Five-cylinder diesel engine crankshaft balance system

A technology of diesel engine and balance system, applied in the direction of inertia force compensation, etc., can solve the problems of engine rotational inertia moment, first-order reciprocating inertia moment and second-order reciprocating inertia moment unbalance, etc., to achieve the effect of promoting application and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

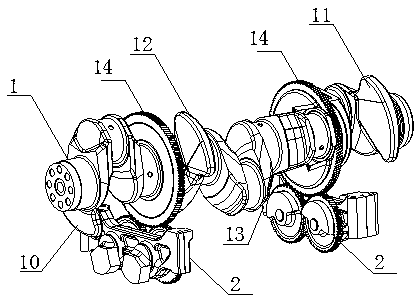

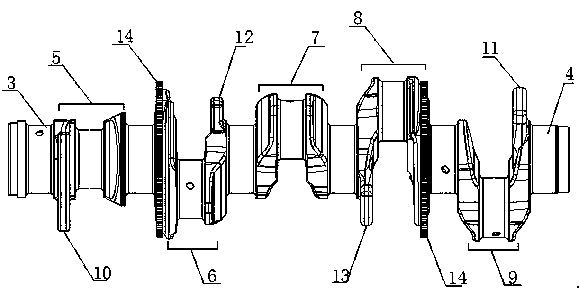

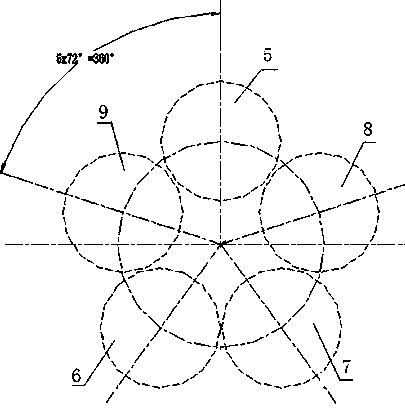

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The crankshaft balance system of a five-cylinder diesel engine shown includes a crankshaft 1 and two sets of balance mechanisms 2. The diesel engine adopts the ignition sequence of 1-2-4-5-3, and the crankshaft 1 includes a free end 3 and a power output end 4 , bellcrank and drive ring gear 14, wherein the bellcrank is followed by the first bellcrank 5, the second bellcrank 6, the third bellcrank 7, the fourth bellcrank 8 and the fifth crank 9, such as image 3 As shown, along the projection from the free end of the crankshaft to the power output end, the first crank throw 5, the fourth crank throw 8, the third crank throw 7, the second crank throw 6 and the fifth crank throw 9 in the clockwise direction, Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com