Patents

Literature

34results about How to "Meet vibration requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

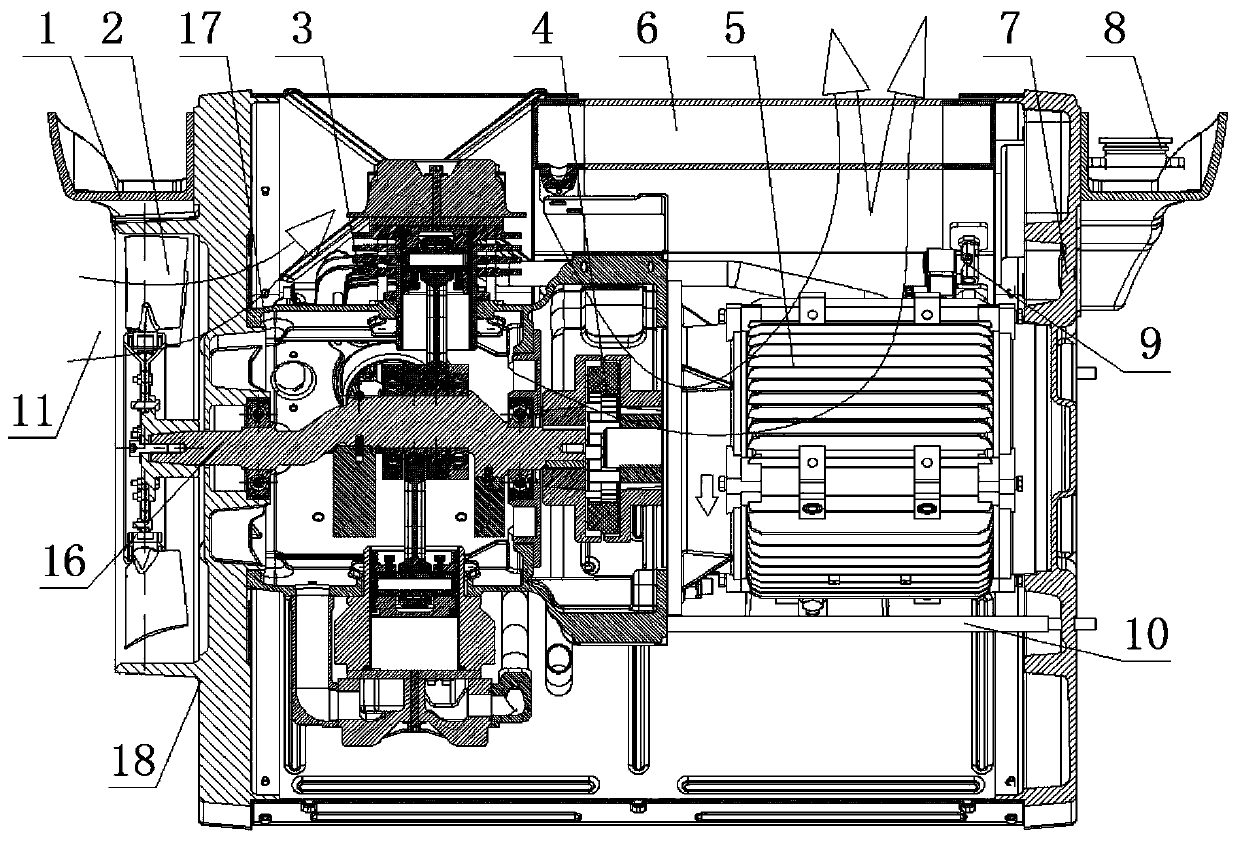

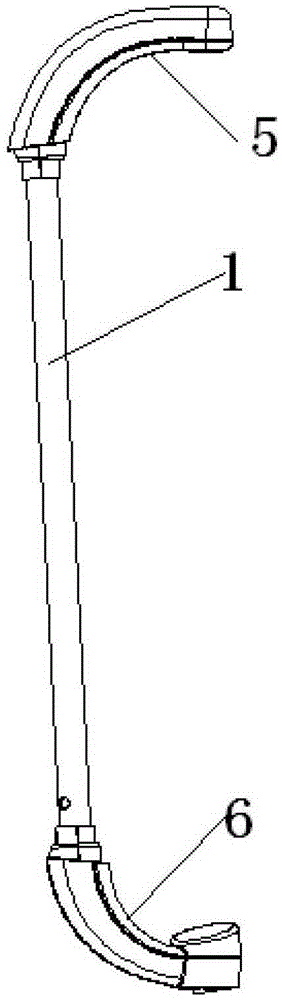

Electric oil-free main air compressor

ActiveCN106194651AReduce vibration shockReduce vibrationPositive displacement pump componentsPump controlAxial compressorOil free

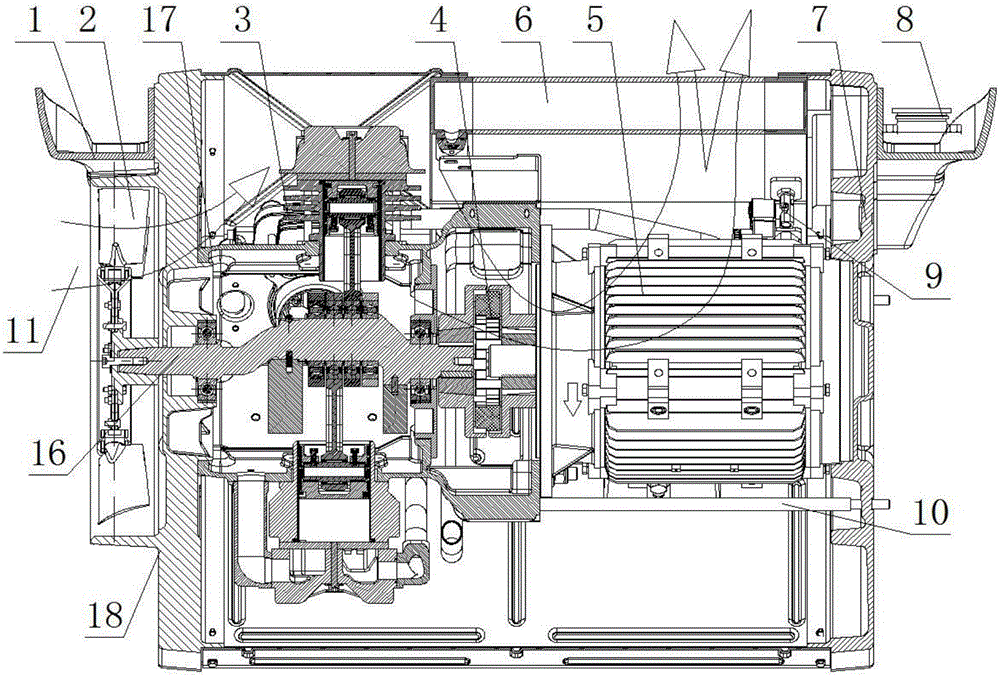

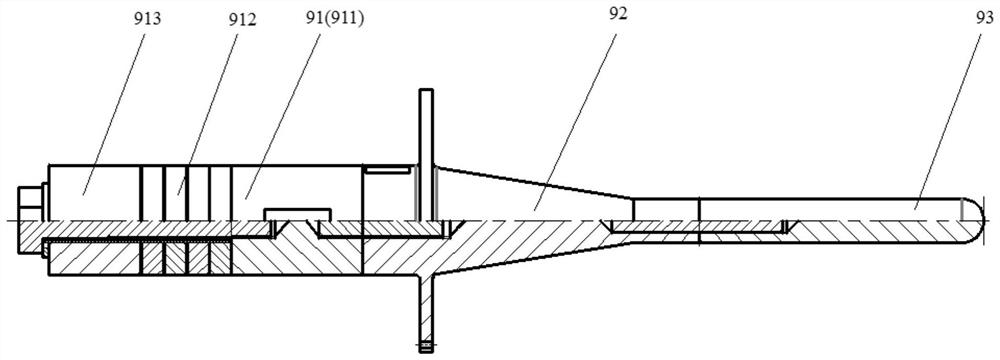

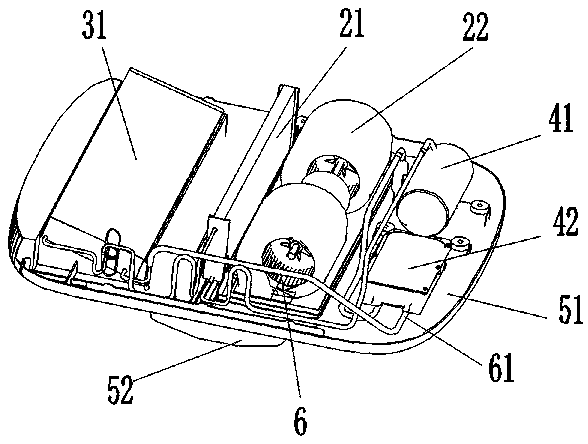

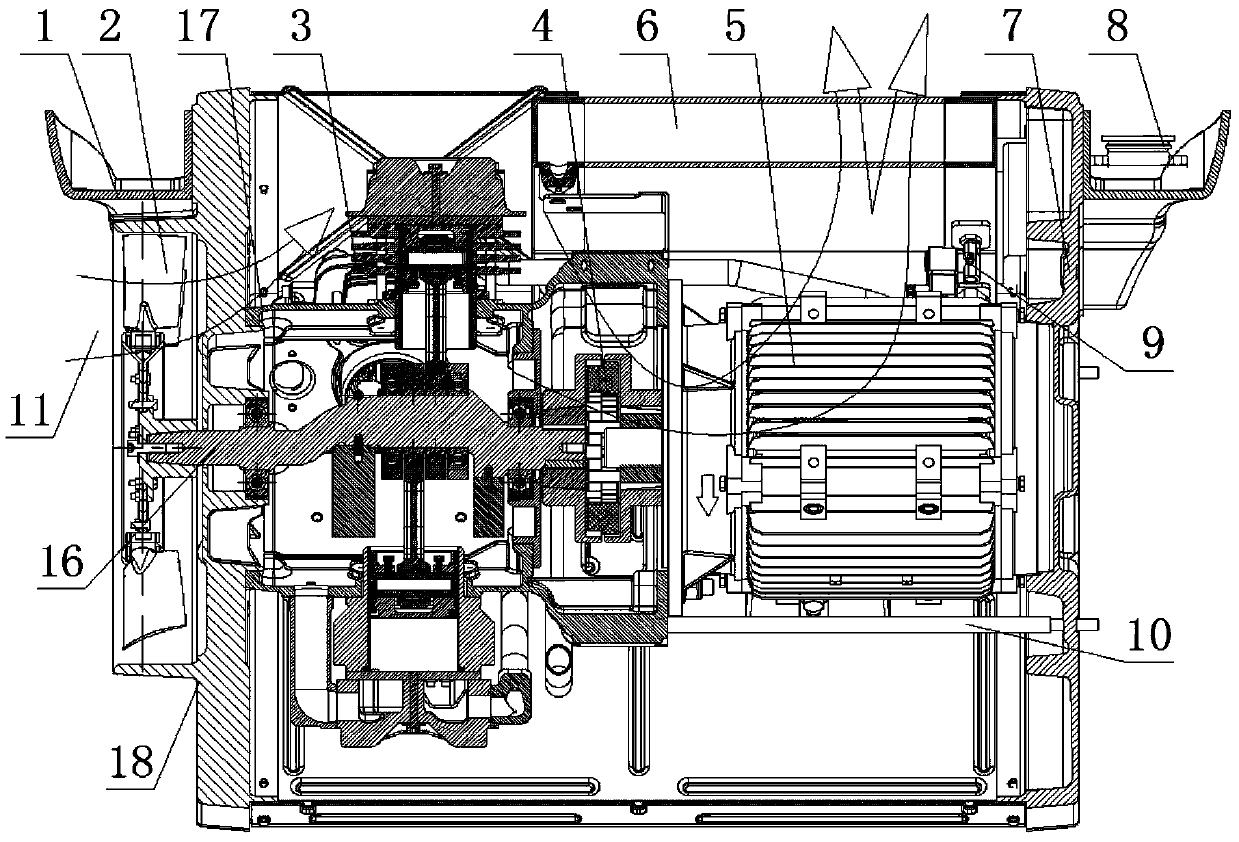

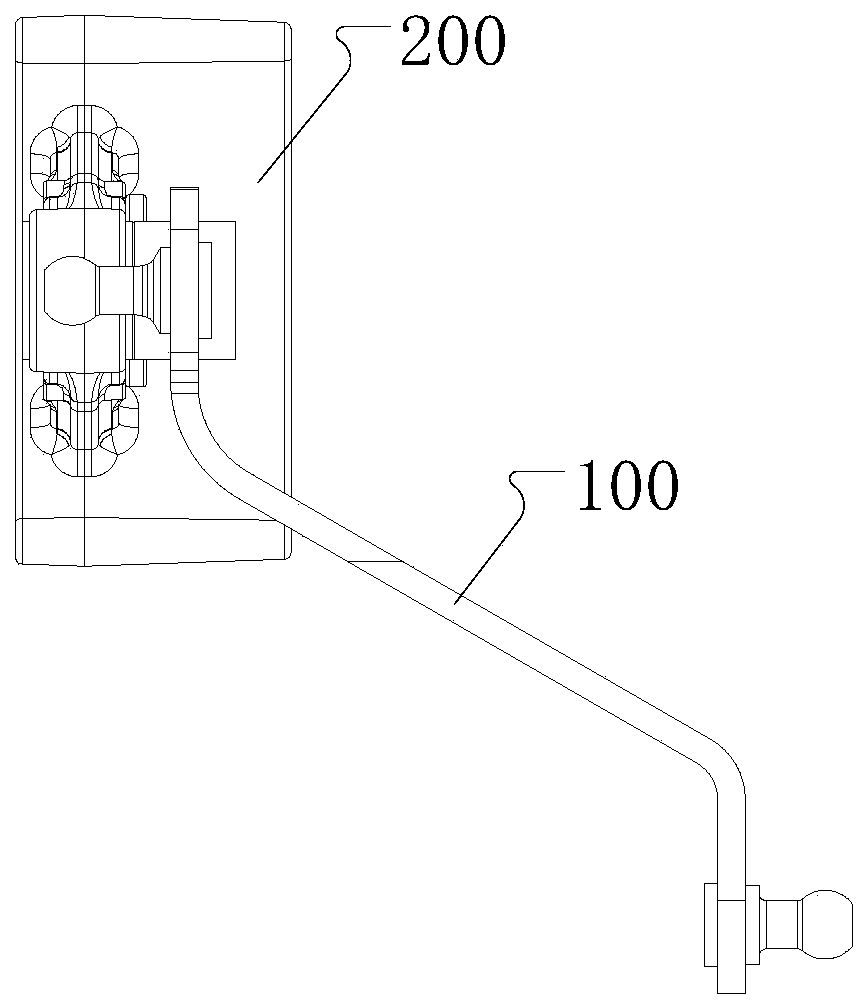

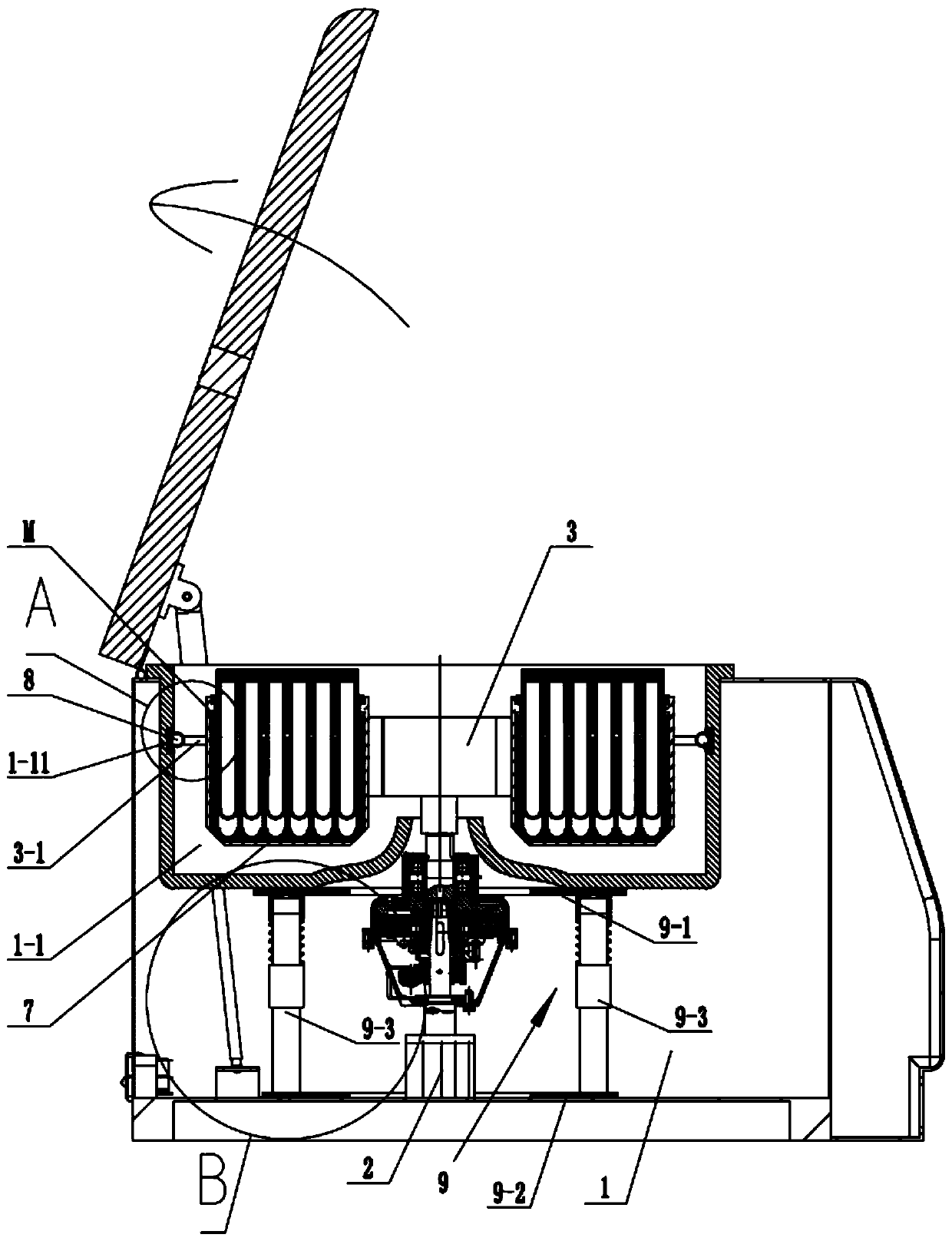

The invention discloses an electric oil-free main air compressor, and belongs to the technical field of air compressors. The electric oil-free main air compressor comprises a fan, an air compressor body, a motor, a cooler, dampers, water drainage electromagnetic valves, a pull rod and a housing. The cooler comprise a middle cooler body and a rear cooler body. At least four dampers are mounted on a fan support and a motor support correspondingly, and are connected with an automobile body. The water drainage electromagnetic valves are mounted at the lower end of the middle cooler body and the lower end of the rear cooler body. The pull rod enables the motor support and the air compressor body to be connected and locked. A damping material layer is arranged in the housing, and the air compressor body is composed of a main shell and a compression cylinder assembly. A bent axle is arranged in the main shell, and the compression cylinder assembly is in an X shape and is composed of at least one high-pressure cylinder assembly and at least two low-pressure cylinder assemblies. According to the electric oil-free main air compressor, the potential hazards of oil leaking and mixing of the air compressor are avoided through air cooling, and the maintaining cost is lowered; the compression cylinder assembly forms reasonable air flow direction, and the maximum cooling efficiency is achieved; damping materials are coated on the housing, and noise is lowered.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

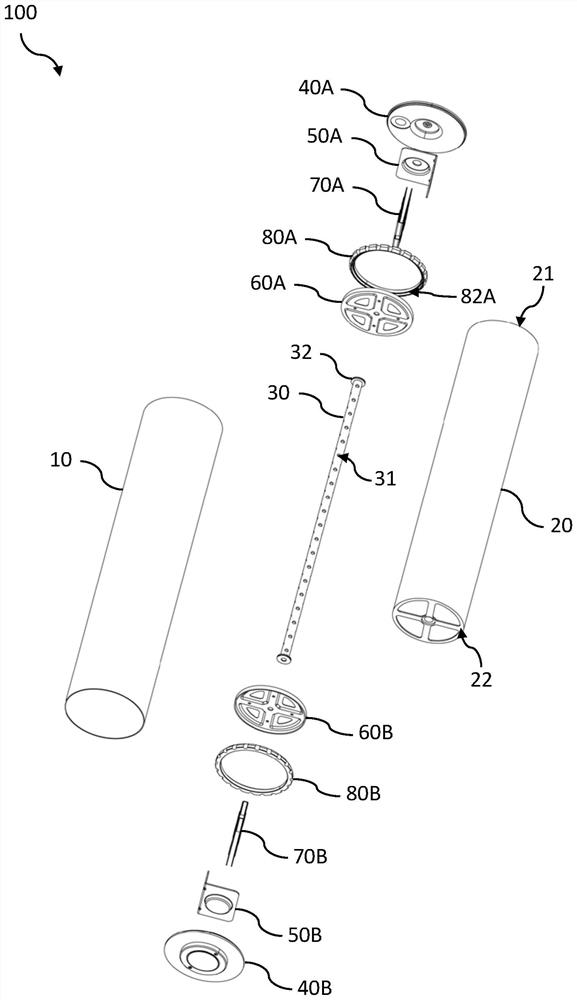

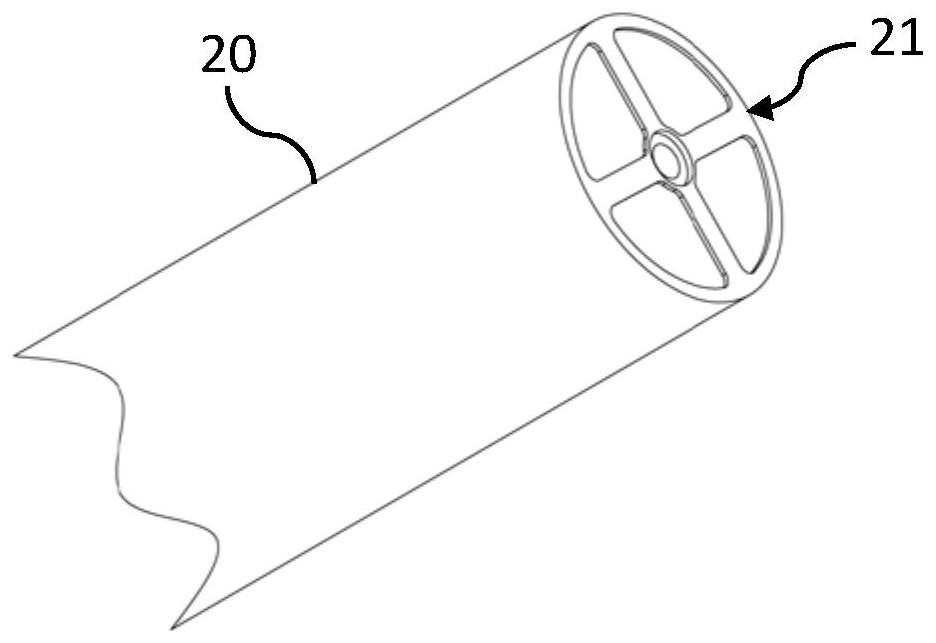

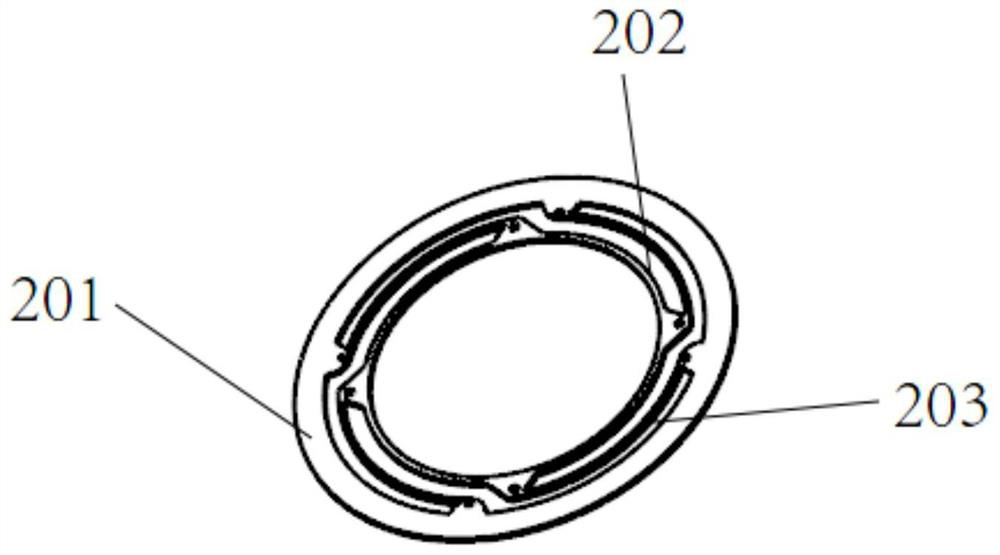

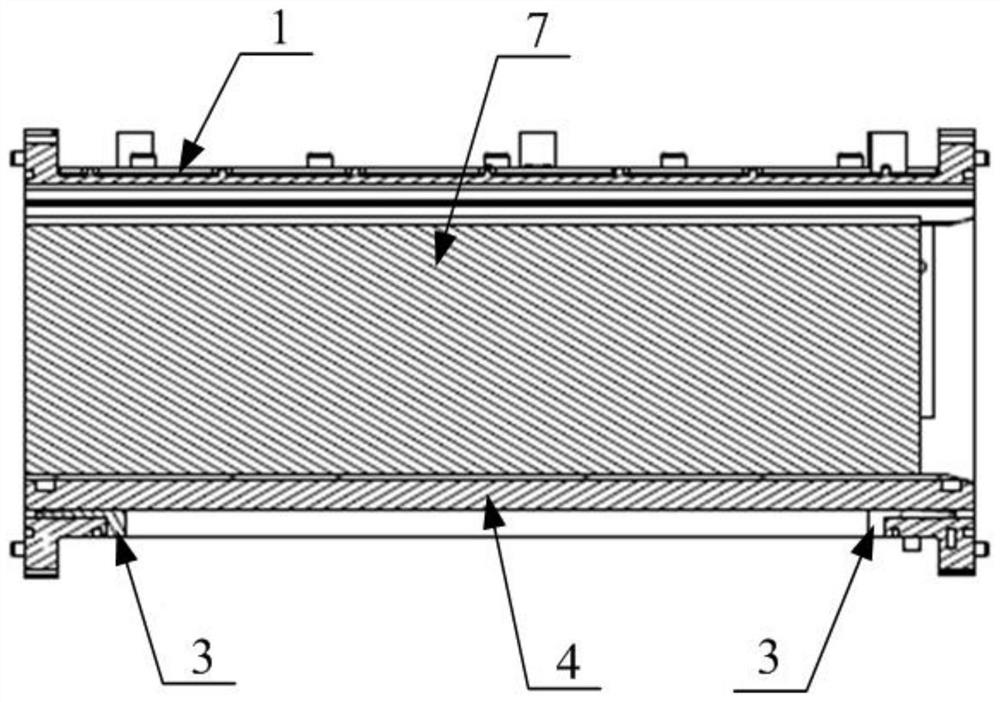

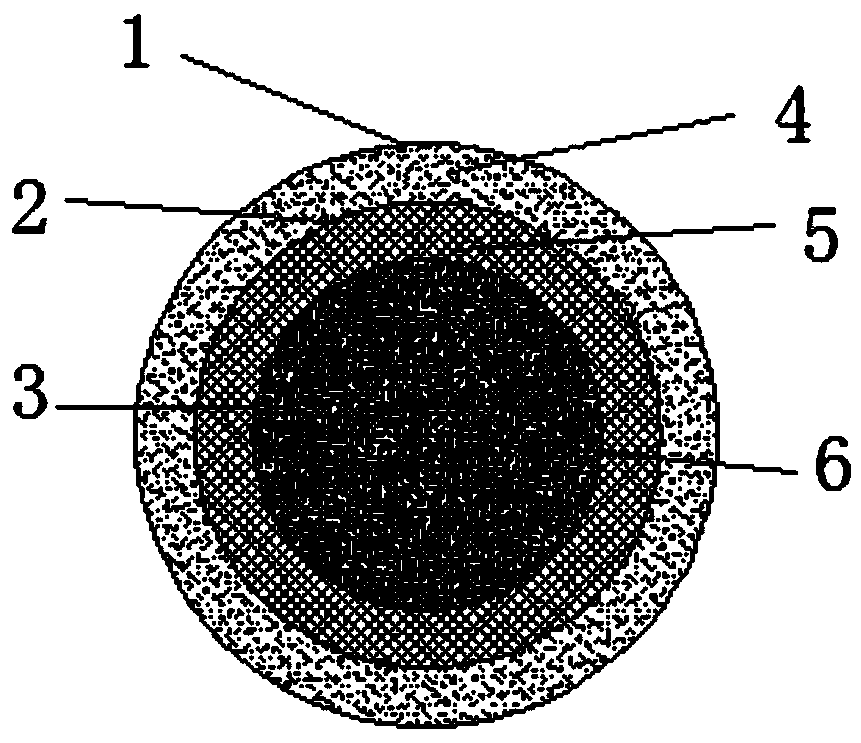

Cylindrical lithium battery and manufacturing method thereof

PendingCN114221073ASolve the diversion bottleneckImprove diversion capacityFinal product manufactureLi-accumulatorsElectrical connectionEngineering

The invention provides a cylindrical lithium battery and a manufacturing method thereof. The cylindrical lithium battery of the present invention comprises: a housing; the full-tab roll core is provided with a kneaded positive end surface and a kneaded negative end surface; a central tube; and two cover plates, two flow deflectors, two current collecting discs, two current collecting sheets and two insulating supports. Wherein the cover plate is welded with one end of the shell in a closed manner, a cover plate boss is punched at the central position of the cover plate, and an electrode column is mounted in the cover plate boss. A flow deflector boss matched with the cover plate boss is punched at one end of the flow deflector, and the flow deflector boss is electrically connected with the electrode column and connected to the cover plate in advance. The current collecting disc is welded with the end face of the rubbing electrode, a central pipe positioning hole is formed in the central position of the current collecting disc, and the current collecting sheet is connected to the central position of the current collecting disc in advance and is connected with the flow deflector after being bent at a preset bending position. And one side end of the insulating bracket is clamped and fixed on the collector plate, the other side end of the insulating bracket is propped against the cover plate, and the outer edge of the insulating bracket is propped against the inner wall of the shell.

Owner:苏州比耐新能源科技有限公司

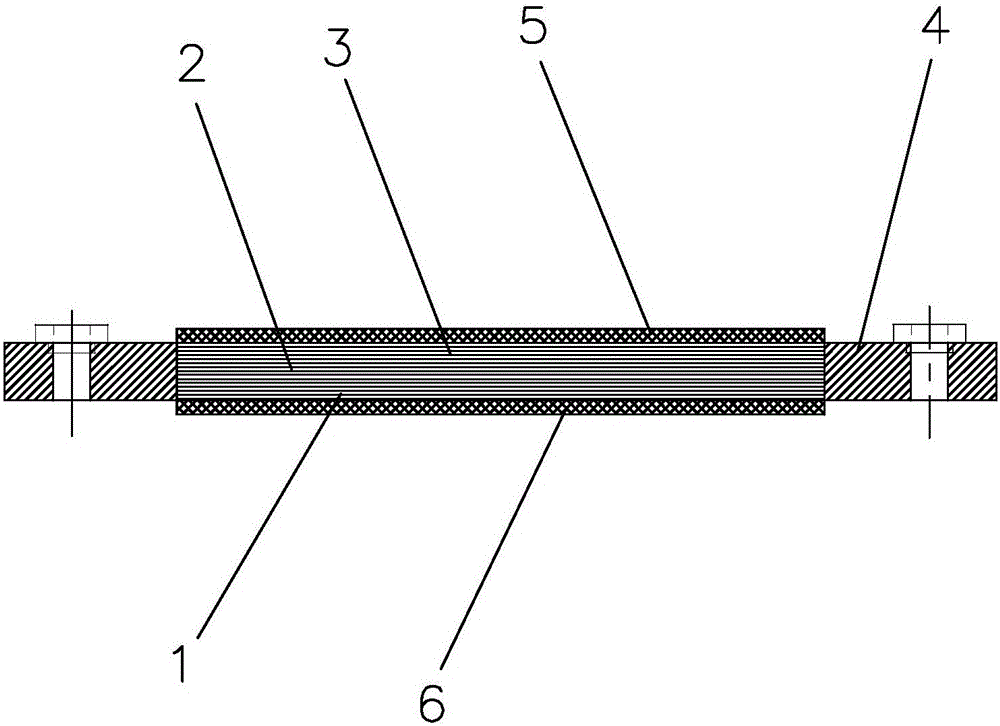

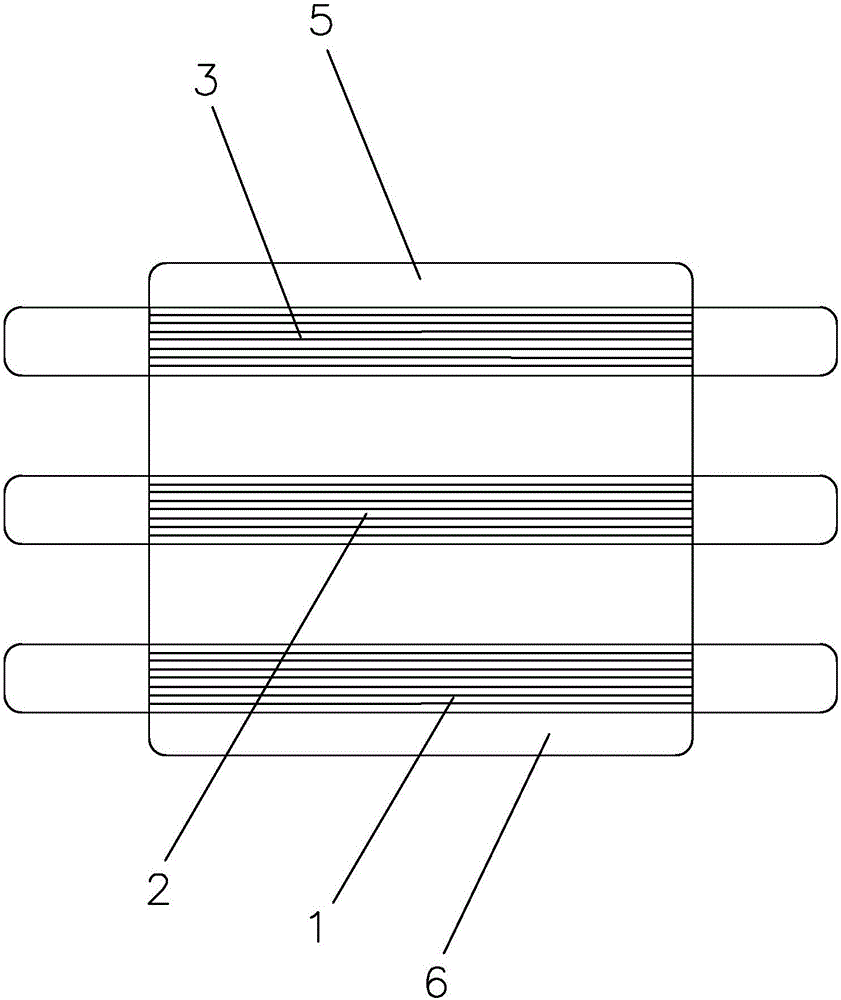

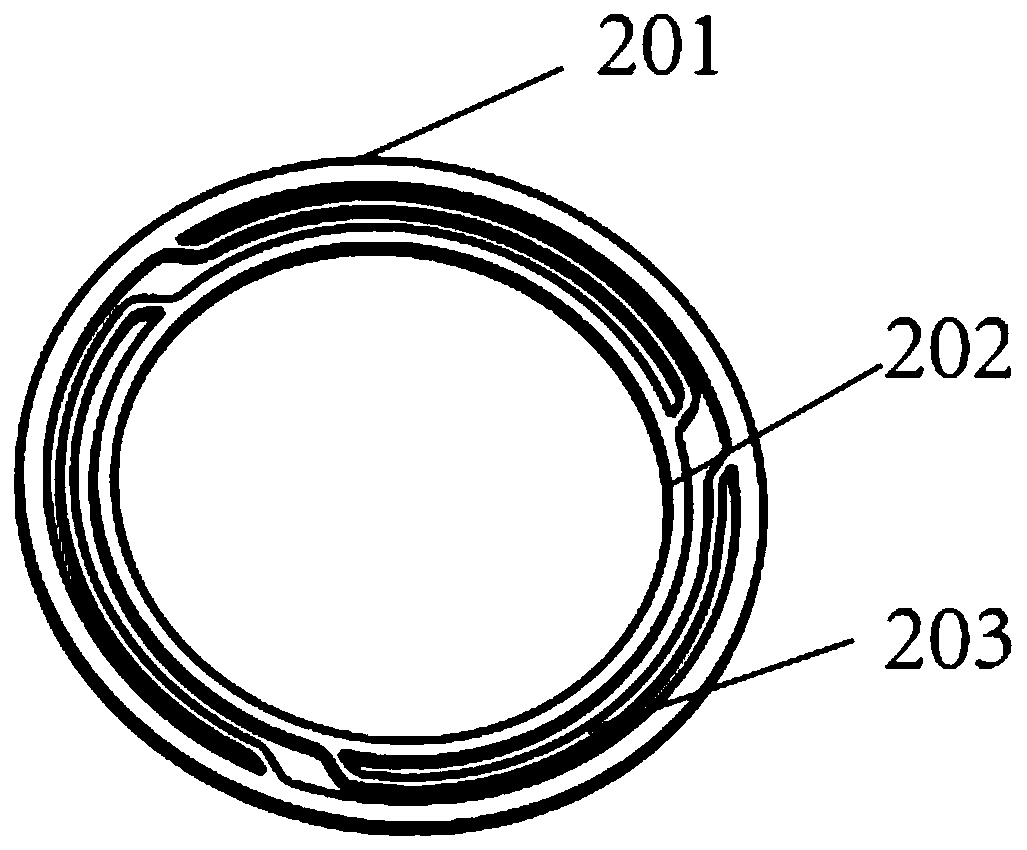

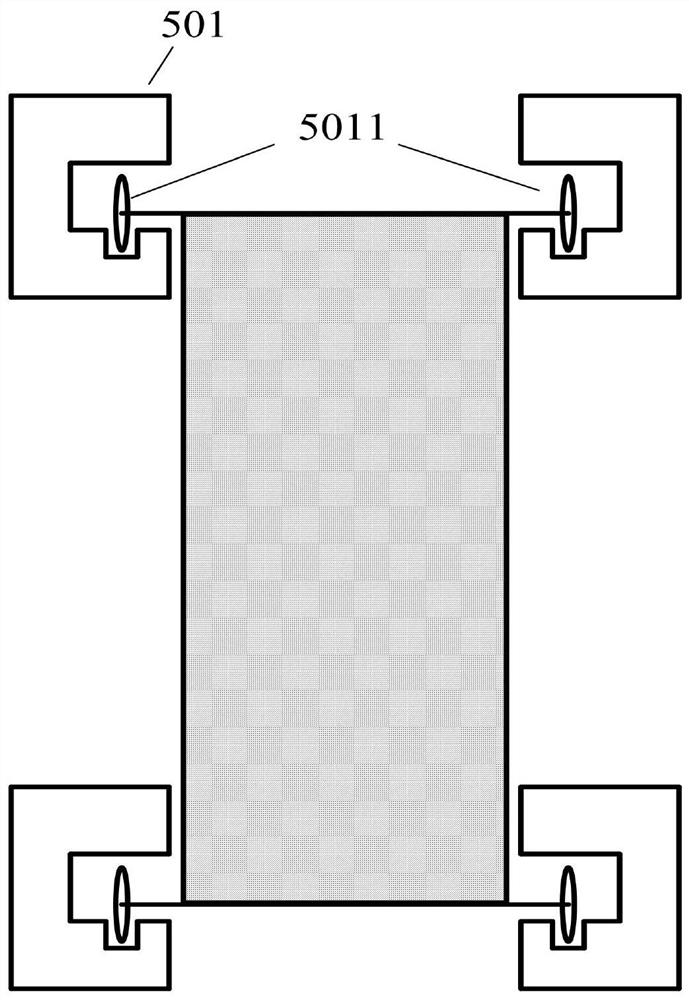

Overlaid insulating flexible busbar

InactiveCN105741911AMeet vibration requirementsEasy to assemblePlastic/resin/waxes insulatorsPower cablesCopper foilDrive motor

The laminated insulated flexible bus bar includes at least three layers of flexible connection copper bars, and fixed connection parts are provided at both ends of the flexible connection copper bars, and the soft connection copper bars and fixed connection parts are made of T2 pure copper, and the fixed connection parts are located on At both ends of the laminated insulated flexible bus bar, the soft connection copper bar is arranged in the middle of the laminated insulated flexible bus bar, and the two ends of the soft connection copper bar are respectively connected to the inner side of the fixed connection part; the soft connection copper bar includes multi-layer laminated together Copper foil layer, the top and bottom surfaces of the laminated multilayer copper foil layer are respectively fixed with an upper insulating layer and a lower insulating layer, and the two ends of the multilayer copper foil layer are welded to each other by polymer diffusion welding or ultrasonic welding. The inner ends of the two fixed connection parts. This bus bar can be connected in different orientations, different heights, different planes and multiple orientations, and has good vibration resistance and firm connection, such as being used for the non-stop vibration during the operation of the electric vehicle, between the battery pack, the drive motor and the control It will not cause the connection part of the end to loosen or fall off between the units.

Owner:SUZHOU CURRENT POWER TECH CO LTD

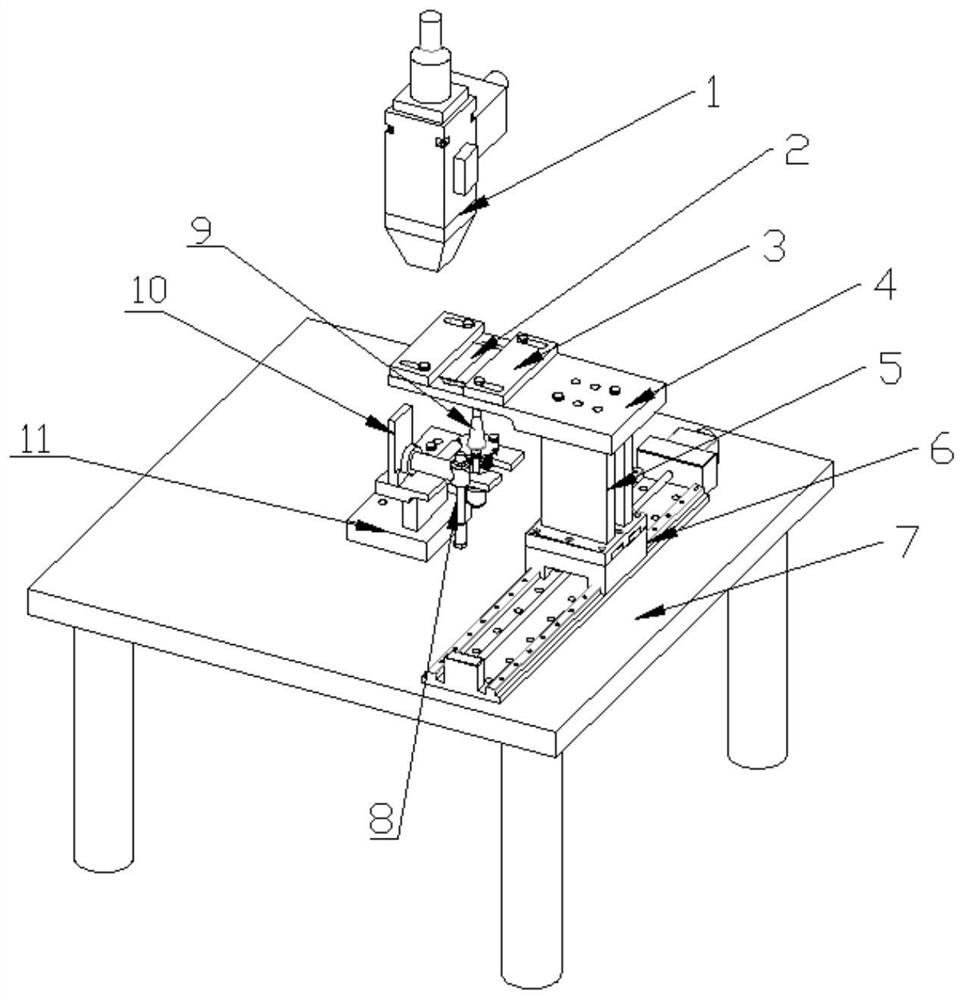

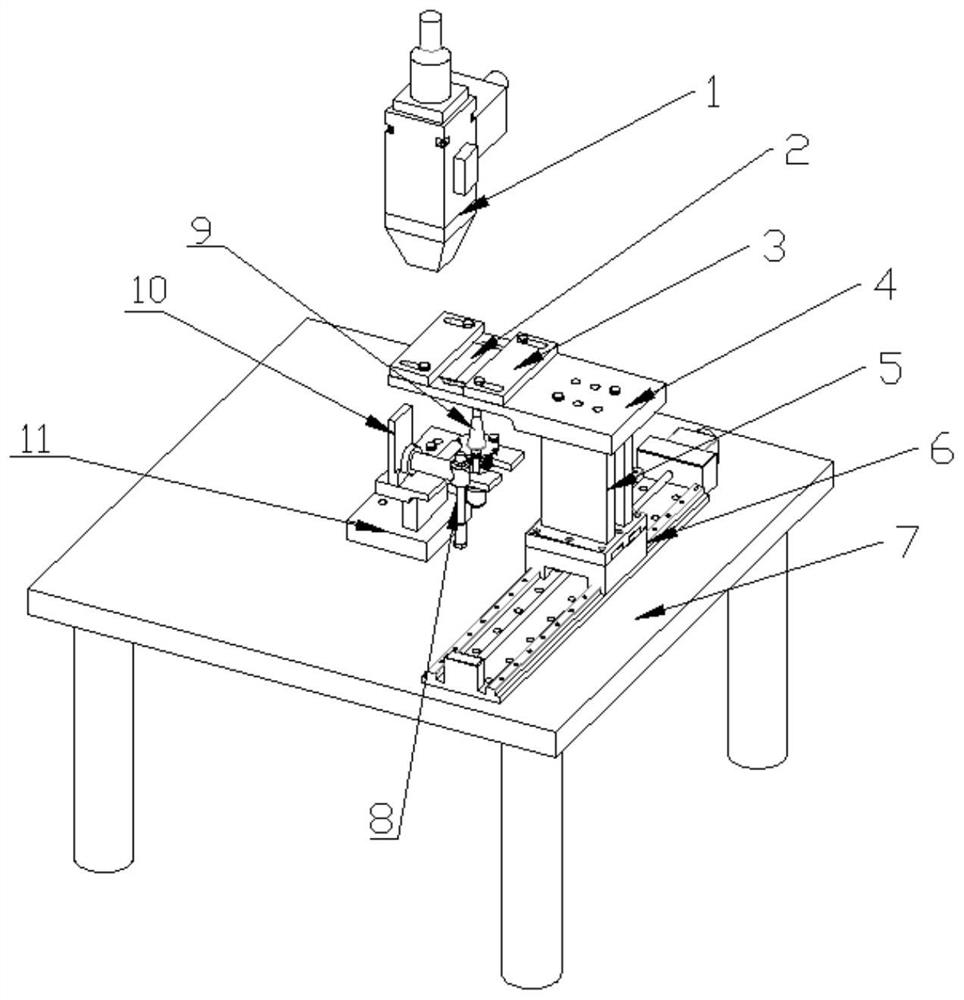

Method for inhibiting laser welding deformation

InactiveCN112475608ARealize researchImplementing Systematic ReviewsMechanical vibrations separationLaser beam welding apparatusUltrasonic vibrationHeat sink

The invention provides a method for inhibiting laser welding deformation, which comprises the step of using a device for inhibiting laser welding deformation. The device comprises a laser welding headfor welding, a sample clamp used for clamping a sample to be welded, a moving structure, a heat sink structure used for cooling a weld joint subjected to laser welding, and an ultrasonic vibration structure used for making contact with the surface of the sample to be welded. The method is characterized in that in the welding process, the moving structure bears the sample clamp and the sample to move, and the laser welding head, the heat sink structure and the ultrasonic vibration structure are all fixed; or the moving structure bears the laser welding head, the heat sink structure and the ultrasonic vibration structure to move, and the sample clamp and the sample are fixed. The method for inhibiting laser welding deformation provided by the invention can effectively inhibit the deformation of the laser welding sample.

Owner:HUNAN UNIV

Gradient thermal insulating layer and preparation method and preparation device thereof

ActiveCN107160748ASatisfy machining accuracy and package requirementsApplicable to practical applicationLamination ancillary operationsThermal insulationHigh concentrationAdhesive

The invention relates to a gradient thermal insulating layer and a preparation method and a preparation device thereof. The preparation method comprises the following steps: cutting two or more pieces of a heat insulating material according to the size of the internal surface of a to-be-heat-insulated workpiece; smearing an adhesive to the internal surface of the workpiece, bonding the cut heat insulating material on the internal surface of the workpiece in sequence, and bonding two adjacent layers of the heat insulating material; spraying steeping liquid of two or more different concentrations on the surface of the heat insulating material; and drying to obtain the gradient thermal insulating layer, wherein the heat insulating material is flexible porous heat insulating material, the steeping liquid has hardening characteristic after drying, and the spraying sequence for the steeping liquid of different concentrations is from high concentration to low concentration. The invention also provides a device for preparing the gradient thermal insulating layer. The gradient thermal insulating layer has gradually changed hardness gradient, which is more suitable for practical applications.

Owner:CHINA BUILDING MATERIALS ACAD

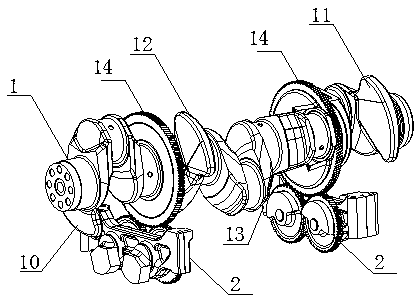

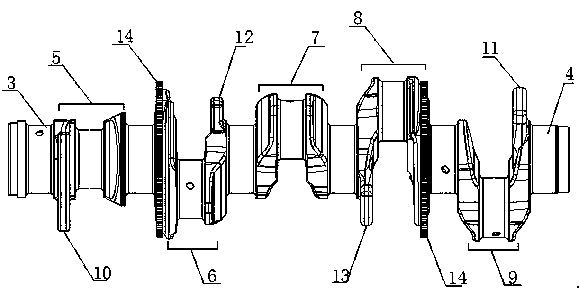

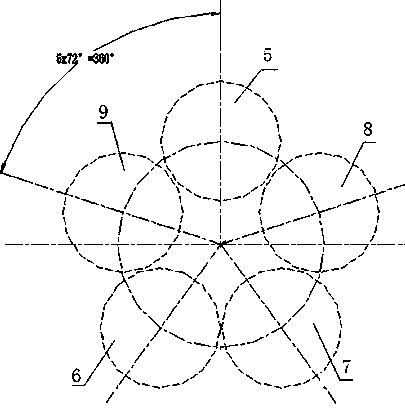

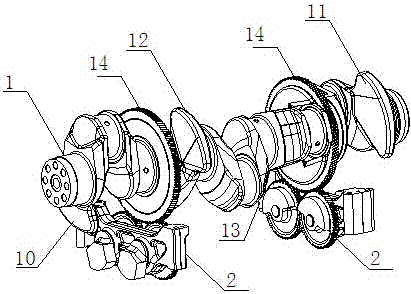

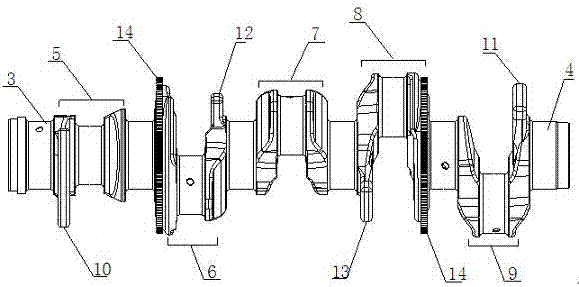

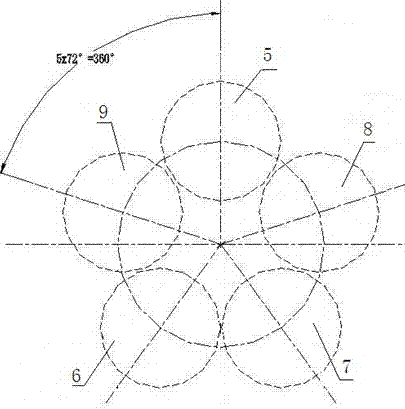

Five-cylinder diesel engine crankshaft balance system

ActiveCN105508502AExpand applications and developMeet vibration requirementsInertia force compensationEngineeringDiesel engine

The invention relates to a five-cylinder diesel engine crankshaft balance system which comprises a crankshaft, balance weights and balance mechanisms, wherein the crankshaft comprises a free end, a power output end and bell cranks, which are sequentially a first bell crank, a second bell crank, a third bell crank, a fourth bell crank and a fifth bell crank along the free end towards the power output end. The five-cylinder diesel engine crankshaft balance system is characterized in that a crank of the first bell crank is provided with the balance weight I; a crank of the fifth bell crank is provided with the balance weight II; a crank in the bell crank adjacent to the power output end is provided with the balance weight III; a crank in the fourth bell crank adjacent to the free end is provided with the balance weight IV; the second bell crank is provided with a first drive tooth ring for driving the first balance mechanism; and the fourth bell crank is provided with a second drive tooth ring for driving the second balance mechanism. The five-cylinder diesel engine crankshaft balance system effectively solves the problem of imbalance among the rotary inertia torque, first-order reciprocating inertia couple and second-order reciprocating inertia couple in the five-cylinder diesel engine, so that the engine can satisfy the vibration requirements, thereby promoting the application and development of the five-cylinder diesel engine.

Owner:SINOTRUK JINAN FUQIANG POWER

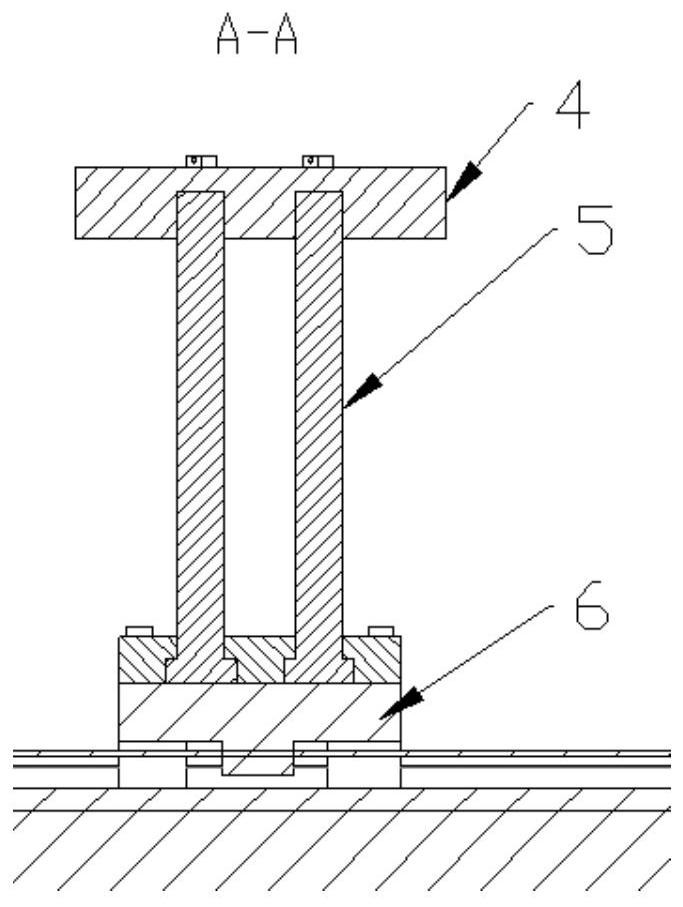

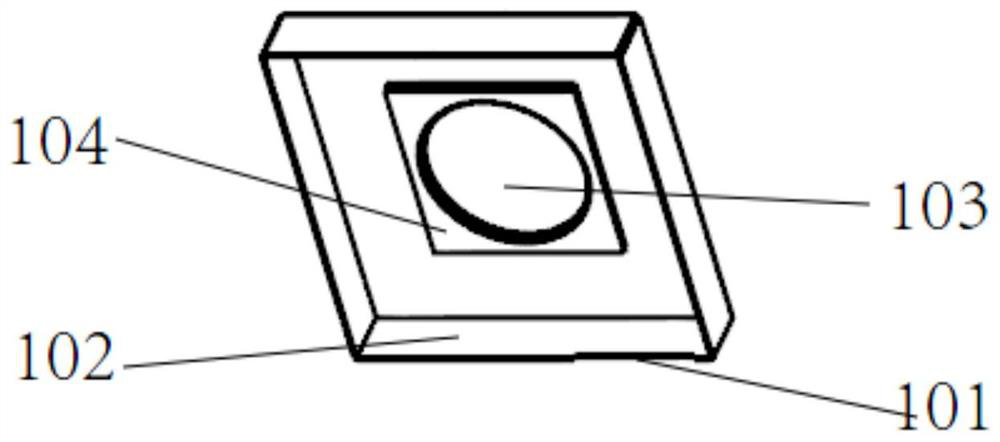

Novel motor controller main shell structure

PendingCN107734941AReduce temperature riseImprove power densityHermetically-sealed casingsCooling/ventilation/heating modificationsDie castingMotor controller

The invention discloses a novel motor controller main shell structure. The novel motor controller main shell structure comprises a controller shell, the middle of the controller shell is divided intoa front side for placing a controller and a reverse side for placing a capacitor core body, a cooling water channel which is formed through integrated die-casting is formed in the front side, a capacitor shell cavity is precast in the reverse side, the capacitor core body and a wire outlet terminal of the capacitor core body are placed inside the capacitor shell cavity, and a cover plate is fixedto the portion, at the outer side of the capacitor core body, of the controller shell through bolts and sealant. By means of the novel motor controller main shell structure, through injection molding,the capacitor core is fixed to the controller shell, the temperature rise of a capacitor is effectively lowered, the capacitor capacity is effectively increased, and the power density of the whole controller is increased. By the adoption of the structure, the IGBT cooling water channel is integrated, the space utilization rate is increased, and then the power density of the whole controller is increased; through the shared shell of the capacitor shell and the controller shell, a capacitor inject molding shell is omitted, and the controller cost is lowered at the same time.

Owner:HEFEI JUYI POWER SYST CO LTD

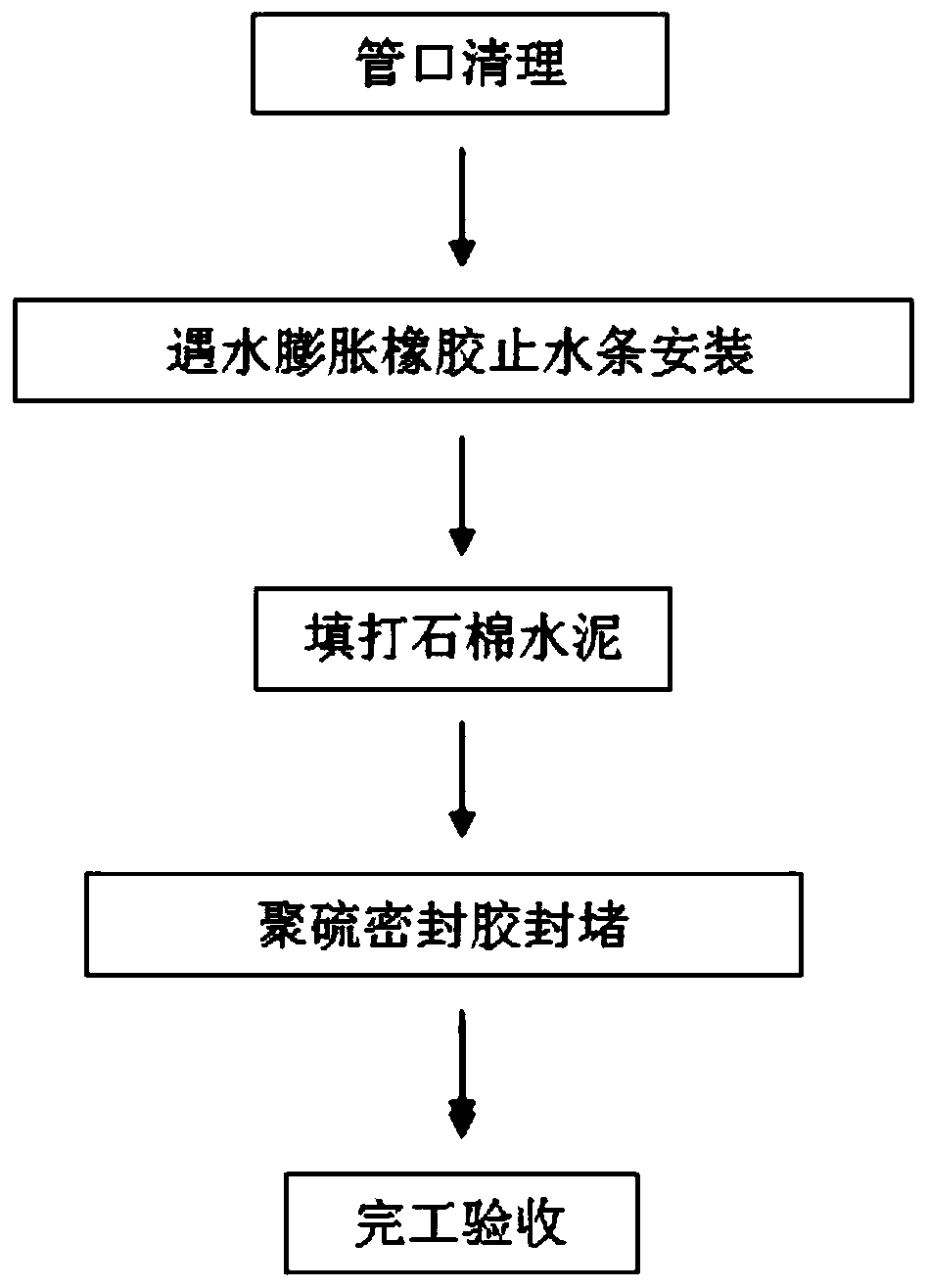

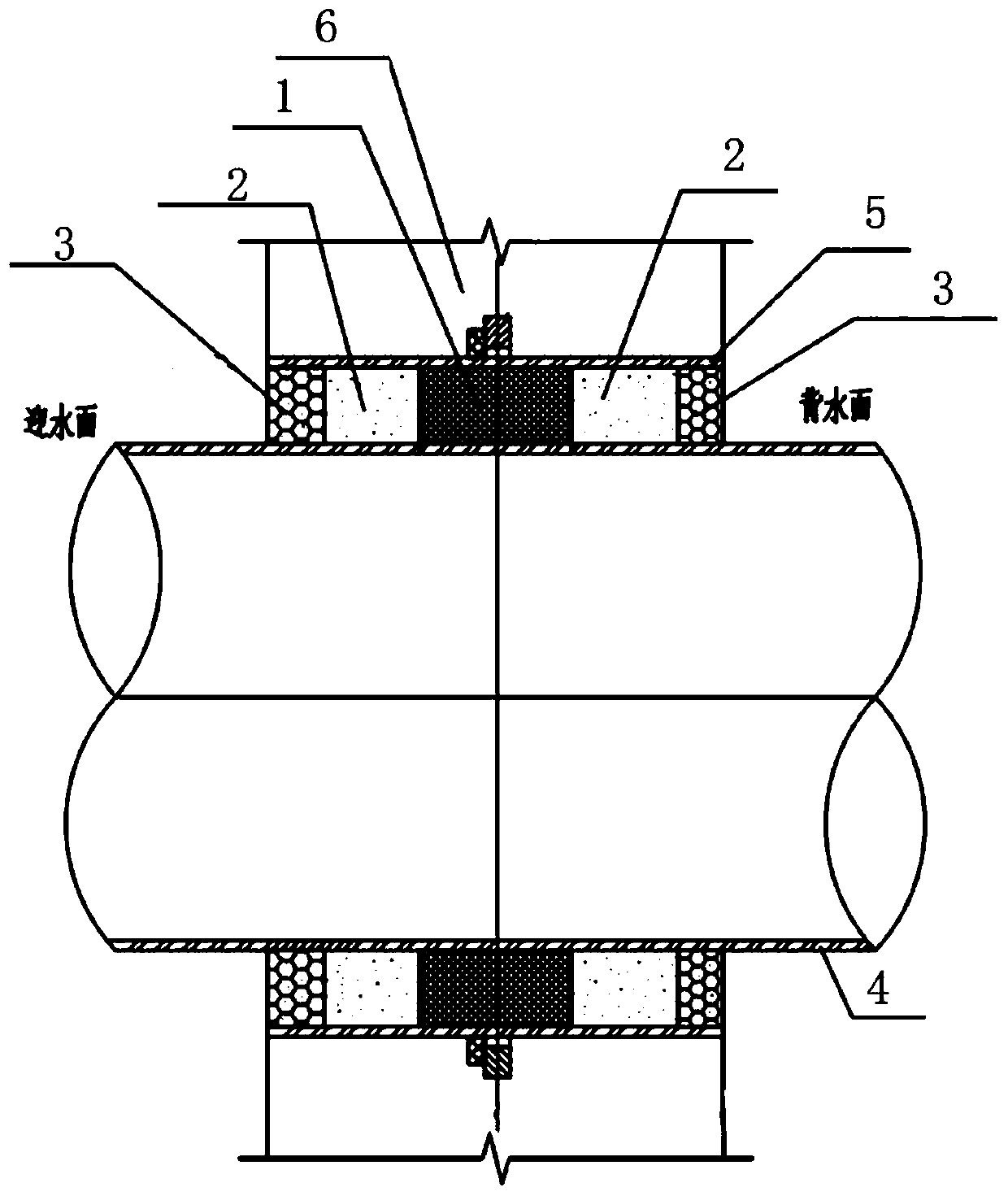

Pipeline culvert filling method

InactiveCN110285266ASolve the phenomenon of repeated leakageProtect environmentPipesEngineeringSealant

The invention belongs to the technical field of pipeline culvert filling water prevention and seepage prevention, and particularly relates to a pipeline culvert filling method. The pipeline culvert filling method comprises the procedures of pipe opening cleaning, mounting of a water-swelling sealing rod, filling and hitting of asbestos cement and polysulfide sealant plugging. The water-swelling sealing rod is hit to the middle of a circular seam between a preburied sleeve and a formal pipeline, and the total length of the water-swelling sealing rod mounted between the preburied sleeve and the formal pipeline in a hit manner is not smaller than 60 mm. The space, on the two sides of the water-swelling sealing rod, of the circular seam is filled with asbestos cement filler, the circular seam of a certain length is preserved to be filled with a polysulfide sealant after an upstream face and a downstream face are filled with the asbestos cement filler, and after the polysulfide sealant is used for plugging and acceptance is achieved, inundating or backfilling starting work can be carried out. The method can be used for culvert filling work of the clearances between the preburied sleeves and the formal pipelines of all structures, and the water prevention and seepage prevention quality is improved.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

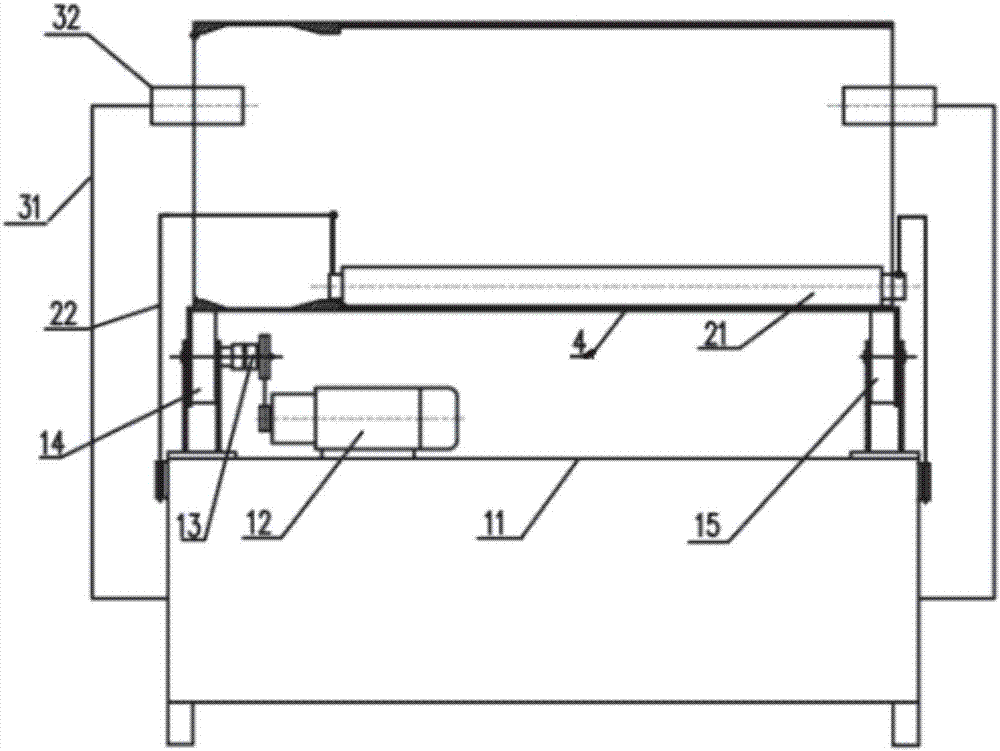

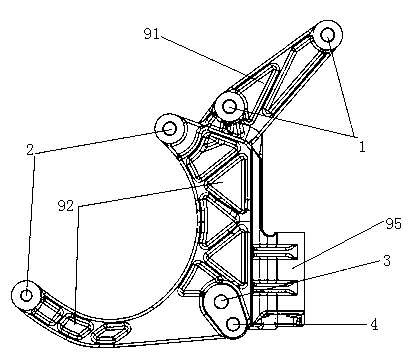

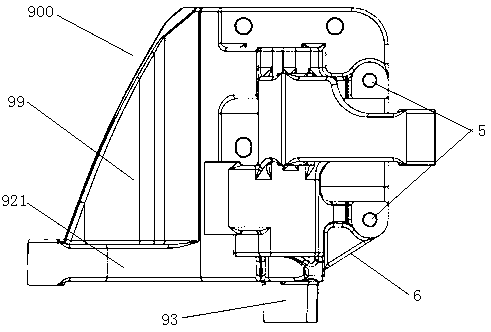

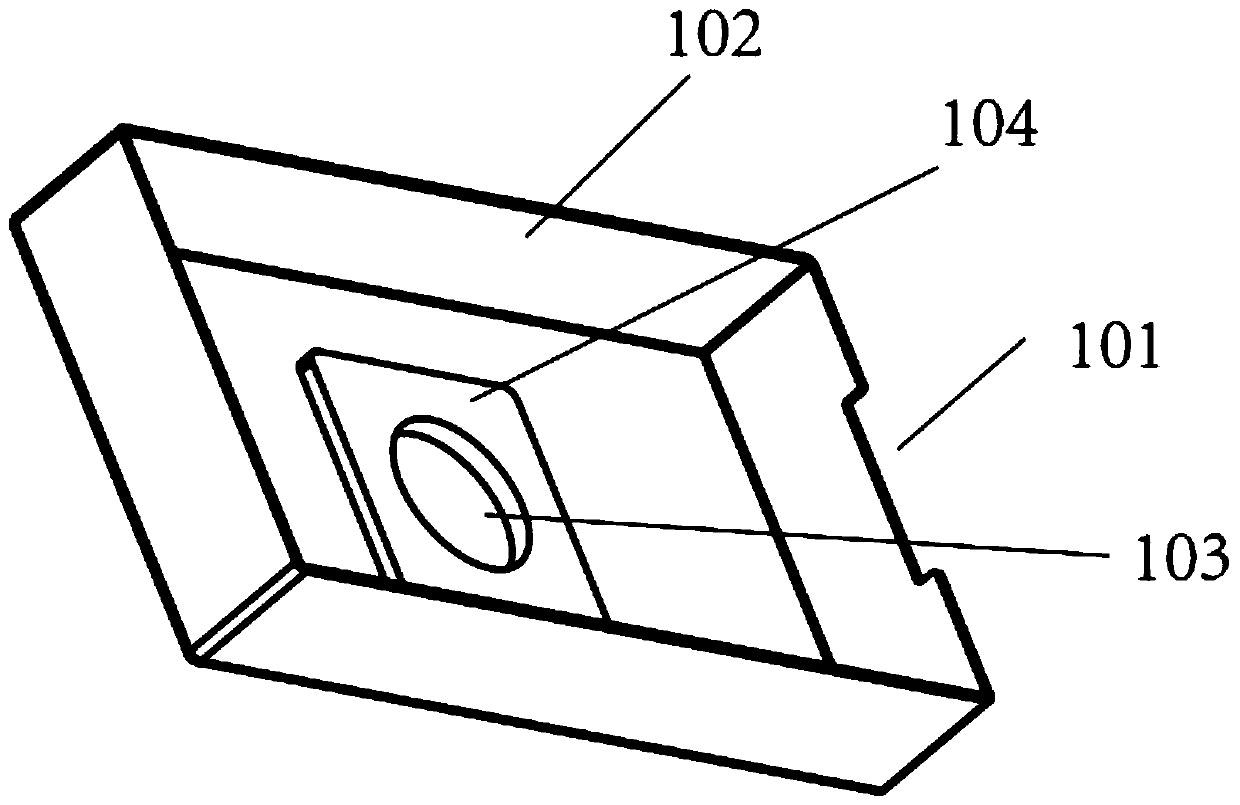

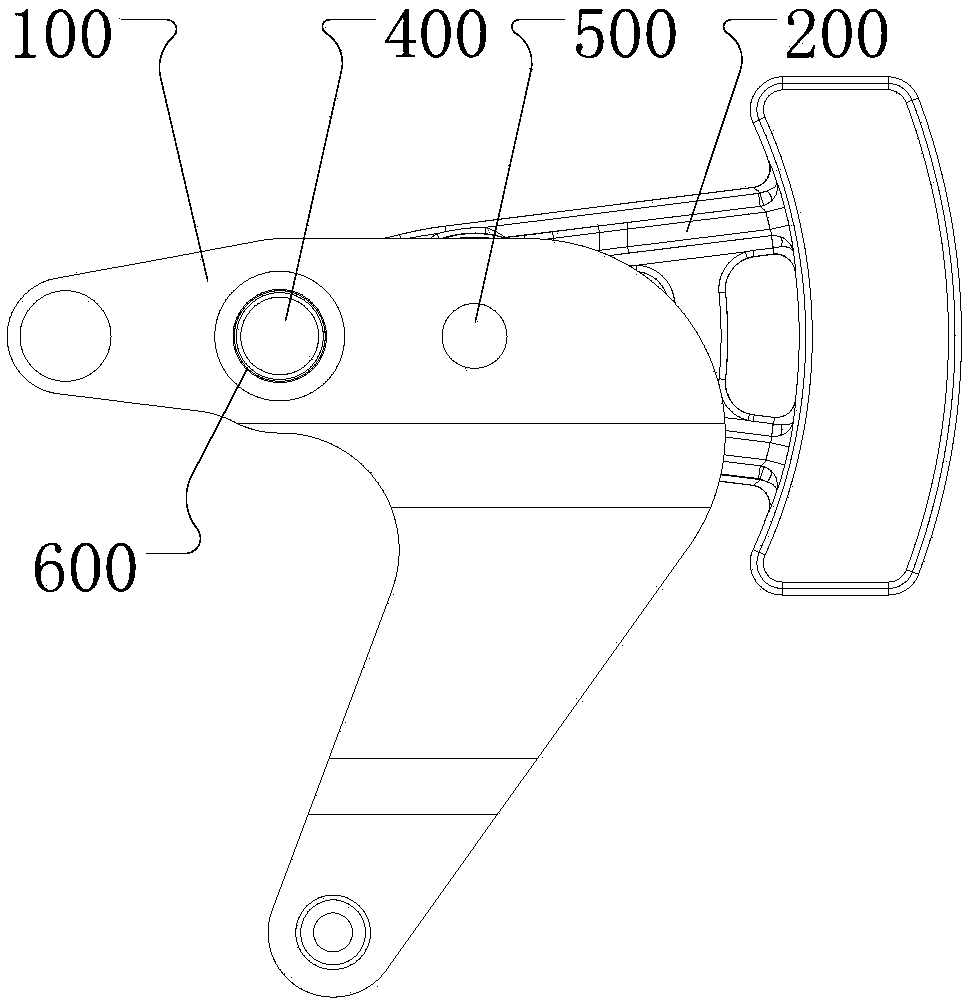

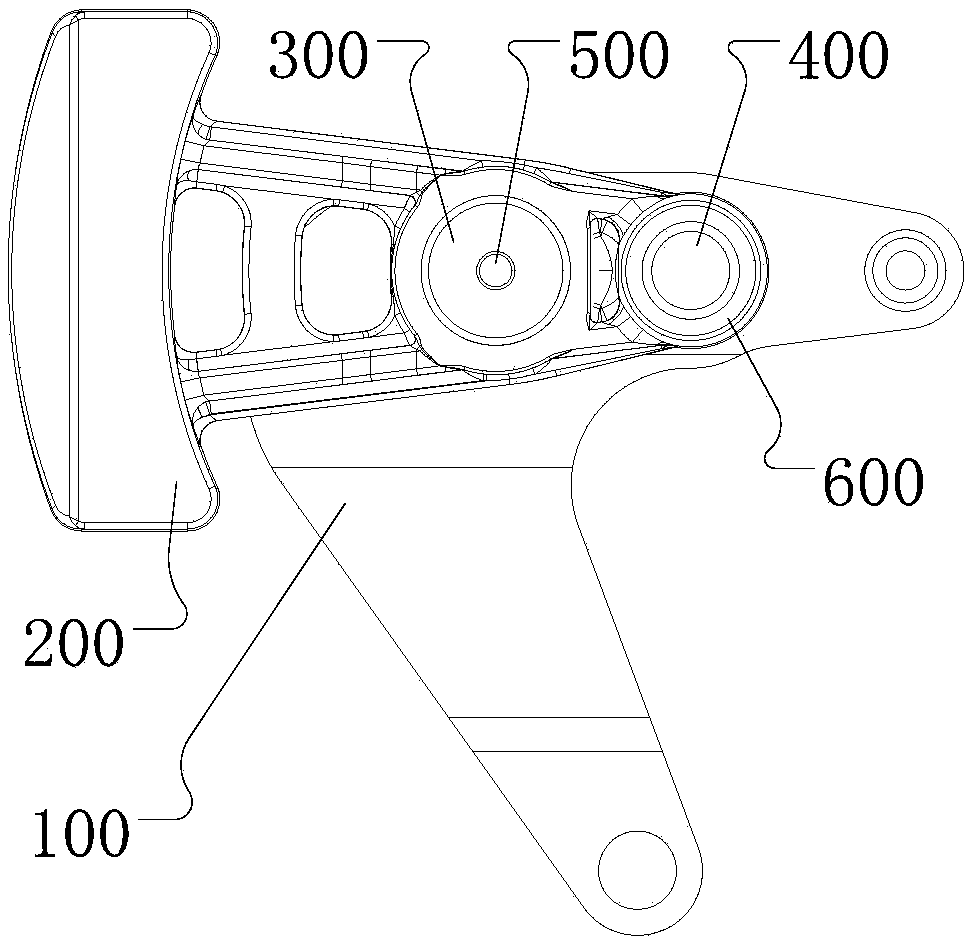

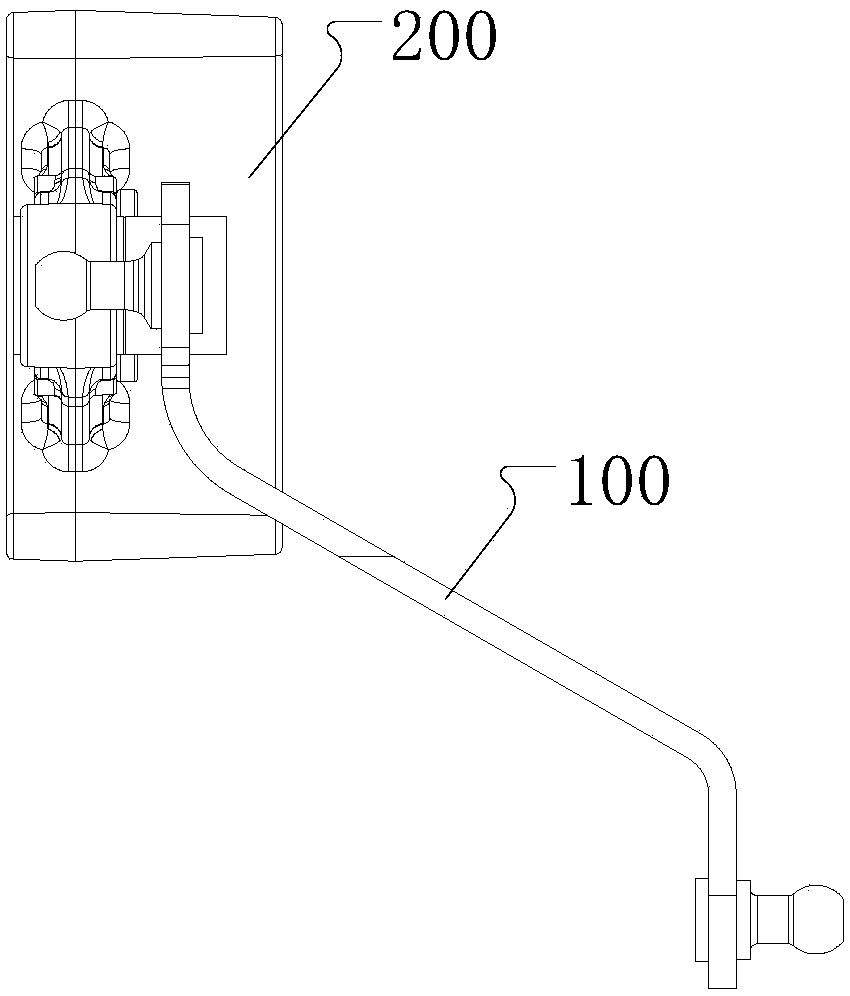

Integrated shock absorption type engine accessory bracket device

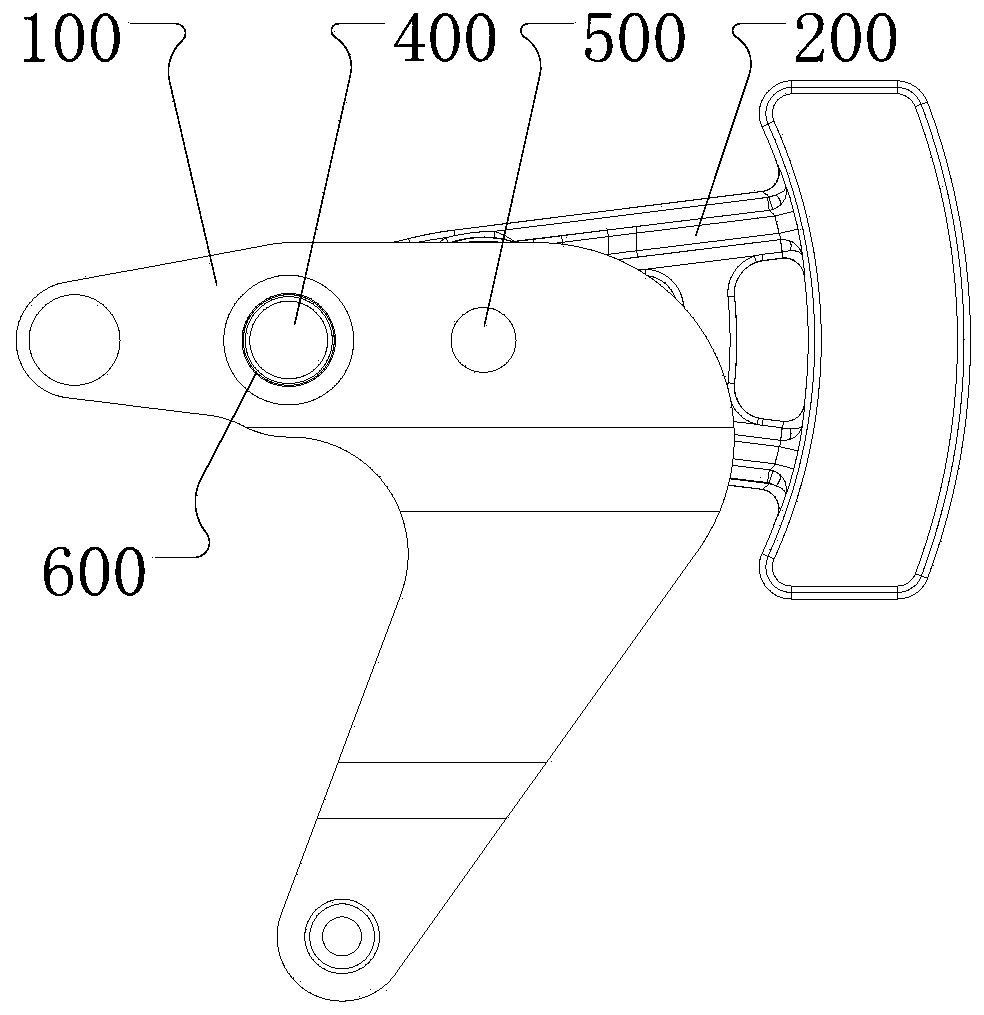

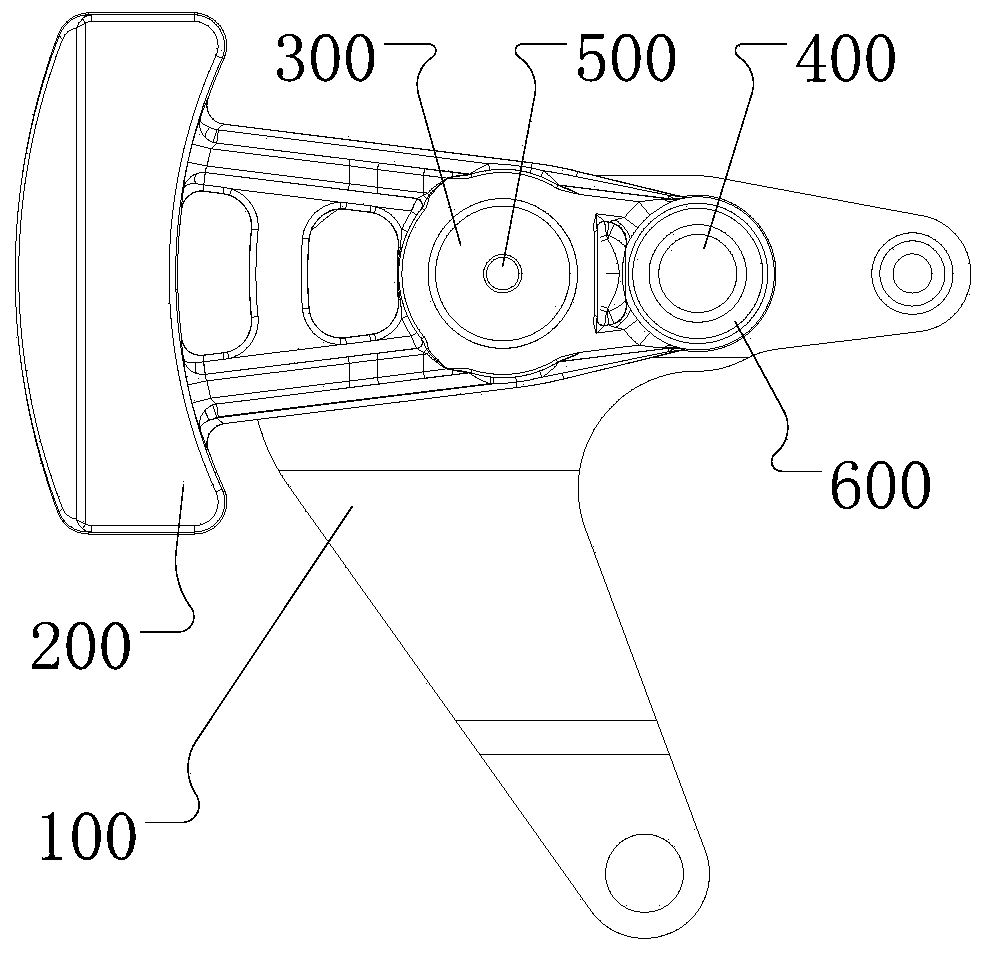

InactiveCN102913327AReduce in quantityReduce extra spaceMachines/enginesEngine componentsMachine partsWheel train

The invention discloses an integrated shock absorption type engine accessory bracket device, belongs to an engineering part working together with an engine, in particular relates to a structural member or a combined piece which is connected through a screw, a clamping hoop and the like and used for fixing machine parts. The integrated shock absorption type engine accessory bracket device comprises a bracket main body and bracket mounting holes (8), a tension wheel mounting hole (3) and generator mounting holes (5) which are connected with the engine, wherein the tension wheel mounting hole (3) and a tension wheel positioning hole (4) are formed in a boss (93) on the left side face (close to the bottom) of the bracket main body; the generator mounting holes are formed in a U-shaped boss (95); the U-shaped boss is arranged at the bottom of the main body and is close to the right side; and the width of the U-shaped boss is smaller than that of the bottom of the bracket main body. The integrated shock absorption type engine accessory bracket device is specially arranged on a specially-shaped bracket and integrates multiple accessory mounting functions; the number of brackets and an occupied space are reduced; the precision of the plane of a wheel train is improved; and the manufacturing and maintenance costs are reduced. Moreover, the belt adjustment range is expanded; mounting is simplified; torque vibration is greatly reduced; the service life of a belt is prolonged; and therefore, the application level of the engine is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

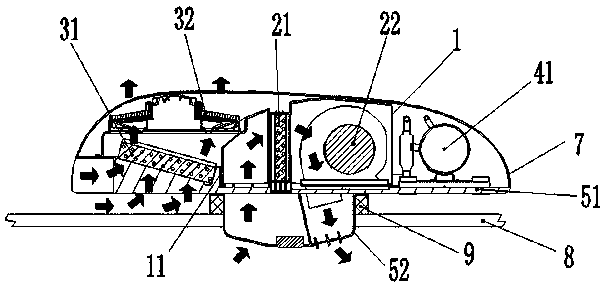

Variable-frequency parking air conditioner

PendingCN110901335AMeet vibration requirementsImprove reliabilityAir-treating devicesVehicle heating/cooling devicesIn vehicleHigh energy

The invention provides a variable-frequency parking air conditioner. The heat exchanger comprises a fan installation part, an inner side heat exchange assembly, an outer side heat exchange assembly, adriving device and a chassis assembly, the driving device is fixed on the chassis assembly; the fan installation part is positioned on one side of the driving device and is fixedly connected with thechassis assembly; a partition plate used for dividing the draught fan installation part into two containing spaces is arranged in the draught fan installation part. The inner side heat exchange assembly and the outer side heat exchange assembly are located on the two sides of the partition plate correspondingly and do not exchange airflow. The driving device communicates with the inner side heatexchange assembly and the outer side heat exchange assembly through pipeline connecting parts. The variable-frequency parking air conditioner has the advantages that extra pipeline connection during installation can be avoided, reliability is high, vehicle-mounted vibration requirements can be met, low energy consumption, high energy efficiency and high energy-saving effect are achieved, and running time of the parking air conditioner is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

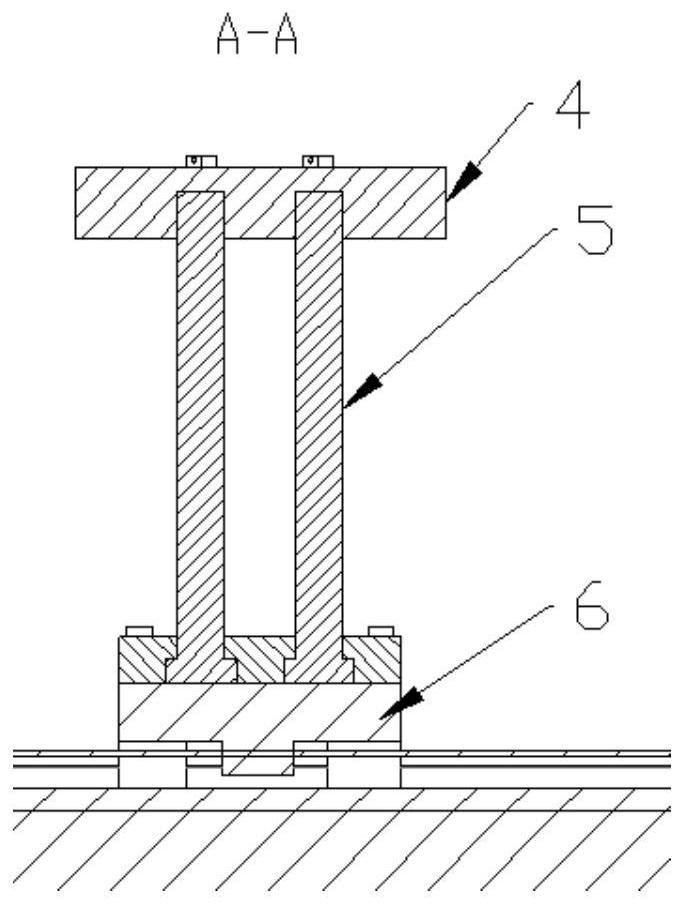

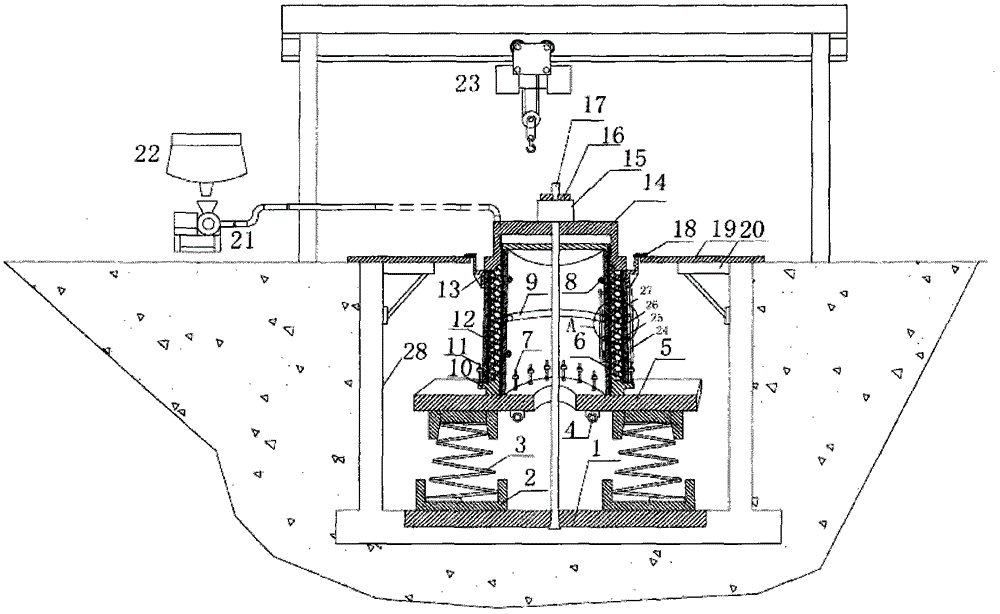

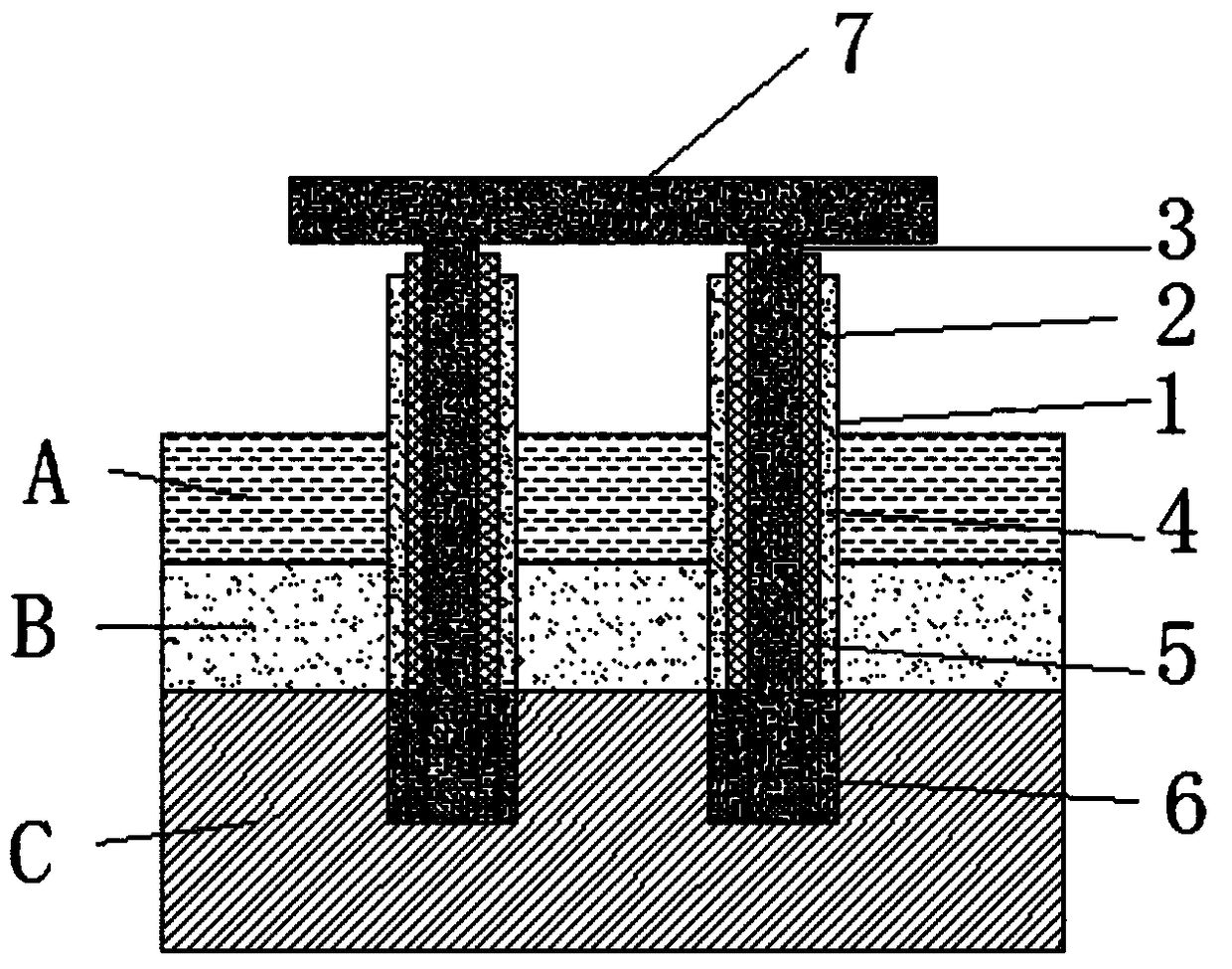

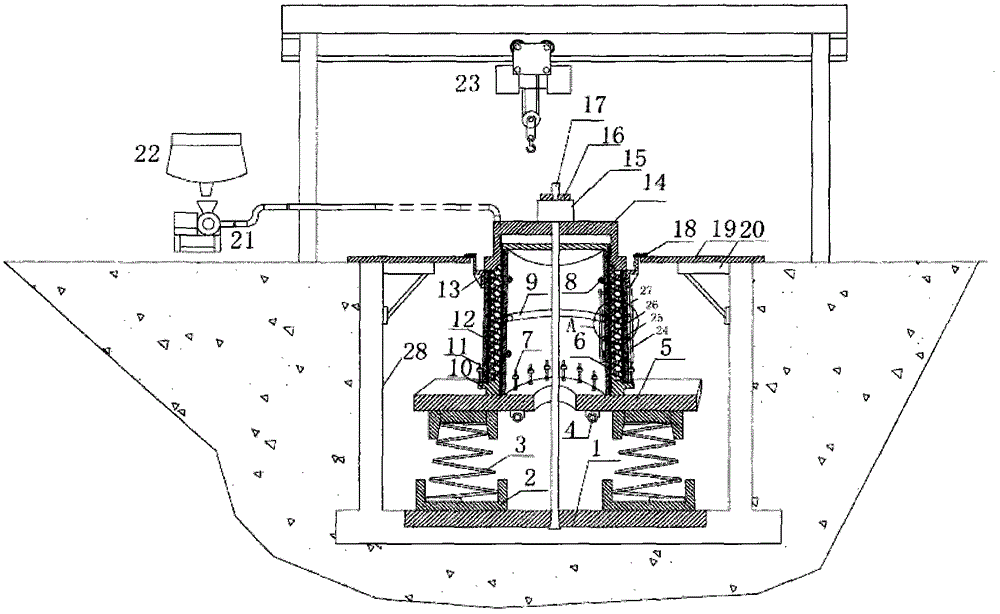

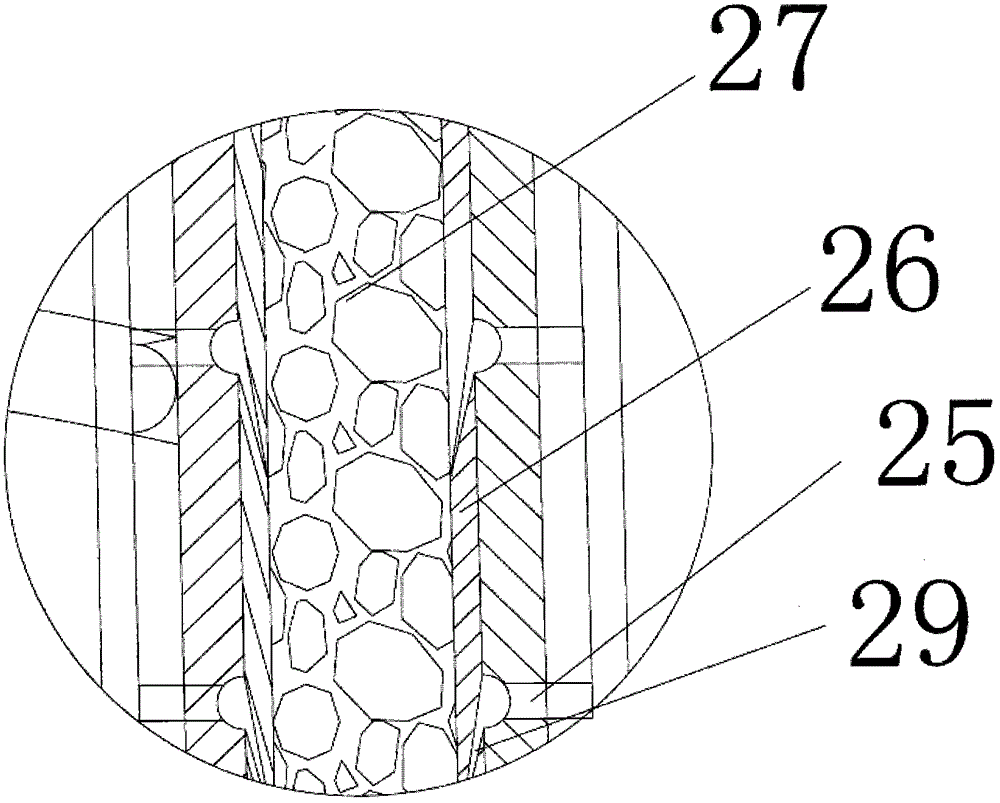

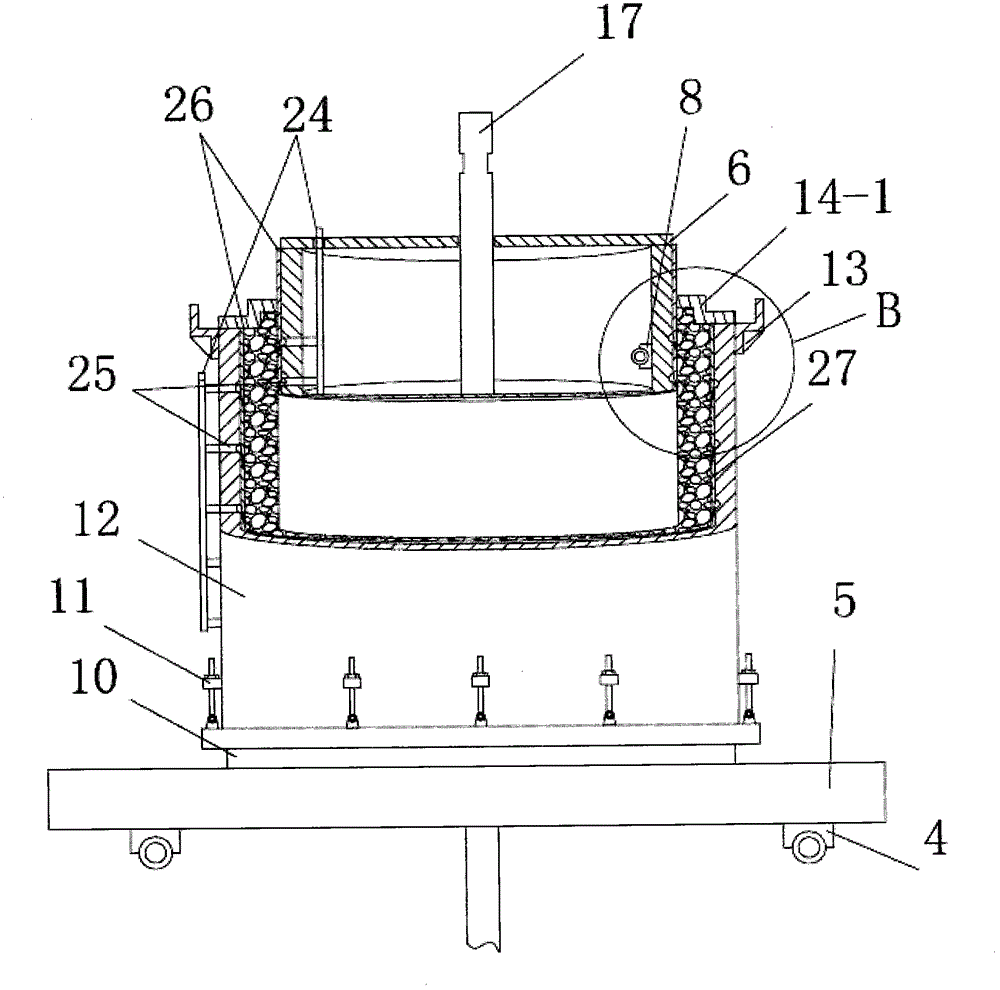

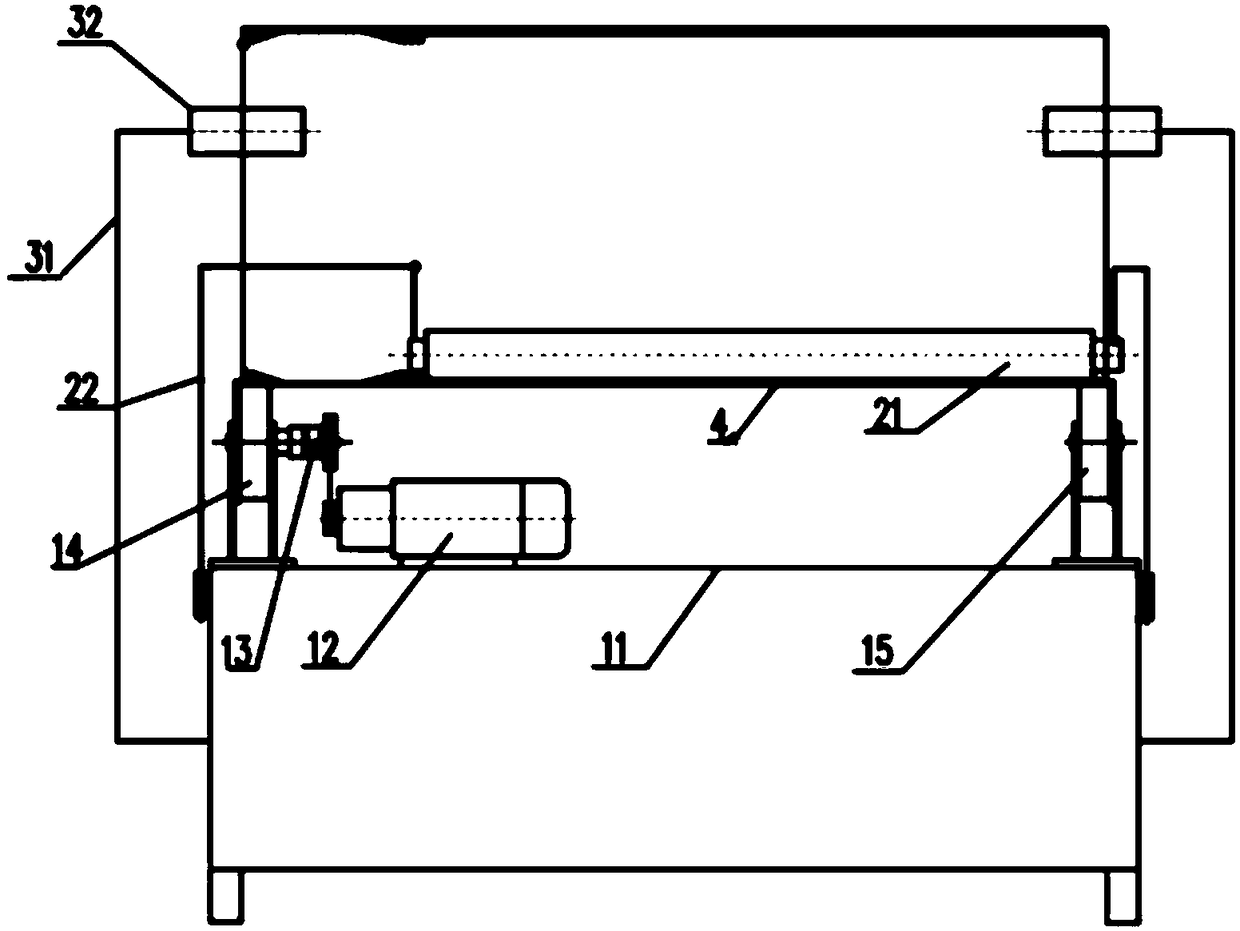

System for producing reinforced concrete pipes through double-vibration source extrusion demoulding

InactiveCN104308986AEasy to operateThere will be no accidents falling into the pipe making equipmentCeramic shaping apparatusEnvironmental resistanceReinforced concrete

The invention discloses a system for producing reinforced concrete pipes through double-vibration source extrusion demoulding. The system comprises a foundation pit, a material conveying device, a lifting device, a vibrating table, an internal circle mold vibrating tube, an external circle mold tube structure and a hydraulic extrusion device, wherein the material conveying device and the lifting device are arranged outside the foundation pit; the vibrating table, the internal mold vibrating tube, the external mold tube structure and the hydraulic extrusion device are arranged in the foundation pit; a baffle support structure covering the foundation pit is arranged above the external circle mold tube structure. Compared with current systems adopting a 'centrifugal manufacturing method', an 'overhang roll manufacturing method' and a 'mandrel vibrating method', during the process of producing the reinforced concrete pipes through double-vibration extrusion, the system disclosed by the invention is small in used power, and is capable of saving energy to a greater degree; moreover, the pipe walls of the produced reinforced concrete pipes are smooth from inside to outside; the system disclosed by the invention is high in safety, convenient in operation, high in production efficiency, convenient to maintain and environmentally friendly during a pipe producing process, and has a significant advantage in producing series large-diameter reinforced concrete pipes.

Owner:李荣耀 +3

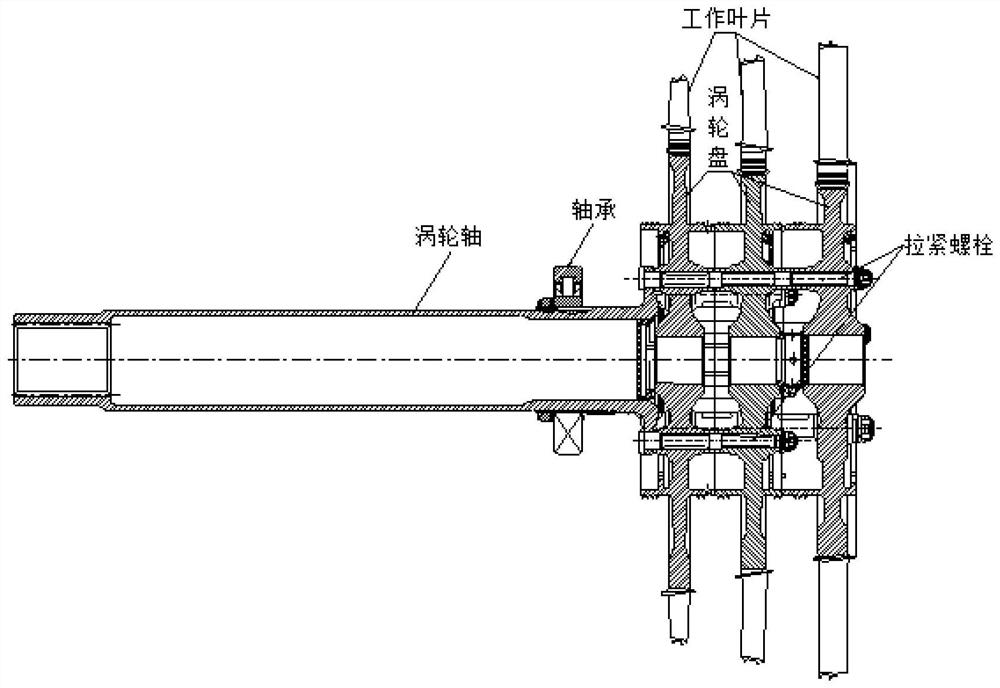

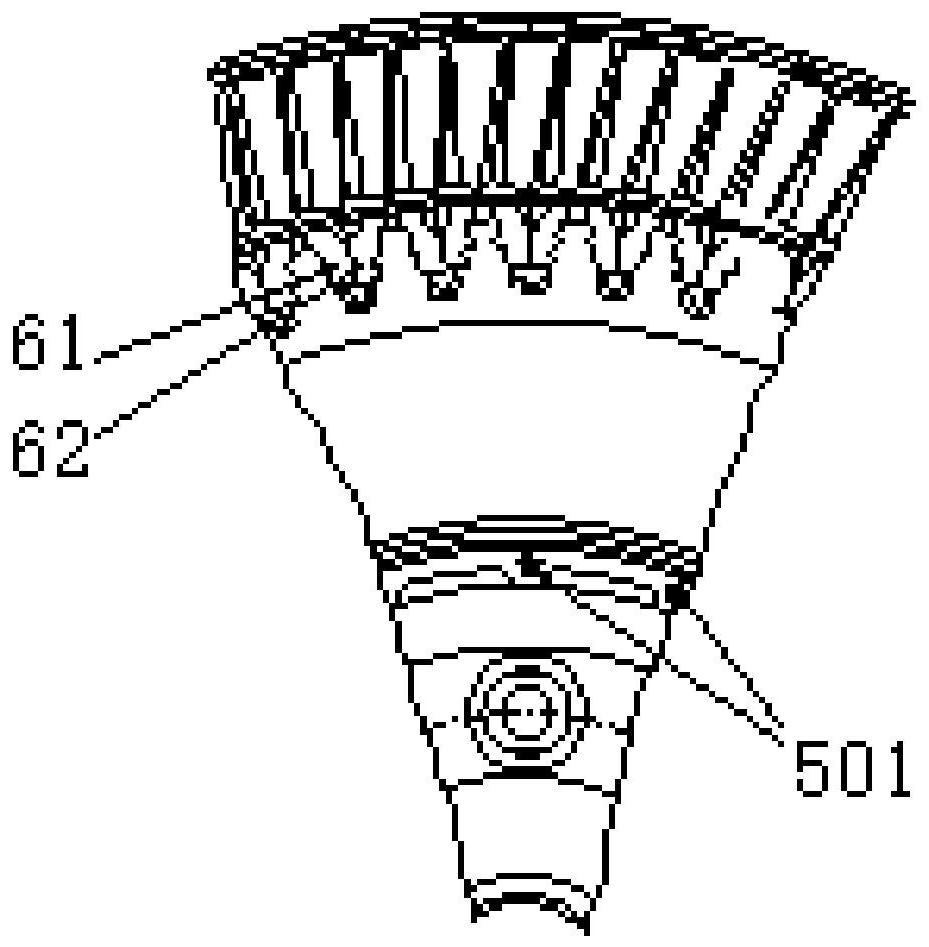

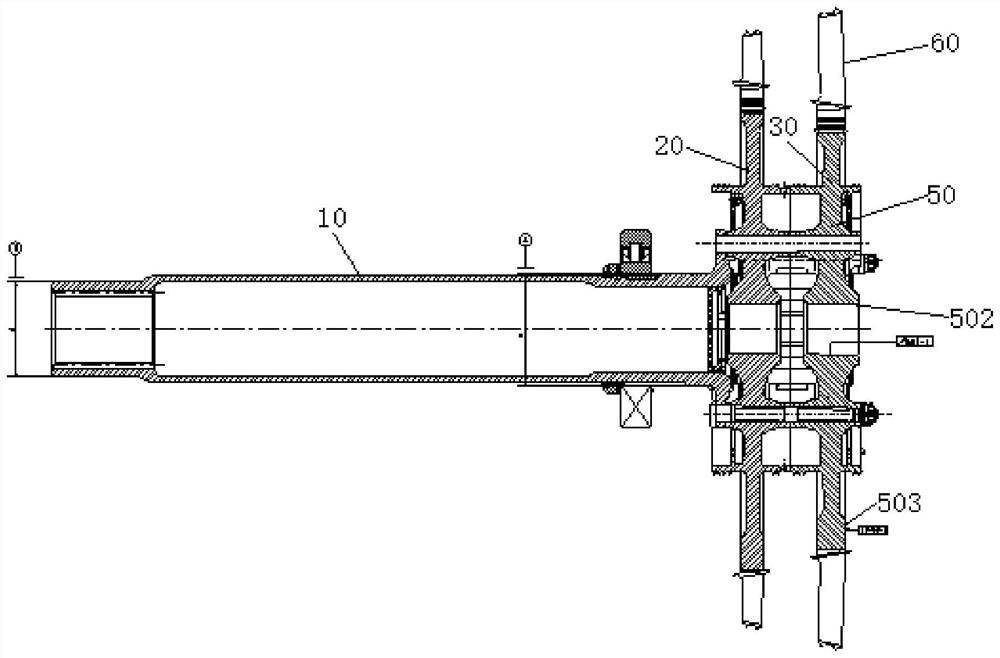

Turbine rotor assembly dynamic balance indirect measurement method

PendingCN114812938AMeet static balance requirementsMeet vibration requirementsBlade accessoriesStatic/dynamic balance measurementDynamic balanceTurbine rotor

The invention discloses a turbine rotor assembly dynamic balance indirect measurement method. The method comprises the following steps: setting the weight difference between a left blade and a right blade of any group of rotor blades and the weight difference between two groups of rotor blades on any diameter; ensuring that the dynamic unbalance amount, the radial runout amount and the end runout amount of the turbine main shaft, the turbine rotor part and the turbine rotor respectively meet the requirements, and marking the number of a rotor blade corresponding to the maximum radial runout amount of the turbine rotor part and the position of the maximum end runout amount of the turbine rotor part; it is guaranteed that the radial jump amount, the end jump amount, the rotor blade corresponding to the maximum part of the radial jump amount, the difference value between the maximum part of the end jump amount and the radial jump amount and the end jump amount in dynamic balance, the position difference of the rotor blade corresponding to the maximum part of the radial jump amount and the position difference of the maximum part of the end jump amount meet the requirements respectively during final assembly of the turbine rotor. According to the indirect measurement method, the dynamic balance of the turbine rotor can be indirectly ensured to meet the requirement during final assembly, so that the workload is small, the labor intensity of workers is low, and the working efficiency is high.

Owner:CHINA HANGFA SOUTH IND CO LTD

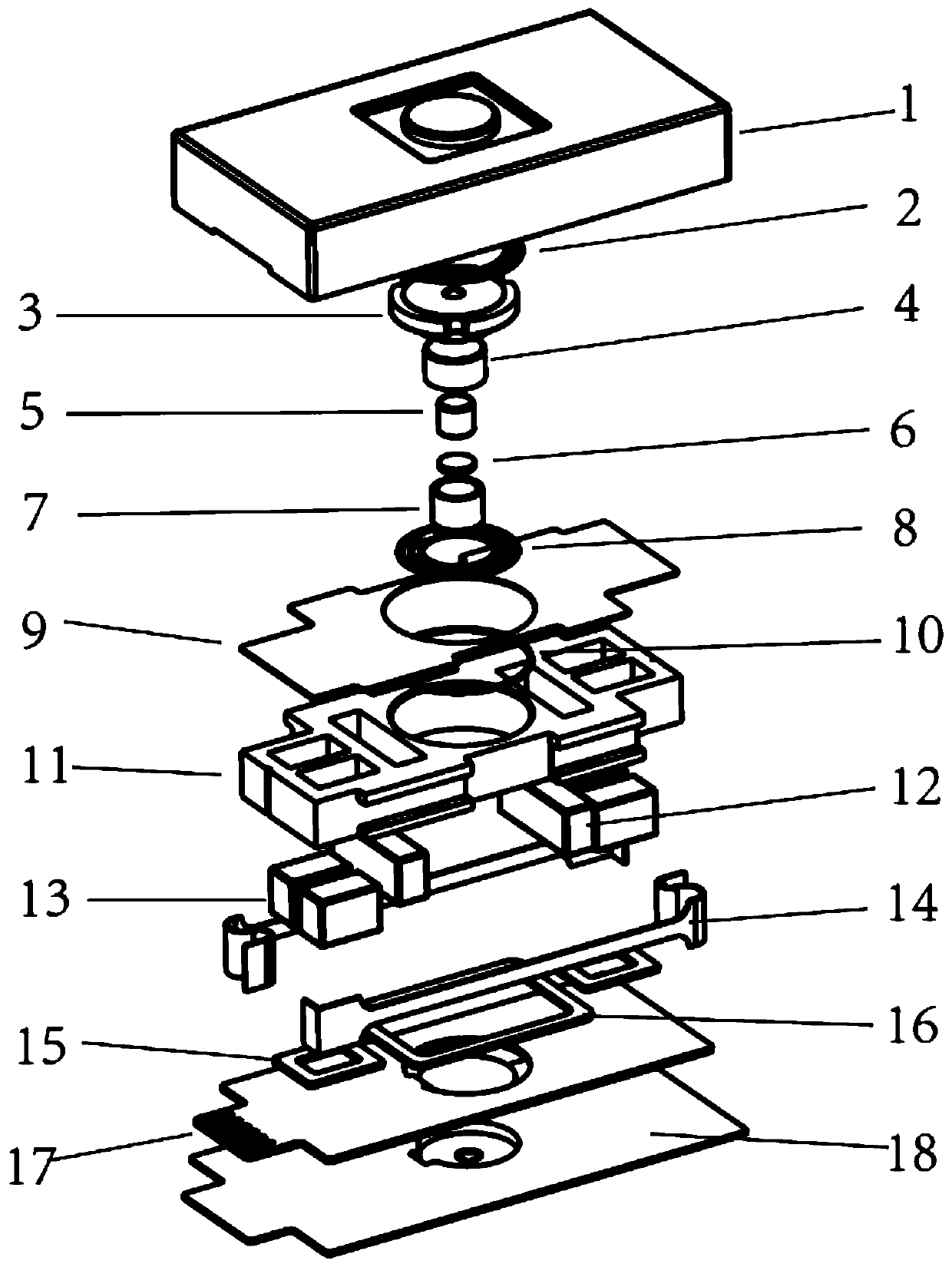

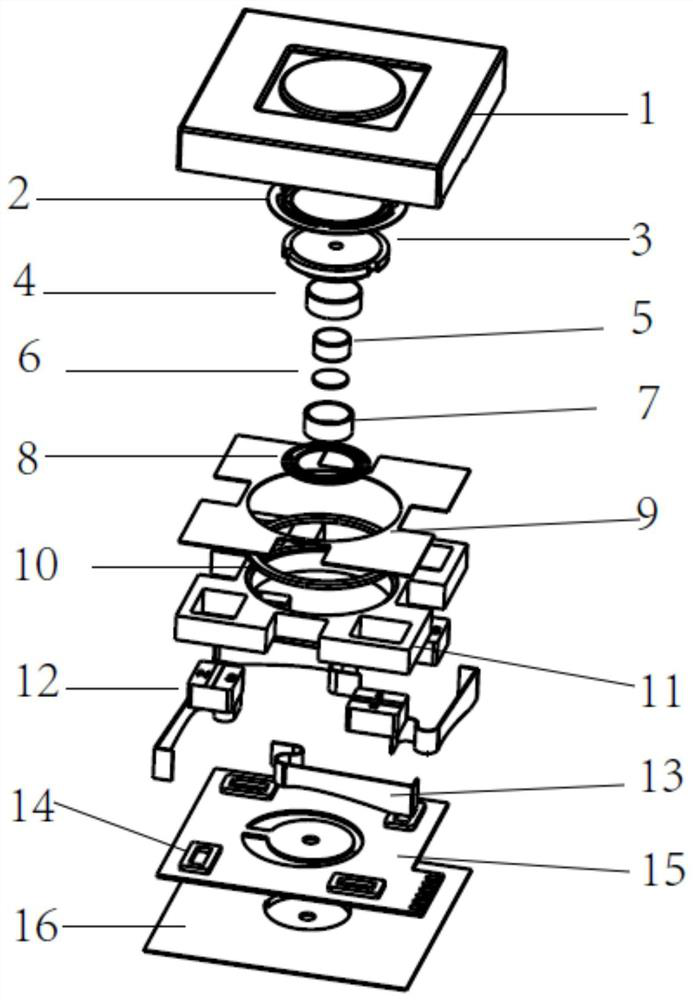

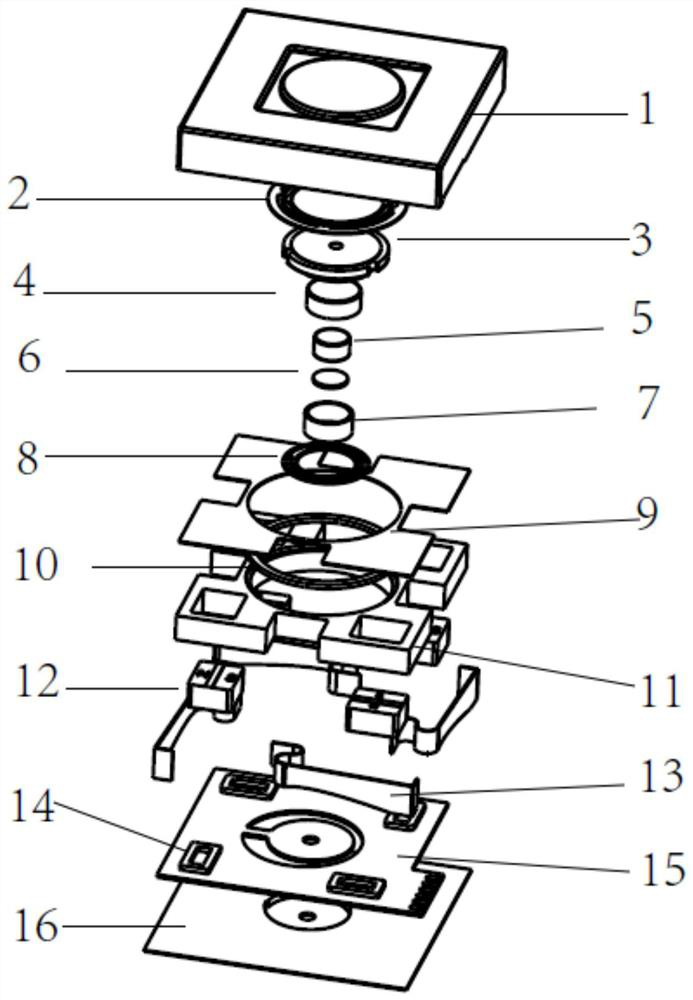

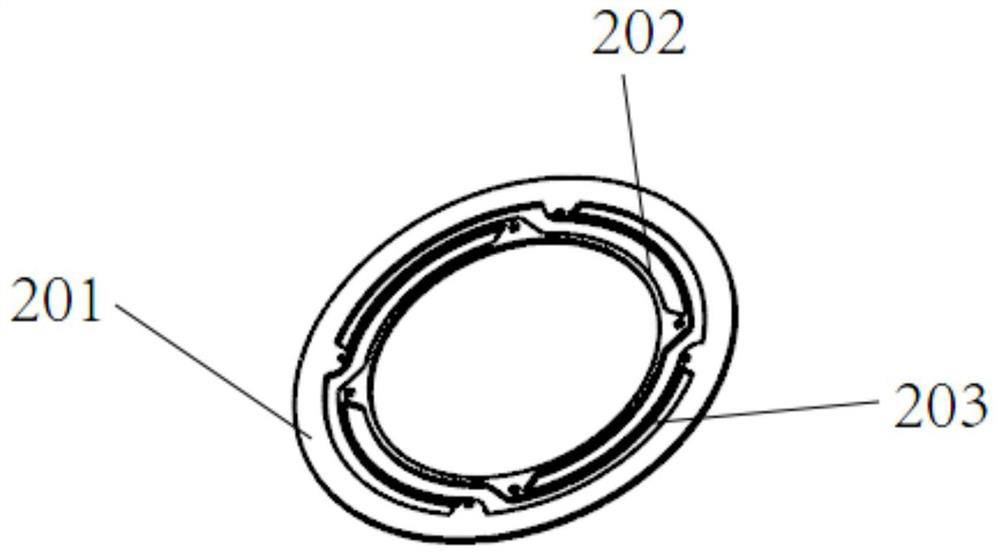

XYZ three-direction vibrator

PendingCN111293851AMeet Vibration FeedbackMeet the Vibration ExperienceDynamo-electric machinesFlexible circuitsEngineering

The invention belongs to the technical field of micro motors, and particularly discloses an XYZ three-direction vibrator, which comprises a housing, a base, a vibrator assembly and a stator assembly,and is characterized in that the housing and the base are combined to form an accommodating space. The vibrator assembly comprises an XY-direction vibration block and a Z-direction vibration block. The stator assembly comprises a coil and a flexible circuit board. The XY-direction vibration block and the Z-direction vibration block are respectively fixed and suspended in the accommodating space through elastic pieces, a round hole is formed in the middle of the XY-direction vibration block, and round holes are formed in the periphery of the Z-direction vibration block; a first magnet assemblyand a second magnet assembly are embedded in the XY-direction vibration block; the first magnet assembly and the second magnet assembly form a symmetrical structure by taking the round hole as the center; and the first magnet assembly and the second magnet assembly are provided with coils corresponding to the direction of the base; the coil is electrically connected with the flexible printed circuit board; and the flexible printed circuit board is arranged on the base. The XYZ three-direction vibrator can realize three-dimensional vibration, can prevent magnetic leakage and collision, is fastin vibration response, and is good in vibration effect.

Owner:SICHUAN AWA SEIMITSU ELECTRIC CO LTD

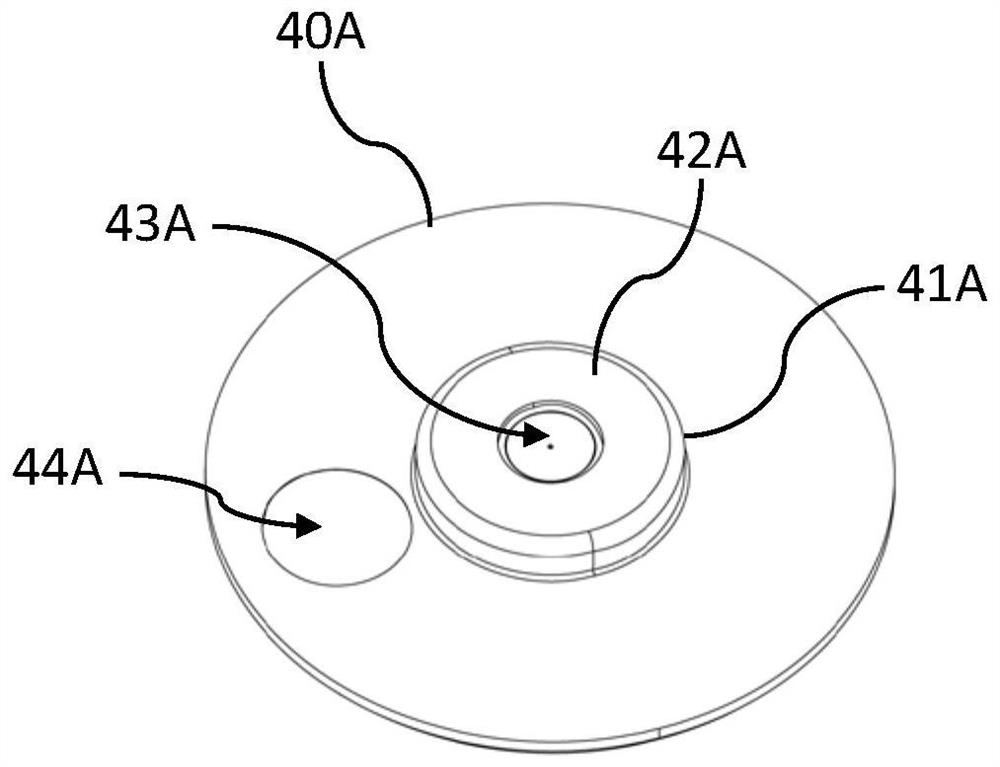

Novel electromagnetic vibrator

InactiveCN105689247AMeet vibration requirementsWide range of weightMechanical vibrations separationWeight rangeLeaf spring

The invention relates to a novel electromagnetic vibrator. The novel electromagnetic vibrator comprises a box body, an armature, a vibration disc fixing supporting frame, an electromagnetic iron core and leaf spring sets. The box body is shaped like an inclined L; the vibration disc fixing supporting frame and the box body are connected through the multiple leaf spring sets which are evenly and obliquely distributed in the horizontal direction at intervals; each leaf spring set is composed of a plurality of parallel leaf springs, wherein the leaf spring, farthest away from the outermost side of the electromagnetic iron core, among the multiple leaf springs is the adjustment leaf spring which is detachably installed between the vibration disc fixing supporting frame and the box body. As the electromagnetic vibrator is provided with the adjustment leaf springs detachably installed between the vibration disc fixing supporting frame and the box body, the electromagnetic vibrator is adaptive to vibration discs with different weights only by detaching and reducing the adjustment leaf springs. In addition, the weight range of the vibration discs is large, and the use range of the electromagnetic vibrator is widened.

Owner:TIANJIN XIYUE TECH

A five-cylinder diesel engine crankshaft balance system

The invention relates to a five-cylinder diesel engine crankshaft balance system which comprises a crankshaft, balance weights and balance mechanisms, wherein the crankshaft comprises a free end, a power output end and bell cranks, which are sequentially a first bell crank, a second bell crank, a third bell crank, a fourth bell crank and a fifth bell crank along the free end towards the power output end. The five-cylinder diesel engine crankshaft balance system is characterized in that a crank of the first bell crank is provided with the balance weight I; a crank of the fifth bell crank is provided with the balance weight II; a crank in the bell crank adjacent to the power output end is provided with the balance weight III; a crank in the fourth bell crank adjacent to the free end is provided with the balance weight IV; the second bell crank is provided with a first drive tooth ring for driving the first balance mechanism; and the fourth bell crank is provided with a second drive tooth ring for driving the second balance mechanism. The five-cylinder diesel engine crankshaft balance system effectively solves the problem of imbalance among the rotary inertia torque, first-order reciprocating inertia couple and second-order reciprocating inertia couple in the five-cylinder diesel engine, so that the engine can satisfy the vibration requirements, thereby promoting the application and development of the five-cylinder diesel engine.

Owner:SINOTRUK JINAN FUQIANG POWER

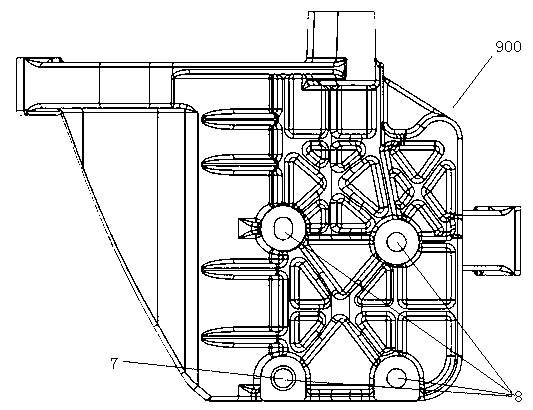

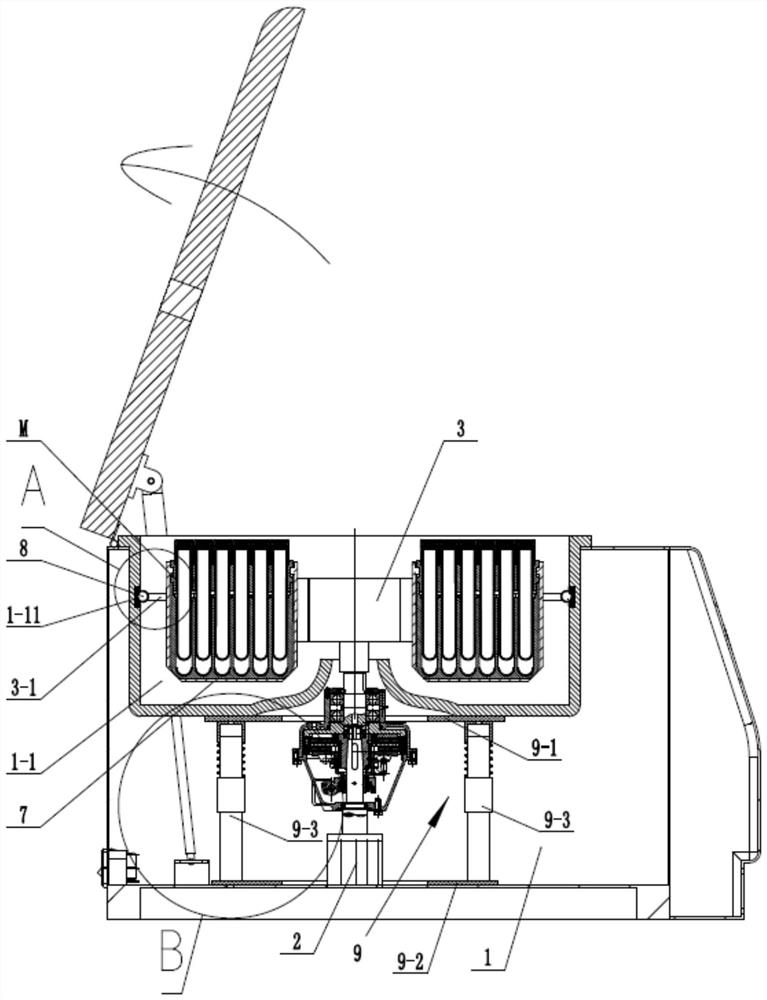

An electric oil-free main air compressor

ActiveCN106194651BReduce vibration shockReduce vibrationPositive displacement pump componentsPump controlLinear compressorOil free

The invention discloses an electric oil-free main air compressor, and belongs to the technical field of air compressors. The electric oil-free main air compressor comprises a fan, an air compressor body, a motor, a cooler, dampers, water drainage electromagnetic valves, a pull rod and a housing. The cooler comprise a middle cooler body and a rear cooler body. At least four dampers are mounted on a fan support and a motor support correspondingly, and are connected with an automobile body. The water drainage electromagnetic valves are mounted at the lower end of the middle cooler body and the lower end of the rear cooler body. The pull rod enables the motor support and the air compressor body to be connected and locked. A damping material layer is arranged in the housing, and the air compressor body is composed of a main shell and a compression cylinder assembly. A bent axle is arranged in the main shell, and the compression cylinder assembly is in an X shape and is composed of at least one high-pressure cylinder assembly and at least two low-pressure cylinder assemblies. According to the electric oil-free main air compressor, the potential hazards of oil leaking and mixing of the air compressor are avoided through air cooling, and the maintaining cost is lowered; the compression cylinder assembly forms reasonable air flow direction, and the maximum cooling efficiency is achieved; damping materials are coated on the housing, and noise is lowered.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

Gear shift damping component and automobile gear shift system

ActiveCN108302190BReduce vibrational energyReduce vibration source energyNon-rotating vibration suppressionGearing controlVibration transmissionControl theory

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

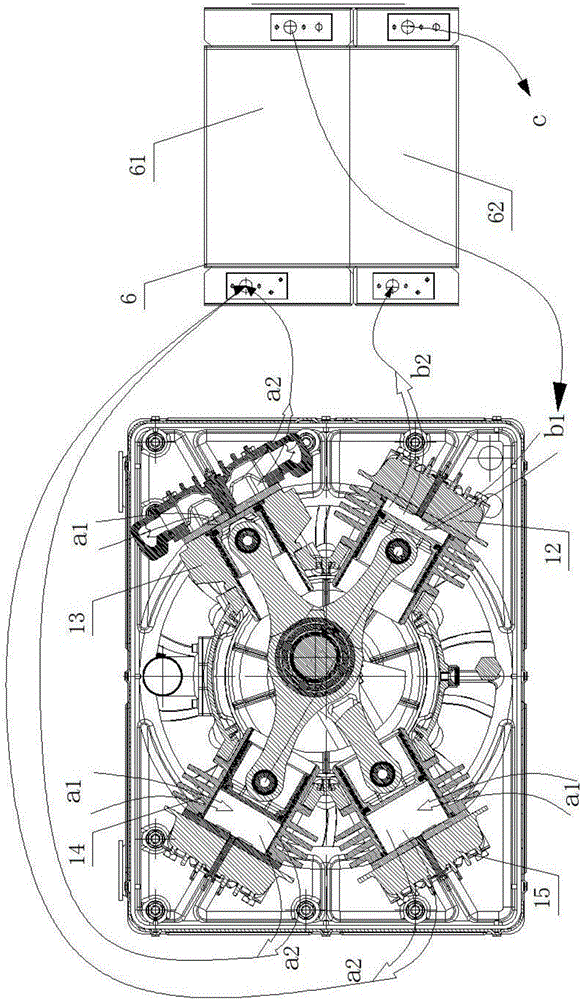

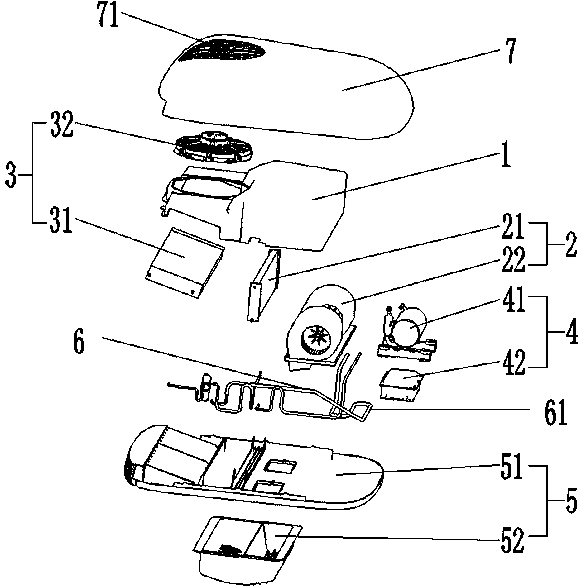

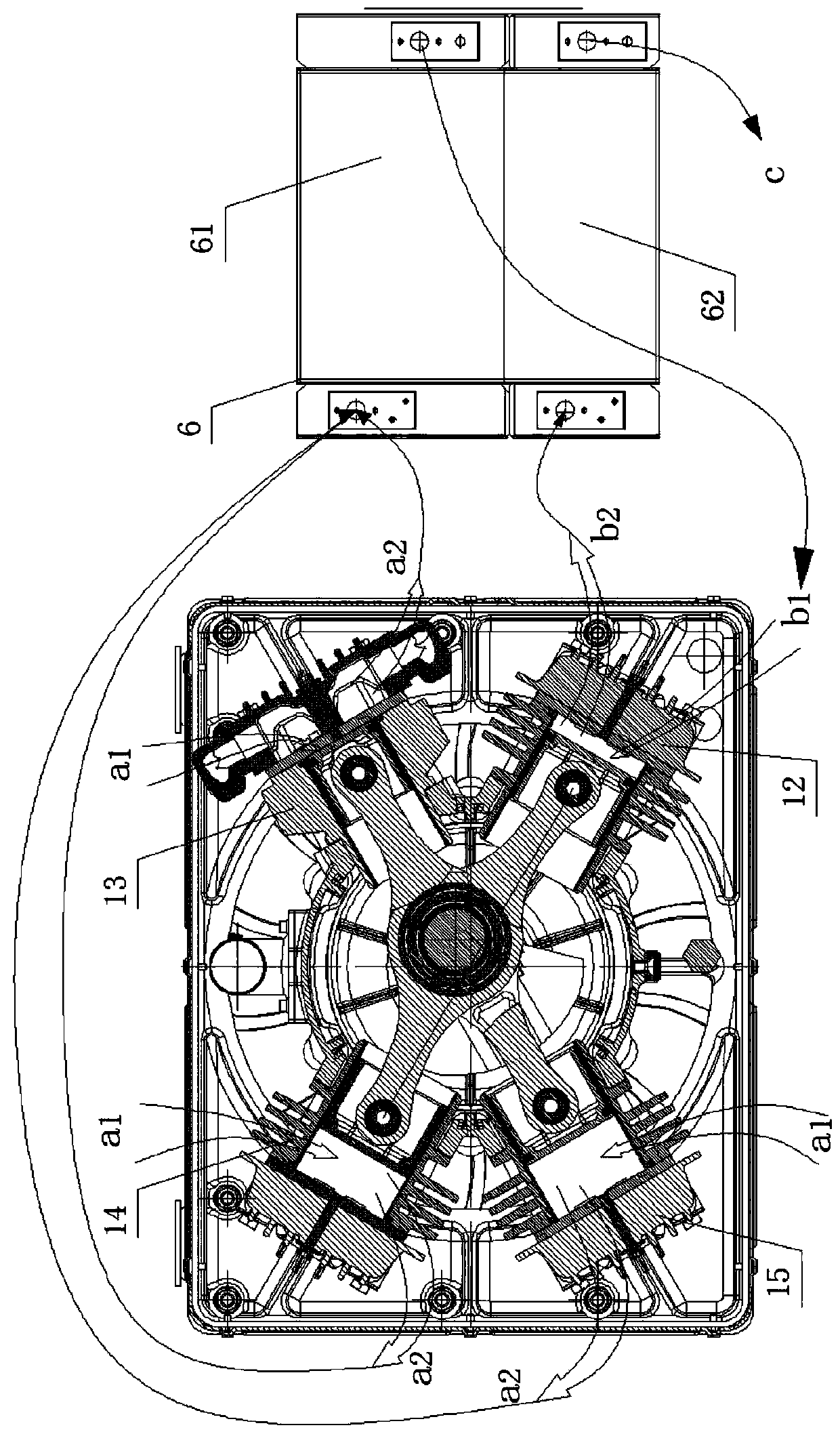

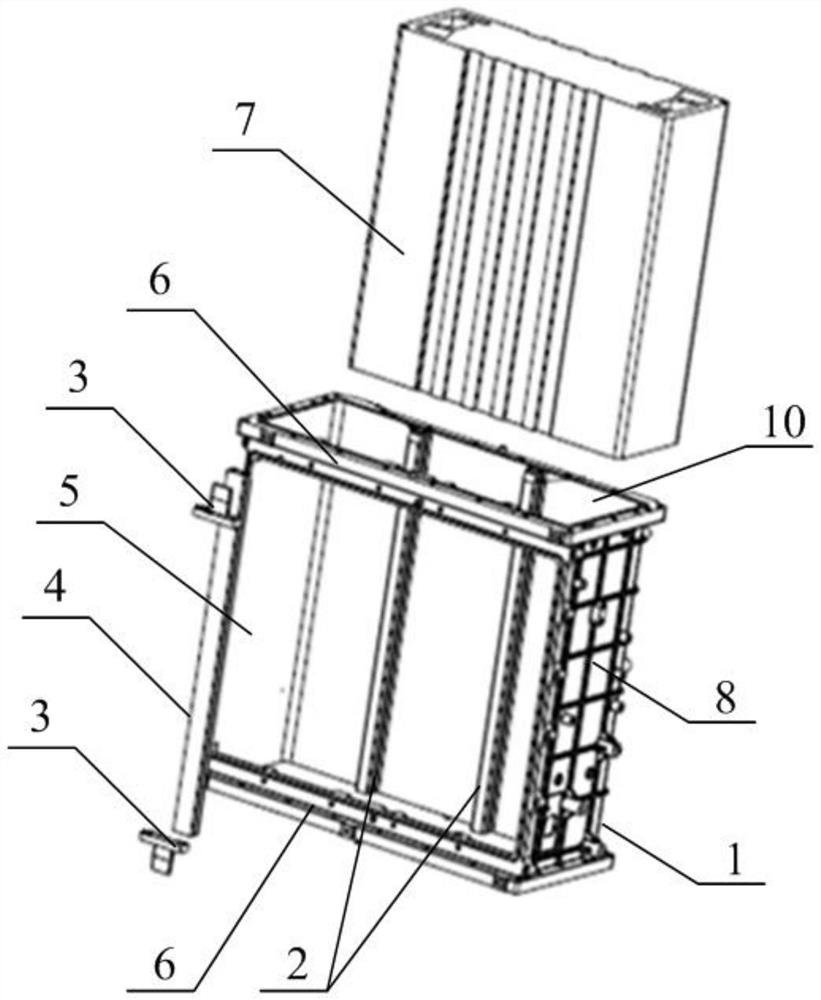

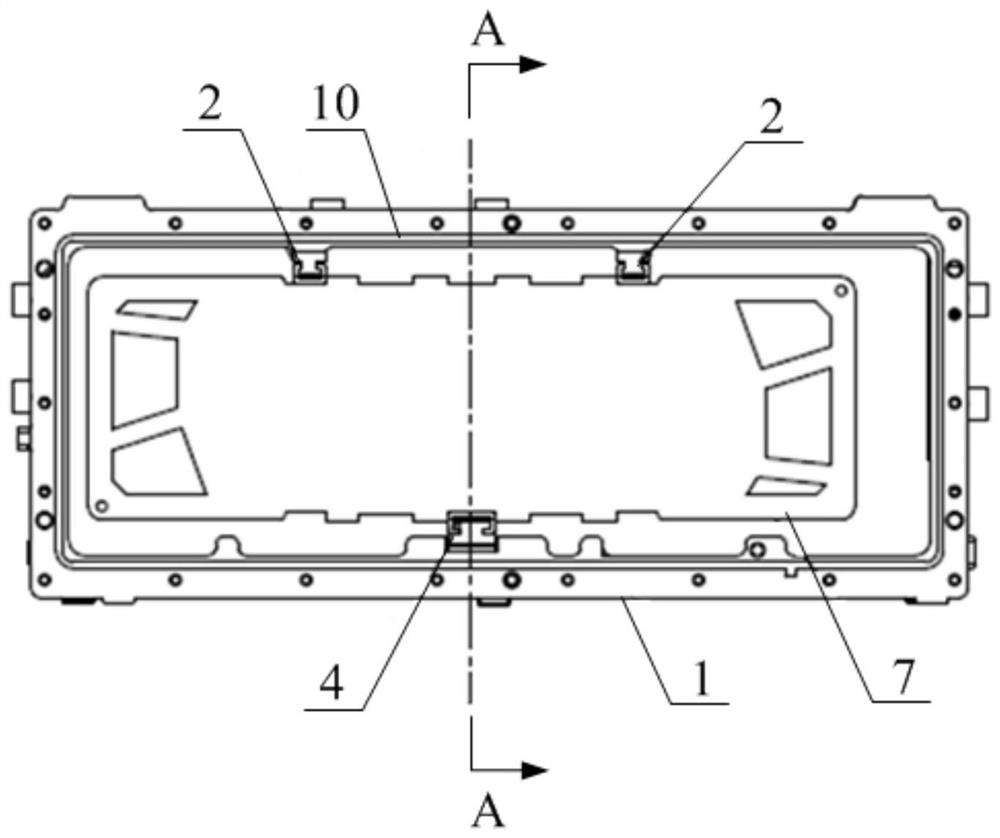

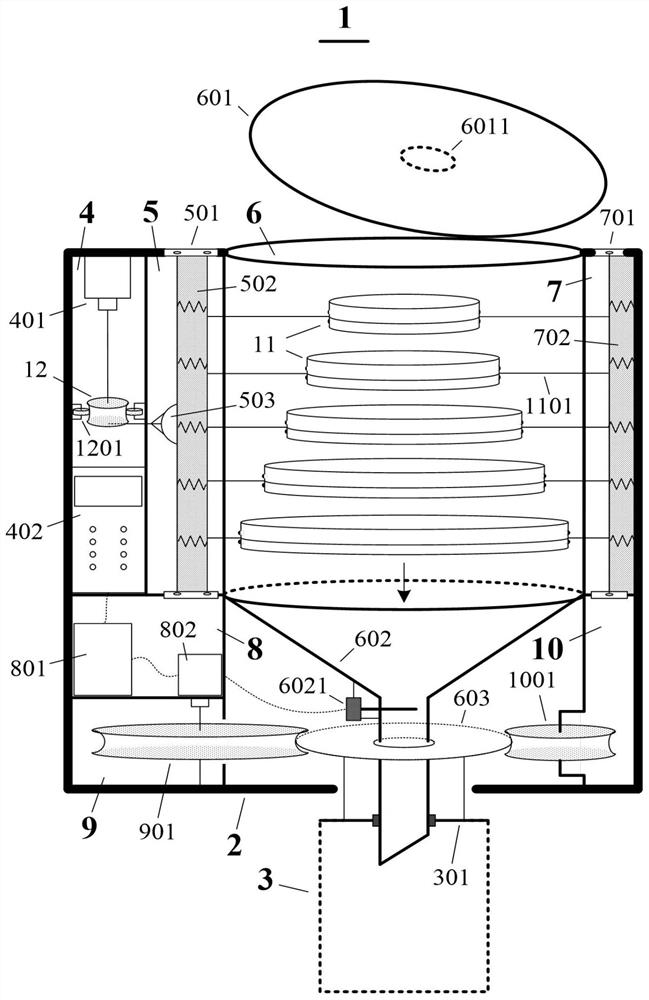

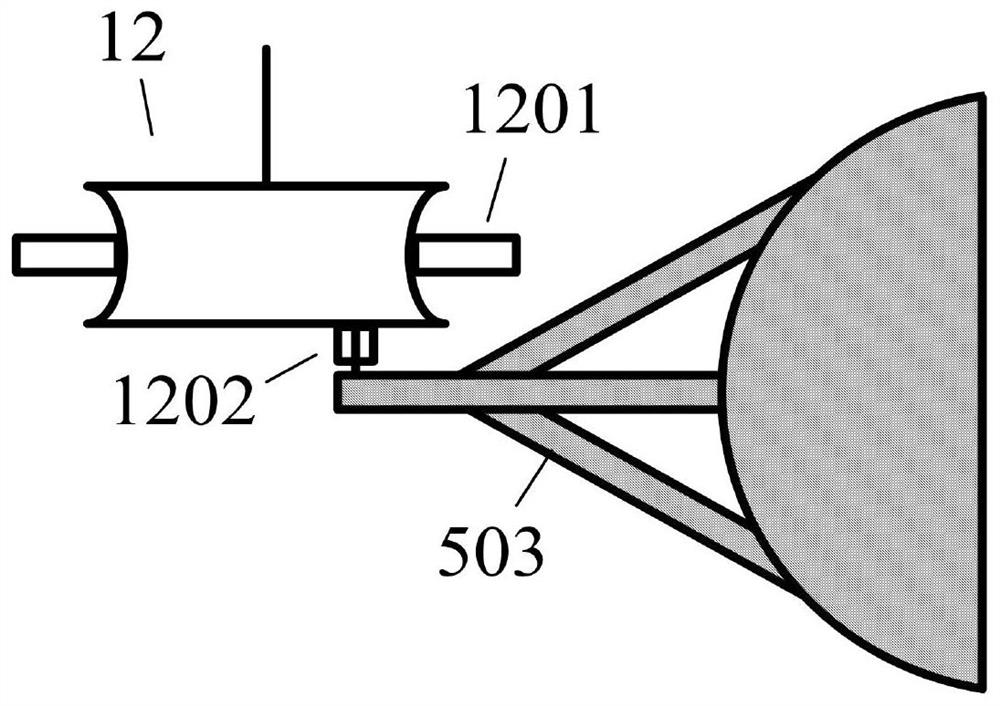

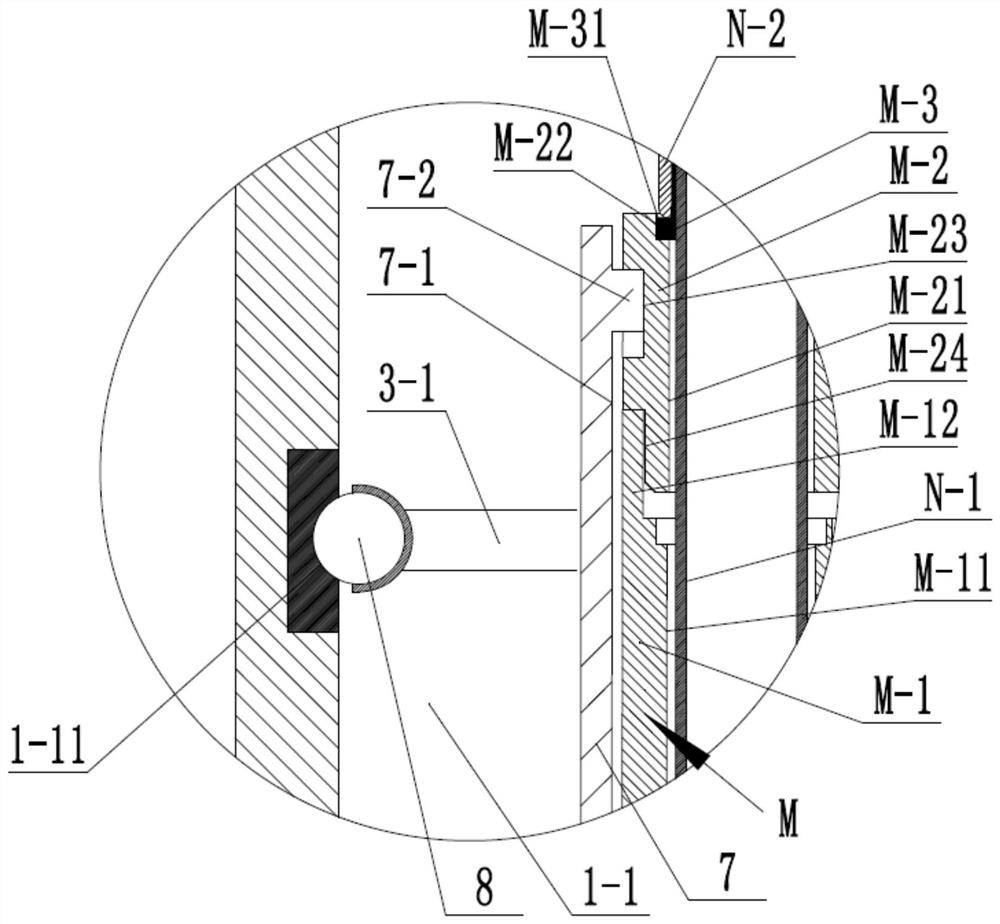

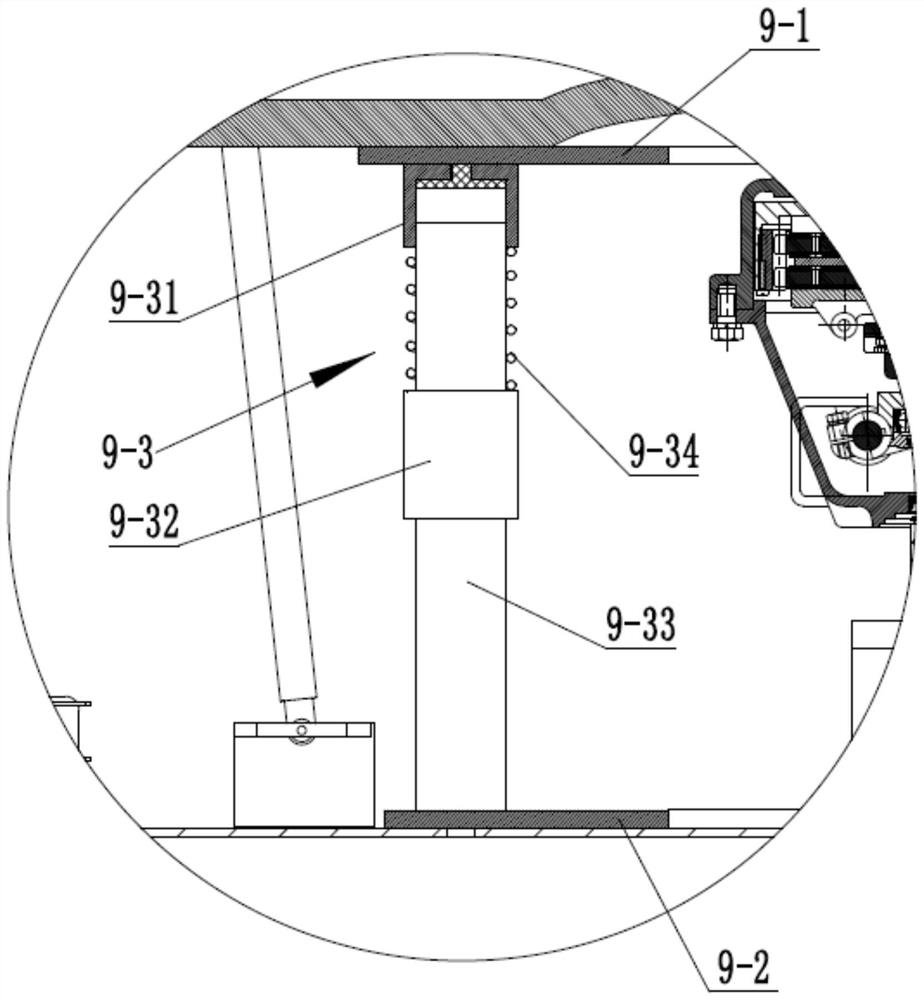

Vacuum blood collection tube centrifuge

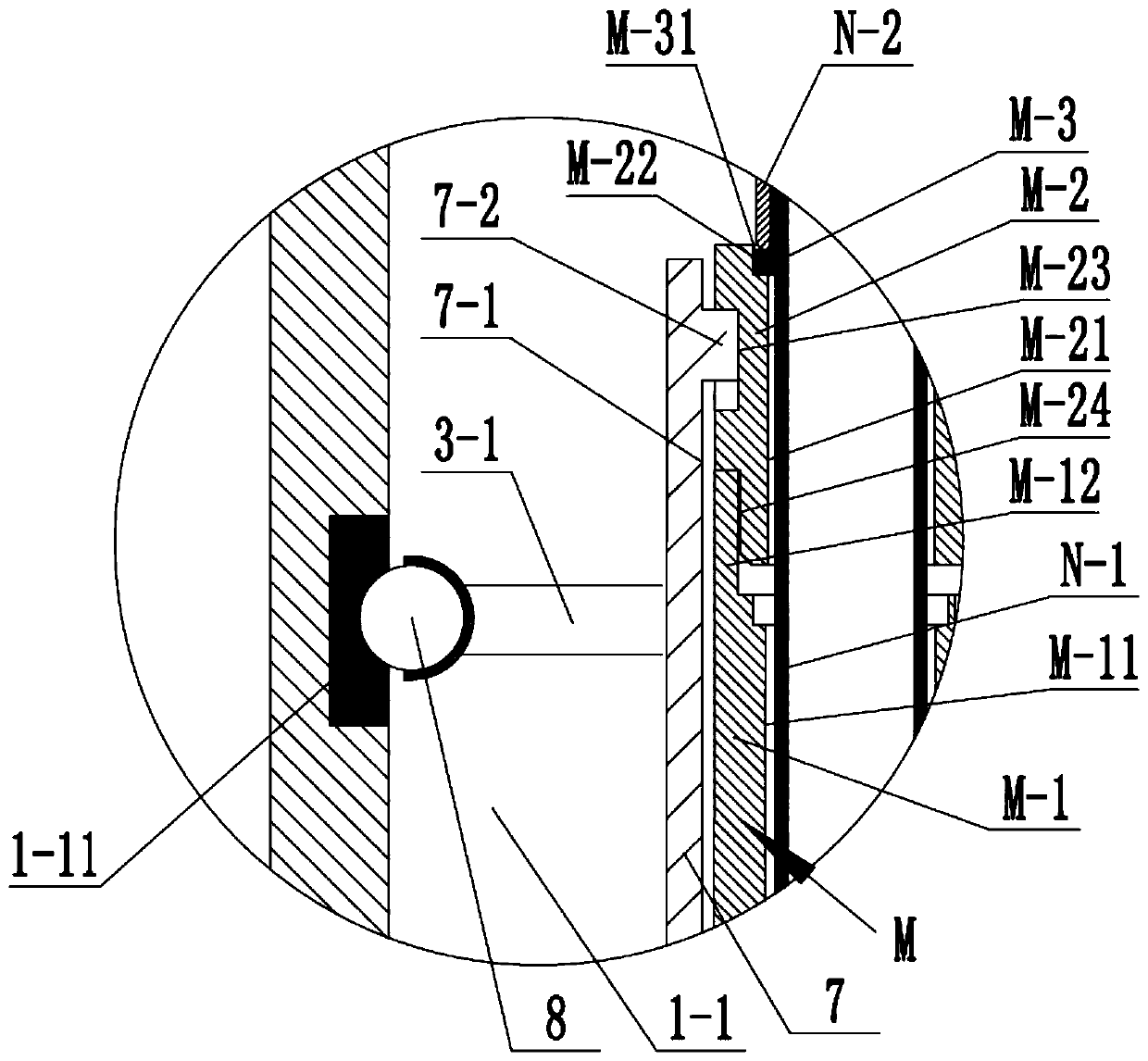

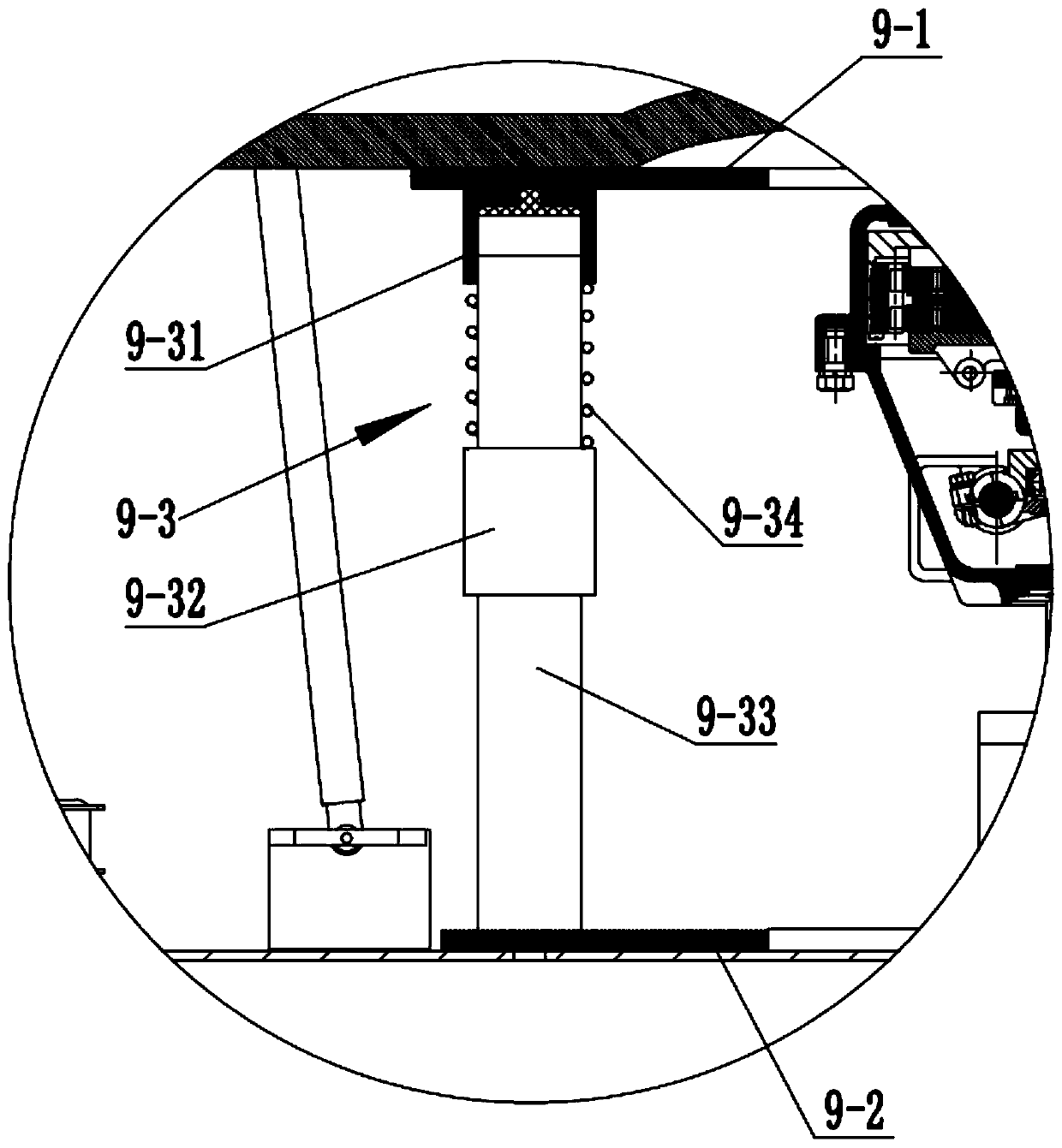

The invention discloses a vacuum blood collection tube centrifuge. The vacuum blood collection tube centrifuge comprises a casing (1), a centrifugal motor (2) and a rotary basket rack (3); the outputend of the centrifugal motor (2) is connected with the rotary basket rack (3) and used for driving the rotary basket rack (3) to rotate; and a plurality of hanging baskets (7) are arranged on the rotary basket rack (3). The vacuum blood collection tube centrifuge is characterized in that a centrifugal chamber (1-1) is arranged in the casing (1); the rotary basket rack (3) is positioned in the centrifugal chamber (1-1); a plurality of radial support rods (3-1) are fixedly arranged on the rotary basket rack (3); and the outer ends of the radial support rods (3-1) are in kinematic pair connectionwith the inner wall of the centrifugal chamber (1-1). The vacuum blood collection tube centrifuge has small vibration and low noise during working and is more suitable for working conditions of highrotating speed and high centrifugal force, and severe limitation to the number and positions of vacuum blood collection tubes is avoided.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

xyz three direction vibration motor

ActiveCN110768503BMeet Vibration FeedbackMeet the Vibration ExperienceDynamo-electric machinesFlexible circuitsEngineering

The invention belongs to the technical field of micro motors. Specifically, it discloses an XYZ three-directional vibration motor, which includes a casing, a base, a vibrator assembly and a stator assembly. The casing and the base are combined to form an accommodation space. The vibrator assembly includes an XY-direction vibration block and a Z-direction vibrator. The vibration block and stator assembly include coils and flexible circuit boards; the XY direction vibration block and the Z direction vibration block are respectively fixed by elastic members and suspended in the accommodation space. A round hole is set in the middle of the XY direction vibration block, and the round hole is surrounded by the Z direction vibration block. All around; the four corners of the XY direction vibration block are inlaid with magnets, and there are corresponding coils directly below the magnets. The Z direction vibration block is equipped with a magnetic conductive shell. The magnetic conductive shell fixes the Z-direction driving magnet. There is a magnetic conductive shell between the magnetic conductive shell and the Z-direction driving magnet. There is a coil; the coil is electrically connected to the flexible circuit board, and the flexible circuit board is arranged on the base. The XYZ three-directional vibration motor provided by the invention can realize three-dimensional vibration, anti-magnetic leakage, anti-collision, fast vibration response, and good vibration effect.

Owner:SICHUAN AWA SEIMITSU ELECTRIC CO LTD

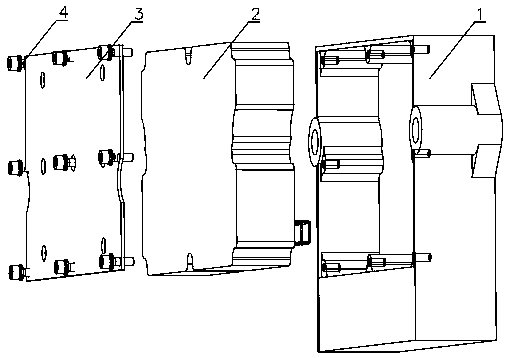

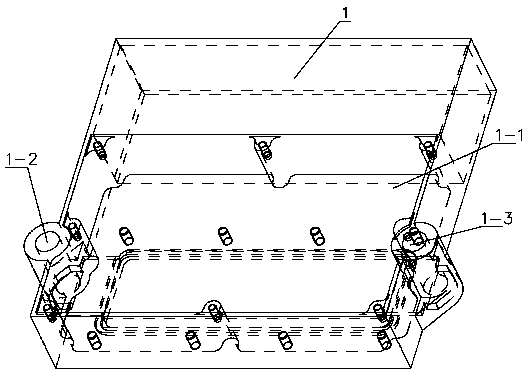

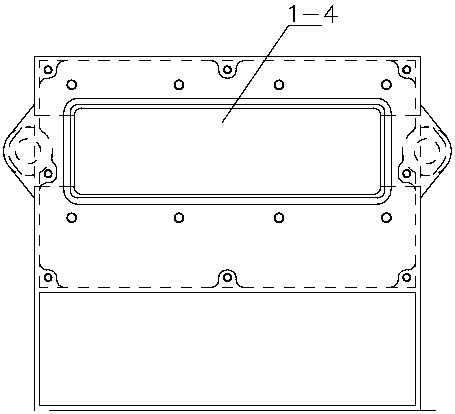

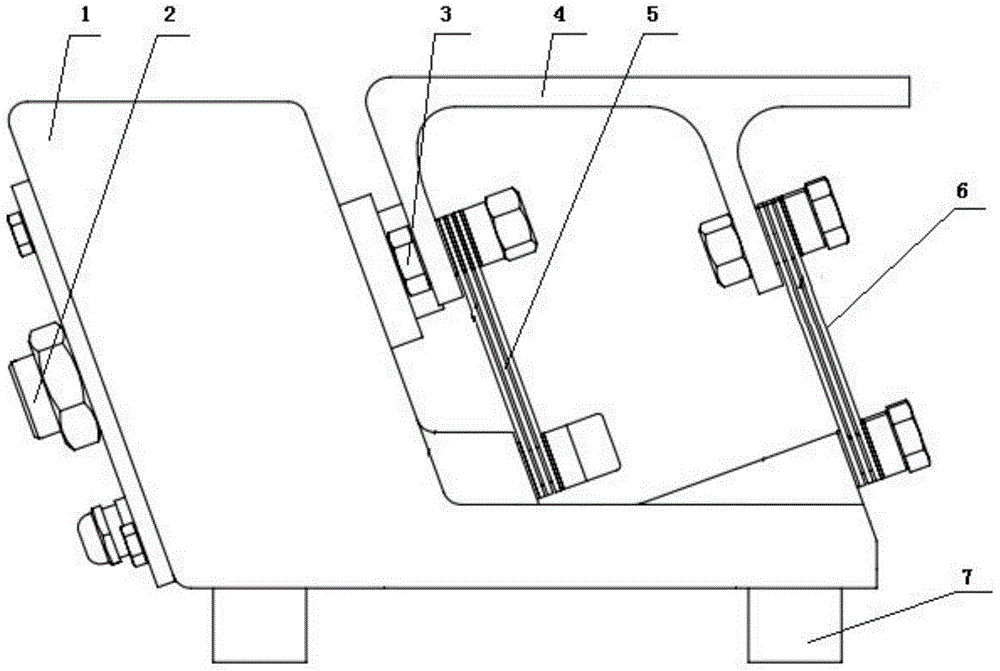

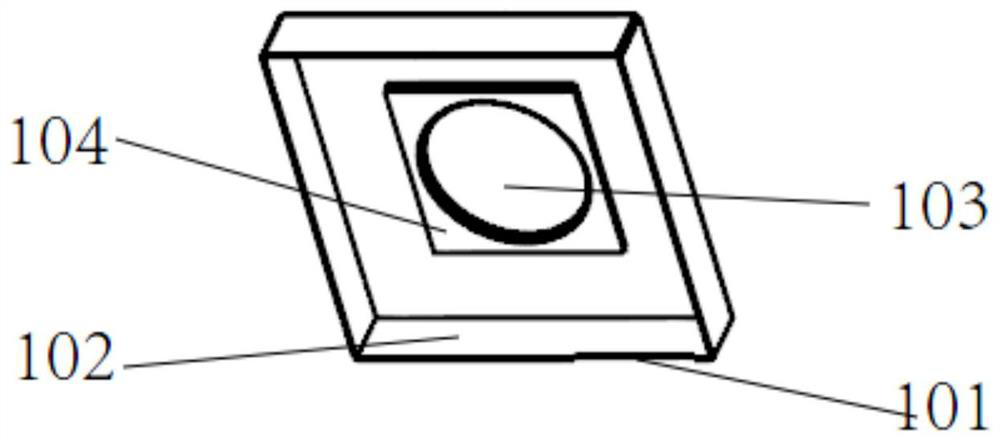

Electric pile packaging box

The invention discloses an electric pile packaging box, which belongs to the technical field of fuel cells. The box comprises a packaging box body and an adjustable support guide rod, at least one side of the periphery of the packaging box body is provided with an opening for a battery cell to pass through, and the adjustable support guide rod is detachably connected to the inner side of the opening through an adjusting support member. The packaging box body comprises a battery cell supporting side wall arranged opposite to the opening, a supporting guide structure used for supporting the battery cell is arranged on the inner side of the battery cell supporting side wall, and the supporting guide structure and the adjustable support guide rod extend in the stacking direction of the battery cell; and the adjusting support member is used for adjusting the distance between the adjustable support guide rod and the opposite battery cell support side wall. According to the scheme, the effective guiding, positioning and supporting functions of the electric pile are achieved through the supporting and guiding structure and the adjustable support guide rod, larger assembling force can be borne, the electric pile can be protected, and the vibration requirement is met; and the opening facilitates automatic assembly of a manipulator and facilitates improvement of the assembly efficiency.

Owner:SHANGHAI HYDROGEN PROPULSION TECH CO LTD

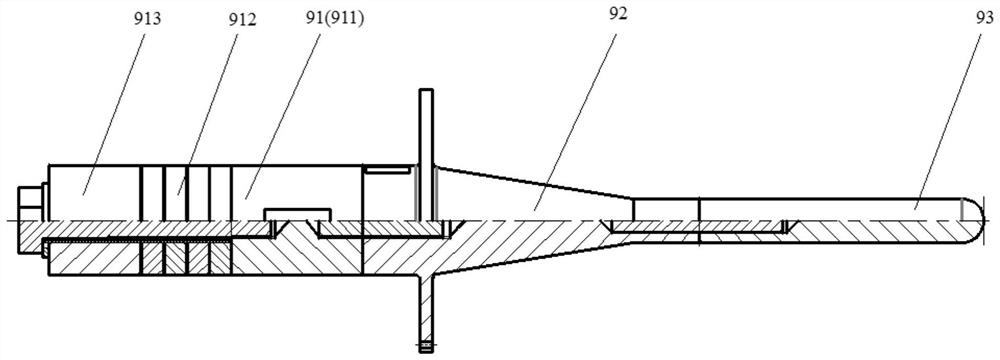

Device for inhibiting laser welding deformation

InactiveCN112570882ARealize researchImplementing Systematic ReviewsLaser beam welding apparatusEngineeringWeld seam

The invention provides a device for inhibiting laser welding deformation. The device comprises a laser welding head for welding, a sample clamp for clamping a sample to be welded, a heat sink structure for cooling a laser welding seam, and an ultrasonic vibration structure for contacting with the surface of the sample to be welded; the heat sink structure is a vortex tube for gas refrigeration andcomprises a cold air outlet end, a hot air outlet end, an air inlet end and a fixed end; the cold air outlet end is used for directly or indirectly blowing cold air generated by the vortex tube to the welding seam of the sample; the ultrasonic vibration structure sequentially comprises a tool head, an amplitude-change pole, and an energy converter from head to tail; the tool head and the amplitude-change pole are both made of titanium alloy materials; and the energy converter sequentially comprises a front cover plate made of aluminum alloy materials, a plurality of pieces of piezoelectric ceramics and a rear cover plate made of steel in the direction from the head to the tail of the ultrasonic vibration structure. The provided device for inhibiting laser welding deformation can effectively inhibit the deformation of the laser welding sample.

Owner:HUNAN UNIV

Aluminum support arm for automobile rearview mirror and its manufacturing process

Owner:东风(十堰)林泓汽车配套件有限公司

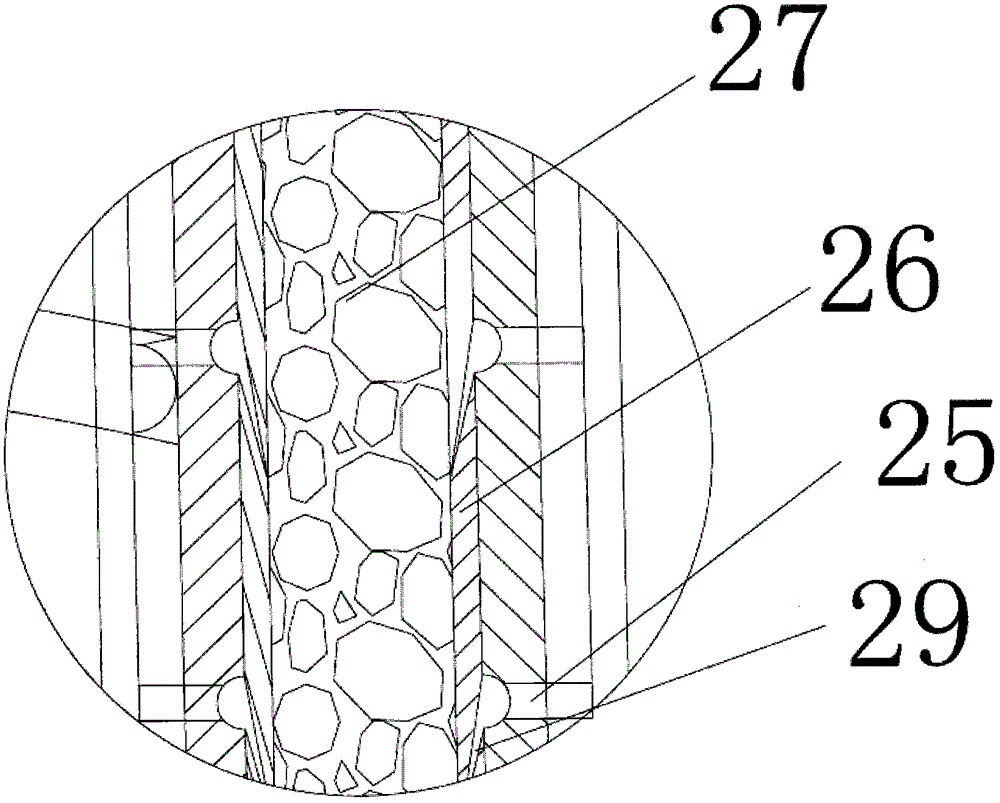

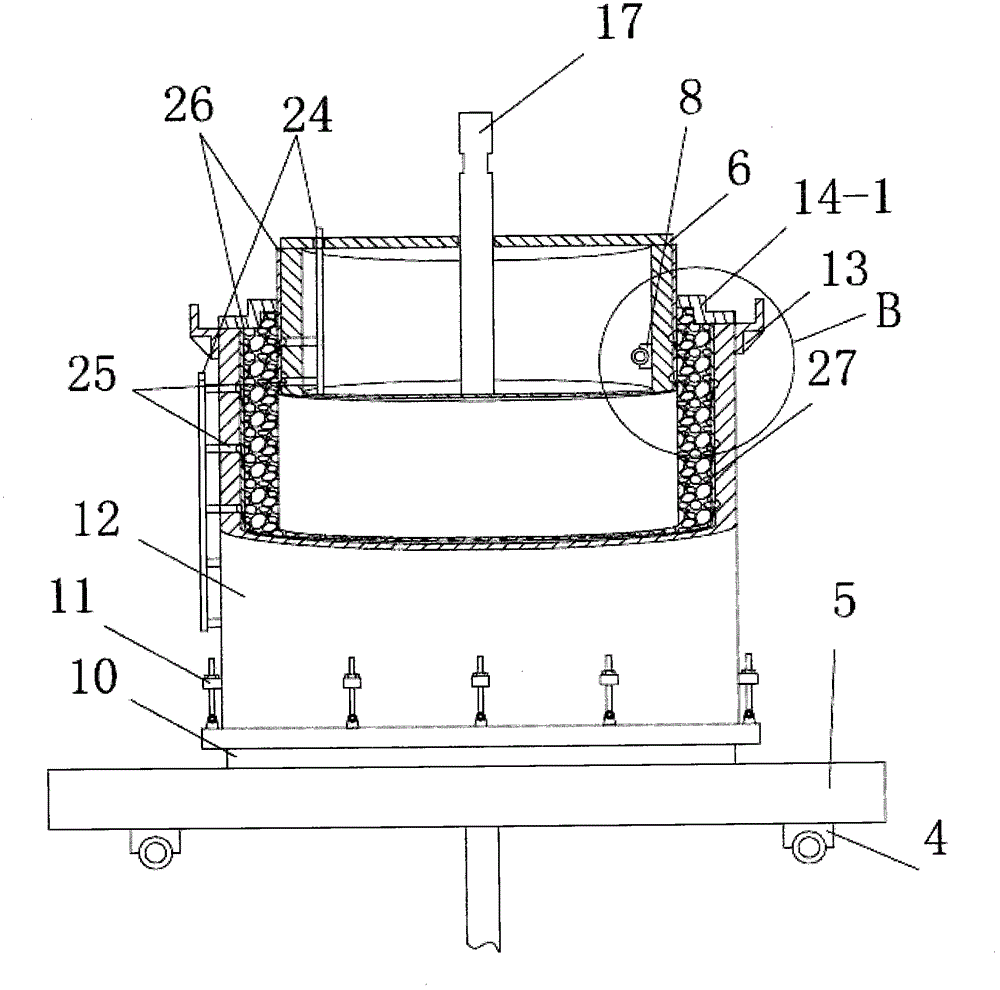

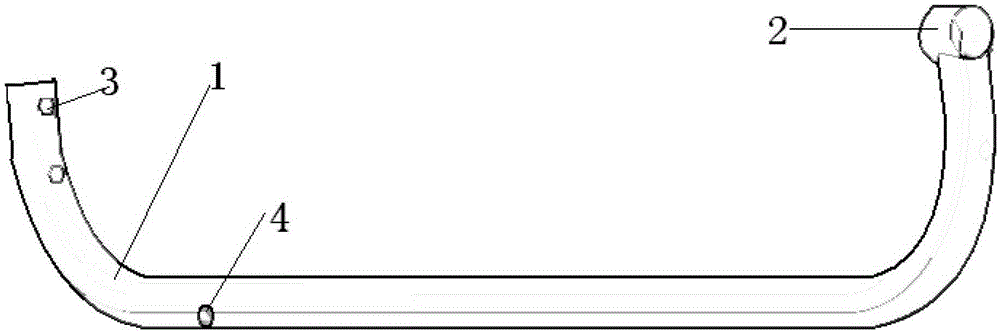

Multi-layer damping pile for overwater measuring platform

PendingCN109306704AMeet vibration requirementsSmall diameterArtificial islandsProtective foundationEngineeringSoil horizon

The invention discloses a multi-layer damping pile for an overwater measuring platform. The multi-layer damping pile is characterized in that the upper end is buried in a water layer and penetrates asoft clay layer until arriving at a hard rock layer, and the upper end is positioned on the water layer and is used for supporting the measuring platform. The multi-layer damping pile comprises a first steel pipe layer, a second steel pipe layer and a third steel pipe layer which sequentially sleeve with each other from an outer layer to an inner layer; the bottom parts of the first steel pipe layer, the second steel pipe layer and the third steel pipe layer are aligned to each other; a filling space is formed between every two adjacent steel pipes; concrete is poured in a lower section of a filling space between the first steel pipe layer and the second steel pipe layer, a lower section of a filling space between the second steel pipe layer and the third steel pipe layer and in the thirdsteel pipe layer; fine sand is filled in the whole upper section of the filling space between the first steel pipe layer and the second steel pipe layer; and rubber is filled in an upper section of aspace between the second steel pipe layer and the third steel pipe layer. The multi-layer damping pile is obvious in damping effect and meets the requirement of a measuring device on vibration.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

A system for the production of reinforced concrete pipes by extruding and demolding with dual vibration sources

InactiveCN104308986BEasy to operateThere will be no accidents falling into the pipe making equipmentCeramic shaping apparatusReinforced concreteEnergy conservation

The invention discloses a system for producing reinforced concrete pipes through double-vibration source extrusion demoulding. The system comprises a foundation pit, a material conveying device, a lifting device, a vibrating table, an internal circle mold vibrating tube, an external circle mold tube structure and a hydraulic extrusion device, wherein the material conveying device and the lifting device are arranged outside the foundation pit; the vibrating table, the internal mold vibrating tube, the external mold tube structure and the hydraulic extrusion device are arranged in the foundation pit; a baffle support structure covering the foundation pit is arranged above the external circle mold tube structure. Compared with current systems adopting a 'centrifugal manufacturing method', an 'overhang roll manufacturing method' and a 'mandrel vibrating method', during the process of producing the reinforced concrete pipes through double-vibration extrusion, the system disclosed by the invention is small in used power, and is capable of saving energy to a greater degree; moreover, the pipe walls of the produced reinforced concrete pipes are smooth from inside to outside; the system disclosed by the invention is high in safety, convenient in operation, high in production efficiency, convenient to maintain and environmentally friendly during a pipe producing process, and has a significant advantage in producing series large-diameter reinforced concrete pipes.

Owner:李荣耀 +3

A gradient heat insulation layer and its preparation method and device

ActiveCN107160748BApplicable to practical applicationComplete structureLamination ancillary operationsThermal insulationHigh concentrationInsulation layer

The invention relates to a gradient thermal insulating layer and a preparation method and a preparation device thereof. The preparation method comprises the following steps: cutting two or more pieces of a heat insulating material according to the size of the internal surface of a to-be-heat-insulated workpiece; smearing an adhesive to the internal surface of the workpiece, bonding the cut heat insulating material on the internal surface of the workpiece in sequence, and bonding two adjacent layers of the heat insulating material; spraying steeping liquid of two or more different concentrations on the surface of the heat insulating material; and drying to obtain the gradient thermal insulating layer, wherein the heat insulating material is flexible porous heat insulating material, the steeping liquid has hardening characteristic after drying, and the spraying sequence for the steeping liquid of different concentrations is from high concentration to low concentration. The invention also provides a device for preparing the gradient thermal insulating layer. The gradient thermal insulating layer has gradually changed hardness gradient, which is more suitable for practical applications.

Owner:CHINA BUILDING MATERIALS ACAD

High-speed dynamic balancing calibration method of gas turbine rotors with power of 254 MW

ActiveCN102374925BMeet vibration requirementsReduce processStatic/dynamic balance measurementLow speedDynamic balance

The invention discloses a high-speed dynamic balancing calibration method of gas turbine rotors with a power of 254 MW and relates to a dynamic balancing calibration method of gas turbine rotors, solving the problem that the existing dynamic balancing calibration method of gas turbine rotors with a power of 254 MW has various processes and long balancing cycle. The method comprises the following steps: 1, rotor turning: arranging preinstalled rotors into a vacuum warehouse to carry out rotor turning; 2, low-speed dynamic balancing: carrying out low-speed dynamic balancing at a rotating speed of 500 r / min; and 3, high-speed dynamic balancing: carrying out high-speed dynamic balancing at a rotating speed of 3000 r / min so as to complete the dynamic balancing of rotors. By using the high-speed dynamic balancing calibration method of the gas turbine rotors disclosed by the invention, an original low-speed dynamic balancing calibration method is greatly simplified, and only once low-speed dynamic balancing and once high-speed dynamic balancing are required to be performed in the whole process, so that the operating procedure is less, the balancing cycle is short, and the balancing effect is good, thereby meeting the field vibration requirements of a machine set, and improving the accuracy level of dynamic balancing. The method is used for the dynamic balancing calibration of gas turbine rotors.

Owner:HARBIN TURBINE +1

Gear shifting and vibration reduction assembly and car gear shifting system

ActiveCN108302190AReduce vibrational energyReduce vibration source energyNon-rotating vibration suppressionGearing controlEngineeringMechanical engineering

The invention provides a gear shifting and vibration reduction assembly and a car gear shifting system, and relates to the technical field of the car gear shifting system. The gear shifting and vibration reduction assembly comprises a gear shifting arm, a balancing weight structure and a vibration reduction structure; the gear shifting arm and a speed changer are connected through a gear shiftingrod pin; the balancing weight structure is rotationally connected with the gear shifting rod pin; the gear shifting arm and the balancing weight structure are connected through a connector; the gear shifting arm can drive the balancing weight structure through the connector to rotate around the gear shifting rod pin; and the vibration reduction structure is arranged between the connector and the gear shifting arm and / or between the connector and the balancing weight structure. The car gear shifting system at least comprises a gear shifter, a gear shifting flexible shaft, the speed changer andthe gear shifting and vibration reduction assembly; the gear shifting flexible shaft is connected between the gear shifter and the gear shifting arm; and the gear shifting arm is arranged on the speedchanger. The problem that in the prior art, a balancing weight is directly connected with a gear shifting arm, so that vibration is transmitted to a gear shifting handball to easily cause numbness issolved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

xyz three direction vibration motor

ActiveCN110855116BMeet Vibration FeedbackMeet the Vibration ExperienceDynamo-electric machinesFlexible circuitsEngineering

The invention belongs to the technical field of micro motors, and specifically discloses an XYZ three-directional vibration motor, which includes a casing, a base, a vibrator assembly and a stator assembly. The casing and the base are combined to form an accommodation space. The vibration block and the stator assembly include coils and flexible circuit boards; the XY direction vibration block and the Z direction vibration block are respectively fixed and suspended in the accommodation space by elastic members, and the circular hole set in the middle of the XY direction vibration block surrounds the Z direction vibration block. Around the block; the four corners of the vibrating block in the XY direction are inlaid with magnets, and there is a coil directly below the magnet. The vibrating block in the Z direction is provided with a magnetic shell, which fixes the Z-direction drive magnet, and the gap between the magnetic shell and the Z-direction drive magnet Coils are provided; the flexible circuit board is arranged on the base, and the first coil and the second coil are fixed on the flexible circuit board. The invention can realize three-dimensional vibration, anti-magnetic leakage, anti-collision, fast vibration response and good vibration effect.

Owner:SICHUAN AWA SEIMITSU ELECTRIC CO LTD

Mine multi-particle-size dust preparation and intelligent spraying device

ActiveCN113893967AStrong controllabilityIt has the function of "spraying while preparing"Spray boothsMaterial analysisDrive wheelElectric machine

The invention discloses a mine multi-particle-size dust preparation and intelligent spraying device. The device comprises a device body, and the device body is provided with a dust preparation cavity and an intelligent spraying cavity; a driving cavity, a transmission cavity, a vibration cavity, a vibration reduction cavity, a control cavity, a rotating cavity and a balance cavity are formed in the dust preparation cavity; a driving motor and a driving wheel are mounted in the driving cavity; and vibration screens, a funnel, an electromagnetic valve and a spraying gear are mounted in the vibration cavity. The use result of the device shows that the device is firm in structure and good in sealing performance, an electrical system is reasonable in layout and stable in control, screen body vibration is stable, motor power is strong, use is convenient, operability is strong, three-door design is achieved, so that maintenance is convenient, dust falls naturally during vibration, spill-proof performance is good, the storage space of the funnel is large, the spraying amount and spraying force are adjustable, accurate preparation and intelligent spraying of test dust with different particle sizes can be well achieved, and the device is suitable for application and popularization.

Owner:ANHUI UNIV OF SCI & TECH

A vacuum blood collection tube centrifuge

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com