Flat knitting machine two-stage stitch controlling device and flat knitting machine

A control device and technology for flat knitting machines, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as poor drive requirements, poor motor consistency, and complex structure, and achieve simplified structure and improved synchronization performance, and the effect of improving positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

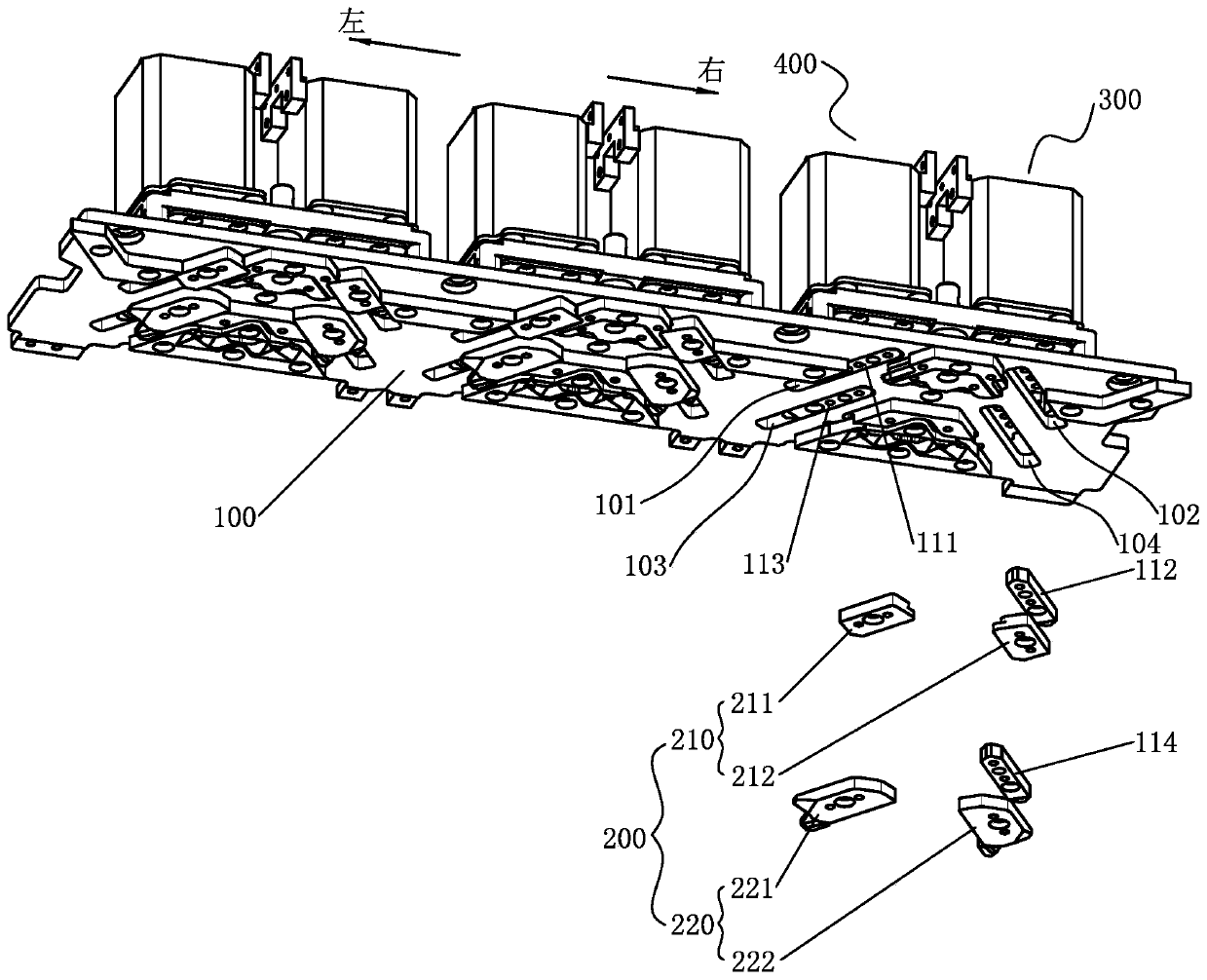

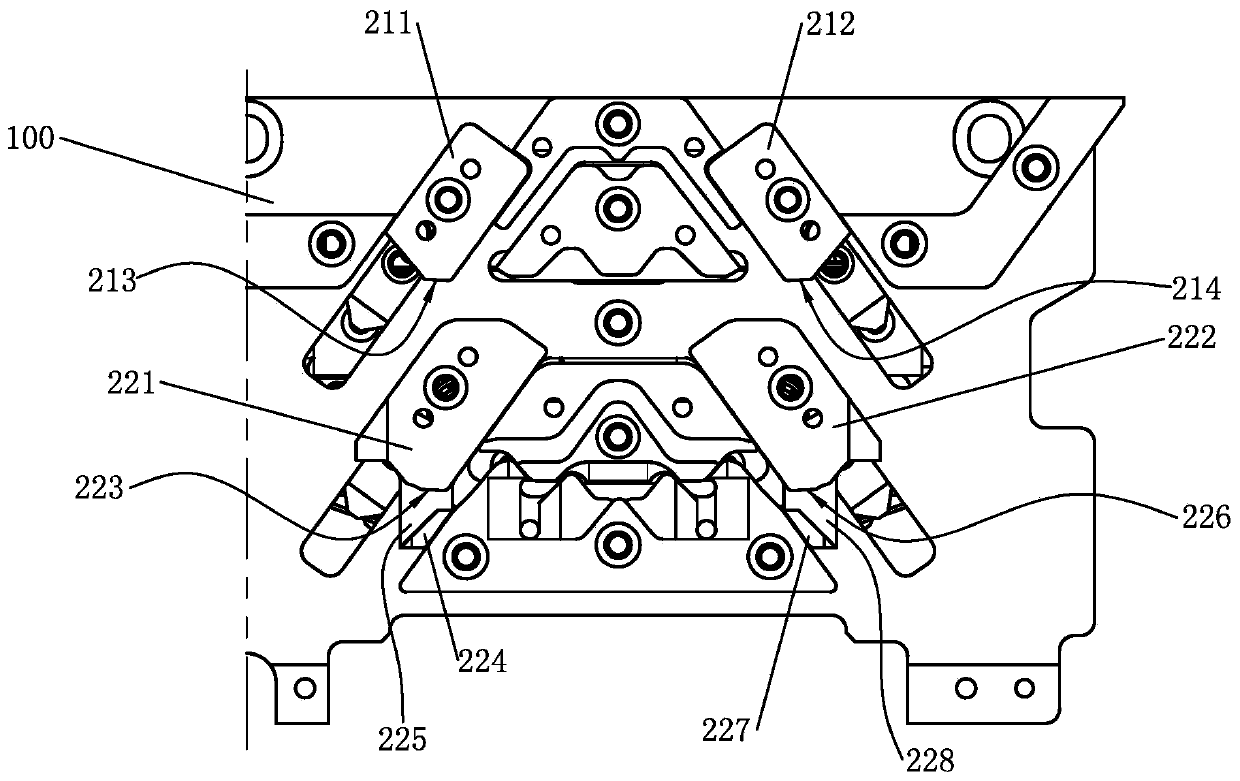

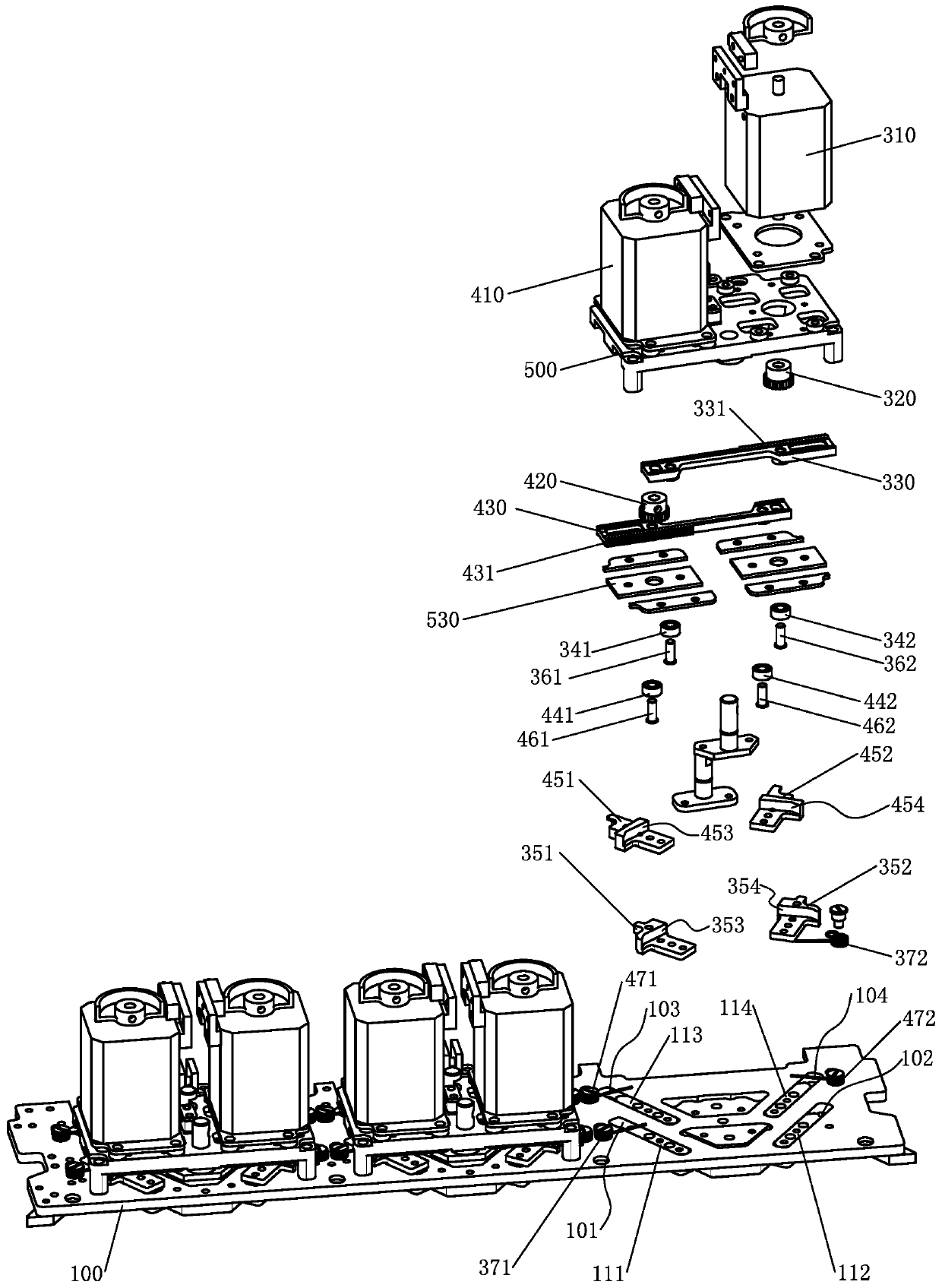

[0037] Such as Figure 1 to Figure 6 As shown, a two-stage stitch control device for a flat knitting machine provided by Embodiment 1 of the present invention includes at least one stitch cam group 200 disposed on the bottom surface of the base plate 100 and a driving mechanism corresponding to the stitch cam group. The stitch triangle group 200 includes an upper stitch triangle group 210 and a lower stitch triangle group 220 arranged at intervals up and down on the bottom surface of the substrate 100. The upper stitch triangle group 210 includes an upper left stitch triangle 211 and an upper right stitch triangle 212 arranged at intervals along the lateral direction. The triangle 220 includes a lower left stitch triangle 221 and a lower right stitch triangle 222 which are arranged at opposite intervals along the lateral direction. The driving mechanism includes a first driving mechanism 300 for driving the upper stitch cam group 210 to move up and down along the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com