Aluminum support arm for automobile rearview mirror and its manufacturing process

A technology for automotive rearview mirrors and support arms, which is applied to vehicle parts, optical observation devices, transportation and packaging, etc., can solve problems such as paint stripping, inner wall rust, and yellow water flow, and achieve simple preparation process steps and realize assembly line The effect of production and avoiding rust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

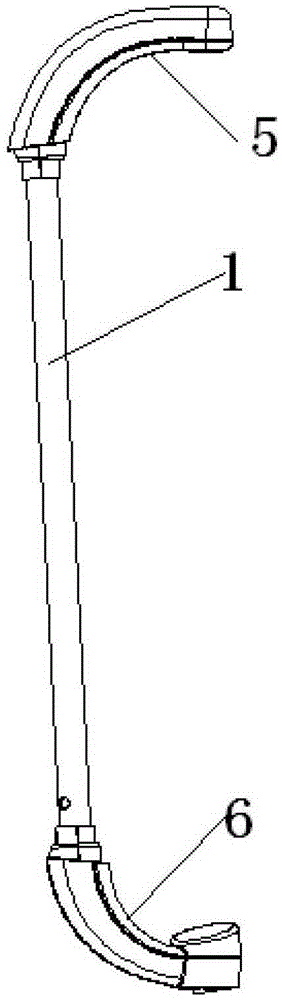

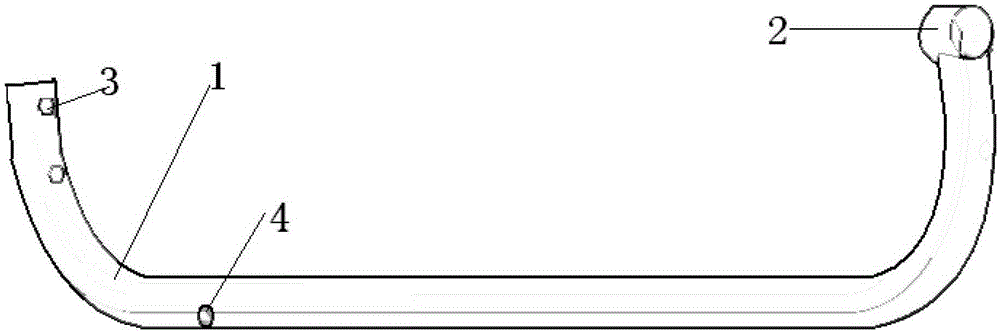

[0020] The structure of the aluminum support arm for the automobile rearview mirror provided by the present invention is as follows: figure 1 As shown, it consists of an aluminum tube 1, an aluminum sleeve 2, an upper protective cover 5 and a lower protective cover 6, and the aluminum tube 1 and the aluminum sleeve 2 are made of aluminum alloy. The structure of aluminum tube 1 is as follows figure 2 As shown, the aluminum tube 1 is C-shaped, the aluminum sleeve 2 is fixedly connected to the top of the aluminum tube 1, the aluminum sleeve 2 is in the shape of a cylinder with openings on both sides, and the top of the aluminum tube 1 is provided with an arc shaped gap, the radius of the arc at the gap is 15 mm, the shape of the gap matches the outer wall of the aluminum sleeve 2, and the aluminum sleeve 2 is fixed on the gap by welding; the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com