A single-input coaxial double-output reducer

A dual-output, reducer technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to ensure mixing uniformity, different mixing effects, large structure, etc., to achieve stable transmission performance, Small size, the effect of meeting the transmission requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

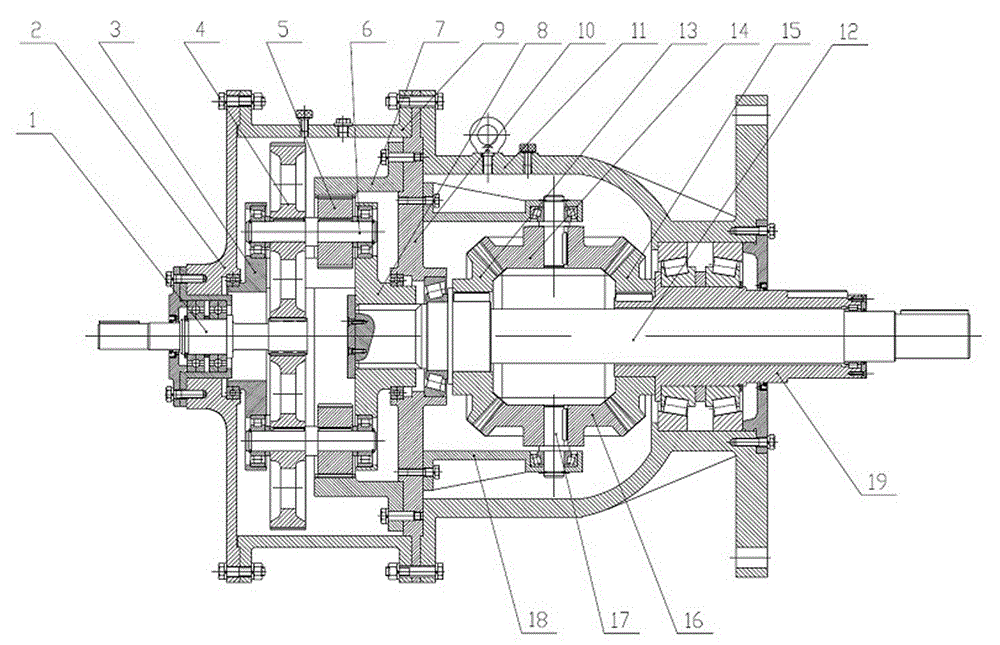

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] As shown in the figure, a single-input coaxial double-output reducer includes an end cover 2, a body I9, a connecting support plate 10, and a body II11 fixedly connected in sequence, and the connecting support plate 10 is connected to the body I9 and the body II11 respectively. Body II11 forms two left and right chambers.

[0014] The left chamber formed by connecting the support plate 10 and the body I9 is provided with a planetary reduction mechanism. The planetary reduction mechanism includes a sun gear, a planetary gear 4, a linkage planetary gear 5, a first planetary carrier 3 and a second planetary carrier 8. The sun gear on the input gear shaft 1 meshes with the three planetary gears 4 supported by the first planetary carrier 3. In this embodiment, the planetary gears 4 and the linkage planetary gears 5 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com