Universal joint transmission inclined shaft type plunger pump

A technology of plunger pump and universal joint, which is applied in the field of oblique shaft plunger pump, can solve the problems of difficulty in processing gears, poor interchangeability, and high machining accuracy of gears, and achieves difficult processing and good interchangeability. Sexual, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

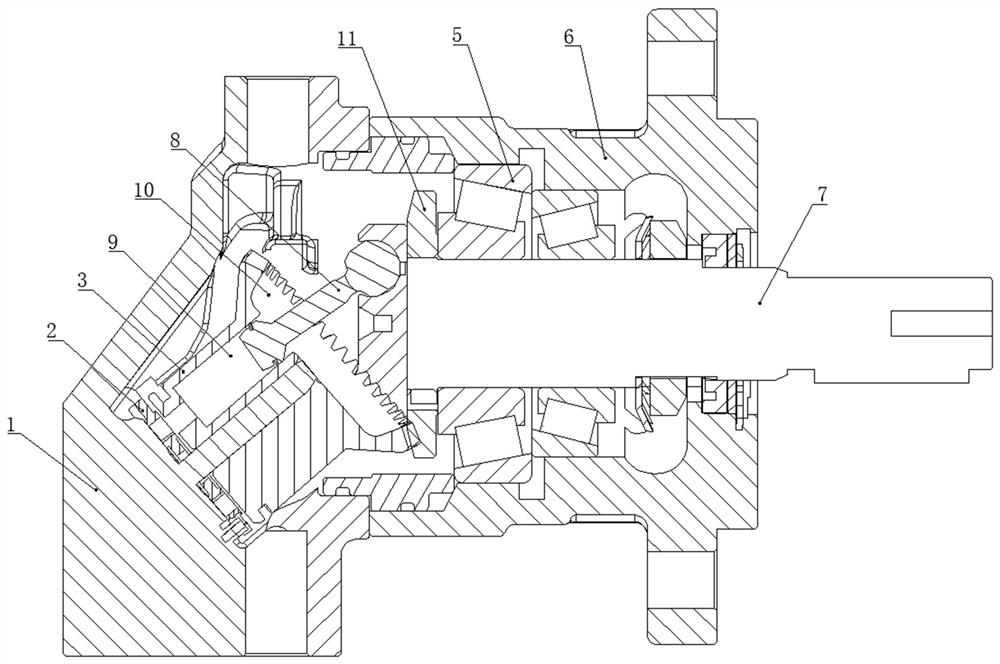

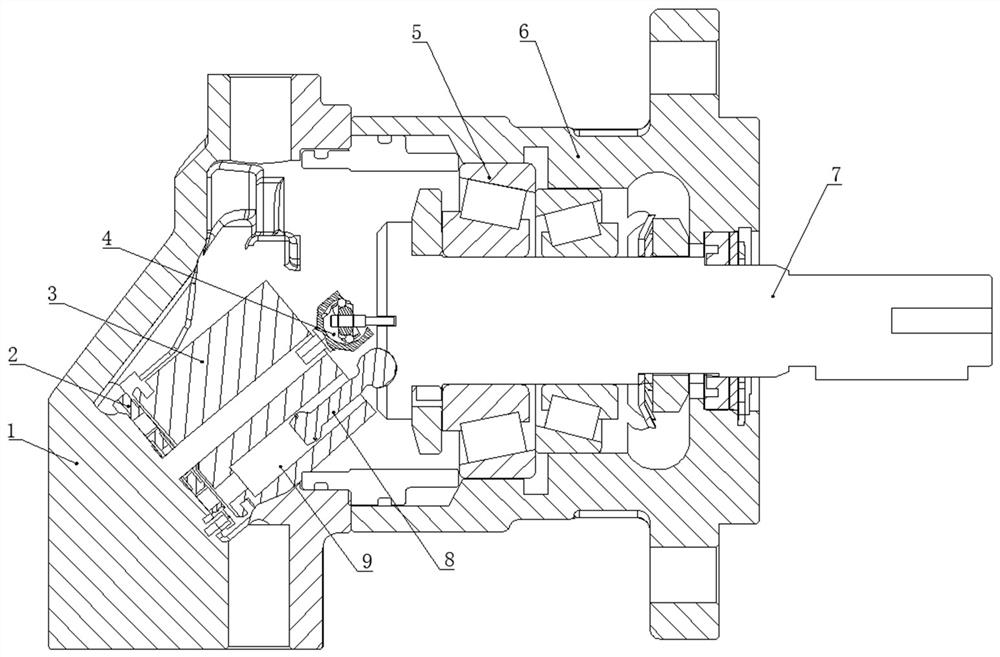

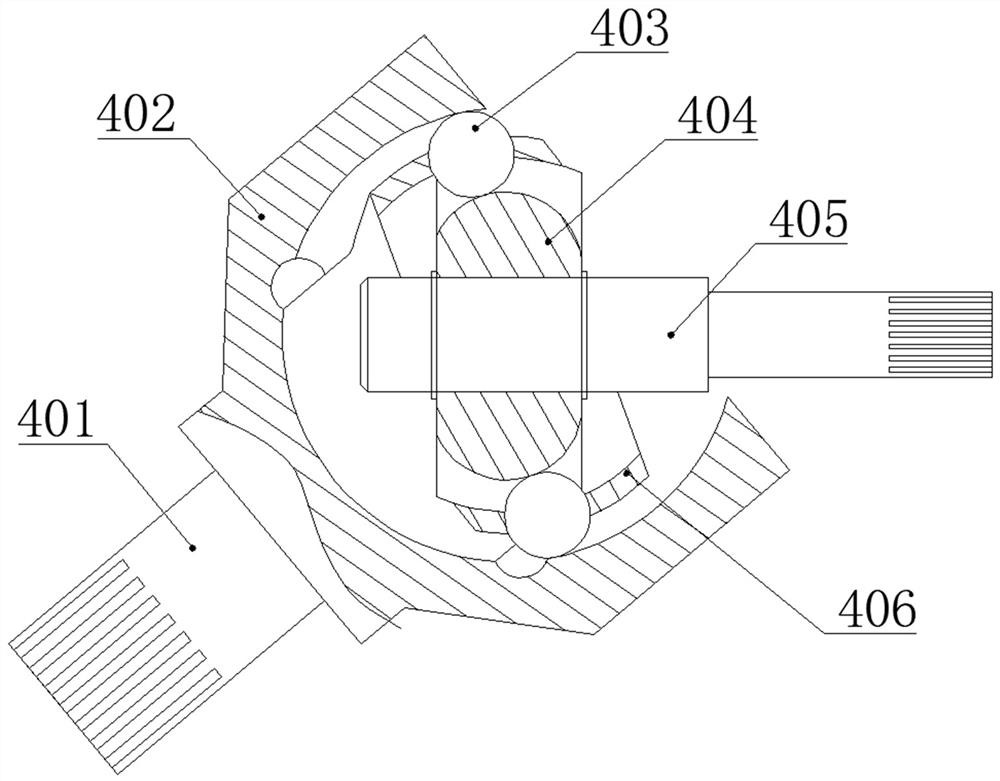

see Figure 1-Figure 3 , a universal joint-driven oblique-axis plunger pump, including a plunger pump body composed of a front pump body 6 and a rear pump body 1, and a main shaft 7 is installed in the front pump body 6 through a bearing assembly 5, and the main shaft 7 It is a stepped shaft. The inner spline hole is provided at the central axis of the end of the main shaft 7 that penetrates into the pump body. The end face of the end of the main shaft 7 that penetrates into the pump body is evenly distributed with seven ball sockets. The ball sockets are annular with the axis of the main shaft 7 as the center. distributed.

[0022] The rear pump body 1 is provided with an oil inlet, an oil outlet, and a drain hole. The rear pump body 1 is provided with a distribution plate 2 and a cylinder block 3, and a spherical flow distribution structure is formed between the distribution plate 2 and the cylinder block 3. , the axis of the cylinder block 3 and the axis of the main shaft 7...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com