GZG-HT photovoltaic automatic tracking system

A GZG-HT, automatic tracking technology, applied in the research field of photovoltaic power generation, to achieve the effect of promoting farmers, improving control efficiency, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

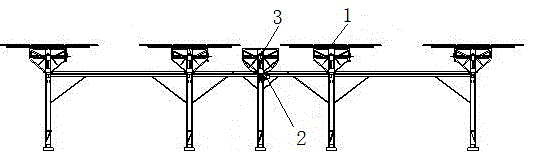

[0041] This embodiment provides a GZG-HT photovoltaic automatic tracking system, including a controller, a sensor 1, and a driving device 2. The controller is arranged in the electrical cabinet of the control room. The controller is equipped with a set of sensors 1, and simultaneously controls multiple sets of drives. The movement of the device 2 is characterized in that: the system also includes a transmission device 3 connected above the drive device 2, and a plurality of independent photovoltaic tracking subsystems;

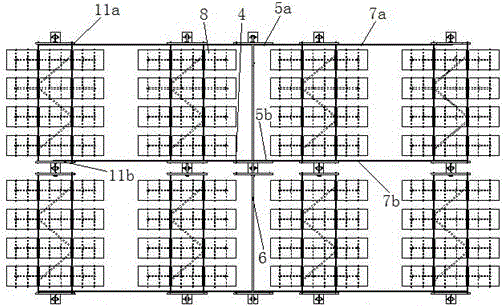

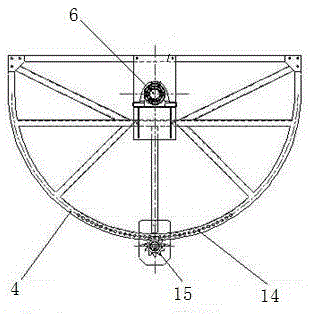

[0042] The transmission device 3 includes a driving wheel 4, a transmission bracket one 5a, a transmission bracket two 5b, a transmission shaft 6, a transmission connecting rod one 7a and a transmission connecting rod two 7b; the transmission shaft 6 and the driving wheel 4 are fixed by bolts Connect, drive shaft 6 both sides are respectively connected with transmission support one 5a and transmission support two 5b, described transmission support one 5a and tr...

Embodiment 2

[0049] On the basis of Embodiment 1, this embodiment provides a GZG-HT photovoltaic automatic tracking system, including a controller, a sensor 1, and a drive device 2. The controller is arranged in the electrical cabinet of the control room, and the controller is equipped with a set of The sensor 1 controls the movement of multiple sets of driving devices 2 at the same time, and is characterized in that: said system also includes a transmission device 3 connected above the driving device 2, and a plurality of independent photovoltaic tracking subsystems;

[0050] The transmission device 3 includes a driving wheel 4, a transmission bracket one 5a, a transmission bracket two 5b, a transmission shaft 6, a transmission connecting rod one 7a and a transmission connecting rod two 7b; the transmission shaft 6 and the driving wheel 4 are fixed by bolts Connect, drive shaft 6 both sides are respectively connected with transmission support one 5a and transmission support two 5b, describ...

Embodiment 3

[0054] On the basis of Embodiment 2, this embodiment provides a GZG-HT photovoltaic automatic tracking system, including a controller, a sensor 1, and a drive device 2. The controller is arranged in the electrical cabinet of the control room, and the controller is equipped with a set of The sensor 1 controls the movement of multiple sets of driving devices 2 at the same time, and is characterized in that: said system also includes a transmission device 3 connected above the driving device 2, and a plurality of independent photovoltaic tracking subsystems;

[0055] The transmission device 3 includes a driving wheel 4, a transmission bracket one 5a, a transmission bracket two 5b, a transmission shaft 6, a transmission connecting rod one 7a and a transmission connecting rod two 7b; the transmission shaft 6 and the driving wheel 4 are fixed by bolts Connect, drive shaft 6 both sides are respectively connected with transmission support one 5a and transmission support two 5b, describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com