Synchronous belt-worm gear and its transmission

A technology of synchronous pulley and synchronous belt, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large occupied space and complex structure, achieve convenient use and maintenance, simplify the transmission chain, and be easy to bend Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

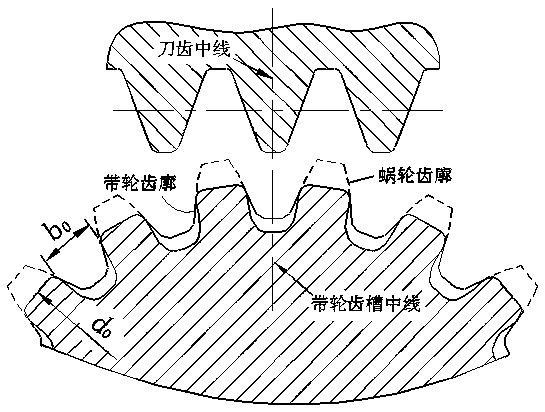

[0021] The tooth surface of the synchronous belt-worm gear provided by the present invention is composed of the tooth surface of the worm gear and the tooth surface of the synchronous belt wheel. The manufacturing process of cutting the tooth surface of the synchronous pulley and then cutting the tooth surface of the worm gear is feasible. For the convenience of the statement, the manufacturing process of first cutting the tooth surface of the synchronous pulley and then cutting the tooth surface of the worm gear is used as an example to illustrate.

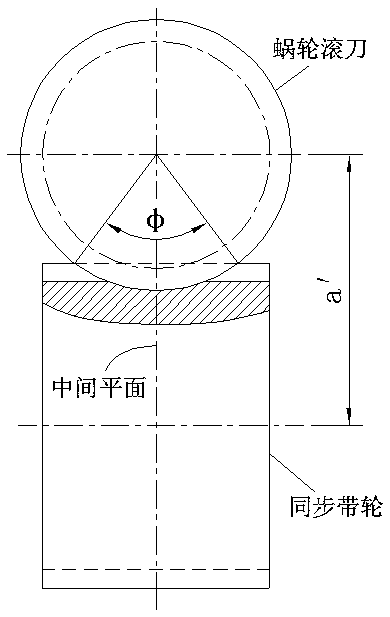

[0022] See attached figure 1 And attached figure 2 , the specific implementation of the synchronous belt-worm gear provided in this example is as follows: In order to avoid the manufacture of special hobs, reduce manufacturing costs and ensure transmission quality, the pitch P b A synchronous pulley slightly greater than or equal to the standard worm shaft pitch mπ, the pitch circle diameter D of this synchronous pulley is slig...

Embodiment 2

[0039] The method of cutting the synchronous belt-worm gear is similar to the above-mentioned embodiment 1, the only difference is that during radial feeding, the hob tooth centerline does not coincide with the tooth groove centerline of the synchronous pulley, so that the cut worm wheel tooth groove centerline Relative to the synchronous pulley cogging center line, a slight angle δ is deviated as in formula (7):

[0040] (7)

[0041] In formula (7), πm is the lead of the single-head hob, D 0 is the diameter of the outer cylinder of the synchronous belt, φ is the central angle of the overlapping part of the hob addendum circle and the outer circle of the synchronous pulley, see the attached figure 1 .

[0042] The above deflection angle δ should be just so that the hob teeth will not cut into the tooth surface of one side of the synchronous pulley, and at the same time, the depth of cutting into the tooth surface of the other side of the synchronous pulley is the minimum, s...

Embodiment 3

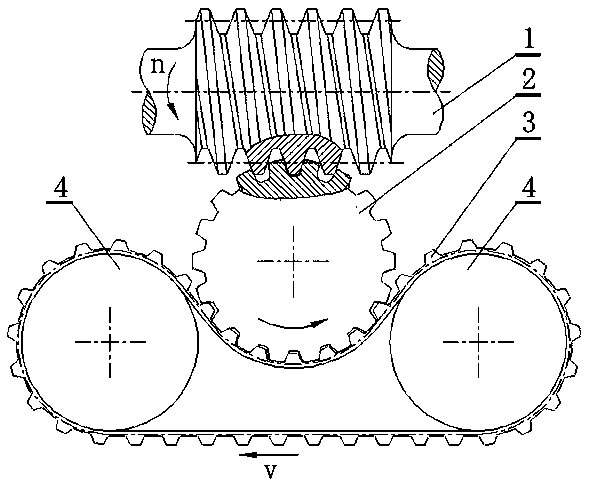

[0044] This embodiment provides a worm-synchronous belt transmission device, which mainly includes a worm, a synchronous belt-worm wheel, a synchronous belt with outer teeth and several pulleys; the synchronous belt-worm wheel is provided by Embodiment 1. See attached image 3 , the structure of the worm-synchronous belt transmission device is: the synchronous belt-worm wheel 2 meshes with the worm 1; Arranged so that the timing belt close to the worm goes around and meshes with the timing belt-worm wheel. The device directly transforms the rotation of the driving worm into the low-speed motion of the synchronous belt in the plane of the worm axis through the synchronous belt-worm gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com