Assembled steel structural integrated house wall

A technology for integrating houses and steel structures, applied in the direction of walls, building components, building structures, etc., can solve the problems of house structure strength, comfort, and fast heat conduction of steel, so as to improve living conditions, reduce heat exchange, prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

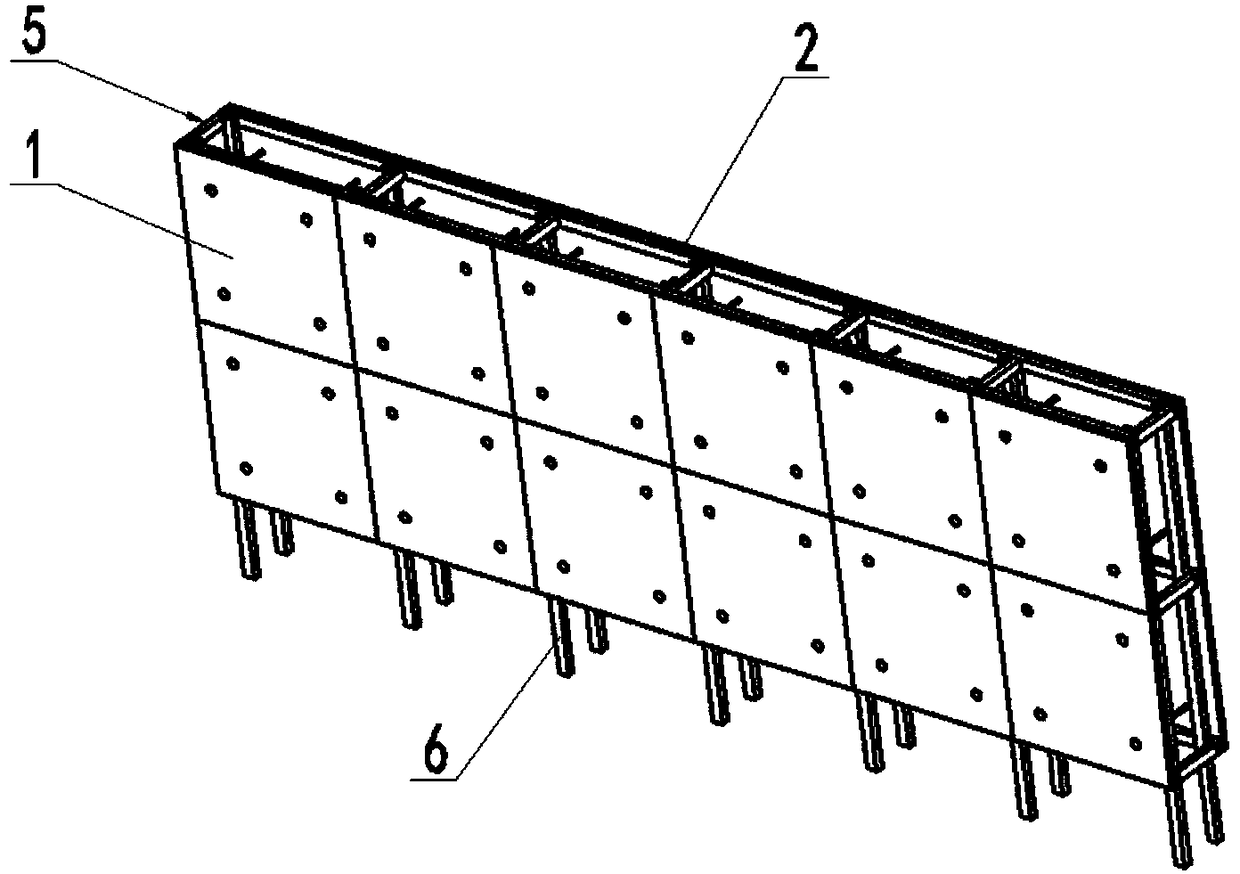

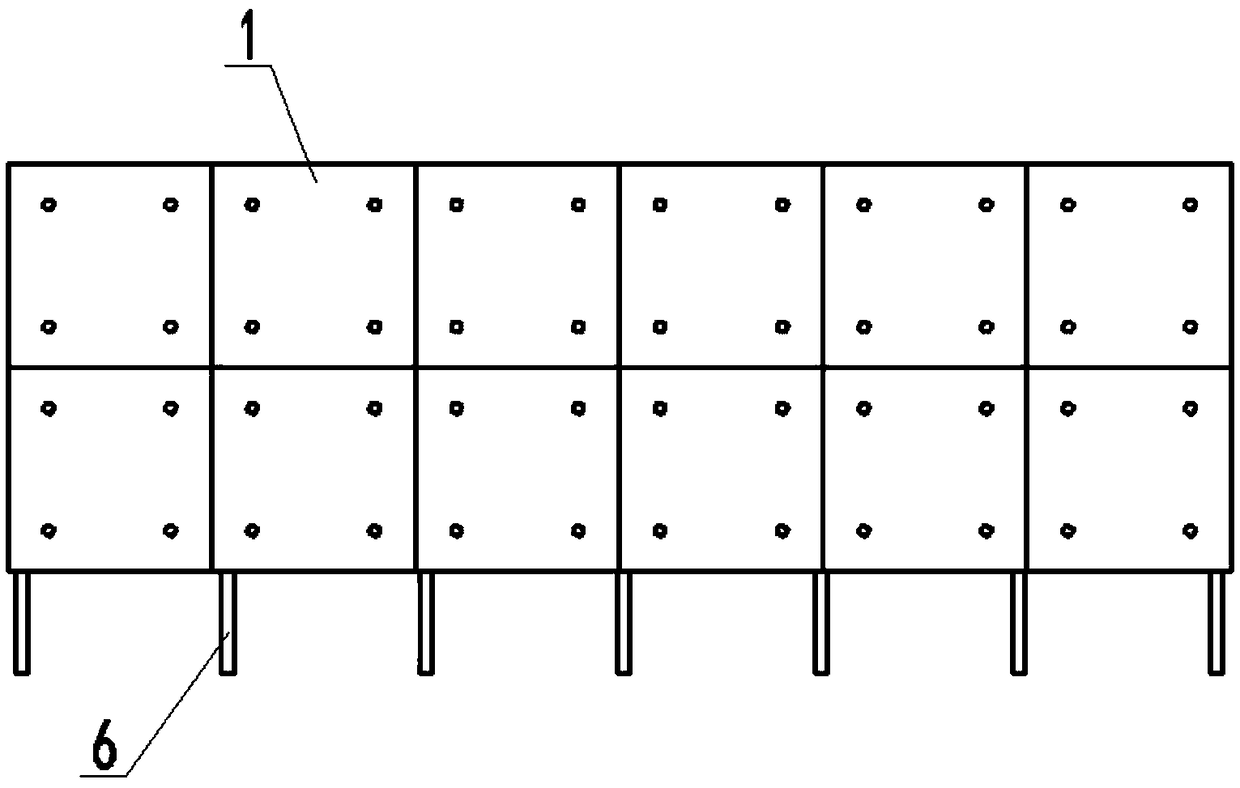

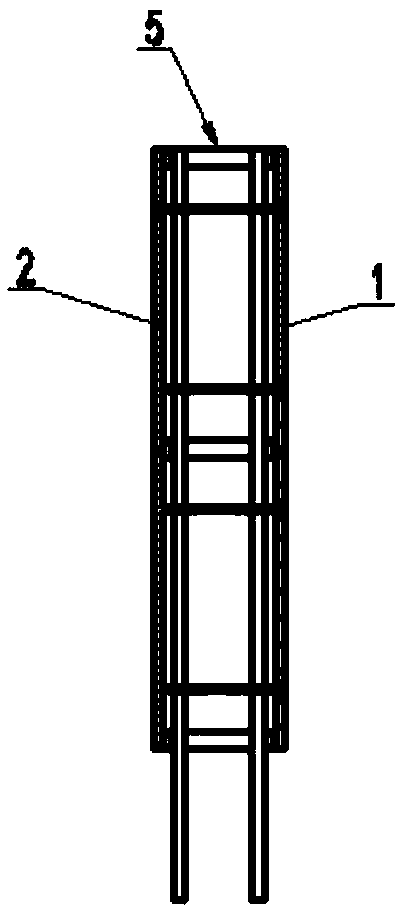

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a prefabricated steel structure integrated house wall, including an outer wall panel 1, an inner wall panel 2, a connecting screw 3, a nut 4 and a steel structure wall skeleton 5, an outer wall panel 1 and an inner wall panel 2 Covering both sides of the wall frame 5, one end of the connecting screw 3 is buried inside the inner wall panel 2, and the outer wall panel 1 is provided with a connecting hole 101 corresponding to the connecting screw 3, and the other end of the connecting screw 3 passes through The connecting hole 101 is screwed with the nut 4, so that the outer wall panel 1, the inner wall panel 2 and the wall frame 5 are connected together.

[0024] By adopting the technical solution of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com