Contracting internal core withdrawing device used for plastic mould and its use method

A plastic mold and internal core-pulling technology, applied in the field of plastic molds, can solve the problems of being unable to meet the requirements of mass production, laborious, time-consuming, etc., and achieve the effects of easy promotion and application, simple structure, and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

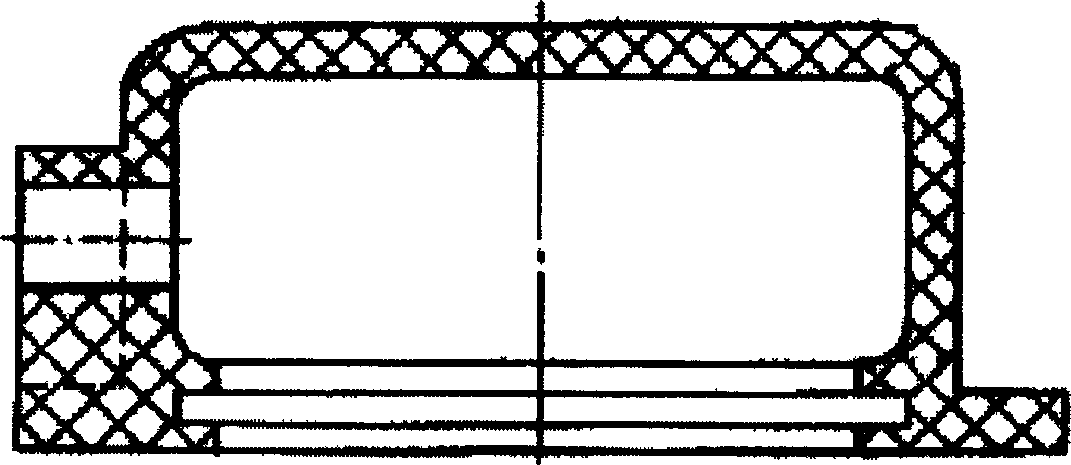

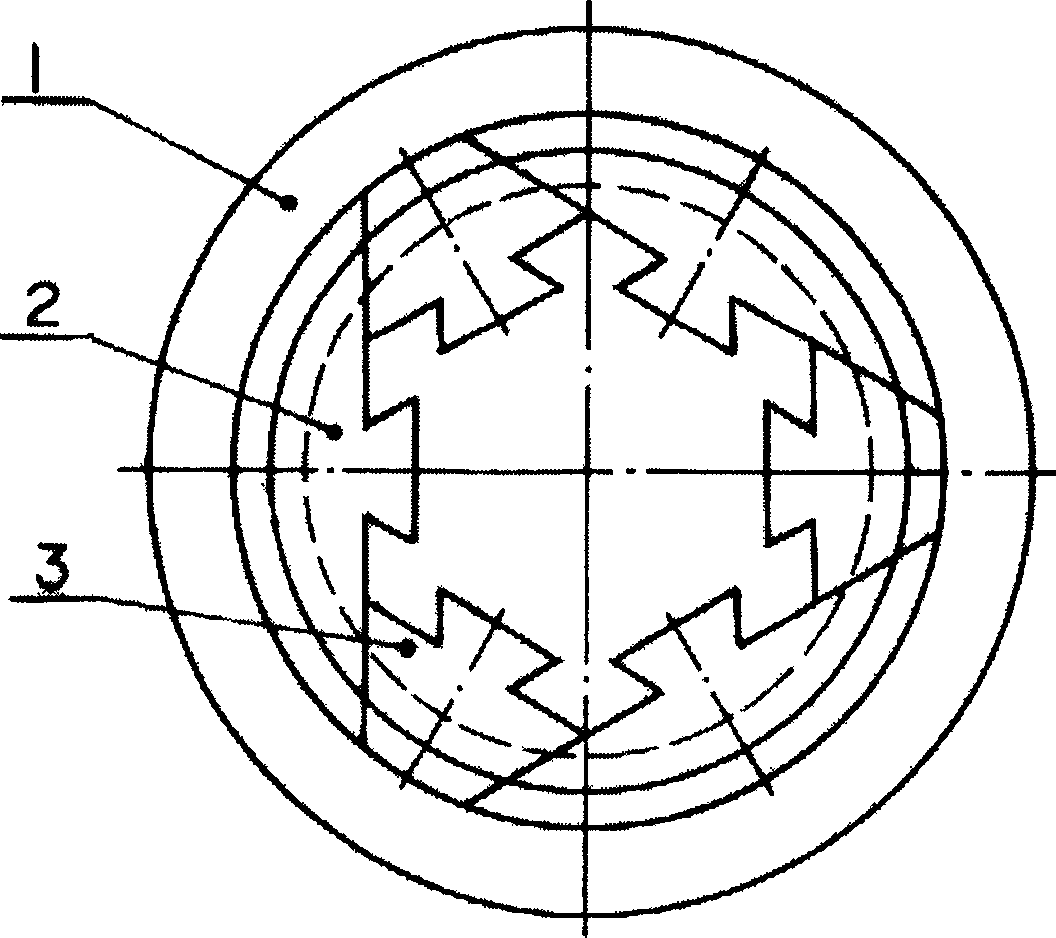

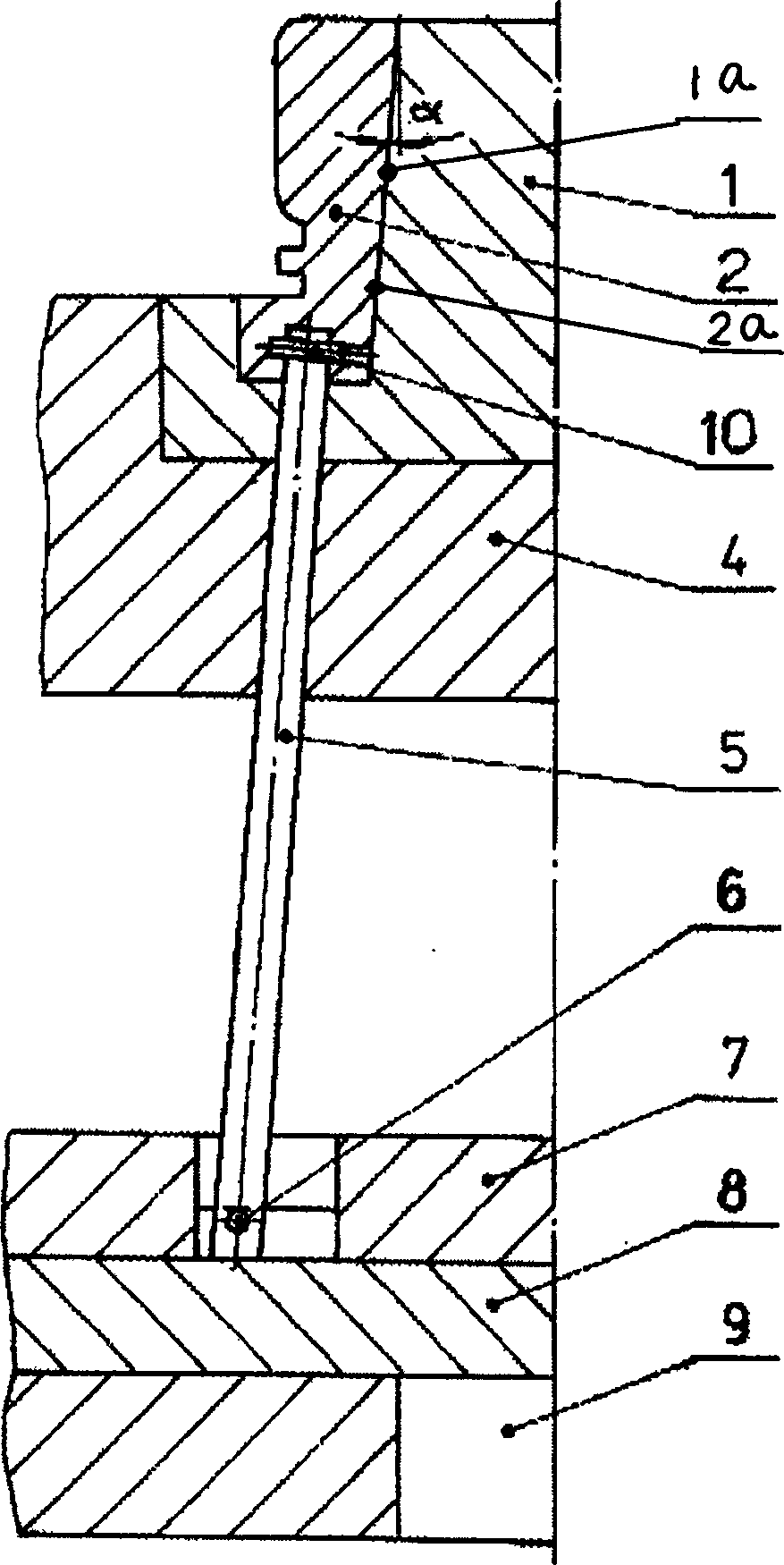

[0019] Embodiment: a kind of core-pulling device in the shrinkage that is used for plastic mold (see Figure 1-5 ), is characterized in that it is composed of core 1, main slider 2, auxiliary slider 3, core fixed plate 4, inclined push rod 5, push rod fixed plate 7, push plate 8, movable mold seat plate 9 and inclined The push rod 5 is composed of the fixing parts of the core 1 and the push rod fixing plate 7. The said main slider 2 and the auxiliary slider 3 are evenly spaced according to six equal parts of the circle. The six oblique push rods 5 connected by the slider 2 and the auxiliary slider 3, the back of the main slider is a plane, the angle between the two sides of the auxiliary slider is 60°, and the back of the main slider is closely matched with the sides of the auxiliary slider; The main and auxiliary sliders are guided by the guide chute, the inclination angle of the back of the main slider is α, the inclination angle of the back of the auxiliary slider is β, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com