Bearing for non-textile machinery

A technology of bearings and textile machinery, applied in the field of non-woven machinery bearings, can solve the problems of low power, unfavorable cost, complex transmission mechanism, etc., and achieve the effects of reducing the overall size, saving production costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

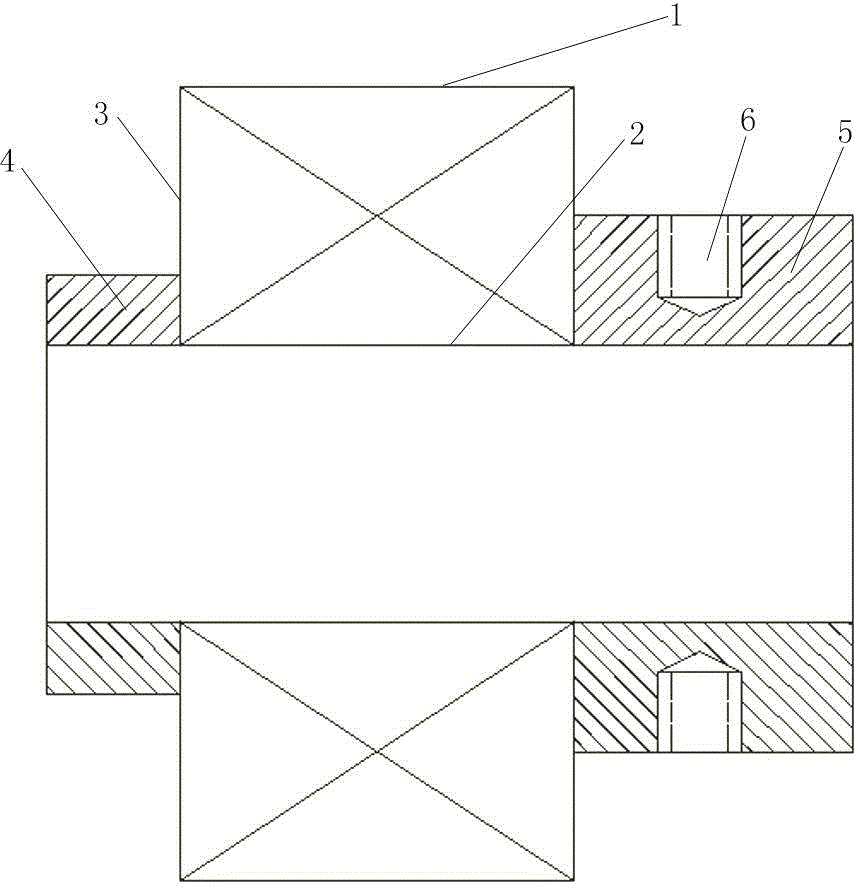

[0016] The design will be further described below in conjunction with the accompanying drawings of the description.

[0017] like figure 1 As shown, a non-woven machine bearing includes an inner ring 1 and an outer ring 2, and is characterized in that it also includes a connecting sleeve 5 and an extension sleeve 4 coaxial with the inner ring 1 and the outer ring 2 .

[0018] The purpose of setting up the extension sleeve is to increase the strength of the bearing. The connecting sleeve can be connected with other transmission parts through various mechanical connection methods. Since the transmission power is not large in the transmission of non-woven machines, the reliability of this design is completely Guaranteed.

[0019] Preferred:

[0020] The above-mentioned non-woven machine bearing is characterized in that a sealing ring 3 is provided between the inner ring 1 and the outer ring 2 .

[0021] In the use of non-woven machines, there are often some floating objects su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com