White master batch as well as preparation method and application thereof

A technology of white masterbatch and masterbatch, applied in the field of masterbatch, can solve the problems of limited product application, numerous steps, and insufficient wetting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

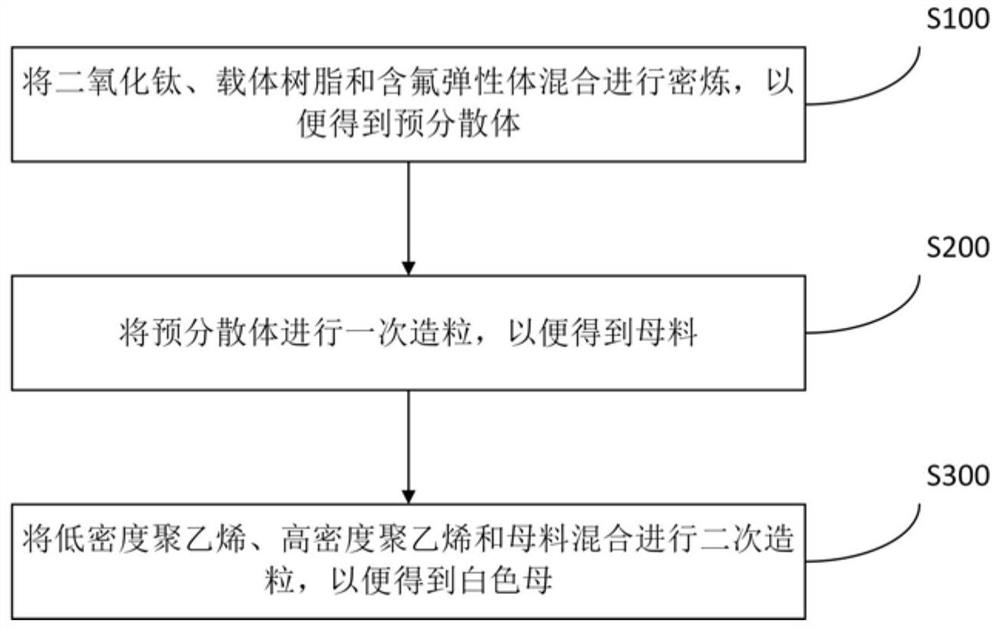

Method used

Image

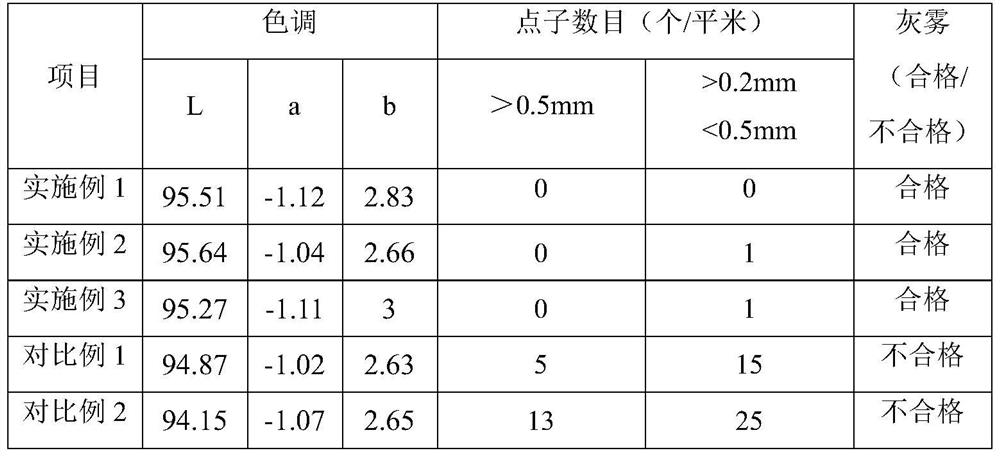

Examples

Embodiment 1

[0070] Step 1: Take 20 kg of titanium dioxide 104 (the diameter of the primary particle is 0.2-0.5 microns) and put it into a banburying container, add 0.9 kg of Hi Former fluoroelastomer (CLARINT) while stirring, mix for 15 minutes, and then add 20 Kilogram linear low density polyethylene (LLDPE, the melt index under 2.16kg, 190 ℃ of conditions is 20g / 10min), keep 100 ℃ banburying for 30 minutes, obtain pre-dispersion;

[0071] Step 2: Granulate the pre-dispersion prepared by banburying on a twin-screw granulator, and set the temperature at 140-220 degrees Celsius;

[0072] Step 3: Add 10.33 kg of low-density polyethylene (LDPE) and 0.966 kg of high-density polyethylene (HDPE) to the masterbatch obtained in step (2), mix well and perform secondary granulation, and set the temperature at 140- 220 degrees Celsius to get the required white mother.

Embodiment 2

[0074] Step 1: Take 33 kg of titanium dioxide 104 (the diameter of the primary particle is 0.2-0.5 microns) into the banburying container, add 1.1 kg of Hi Former fluoroelastomer (CLARINT) while stirring, mix for 15 minutes, and then add 7.3 Kilogram of LLDPE (melt index under 2.16kg, 190 DEG C is 20g / 10min), keep banburying at 100 DEG C for 30 minutes to obtain pre-dispersion;

[0075] Step 2: Granulate the pre-dispersion prepared by banburying on a twin-screw granulator, and set the temperature at 140-220 degrees Celsius;

[0076] Step 3: Add 4.33 kg of LDPE and 1.96 kg of HDPE to the masterbatch obtained in step (2), mix evenly and carry out secondary granulation, and set the temperature at 140-220 degrees Celsius to obtain the required white masterbatch.

Embodiment 3

[0078]Step 1: Take 8.26 kg of titanium dioxide 104 (the diameter of the primary particle is 0.2-0.5 microns) into the banburying container, add 0.3 kg of Hi Former fluoroelastomer (CLARINT) while stirring, mix for 10 minutes, and then add 8 Kilogram of LLDPE (melt index under 2.16kg, 190°C is 20g / 10min), kept banburying at 100°C for 10 minutes to obtain pre-dispersion;

[0079] Step 2: Granulate the pre-dispersion prepared by banburying on a twin-screw granulator, and set the temperature at 140-220 degrees Celsius;

[0080] Step 3: Add 2 kg of LDPE and 1.5 kg of HDPE to the masterbatch obtained in step (2), mix evenly and carry out secondary granulation, and set the temperature at 140-220 degrees Celsius to obtain the required white masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com