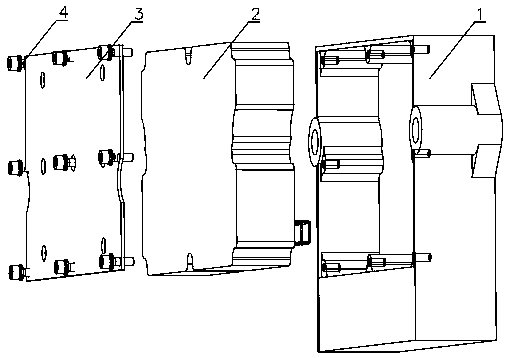

Novel motor controller main shell structure

A technology of motor controller and main casing, which is applied in the direction of electrical equipment structural parts, electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of low space utilization, large height and size, and high cost. Achieve flat design, reduce capacitor temperature rise, improve reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

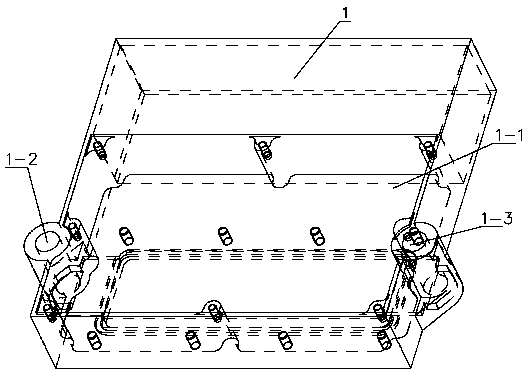

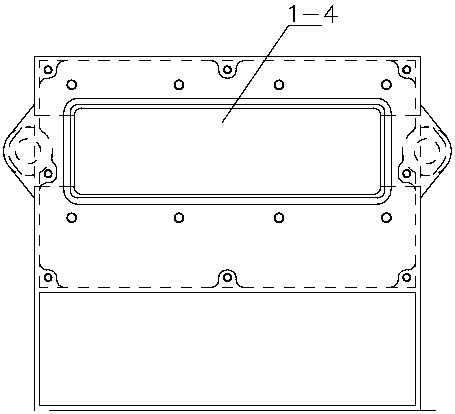

[0025] This embodiment provides a new type of controller structure, which subverts the traditional capacitor installation method. On the controller housing, the external envelope cavity size space required by the capacitor core body and the outgoing copper bar is pre-cast, that is, The cavity of the capacitor shell, use the positioning tool to place the capacitor core body and the outgoing copper bar in the cavity of the capacitor shell of the controller shell, and inject epoxy resin into the cavity of the capacitor shell through injection molding, so that the capacitor core body, The outlet terminals and the controller casing are plastic-sealed as one, and the cavity of the capacitor casing is on the opposite side of the controller casing, which facilitates the placement and fixing of the capacitor core body and the outlet terminals. The cavity of the capacitor housing is fixed and sealed by the cover plate, screws and sealant, which improves the reliability of the capacitor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com