Environment-friendly auxiliary mechanism for high-end equipment manufacturing tailoring machine

An auxiliary mechanism and cutting machine technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of cutting errors, damaged fabrics, uneven incisions, etc., achieve simple equipment structure, improve environmental protection, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

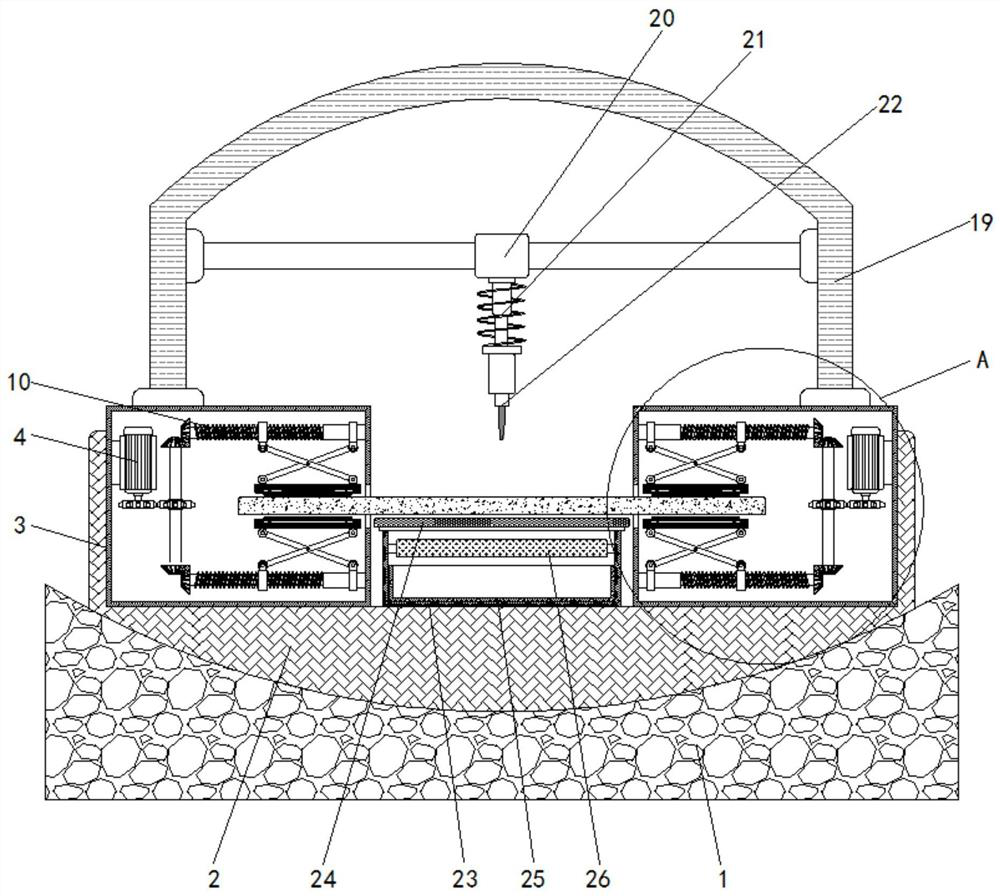

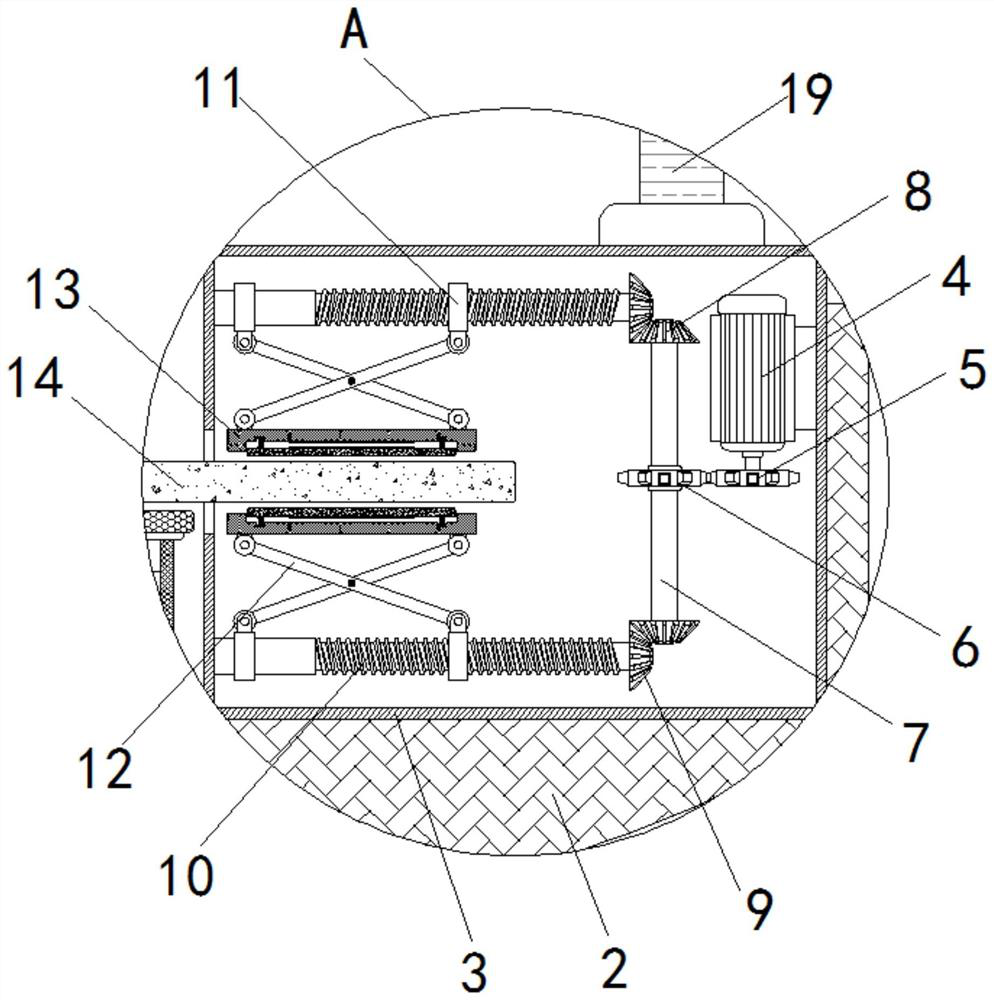

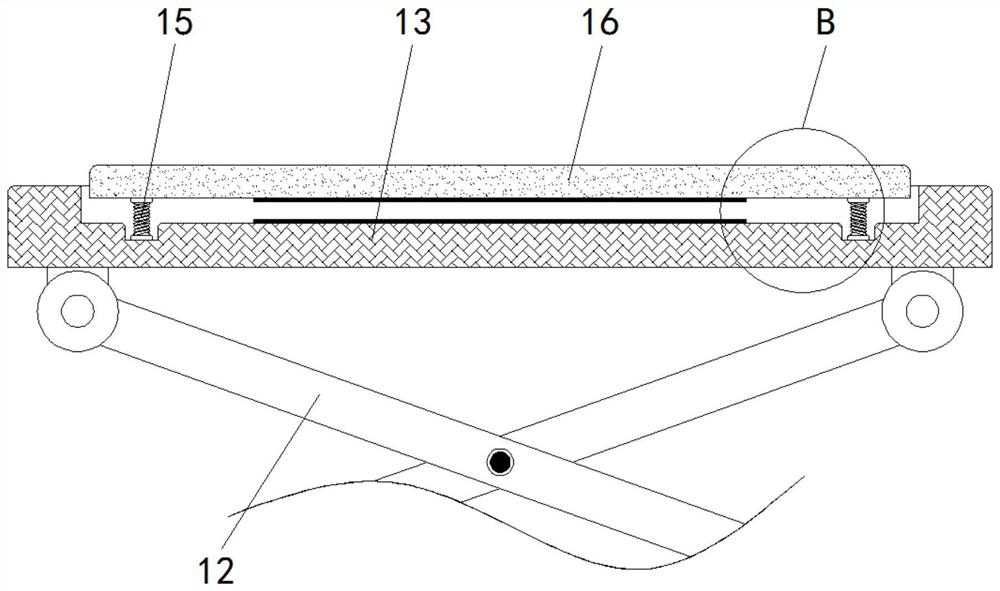

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The invention provides an environment-friendly auxiliary mechanism for high-end equipment manufacturing cutting machines, which includes a base 1, a fixing part 2 is fixedly installed on the upper side of the base 1, a housing 3 is fixedly installed on the inner wall of the fixing part 2, and the inside of the housing 3 A motor 4 is installed, and a driving gear 5 is movably installed on the lower side of the motor 4, and a driven gear 6 is connected to the outside of the driving gear 5 through meshing, and a rotating shaft 7 is movably installed at the central axis of the driven gear 6, and the driven gear 6 and the rotating shaft 7 are movably installed through movable bearings, and the effective installation of the driven gear 6 is facilitated by setting the bearings. The upper and lower ends of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com