Electric roller conveyor with aluminum alloy beams

An aluminum alloy and conveyor technology, applied in conveyor objects, conveyor control devices, roller tables, etc., can solve the problems of many production process links, difficult cleaning, complex structure, etc., and achieve high overall space utilization and savings. The effect of energy consumption, simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

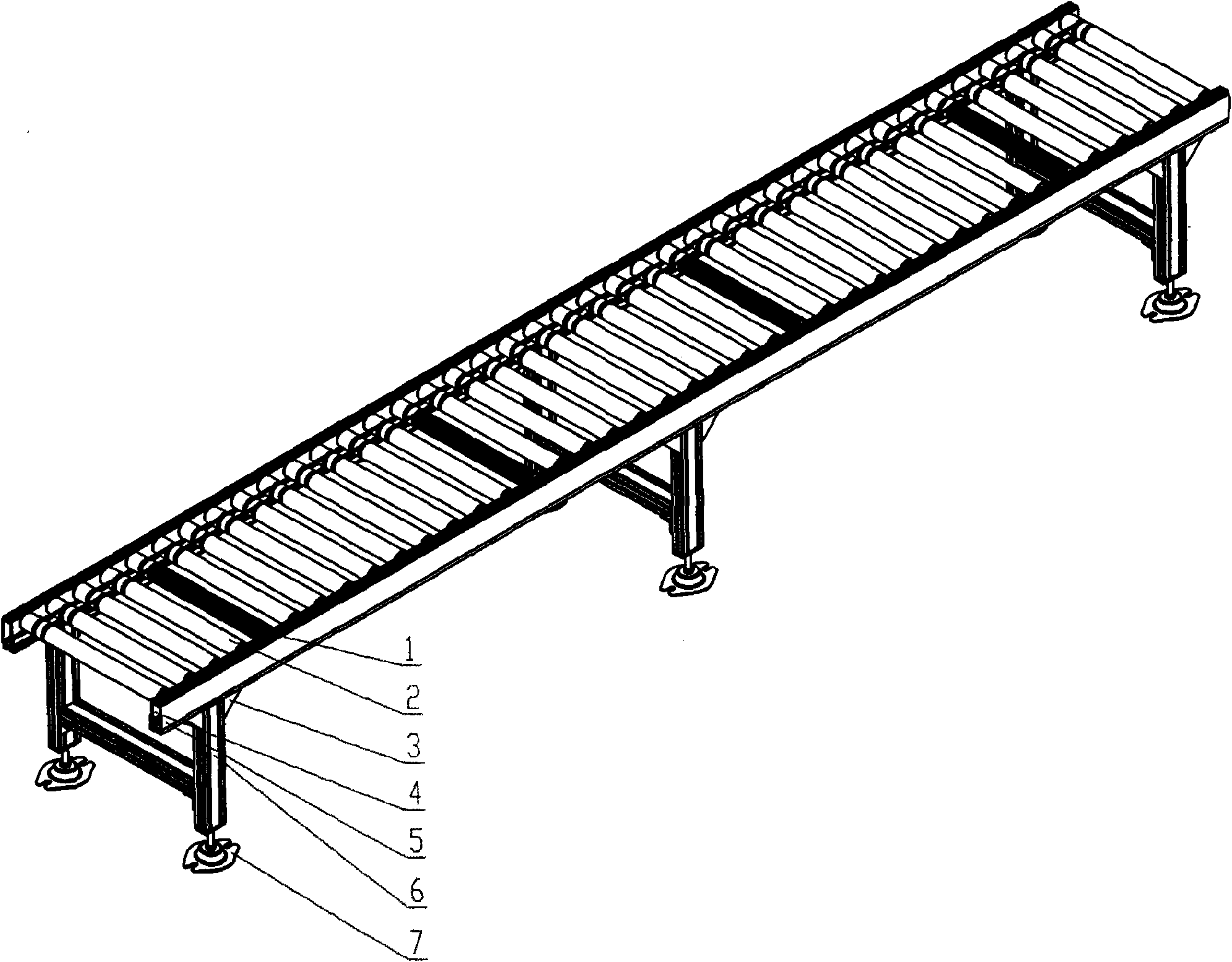

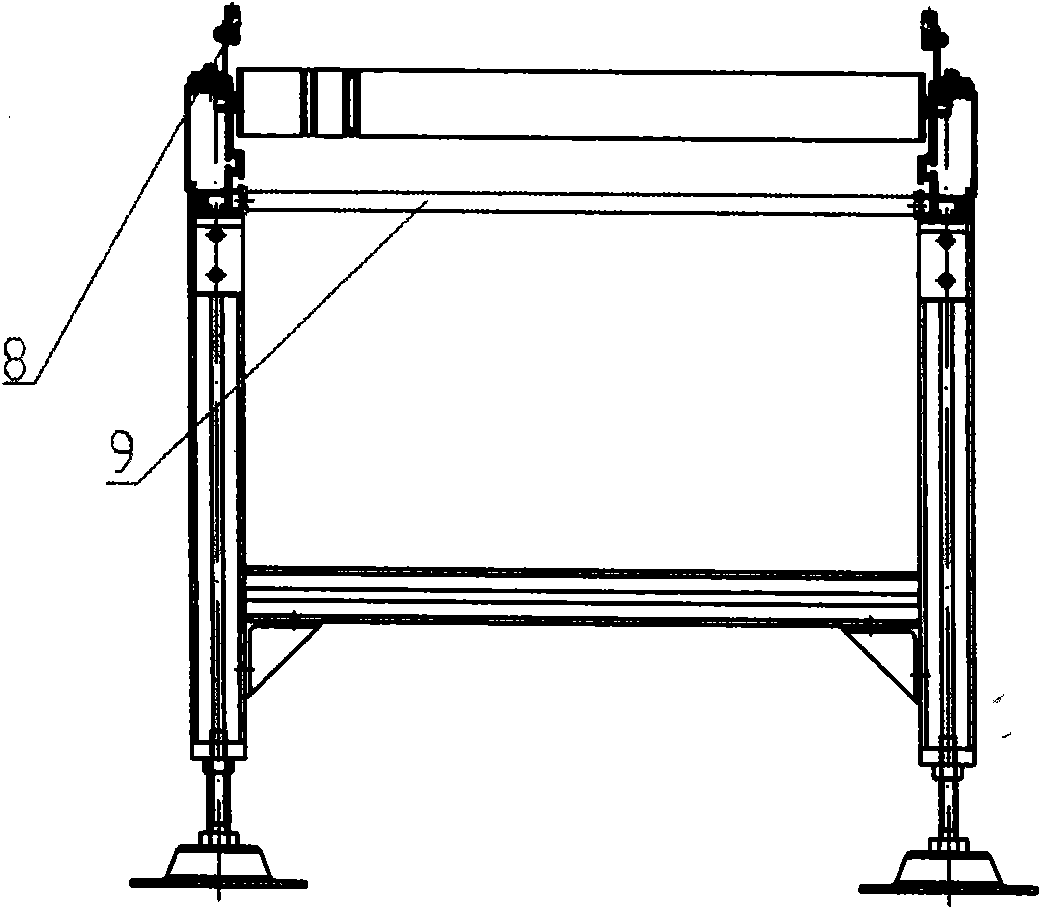

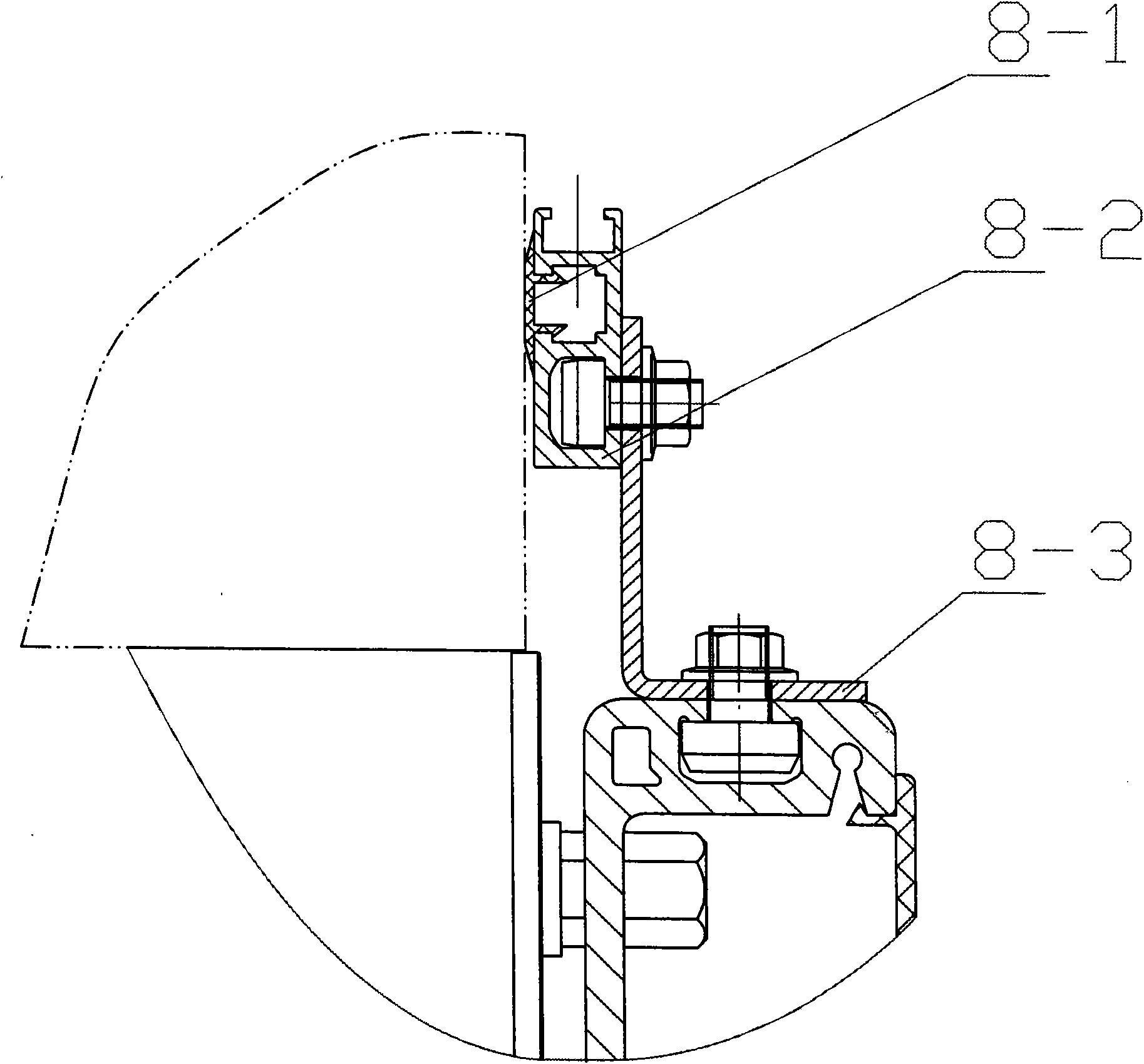

[0015] Such as Figure 1A and Figure 1B As shown, it is a structural schematic diagram of an aluminum alloy beam electric roller conveyor provided by the present invention, which consists of electric roller 1, unpowered roller 2, corner connector 3, aluminum alloy beam 4, sealing plate 5, and aluminum alloy support foot 6 , Ground ankle 7, guiding device 8, connecting beam 9 and PLC system form.

[0016] Aluminum alloy beam 4, aluminum alloy support foot 6, and corner connector 3 are fixedly connected by bolt groups to form an overall frame. Aluminum alloy beam 4 is installed above the aluminum alloy support foot 6, and the bottom of the aluminum alloy support foot 6 is installed Wrist 7 is provided with corner connector 3 at the corner formed by aluminum alloy support foot 6 and aluminum alloy beam 4; two pieces of aluminum alloy beam 4 are reinforced with connecting beam 9; in the present embodiment, each electric roller 1 It is a group with nine unpowered rollers 2, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com