index of 1.48 for 18 hours, and then taken out for static pressure molding. The molding pressure is 0.5MPa, and the larger molding pressure is formed The transparent composite film has better lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com