High-transmittance and low-resistance composite ITO film

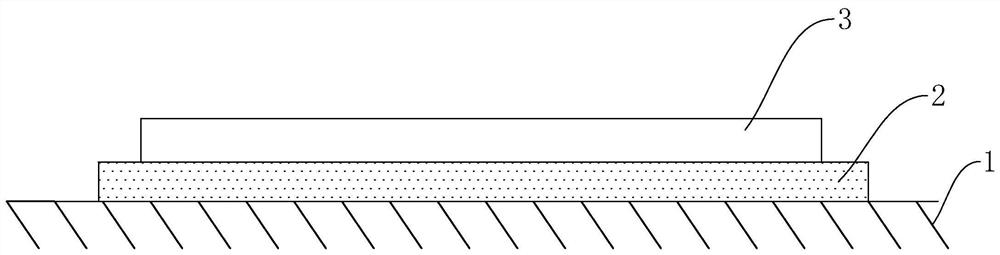

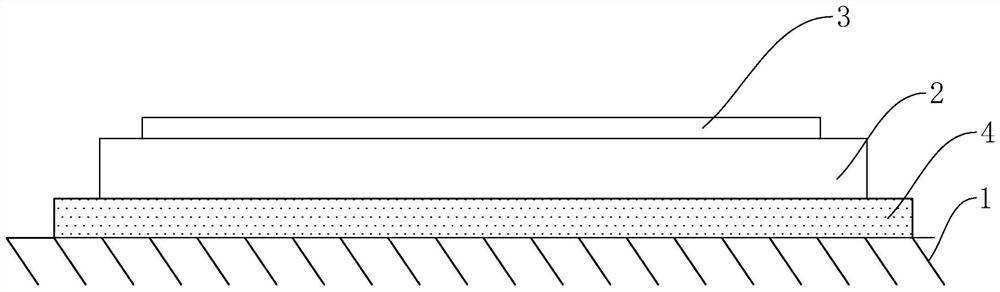

A low-resistance, film-layer technology, applied to the direction of the conductive layer on the insulating carrier, can solve the problems of poor conductivity and light transmittance of ITO films, improve oxidation resistance, improve light transmittance, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

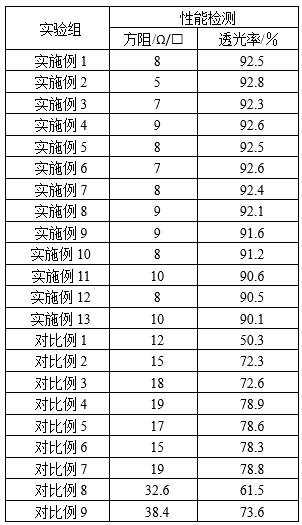

Examples

preparation example 1

[0041] 85% by mass percentage of nano-Ag particles and 15% of nano-Ni particles were doped and mixed with stirring to collect a mixed noble metal doped layer target 1 .

preparation example 2

[0043] 90% by mass percentage of nano-Ag particles and 10% of nano-Ni particles were doped and mixed with stirring, and the mixed noble metal doped layer target 2 was collected.

preparation example 3

[0045] 85% by mass percentage of nano-Ag particles and 15% of nano-Ni particles were doped and mixed with stirring to collect a mixed noble metal doped layer target 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com