Lollipop self-rotatingmachine for lollipop packaging

A technology for packaging and lollipops, applied in the field of lollipop packaging, can solve the problems of lack of special production equipment and achieve the effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

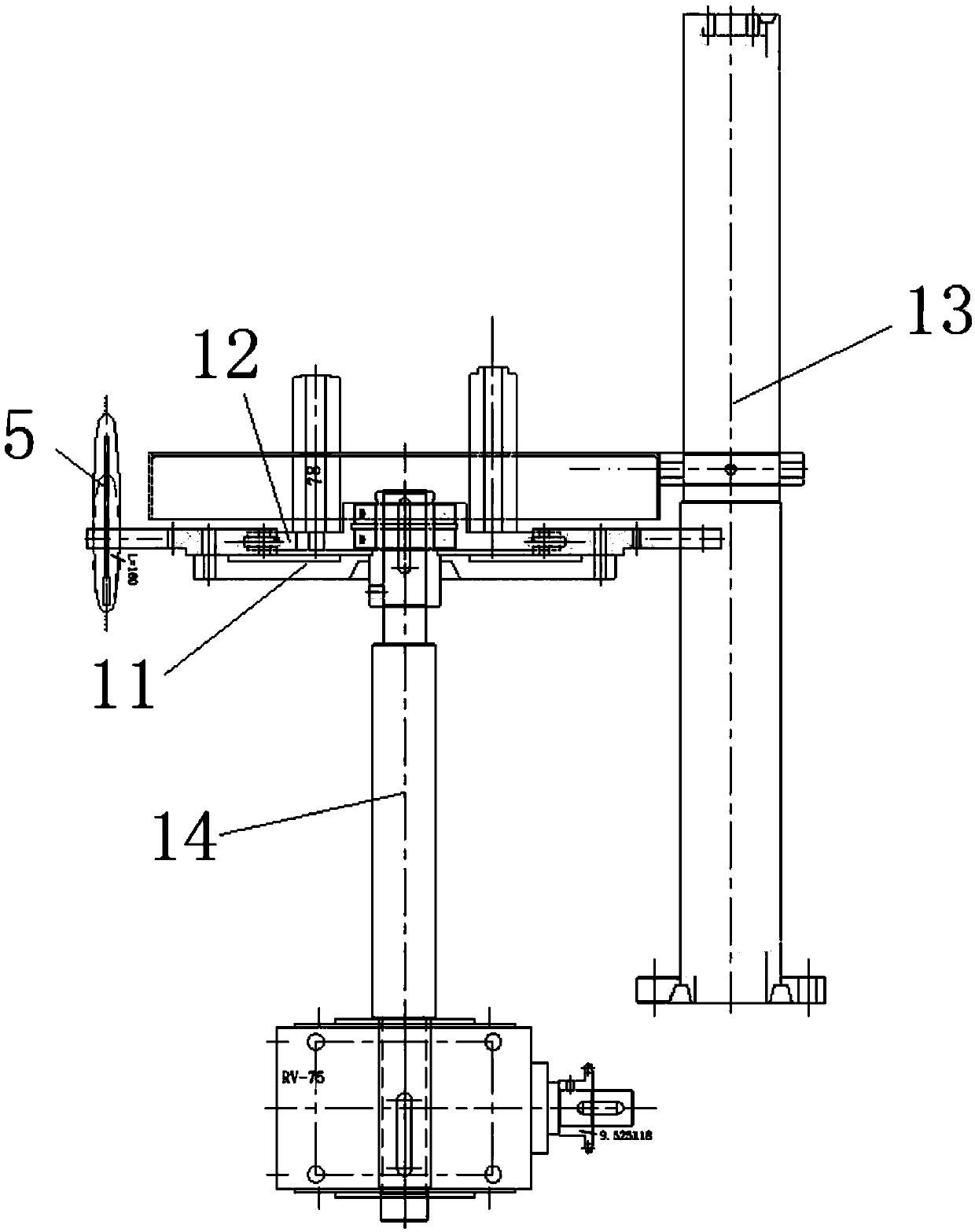

[0055] Example 1: See Figure 1-26 , the present invention provides a technical solution: a lollipop rotary machine for lollipop packaging, including a lollipop conveyor, a sugar feeding gripper assembly, a heat sealing tongs assembly, a candy head tongs assembly, a sugar outlet gripper assembly, Mounting frame 6 and positioning shaft 13;

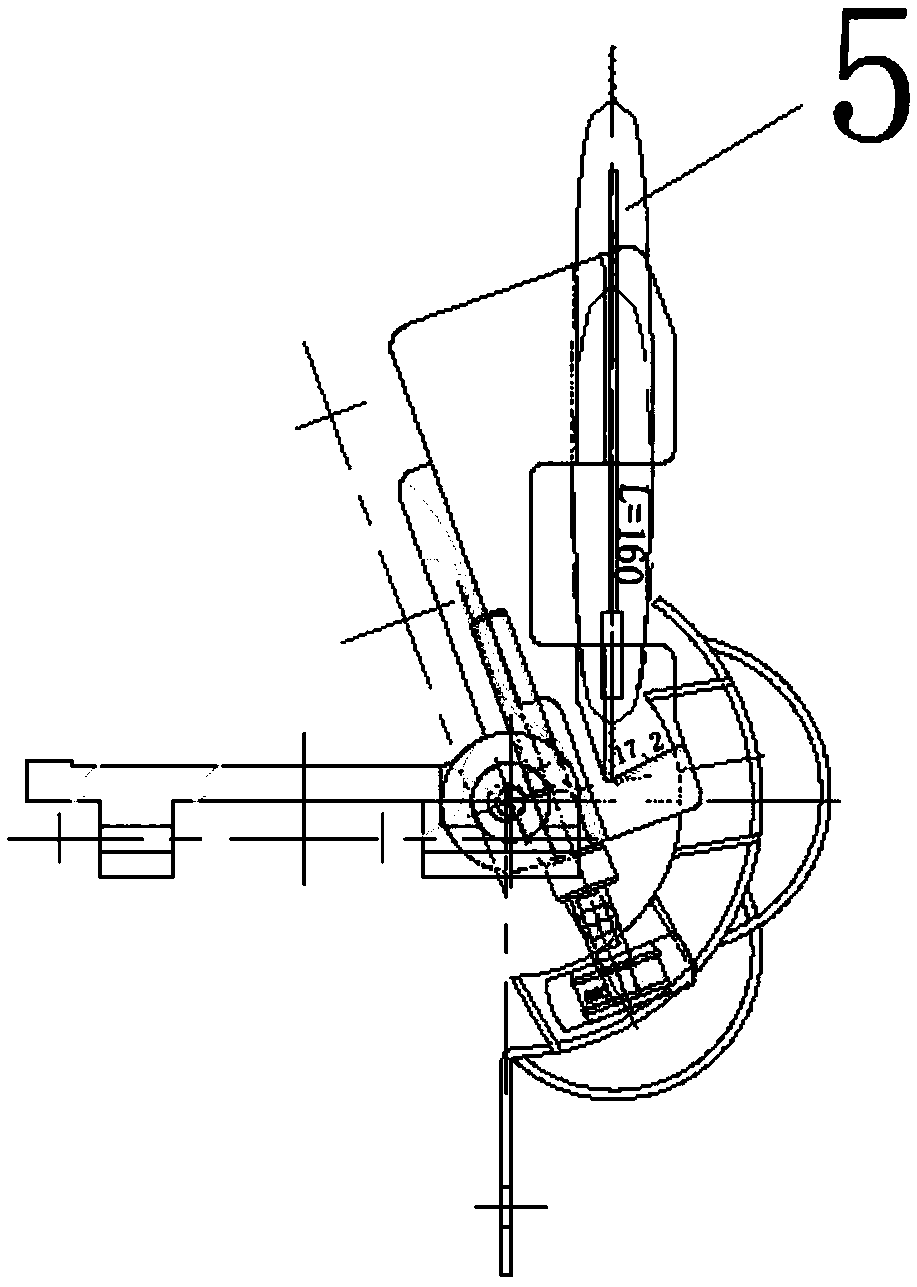

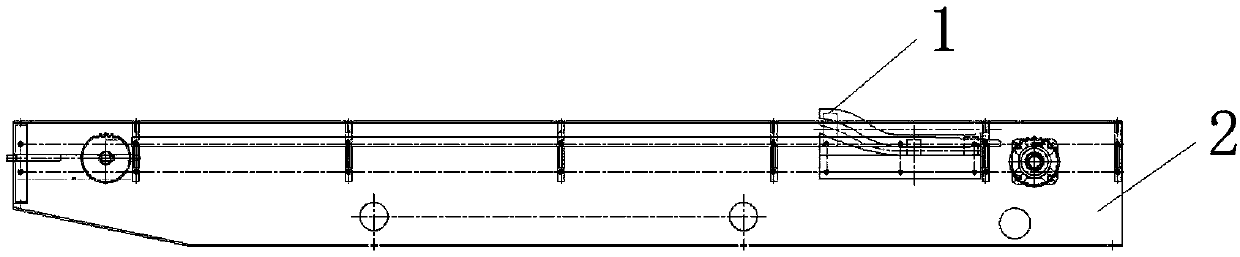

[0056] The lollipop conveyor includes a conveyor 2 installed on a mounting frame 6, several holders 4, several lollipop placers 3 and a lollipop turner 1;

[0057] Wherein, the conveyor belt in the conveyor 2 does rotary motion; the holder 4 is a strip structure, and several holders 4 are evenly installed on the outer ring of the conveyor belt, and the length direction of the holder 4 is in line with the conveyor belt. The central axis of rotation is parallel; the lollipop placer 3 is a bar-shaped structure, and the upper surface of the lollipop placer 3 is provided with a concave bar-shaped lollipop placement nest, and the length of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com