A vacuum blood collection tube centrifuge

A technology of vacuum blood collection tubes and centrifuges, which is applied to centrifuges and other directions, and can solve problems such as high noise and large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

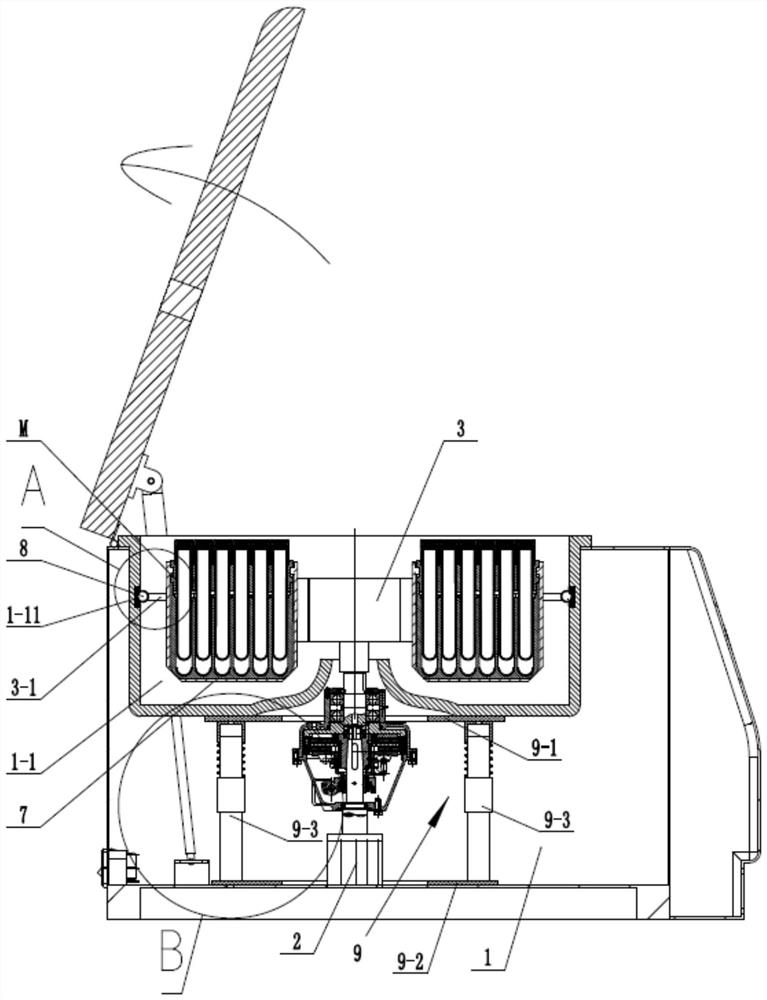

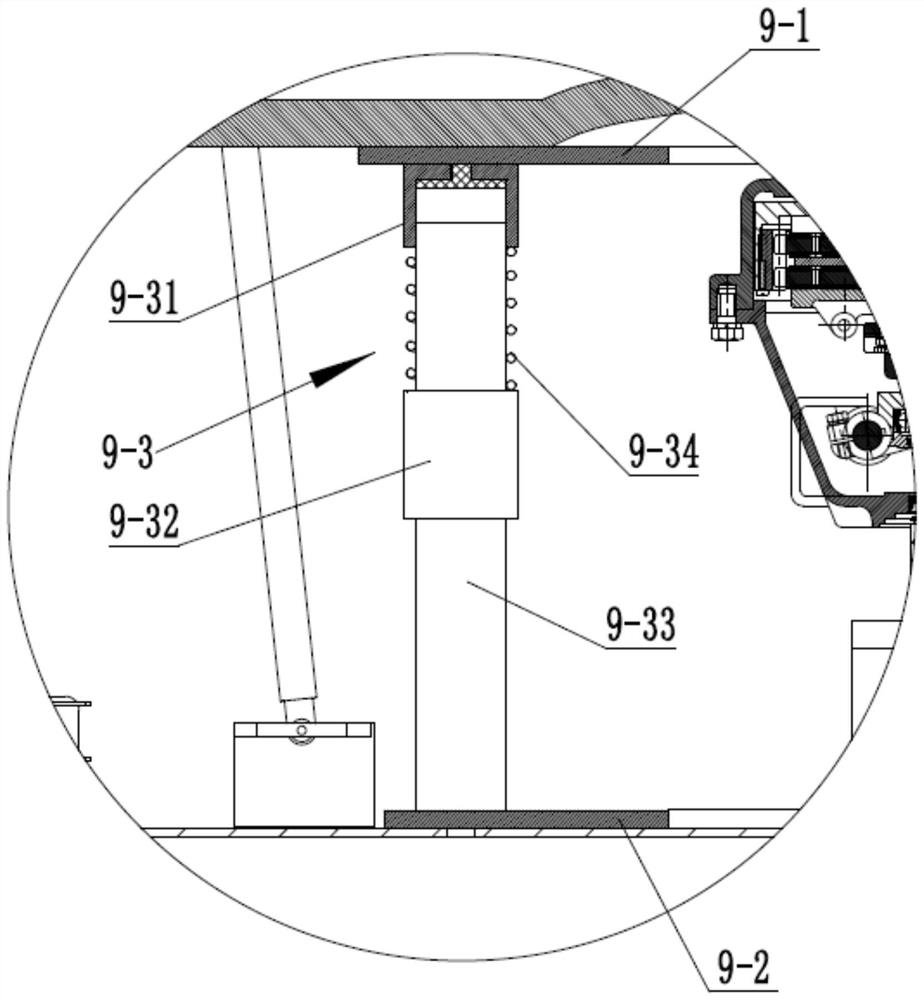

[0045] Embodiment one: see Figure 1-12 , a vacuum blood collection tube centrifuge, including a casing 1, a centrifugal motor 2 and a rotating basket 3.

[0046] The output end of the centrifugal motor 2 is connected with the rotating basket 3 and is used to drive the rotating basket 3 to rotate; the rotating basket 3 is provided with four hanging baskets 7 .

[0047] see Figure 1-4 , The casing 1 is provided with a centrifuge cylinder, the centrifuge cylinder has a centrifuge chamber 1-1 inside, and the rotating basket 3 is located in the centrifuge chamber 1-1.

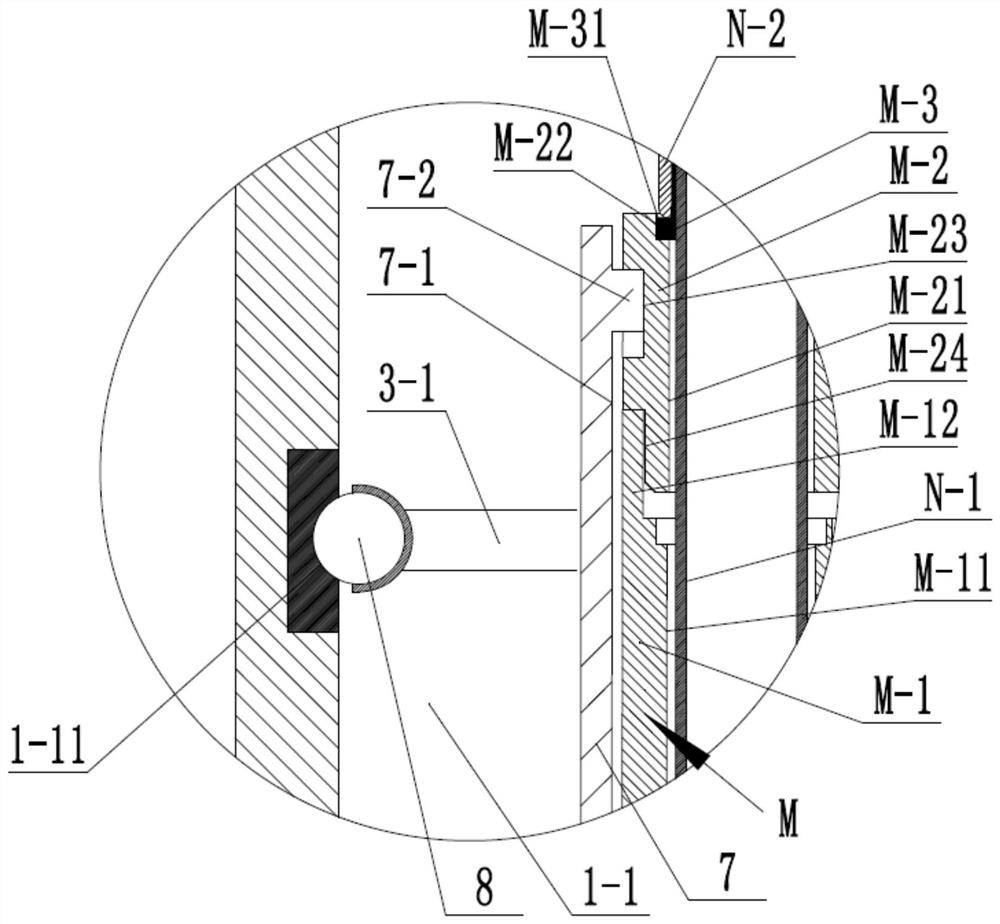

[0048] see Figure 5-6 The rotating basket 3 is fixed with four radial struts 3-1, and the outer end of each radial strut 3-1 is connected to the inner wall of the centrifuge chamber 1-1 by a kinematic pair.

[0049] In the present invention, since the outer ends of a plurality of radial struts 3-1 on the rotating basket 3 are connected to the inner wall of the centrifuge chamber 1-1 by the kinematic pairs, the...

Embodiment 2

[0069] Embodiment 2: This embodiment is basically the same as Example 1, the difference lies in the specific structure of the connection between the outer end of each radial strut 3-1 and the inner wall of the centrifugal chamber 1-1.

[0070] In this example, see Figure 13-14 , the inner wall of the centrifugal chamber 1-1 is fixedly provided with a bearing outer ring 6-1, and the outer end of each radial strut 3-1 is fixedly connected to the bearing inner ring 6-2, and the bearing outer ring 6-1 is connected to the bearing The inner rings 6-2 are connected by rollers 6-3. Since the bearing outer ring 6-1 and the bearing inner ring 6-2 are connected by the roller 6-3, when the bearing outer ring 6-1 and the bearing inner ring 6-2 rotate with each other, the movement process can be reduced. The friction coefficient in the middle, and at the same time ensure its rotation accuracy, it has the advantages of high precision, good rigidity, fatigue resistance, high speed and so on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com