Silencer

A muffler and compensator technology, applied in intake mufflers, mufflers, machines/engines, etc., can solve problems such as design frequency imbalance, insufficient effectiveness, weakened damping effect, etc., and achieve the effect of reducing transmission noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

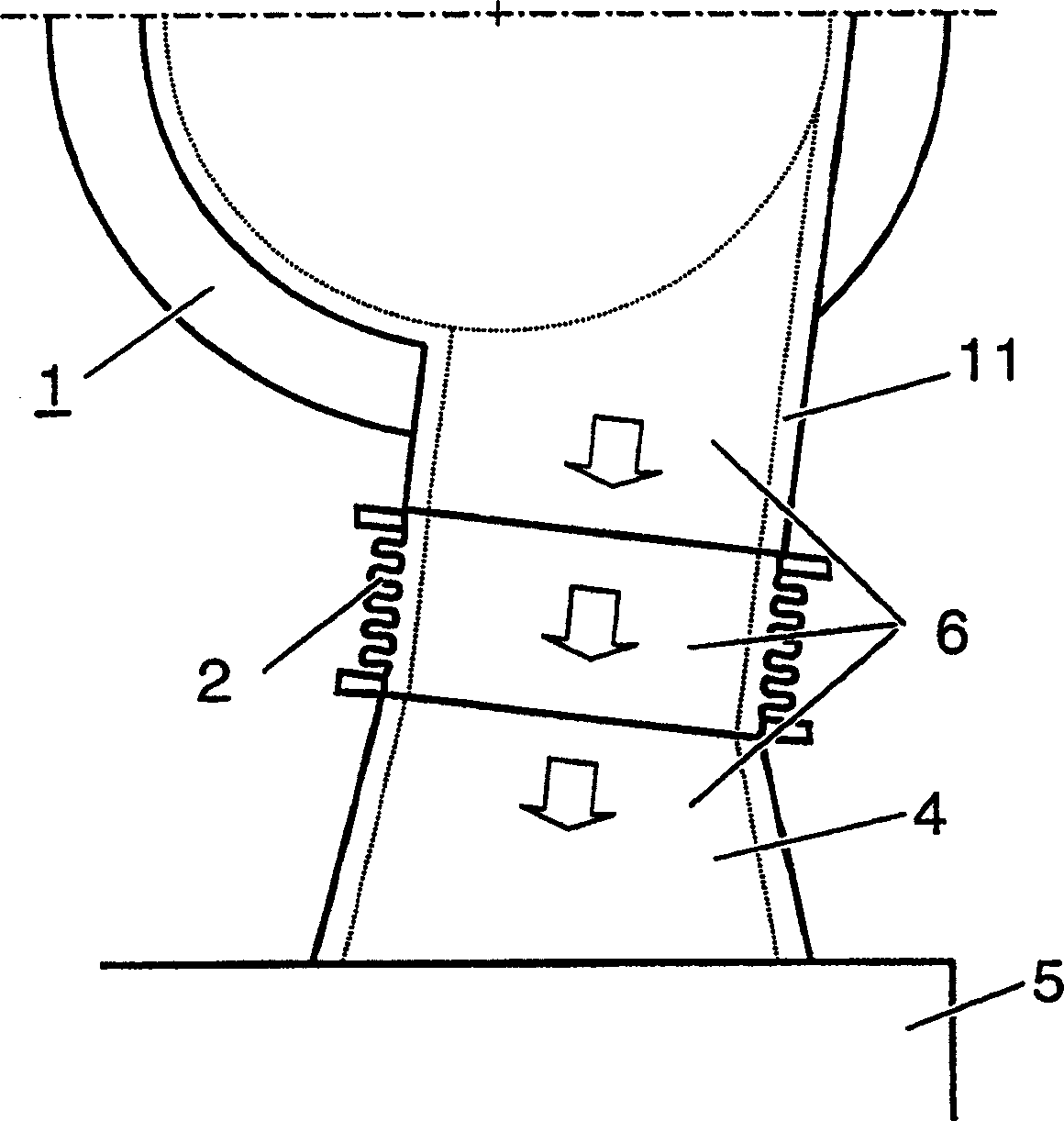

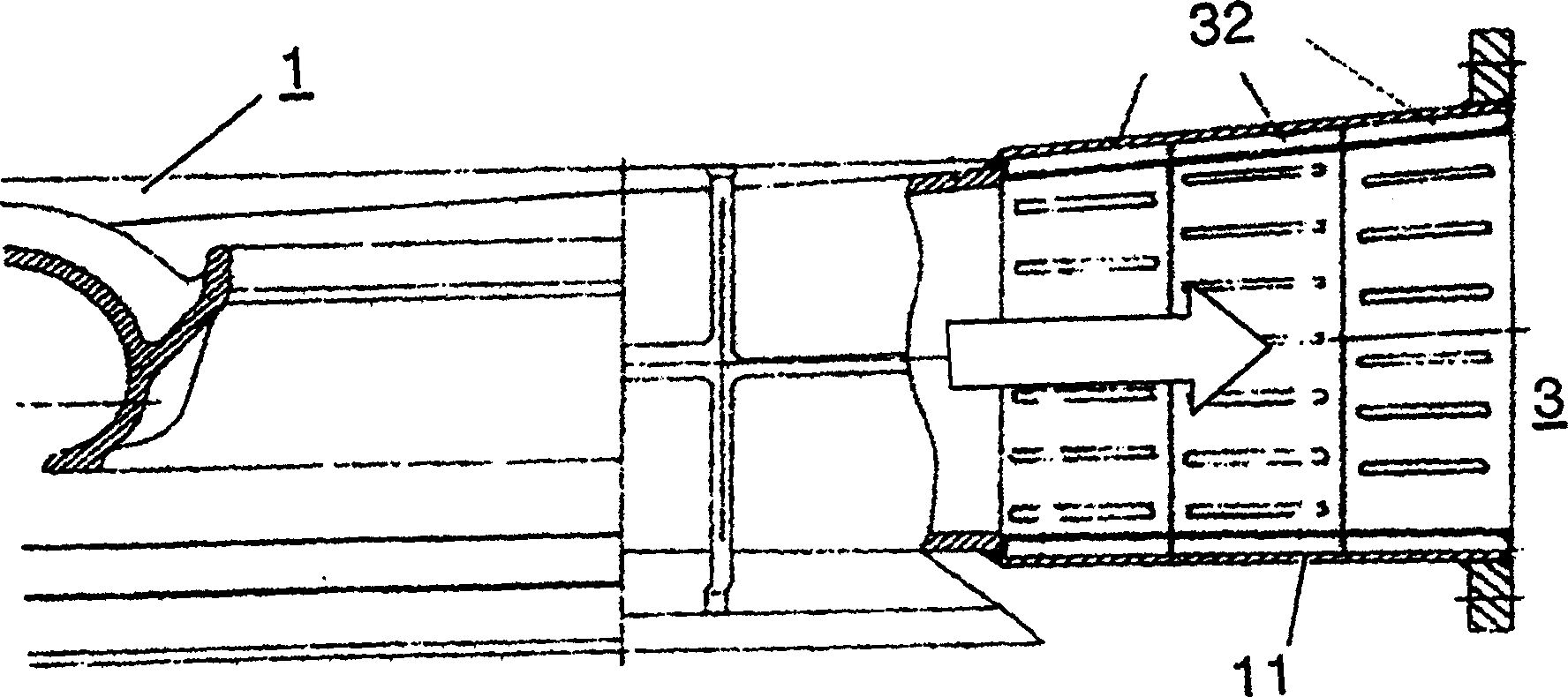

[0021] figure 1 Schematic representation of part of an internal combustion engine with a turbocharger. For example, the internal combustion engine is a large diesel engine, such as is used in ships or stationary power plants. The turbocharger comprises a compressor 1 into which air is drawn in and compressed in order to be subsequently supplied to a charge air cooler 5 of the internal combustion engine via a compressor outlet 11 and a connecting line 4 . In the city, the compressed air flows in the direction of the arrow through a flow channel 6 which, depending on the arrangement of the turbocharger on the internal combustion engine, can be longer or shorter and can include one or more tubular intermediate pieces. One of these intermediate pieces is the schematically shown compensator part 2 .

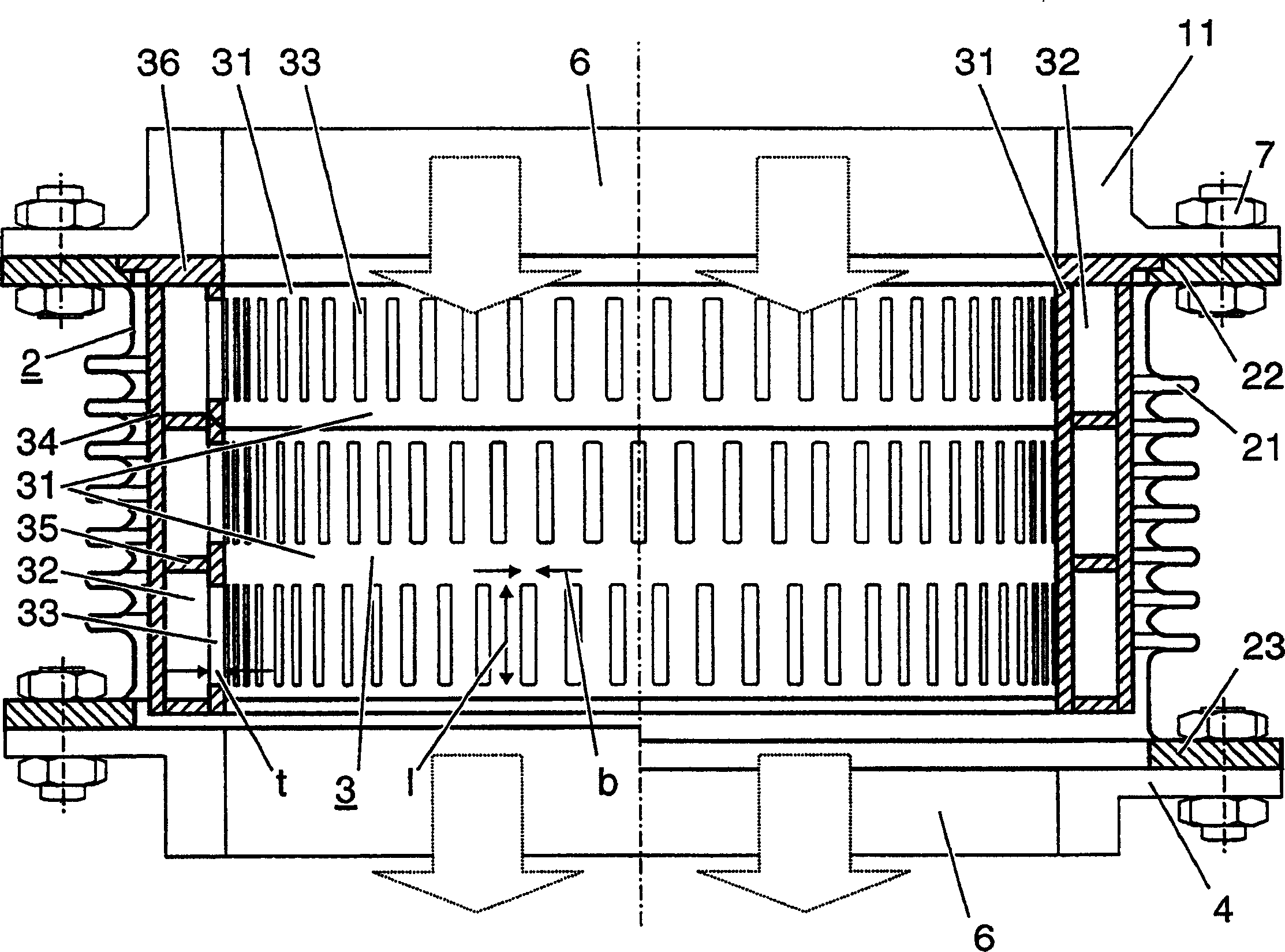

[0022] exist figure 2 The compensator part, shown enlarged in , comprises a compensating element 21 which is formed by an elastic sheet and is arranged between two fastening flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com