Patents

Literature

32results about How to "Short production period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stereo trough type nutrition providing cultivating method for dendrobium

InactiveCN1820569AStable conditionsShort production periodOrganic fertilisersHorticulture methodsDendrobiumFertilizer

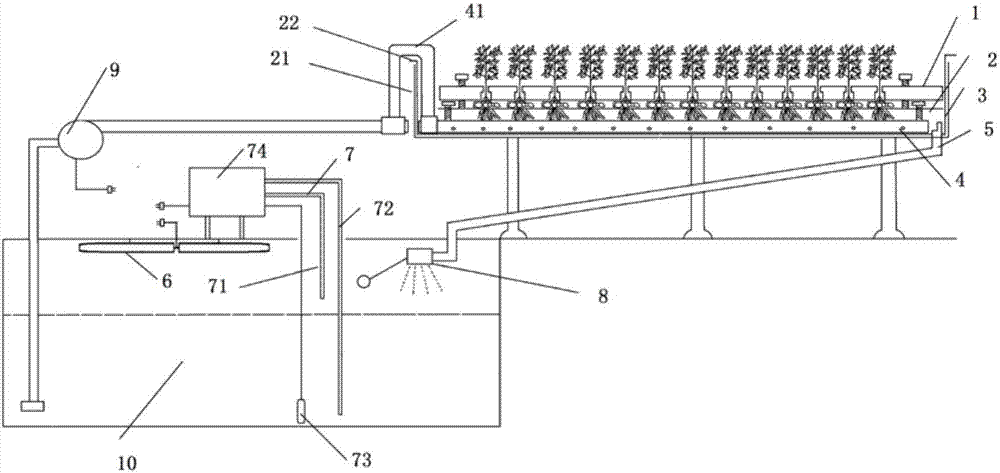

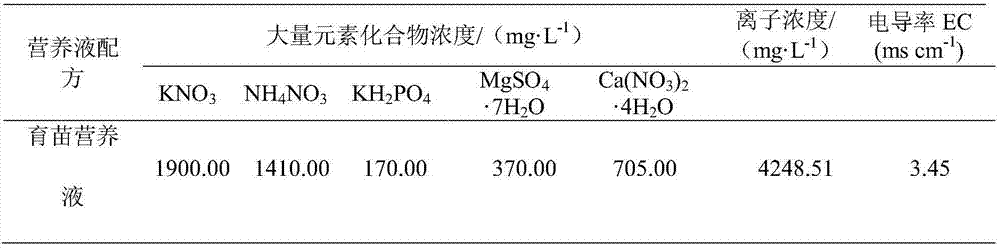

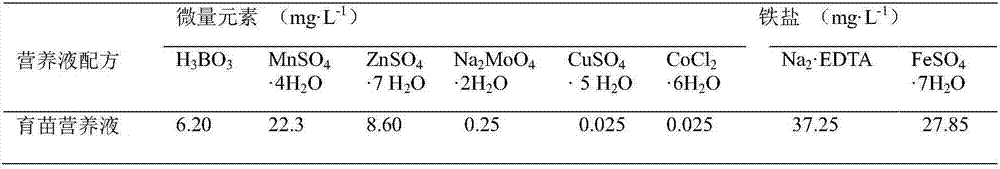

The stereo trough type nutrition providing cultivating method for dendrium includes the planting material selecting process, the planting process, and the water and fertilizer managing process. The stereo trough type nutrition providing cultivating method can speed the growth of dendrium through providing a stable comprehensive and balanced nutrition providing system and has shortened production period and lowered production cost. The present invention provides technological foundation for the development and utilization of dendrium.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

Environment protection baking-free sludge brick and production method thereof

The invention relates to an environment-friendly baking-free sludge brick and a production method thereof. The main compositions of the sludge brick are sludge, sand and cement, and auxiliary chemical raw materials are saturated solvent of potassic salts such as potassium permanganate taken as an oxidant. The invention adopts production processes of waterlogging, oxidation, curing, condensation, moulding and demoulding, fully and effectively utilizes various types of sludge, purifies the environment, does not need to chop hills to unload soil, and protects natural resources; the baking-free technology not only is energy-saving but also reduces the production cost, and has reasonable technological design, simple and convenient operation and no secondary pollution; the brick can be delivered after naturally dried in the air for 15 days, and the quality of the brick completely accords with the national standards; the shaping randomness is strong, and tiles, street bricks and so on can be manufactured only by adoption of different dies; and the environment-friendly baking-free sludge brick has considerable social benefit and economic benefit and obvious promotion value and application value.

Owner:汉寿县永兴砖厂

Time-saving and labour-saving cultivation method for chrysanthemum cut flower

The invention provides a time-saving and labour-saving cultivation method for chrysanthemum cut flowers. The time-saving and labour-saving cultivation method comprises a stage of straight cutting for raising seedlings and production of finished product flowers, wherein the production of the finished product flowers comprises a nutritional growth stage and a reproductive growth stage, the straight cutting for raising seedlings comprises four stages of tidying in a planting shed, preparation of chrysanthemum seedlings, cottage and seedling management. With the adoption of the cultivation method disclosed by the invention, a production period is shortened for at least nine days on year-on-year basis, utilization rate of land is improved, planting work load is also saved, and chrysanthemum cultivation efficiency is also improved.

Owner:JIANGSU JUNMA AGRI & FORESTRY TECHINDAL

Integrated high propagation method of water planting of virus-free potato seeds and seedlings

InactiveCN107347608APromote circulationReduce holdupAgriculture gas emission reductionCultivating equipmentsNutrient solutionPlant propagation

The invention relates to an integrated high propagation method of water planting of virus-free potato seeds and seedlings. The method comprises the steps that a multiplication technology of the water-planting virus-free seedlings and a water planting production technology of the seedlings and the seeds are integrated, and the concentration of nutrient solution components, the light quality of a supplementary light source, hormone components, seedling cutting times and the like are optimized at the same time. According to the method, the stability and security are high, operation and daily management are simple and convenient, the maintenance and production costs are low, the sound seedling index of water-planting potato plants are significantly improved, the yield and quality of the seedlings and mini-potato are improved, the plant propagation coefficient is enlarged, the production cycle of the mini-potato is shortened, and the method is of great importance in breeding of the potato seeds and seedlings.

Owner:SOUTHWEST UNIVERSITY

A kind of manufacturing method of plastic forming mold

The invention discloses a manufacturing method of a plastic forming mold, which is characterized in that it comprises the following steps: (1) molding the mold according to the shape of the product; (2) pre-processing the The metal part is placed on the molding module, and the metal base frame is fixed on the metal part; (3) Evenly coat a layer of release wax on the surface of the modeling module, and after the resin glue and the reinforcing powder are mixed evenly, Coating on the surface of the modeling module, curing for 3 hours to make the green body, and then sticking the glass fiber cloth layer on the inside of the green body with resin glue; (4) Inserting steel wires in the base mold frame to form a three-dimensional network structure, Then pour concrete into the void in the mold frame, and then form it after curing. The manufacturing method of the plastic forming mold involved in the present invention is a manufacturing method of the molding mold which is completed synchronously by molding, edge trimming, hole opening and the like, and the mold making period is short, the cost is low, the performance and dimensional stability are good, and the production efficiency is high.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

High-efficiency diatomaceous earth clarification tank

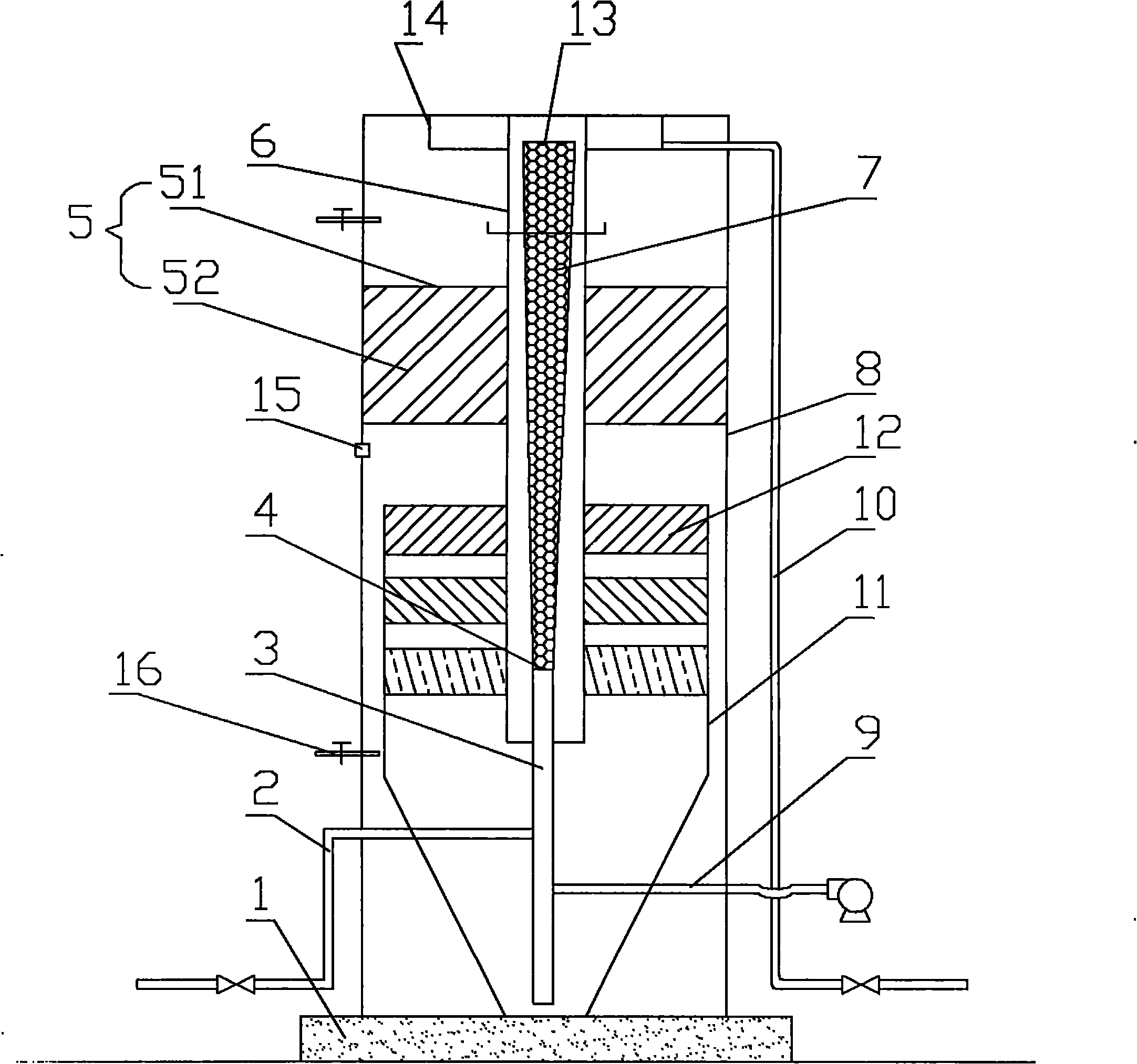

InactiveCN101928079AStrong resistance to shock loadsEasy to handleMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationAir compressionSludge

The invention discloses a high-efficiency diatomaceous earth clarification tank. The lower part of the tank body is provided with a sludge tank; a support mesh is fixed in a center reaction barrel; a plastic ball with cellular holes is arranged in the center reaction barrel; the center reaction barrel positioned under the support mesh is communicated with a sewage inlet pipe and an air compression pipe; the center reaction barrel is arranged in the middle of a center pipe; the center pipe is fixed on a tank body; the lower part of an inner diatomaceous earth filter chamber is tapered and is communicated with the sludge tank; at least two inner inclined tube filter layers are fixed between the inner diatomaceous earth filter chamber and the center pipe; the center pipe extends out of the lowermost inner inclined tube filter layer; two ends of an outer inclined pipe filter layer are respectively fixed on the tank body and the center pipe; the outer inclined pipe filter layer is positioned above the inner inclined tube filter layers; and a clear water outlet pipe is communicated with the upper part of the tank body. The high-efficiency diatomaceous earth clarification tank has the advantages of high stability of a suspension layer, low medicament consumption, low cost of sewage treatment, small equipment volume, small occupied area and low production cost.

Owner:浙江永洋复合材料科技有限公司

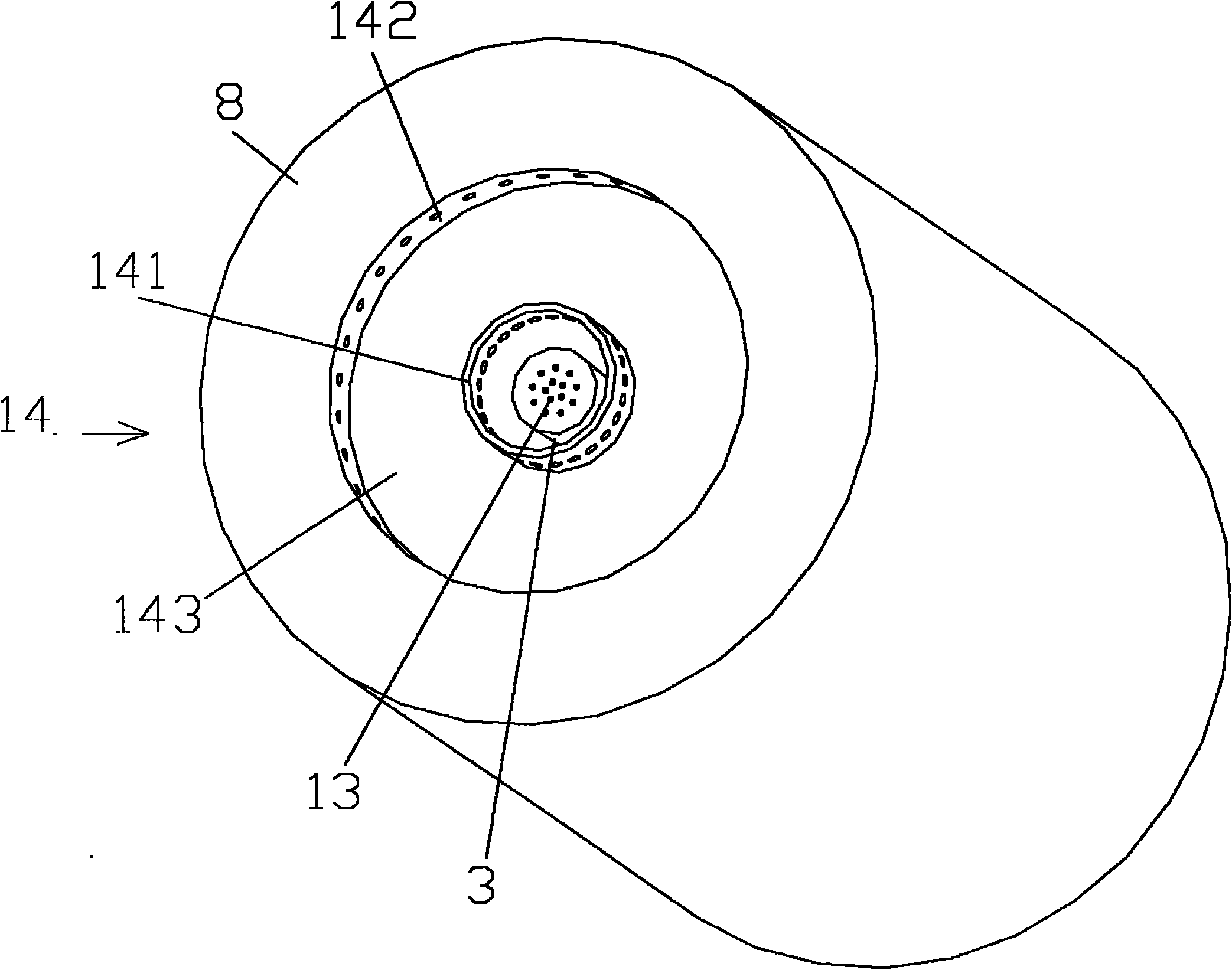

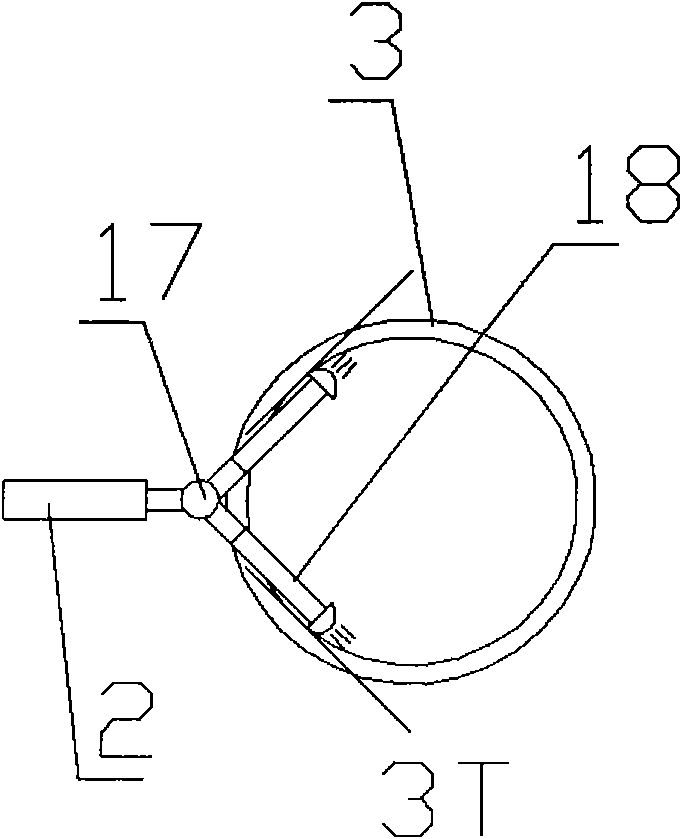

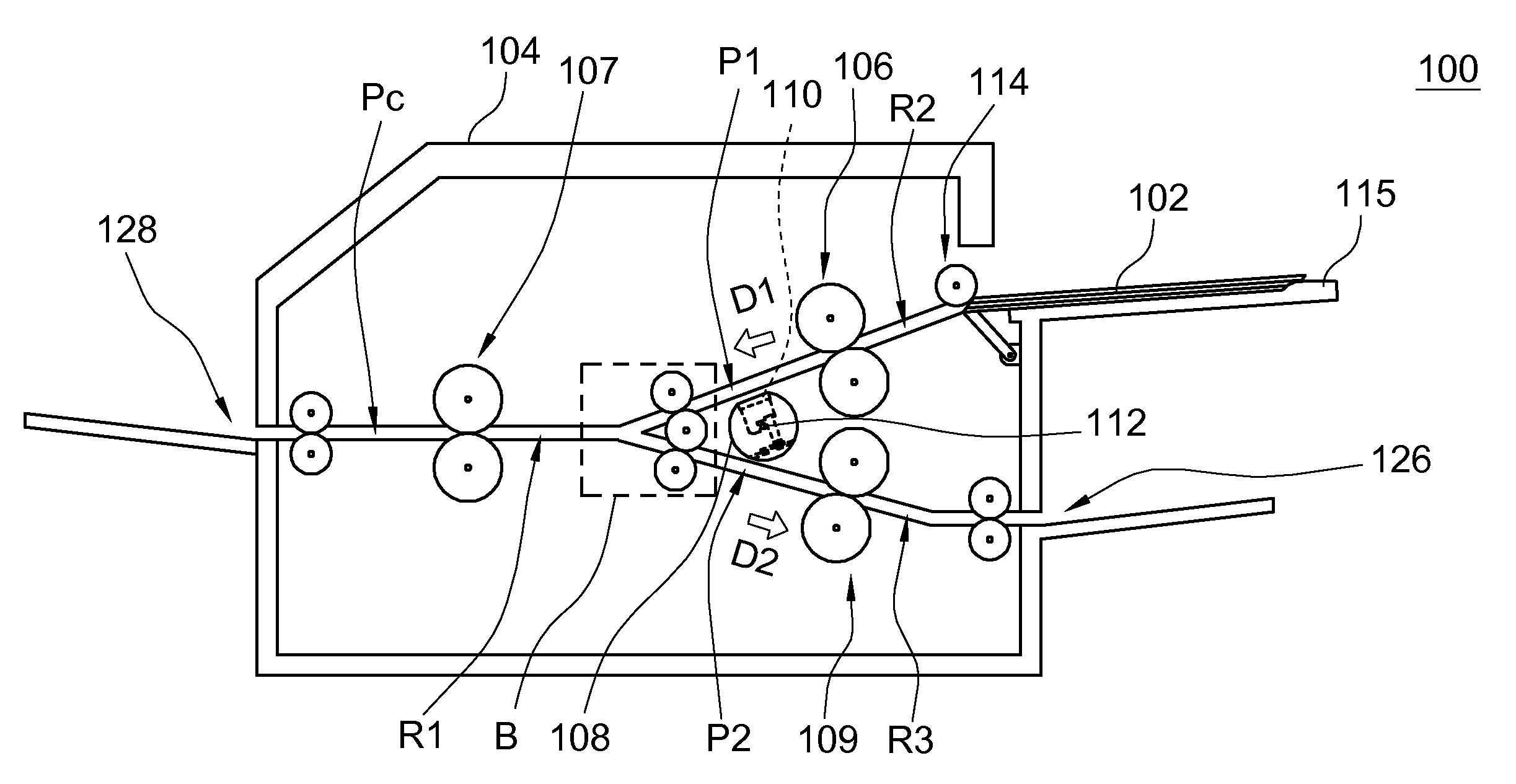

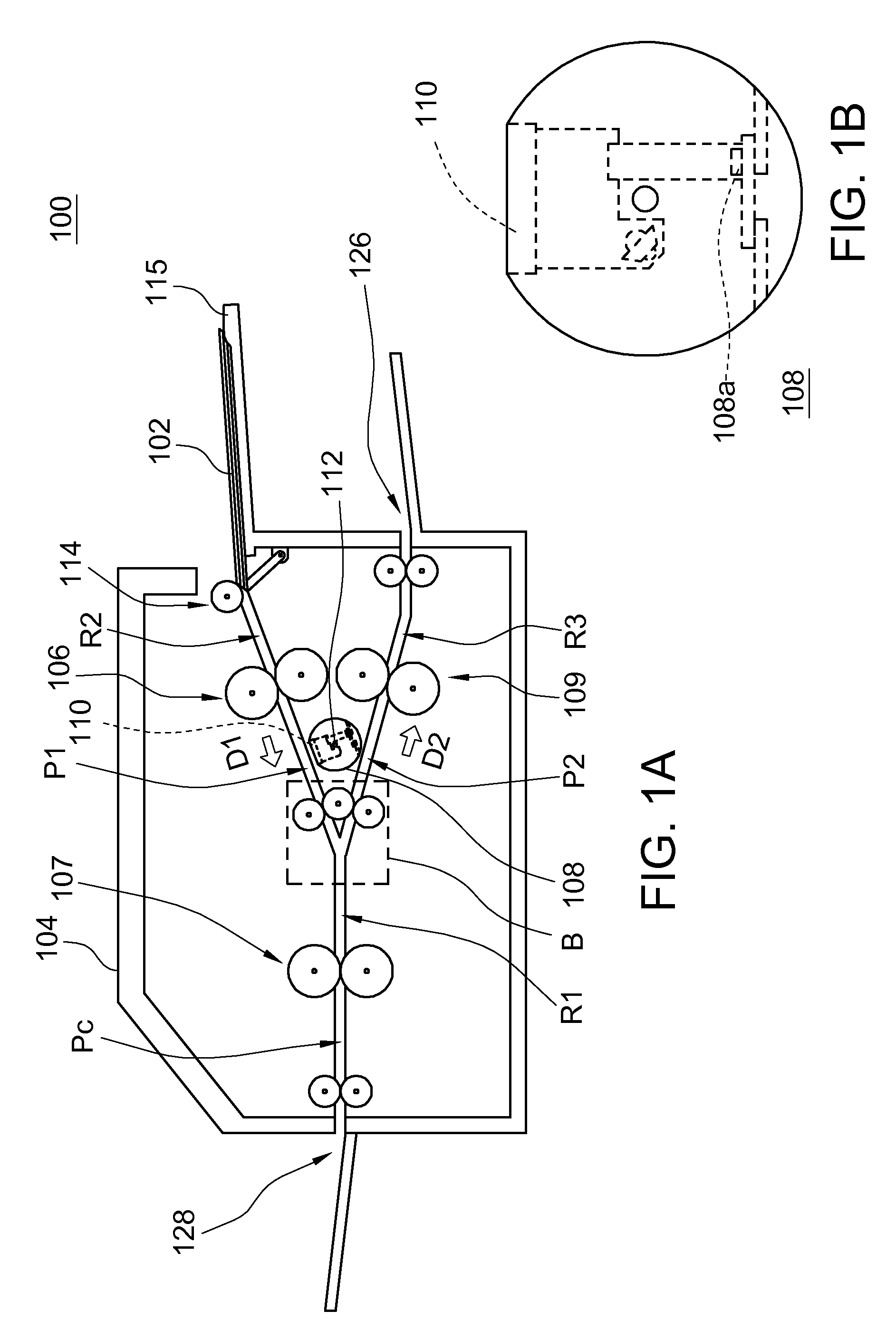

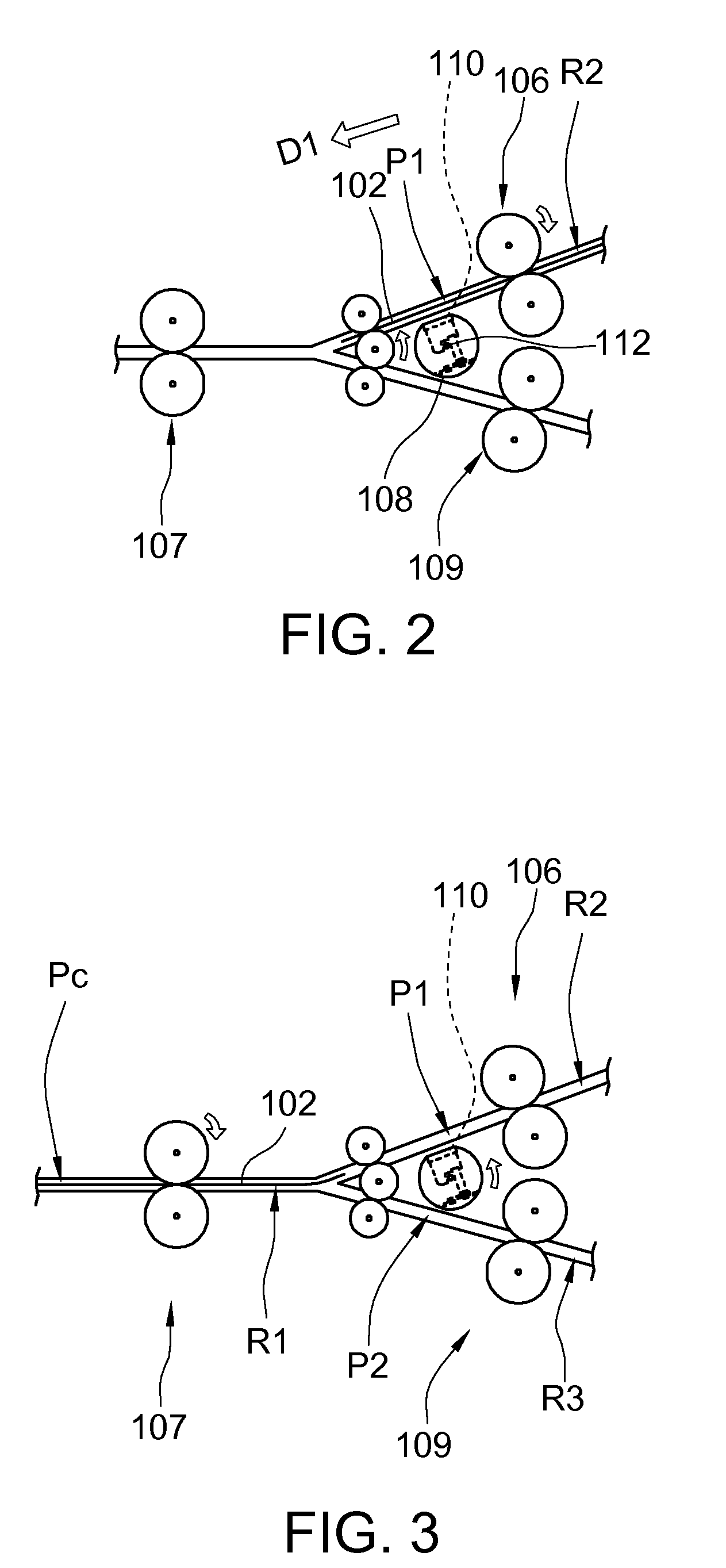

Scanner with Simplified Document Feeding Path

InactiveUS20090279149A1Lower costShort production periodAnalysis by subjecting material to chemical reactionBiological testingOptical ModuleComputer science

A scanner with a simplified document feeding path is provided for scanning a document. The scanner includes a paper path, a conveying mechanism, an optical module and a scan window. The conveying mechanism conveys the document along the paper path. The optical module, rotatably disposed, captures an image of the document conveyed to a first position and a second position in the paper path, wherein the optical module captures a front-side image of the document at the first position and a back-side image of the document at the second position. The scan window, mounted on the optical module, is turned toward the first position and the second position as the optical module rotates, and the optical module captures the image of the document through the scan window.

Owner:AVISION

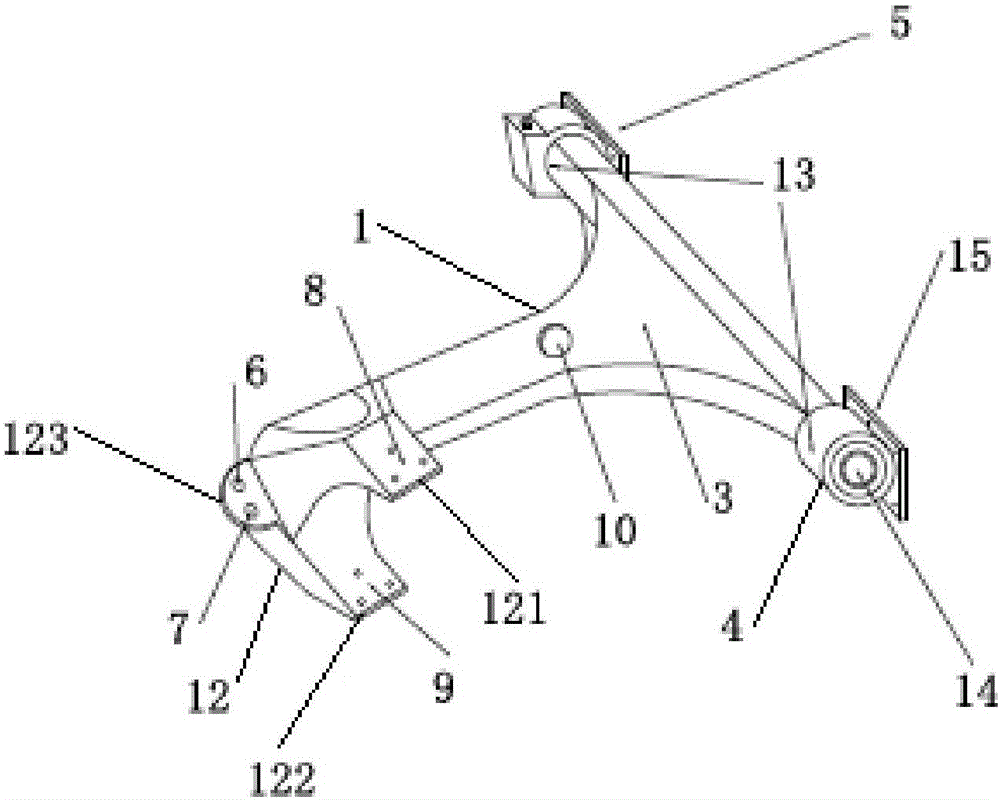

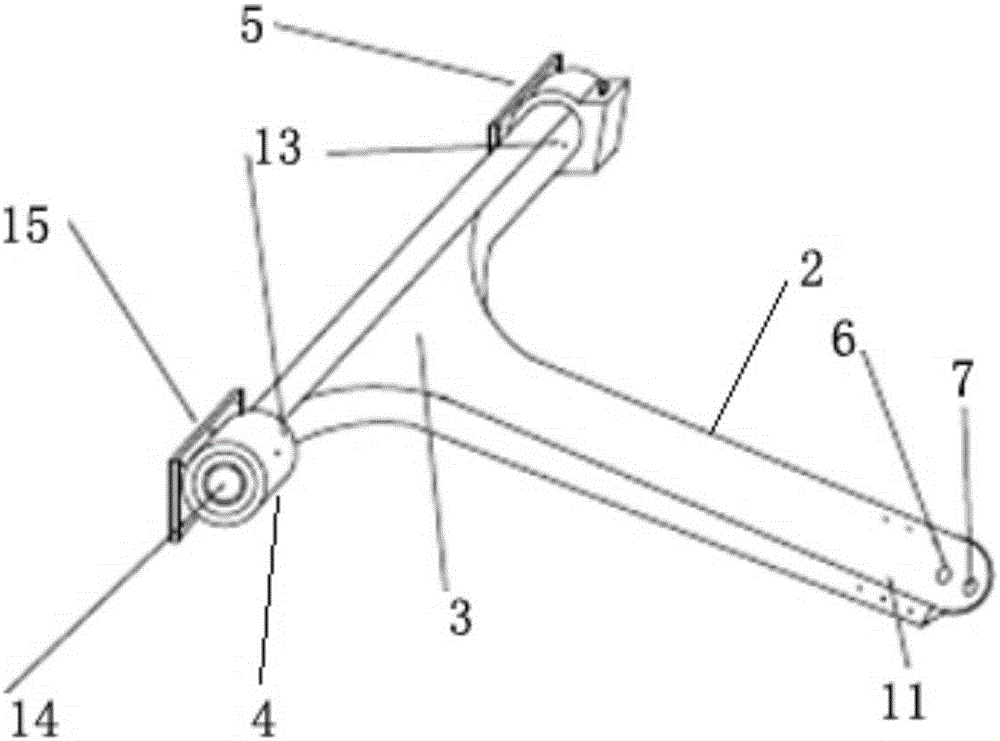

Automotive longitudinal and transverse arm independent suspension system

ActiveCN106627016AImprove accuracyImprove ride comfort performanceResilient suspensionsPivoted suspension armsAutomatic controlGyroscope

The invention discloses an automotive longitudinal and transverse arm independent suspension system. The system comprises a front suspension system and a back suspension, the front suspension system is composed of first cantilevers which are located on the left side and the right side of the front of a vehicle, and the back suspension system is composed of second cantilevers which are located on the left side and the right side of the back of the vehicle; the first cantilevers and the second cantilevers each comprises a cantilever main body, a cantilever shaft sleeve, a worm gear assembly fixing base, a shock absorber fixing portion and a transverse stable rod fixing portion; each first cantilever is further provided with an upper steering ball head fixing portion, a lower steering ball head fixing portion and a steering interim swing arm fixing shaft sleeve; each second cantilever is further provided with a back wheel hub support fixing portion. The back suspension system is free of steering; if servo motors are installed on the worm gear assembly fixing bases, free adjustment can be achieved when the vehicle body height is different from the road height, and stepless automated control requirements can be achieved under control of a four-wheel height sensor, a gyroscope and an ECU. Accordingly, the system not only has the comfort of limousine, but also has the high trafficability of off-road vehicles.

Owner:江西韵动新能源科技有限公司

A Method of Establishing the Model of Geographical Photographs Captured by Aerial Oblique

The invention discloses a building method of a model of aviation inclined shooting geographic photos. The method comprises the steps that a virtual camera model of each photo is restored in an internal storage, photos corresponding to roughly positioned three-dimensional space coordinates are inquired, pixel homonymy points are inquired for all drawn peaks on the photos, three-dimensional space coordinates of the pixel homonymy points are obtained by back calculation, accurate three-dimensional space coordinates of the peaks are calculated by fitting, a building outline is drawn on the aviation photos, and a three-dimensional building model is generated. The building method is low in requirement for professional technical level of operators and less in operation, the whole procedure is low in production cost and short in production period, the obtained model is high in precision and good in visual effect and can highly coincide with the terrain, and the site can be effectively and really reflected.

Owner:广西界围信息科技有限公司

Lemon fruit wine and production method thereof

InactiveCN107541396AShort production periodSmooth tasteDigestive systemAlcoholic beverage preparationMedicinal herbsLimonium

The present invention involves the field of fruit wine brewing, which specifically involves a lemon fruit wine and production method. It is based on lemon as the main raw material, supplemented by Chinese medicinal materials such as thorns, white thorns, Tangli leaves, honeycomb grass, angelica, and angelica., Eased, fermentation, preparation of traditional Chinese medicine solution and preparation of fruit wine and other steps.The present invention uses low temperature fermentation, which is conducive to enhancing the aroma of fruit wine and improving the color and taste of fruit wine; solve the lack of traditional winemaking methods, simple production technology, short production cycle, greatly reduced production costs, improved production efficiency, easy -to -large production productionEssence

Owner:HARBIN SHANBAO LIQUOR IND

Mango fruit wine and production method thereof

InactiveCN107541395AShort production periodSmooth tasteMetabolism disorderDigestive systemHorticultureMushroom

The invention relates to the field of fruit wine brewing, in particular to a mango wine and a production method. It uses mango as the main raw material, supplemented with Chinese medicinal materials such as chrysanthemum, angelica, orange stem, Atractylodes macrocephala, and straw mushroom. After raw material treatment, enzymatic hydrolysis, Fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine and other steps of processing and production. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

Orange fruit wine and production method thereof

InactiveCN107541400AShort production periodSmooth tasteNervous disorderDigestive systemFlavorClam shell

The invention relates to the field of fruit wine brewing, in particular to an orange fruit wine and a production method, which uses oranges as the main raw material, supplemented with traditional Chinese medicinal materials such as liquorice grass, thorn pear, water shield, melaleuca leaf, clam shell grass root, etc. Processing, enzymatic hydrolysis, fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine and other steps of processing and production. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

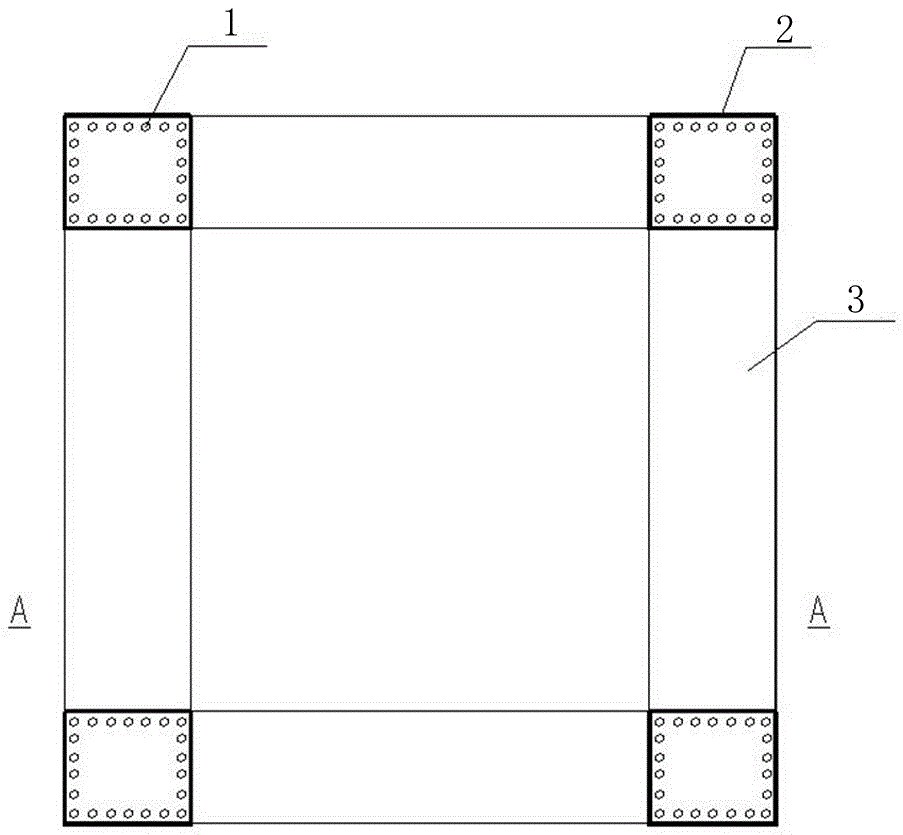

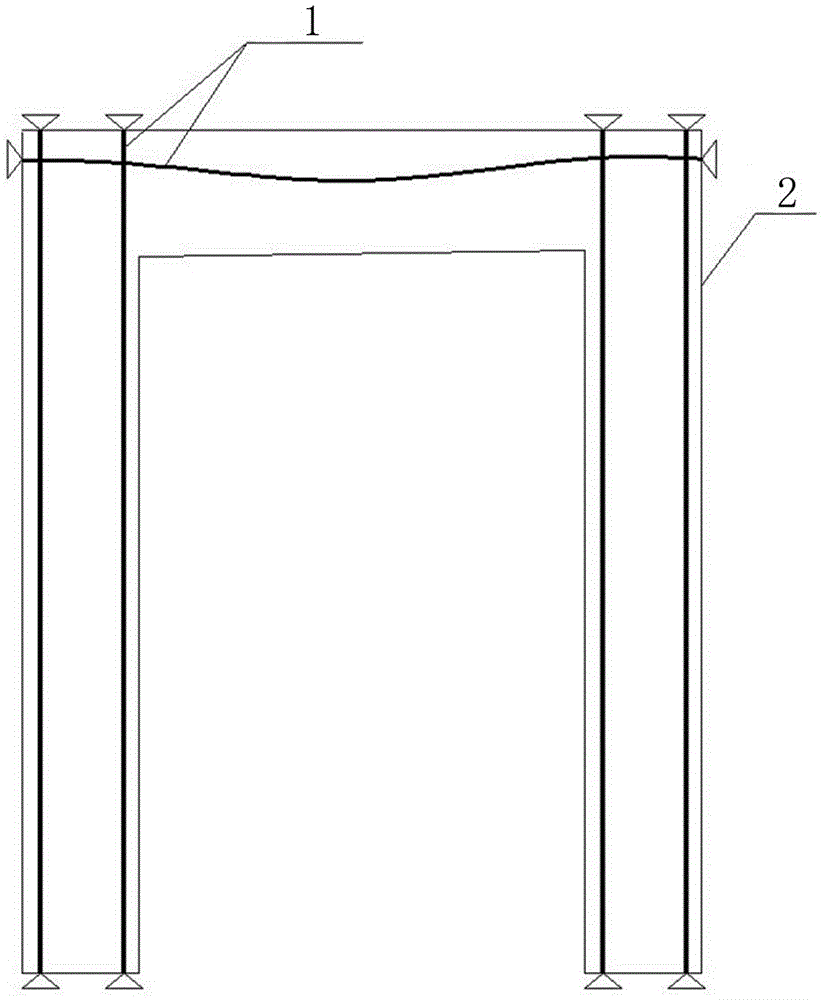

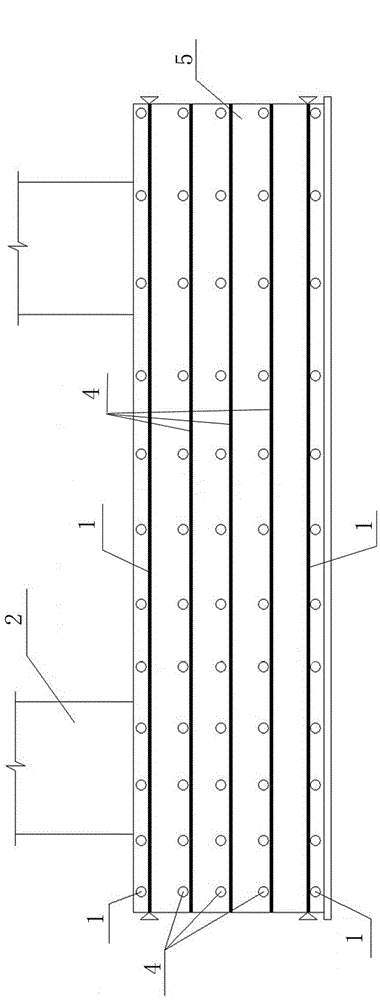

Prestressed reinforced concrete cast-in-place turbine generator base

InactiveCN105544595AReduce vibrationIncrease stiffnessFoundation engineeringReinforced concretePre stress

The invention discloses a prestressed reinforced concrete cast-in-place turbine generator base which comprises a base bottom plate, frame columns and frame beams. Prestressed reinforcements tensioned through a post-tensioning method are arranged in the base bottom plate, the frame columns and the frame beams. The two ends of each prestressed reinforcement are anchored at the ends of the base bottom plate or the corresponding frame column or the corresponding frame beam through a tensioned end anchorage device and a fixed end anchorage device. A cavity mold is reserved at the end of the base bottom plate or the corresponding frame column or the corresponding frame beam where each tensioned end anchorage device is located, and the tensioned end anchorage devices are fixed into the reserved cavity mold. Unbounded prestressed reinforcements are adopted as the prestressed reinforcements. The prestressed reinforcements tensioned through the post-tensioning method are arranged in all the components of the turbine generator base, and compared with a common turbine generator base, the turbine generator base has the beneficial effects of being high in integral rigidity, small in overall deformation, small in base vibration and short in production period and reducing cost.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

Elatagnus conteta Roxb. fruit wine and production method thereof

InactiveCN107541392AShort production periodSmooth tasteAntipyreticDigestive systemMedicinal herbsFlavor

The present invention relates to the field of fruit wine brewing, in particular to a goat's milk fruit wine and a production method, which uses goat's milk fruit as the main raw material, supplemented with traditional Chinese medicinal materials such as Burnet, sage, ginkgo, fat sea, dwarf gooseberry, etc. It is processed through the steps of raw material treatment, enzymolysis, fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

Coconut fruit wine and production method thereof

InactiveCN107541389AShort production periodSmooth tasteDigestive systemAntinoxious agentsMedicinal herbsFruit wine

The invention relates to the field of fruit wine brewing, in particular to a coconut fruit wine and a production method. It uses coconut as the main raw material, supplemented with traditional Chinese medicinal materials such as jujube, antler, elderberry, thyme, lentils, etc., after raw material treatment, enzymatic hydrolysis, Fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine and other steps of processing and production. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

Ecological face brick construction process for old wall surface renovation

PendingCN114352056AShort production periodLow output durationCovering/liningsBuilding repairsEnvironmental resource managementBrick

The invention discloses an old wall surface renovating ecological face brick construction process which comprises the steps of construction starting pretreatment, base layer treatment, marking brick pasting, ecological face brick inlaying and pasting, seam wiping and cleaning, an old base surface does not need to be knocked off, construction is convenient, no garbage is produced, the construction period is short, cost is low, and ecological soft magnetic face bricks are light, thin, space-saving, cement-saving, anti-pollution and self-cleaning. The fireproof, anti-seismic, anti-cracking, good in texture, good in ductility, resistant to freezing and thawing, durable, resistant to acid and alkali, high in weather resistance, breathable, fireproof, ecological, safe, environment-friendly, healthy in living, capable of being completely regenerated and free of three-waste discharge.

Owner:SHANGHAI CONSTRUCTION GROUP

Rambutan fruit wine and production method thereof

InactiveCN107541404AShort production periodSmooth tasteDigestive systemAlcoholic beverage preparationFruit wineEnzymatic hydrolysis

The invention relates to the field of fruit wine brewing, in particular to a rambutan fruit wine and a production method, which uses rambutan as the main raw material, supplemented with Chinese herbal medicines such as rambutan, Prunella vulgaris, jujube, Ziheche, astragalus, etc. , processed through the steps of raw material treatment, enzymolysis, fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

Preparation method of breast recovering tablet

ActiveCN102614457BKeep active ingredientsImprove stabilityPill deliverySexual disorderAlcoholCurative effect

The invention discloses a preparation method of a breast recovering tablet. Based on the prior art, the preparation method is characterized in that chitin or chitosan is adopted to serve as fining agent, and active ingredient of drug is well kept while the traditional Chinese medicine extracting solution impurities are removed, so that the problems of a conventional water-extraction and alcohol-precipitation method are solved that the active ingredient of drug is removed while the impurities are removed, and the curative effect of the breast recovering tablet is influenced.

Owner:ANKANG CHIA TAI PHARMA

A method and application of tartary buckwheat total flavonoids prepared from tartary buckwheat leftovers

InactiveCN104306463BImprove bioavailabilityImprove efficiencyMetabolism disorderPharmaceutical non-active ingredientsAnhydrous ethanolPolygonum fagopyrum

The invention discloses a method for preparing buckwheat total flavone from buckwheat leftovers and application thereof. The method comprises the following steps: extracting buckwheat bran by three times; when extracts are hot, filtering the extracts respectively; recycling ethanol from obtained filtrates at normal pressure respectively; concentrating respectively, and leaving to stand and crystallizing; filtering out crystals to obtain a buckwheat total flavone crude product; adding water or anhydrous ethanol into the buckwheat total flavone crude product; heating to a boiling state; filtering when a mixture is hot; leaving to stand and crystallizing filtrate till the total flavone is separated out; washing, and drying to obtain the buckwheat total flavones. The obtained buckwheat total flavone is applicable to health-care products including a buccal tablet. The method is high in efficiency, low in cost and short in production period; the obtained buckwheat total flavone contains 80-90% of rutin and 10-15% of other flavonoids such as quercetin; the prepared buccal tablet has many health-care functions.

Owner:云南谷冠生物科技有限公司

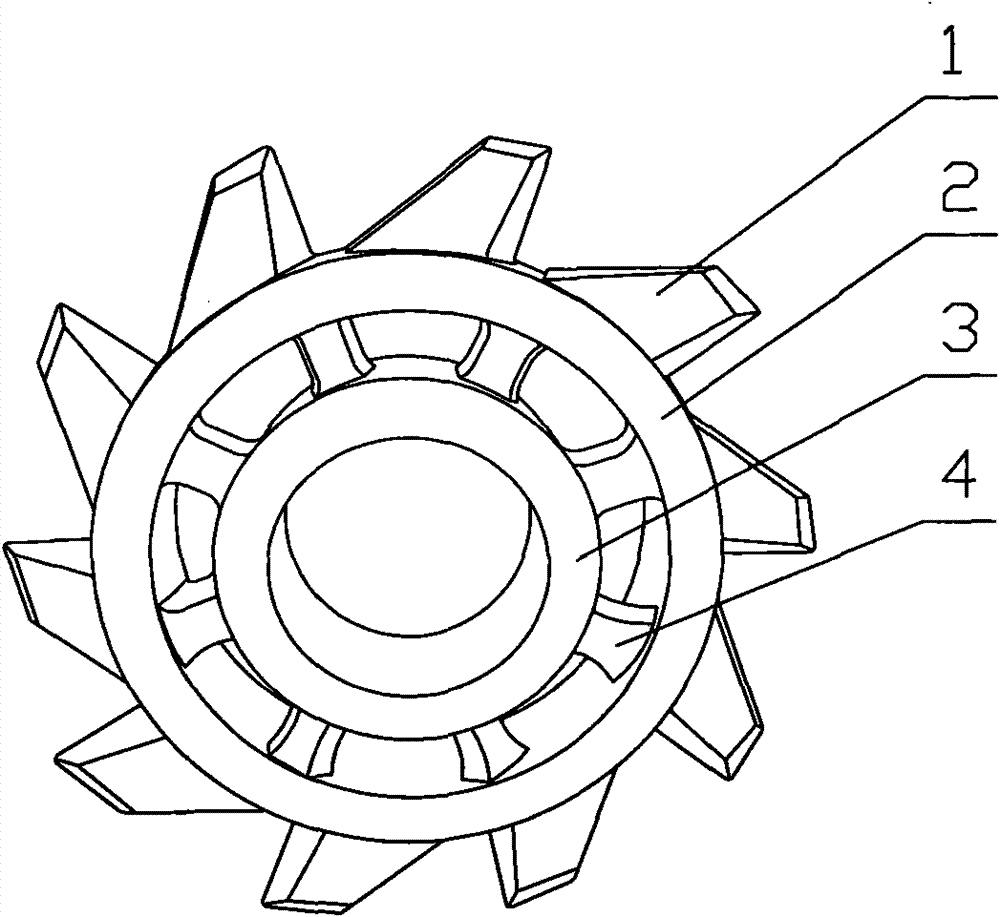

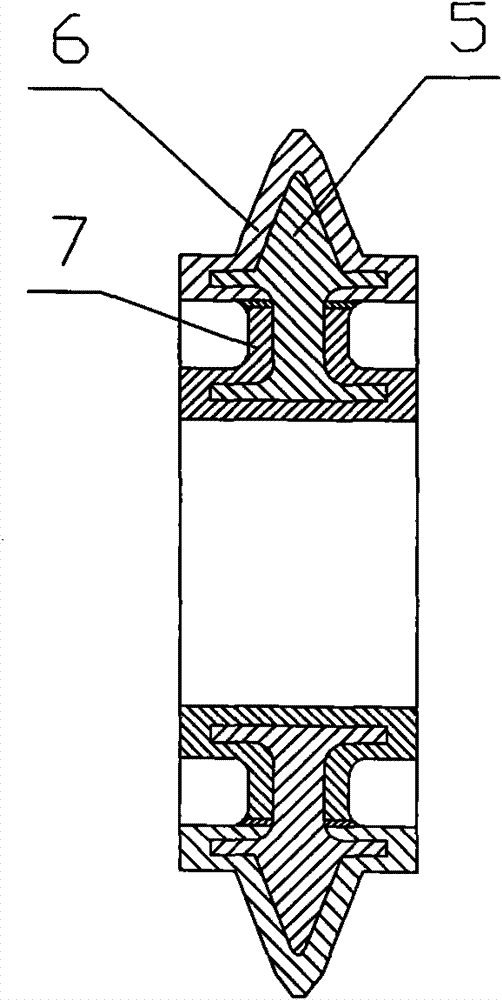

Process for manufacturing fluted disc for roll crusher

Disclosed is a process for manufacturing a fluted disc for a roll crusher. The fluted disc is cast with three different materials. Firstly, an inner core of the fluted disc is cast with ZG 40Cr (chromium) metal materials by a mould and comprises an inner hoop, an outer hoop, ribs and teeth; secondly, the inner core of the fluted disc is placed in the middle of the mould, and outer materials A of the fluted disc are cast in the teeth and the outer hoop of the inner core of the fluted disc by a centrifugal casting method; thirdly, outer materials B are also cast in the ribs and the inner hoop of the fluted disc by the centrifugal casting method, wherein the outer materials B are ZGQ235 metal materials; and fourthly, after the casting procedures are completed, a casting is demolded, heat treatment is performed after a die forging is performed at a temperature, and then the finished special fluted disc for the crusher can be manufactured. The manufacturing process is low in production cost and short in production period, the labor intensity of workers is reduced, and the fluted disc for the roll crusher produced by the process is high in strength, long in service life and can be used for crushing various blocky materials.

Owner:关润雄

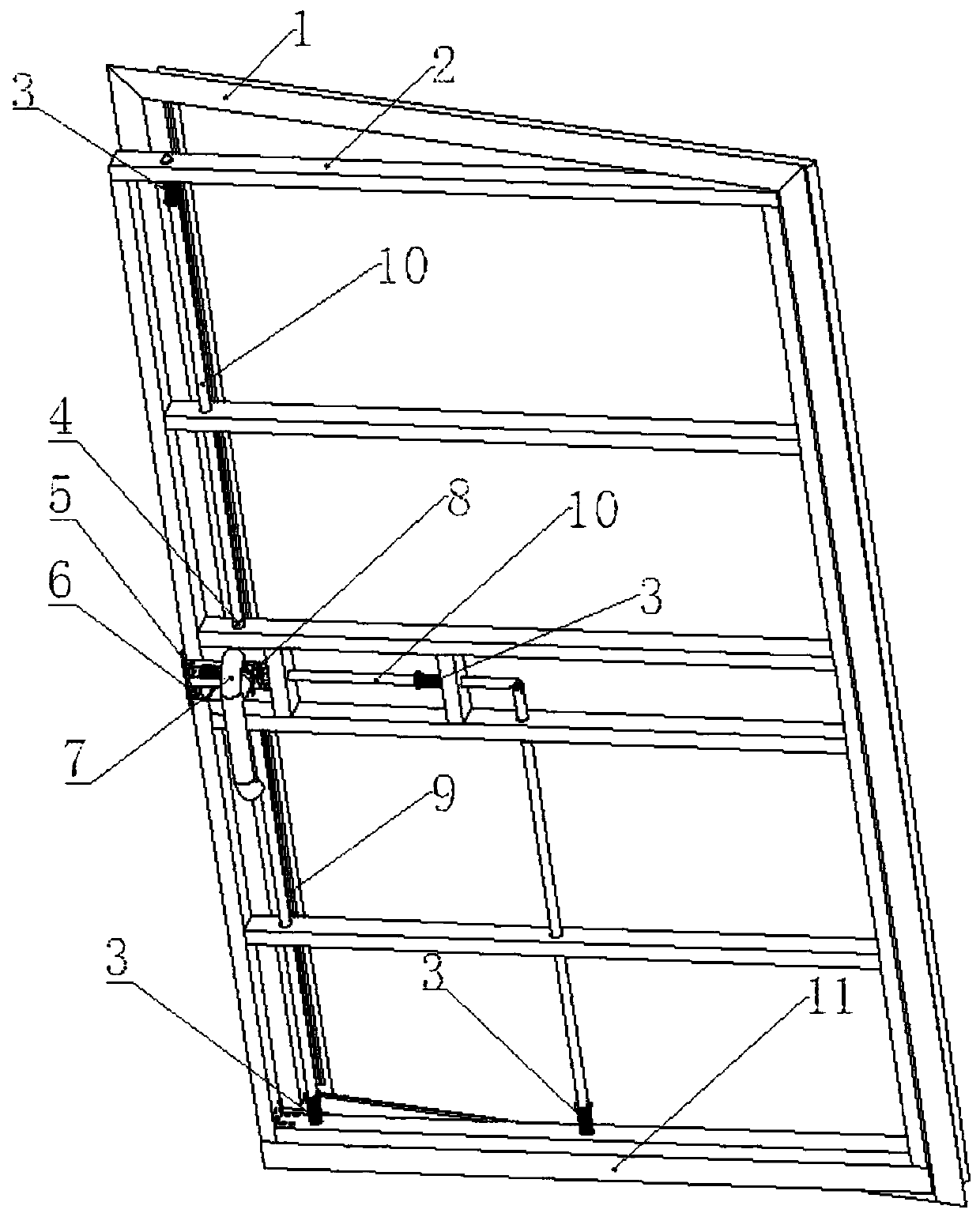

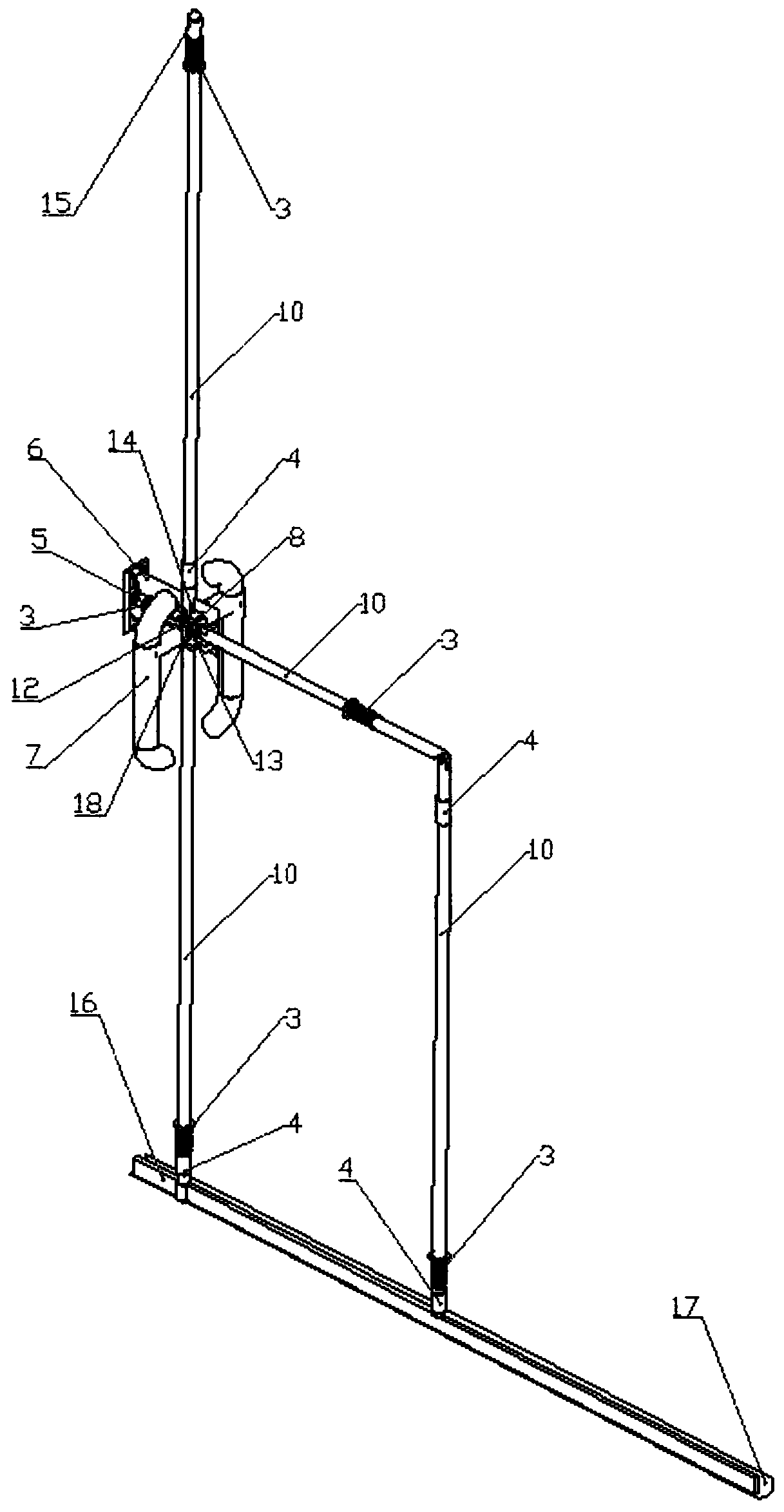

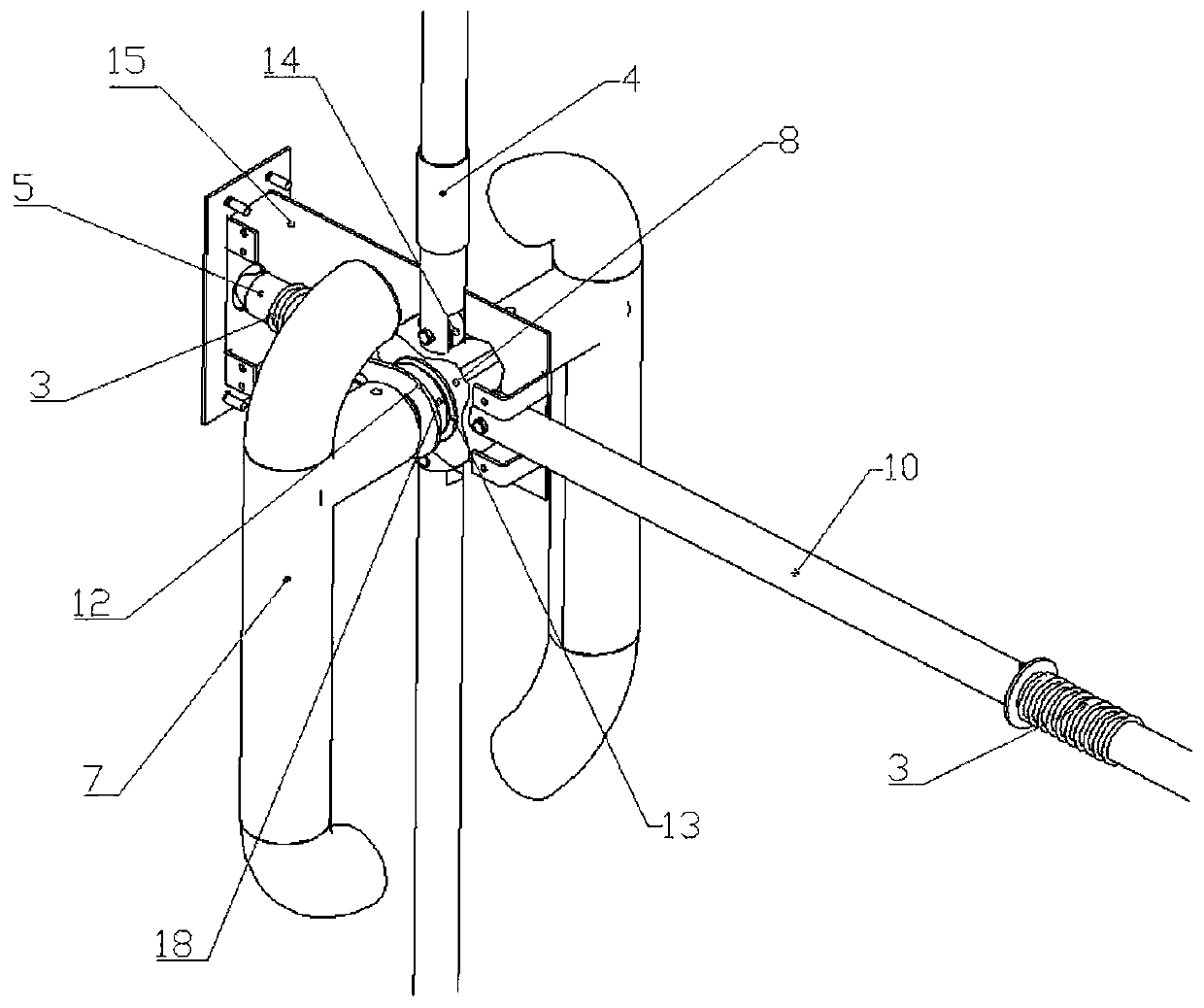

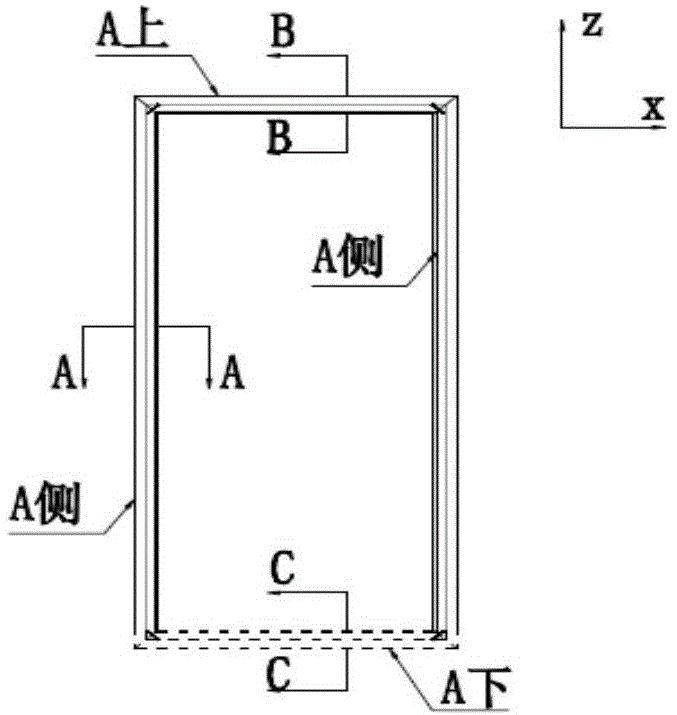

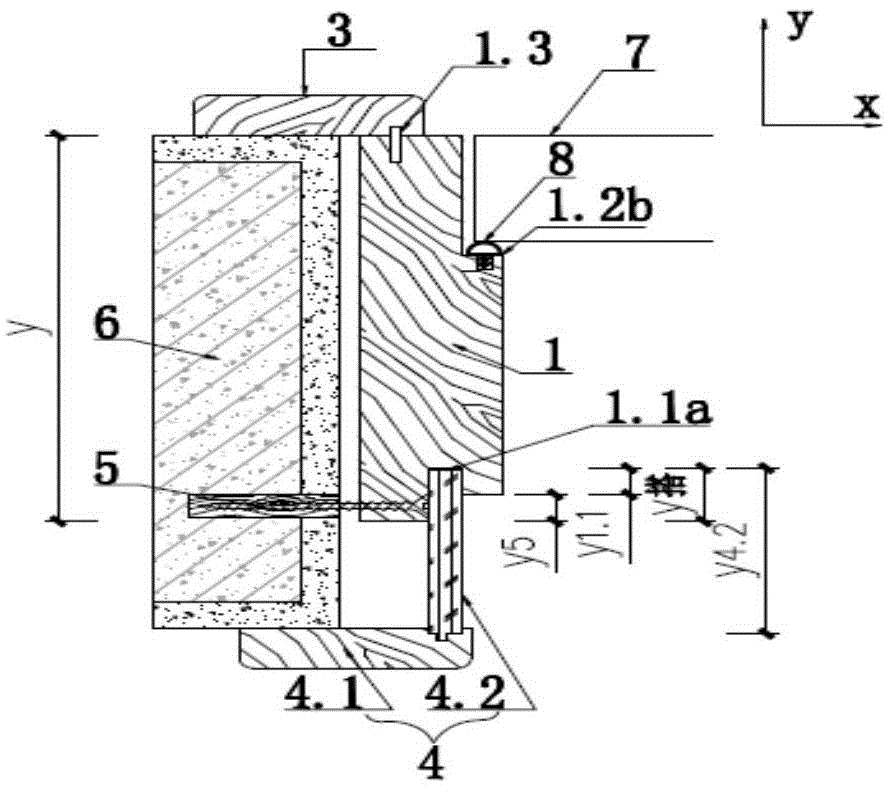

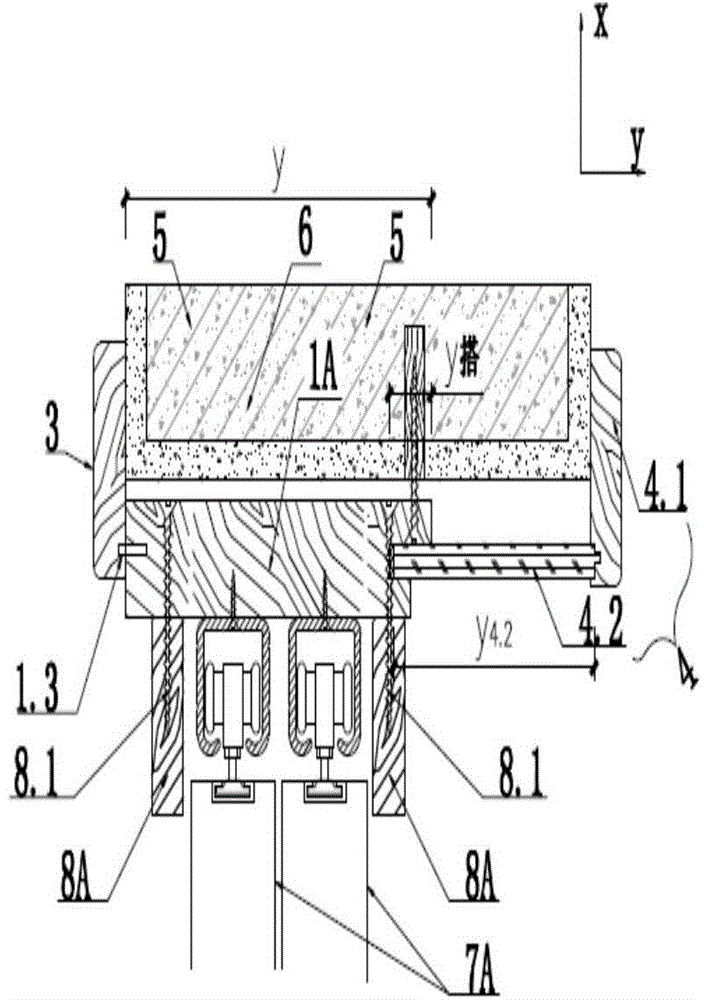

Novel electromagnetic shielding door

PendingCN111364897ASimple structureImprove assembly accuracyRadiation protectionConstruction fastening devicesStructural engineeringElectromagnetic shielding

The invention discloses a novel electromagnetic shielding door, and belongs to the technical field of shielding doors. The novel electromagnetic shielding door comprises a door frame and a door leaf;one side of the door frame is connected to one side of the door leaf through a hinge; a shielding protective device is arranged on the door frame; a mechanical door lock and a pushing rod pressing mechanism connected with the door lock are arranged on the door leaf; a door lock handle is arranged to connect the mechanical door lock; the mechanical door lock is connected with the pushing rod pressing mechanism and controls the pushing rod pressing mechanism; and the pushing rod pressing mechanism resets or respectively generates locking force to the periphery to jack into the door frame. The novel electromagnetic shielding door adopts a purely mechanical door lock, is simple in structure, higher in assembling precision compared with that of a pneumatic door, stable in performance, easy to maintain, short in production period and low in cost, and has certain advantage in the market; shielding pressing strips and shielding strip elastic pieces are in linkage with the overall mechanical structure; effective shielding of the periphery of the door is realized by extruding shielding strips of the door frame; and the operation of the handle is the same as the using method of a common household door lock through fool-proofing measures, which meets the living habits of people, so that human failure is prevented.

Owner:ZHUZHOU HELI ELECTROMAGNETIC TECH

Kiwi fruit wine and production method thereof

InactiveCN107541383AShort production periodSmooth tasteAntipyreticDigestive systemActinidiaKiwi fruit

The present invention relates to the field of fruit wine brewing, in particular to a kiwi fruit wine and a production method, which uses kiwi fruit as the main raw material, supplemented with traditional Chinese medicinal materials such as banyan tree, winter lily, non-ash wood, wild rice, Shandong swollen foot fern, etc. Raw material processing, enzymatic hydrolysis, fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine and other steps of processing and production. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

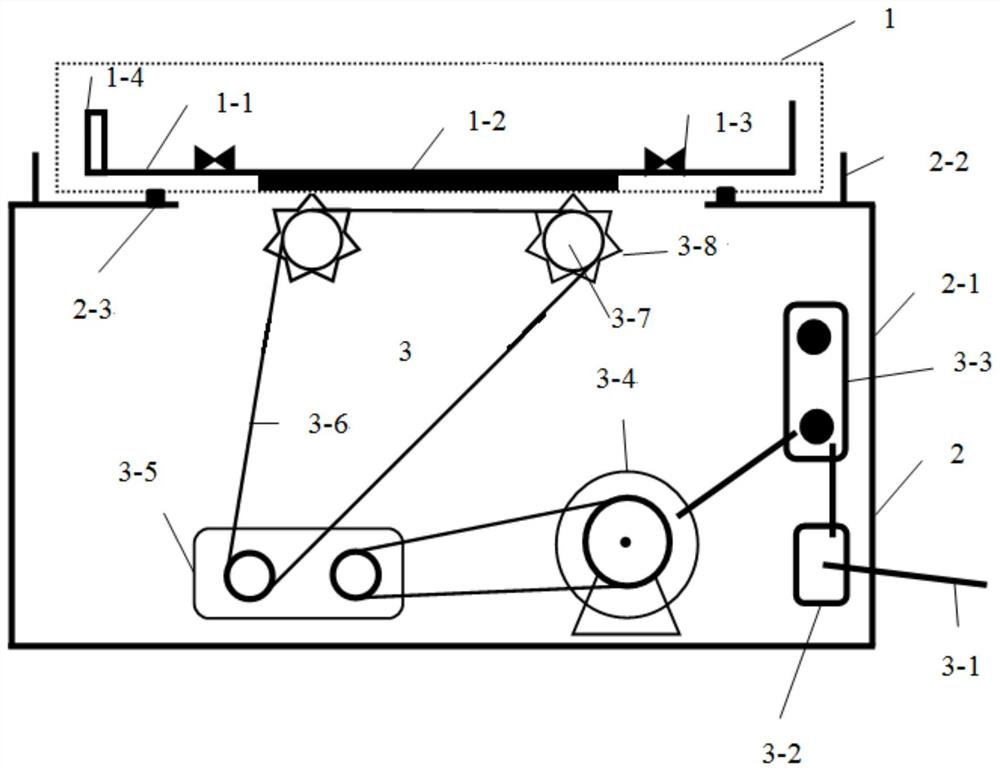

Shaping manufacturing device for reinforced concrete window sill

InactiveCN111958812AHigh degree of manufacturing standardizationManufacturing cost good qualityAuxillary shaping apparatusReinforced concreteElectric machine

The invention provides a shaping manufacturing device for a reinforced concrete window sill. The shaping manufacturing device comprises a concrete tray system, a shell system and a power vibration system. The top of the shell system is provided with an opening, the concrete tray system is mounted at the opening in the top of the shell system, and the power vibration system is disposed inside the shell system. The concrete tray system comprises a tray for containing concrete. The power vibration system comprises a motor and vibrators, the vibrators are arranged at the opening in the top of theshell system, and the upper ends of the vibrators are in contact with the bottom of the concrete tray system to drive the concrete tray system to vibrate.

Owner:MCC NORTHEAST CONSTR SHENYANG ENGTECH CO LTD

Pomegranate fruit wine and production method thereof

InactiveCN107541391AShort production periodSmooth tasteNervous disorderDigestive systemFruit wineSenecio

The present invention relates to the field of fruit wine brewing, in particular to a pomegranate fruit wine and a production method, which uses pomegranate as the main raw material, supplemented with traditional Chinese medicinal materials such as wild peony, golden cherry, half-side flag, long-stemmed Senecio, chuanxiong, etc. Processing, enzymatic hydrolysis, fermentation, preparation of traditional Chinese medicine liquid and preparation of fruit wine and other steps of processing and production. The invention adopts low-temperature fermentation, which is beneficial to enhance the aroma of the fruit wine, improve the color and taste of the fruit wine; solve the shortcomings of the traditional wine making method, the production process is simple, the production cycle is short, the production cost is greatly reduced, the production efficiency is improved, and it is easy for large-scale production .

Owner:HARBIN SHANBAO LIQUOR IND

Time-saving and labour-saving cultivation method for chrysanthemum cut flower

The invention provides a time-saving and labour-saving cultivation method for chrysanthemum cut flowers. The time-saving and labour-saving cultivation method comprises a stage of straight cutting for raising seedlings and production of finished product flowers, wherein the production of the finished product flowers comprises a nutritional growth stage and a reproductive growth stage, the straight cutting for raising seedlings comprises four stages of tidying in a planting shed, preparation of chrysanthemum seedlings, cottage and seedling management. With the adoption of the cultivation method disclosed by the invention, a production period is shortened for at least nine days on year-on-year basis, utilization rate of land is improved, planting work load is also saved, and chrysanthemum cultivation efficiency is also improved.

Owner:JIANGSU JUNMA AGRI & FORESTRY TECHINDAL

Stereo trough type nutrition providing cultivating method for dendrobium

InactiveCN100401874CStable conditionsShort production periodHorticulture methodsReceptacle cultivationDendrobiumFertilizer

The stereo trough type nutrition providing cultivating method for dendrium includes the planting material selecting process, the planting process, and the water and fertilizer managing process. The stereo trough type nutrition providing cultivating method can speed the growth of dendrium through providing a stable comprehensive and balanced nutrition providing system and has shortened production period and lowered production cost. The present invention provides technological foundation for the development and utilization of dendrium.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

Novel universal-deployment fast-assembly door-and-window frame and manufacturing method thereof

The invention discloses a novel universal-deployment fast-assembly door-and-window frame and a manufacturing method thereof. The novel universal-deployment fast-assembly door-and-window frame comprises a horizontal sliding door sleeve, a sliding door sleeve, an idle door sleeve, a window sleeve and a thick-wall door sleeve. Each pattern comprises a main board with a unified width of about 150 mm or 90 mm, adjustable L-shaped decorative plates at front and rear sides of the thick wall or an L-shaped plate at the front side and a fixed rectangular decorative plate at the rear side. The L-shaped plate consists of a high-quality decorative strip and an embedded manmade plate with width not more than 230 mm or 290 mm. The main board with a designed dimension is manufactured into an inverted U-shaped board by slitting through a standard board and the like, various L-shaped and rectangular boards are optimized and slit on the spot to deploy a width adjustment range produced by a two-main-board combined structure and the like, so that adjustment needs of the existing door-and-window frame with various standard and nonstandard wall thickness differences are completely met. The inverted U-shaped plate is sent to an installation site as a standard part, a simple cutter storeroom is only arranged, the inverted U-shaped plate is optimized and slit into boards of various specifications according to the practical wall thickness, and the installation site is free of noise pollution. The novel universal-deployment fast-assembly door-and-window frame is standard, large-scale, short in production period, quick and convenient to mount, and high in product quality, and especially suitable for lots of existing door-and-window frames on high-rise nonstandard walls.

Owner:湖北千川门窗有限公司

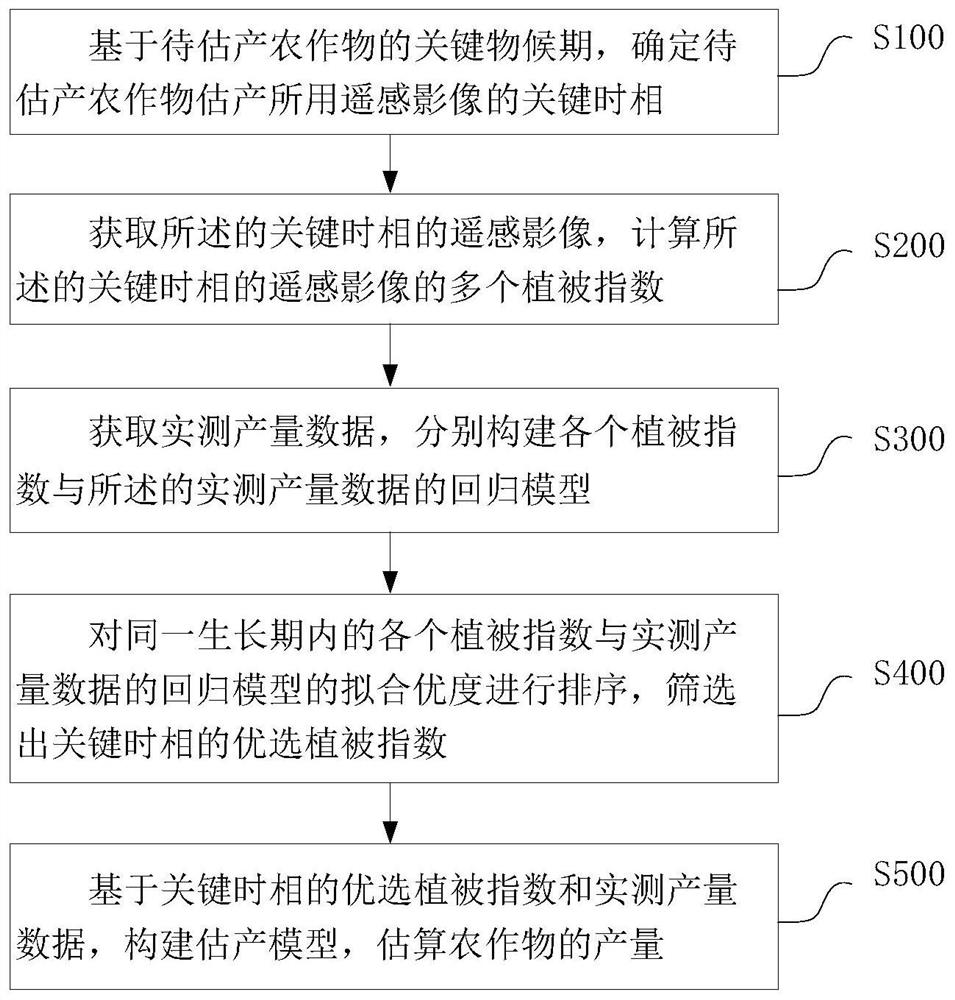

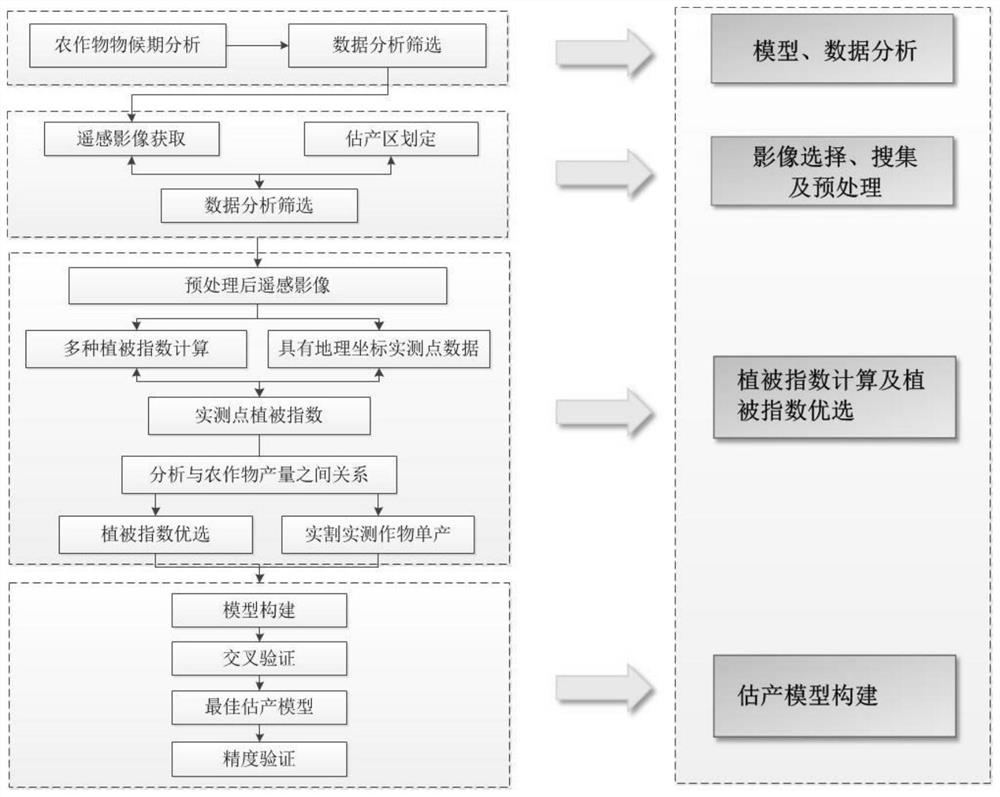

Crop yield estimation method and device, electronic equipment and storage medium

PendingCN113743819AYield estimates are accurateQuick Yield EstimationResourcesSensing dataVegetation

The invention relates to a crop yield estimation method and device, electronic equipment and a storage medium, and the method comprises the steps of determining a key time phase of a remote sensing image based on a key phenological period of a to-be-estimated crop; acquiring a remote sensing image of the key time phase, and calculating a plurality of vegetation indexes; respectively constructing a regression model of each vegetation index and the actually measured yield data; sorting the goodness of fit of the regression model of each vegetation index and the actually measured yield data in the same growth period, and screening out the optimal vegetation index of the key time phase; and constructing a yield estimation model based on the optimal vegetation index of the key time phase and the actually measured yield data, and estimating the yield of the crops. The regional crop yield estimation model is constructed on the basis of remote sensing data, in combination with crop growth characteristics, through crop key phenological period analysis, in combination with optimal vegetation indexes and actually measured data, the method can be used for rapid regional yield estimation, and the reliability of a yield estimation result is improved.

Owner:TWENTY FIRST CENTURY AEROSPACE TECH CO LTD

Production of compound microbial fertilizer using beer dregs as strain raw material and production method thereof

ActiveCN103570421BIncrease vitalitySimple production equipmentBio-organic fraction processingOrganic fertiliser preparationCelluloseBULK ACTIVE INGREDIENT

The invention discloses a compound microbial fertilizer produced by utilizing beer residues as strain active ingredients, and a production method thereof. The production method is characterized by comprising the following steps: mixing and sealing beer residues, calcium hydrophosphate, Muru residues and honey for fermentation at the fermentation temperature of 35-45DEG C for five to seven days to produce a compound microbial fertilizer which is rich in protein, residual sugar, cellulose, probiotics, carbon source and chloride source. The compound microbial fertilizer and the production method thereof have the advantages that the compound microbial fertilizer can achieve the NY / T797-2004 standard of National Agricultural Department, the probiotics is increased to more than 300 million / g from the originally 20million / g, the compound microbial fertilizer can change wastes into valuables to reduce the environmental pollution, and has the characteristics of being improving the soil structure, loosening the soil, increasing the air permeability, enhancing the fertilizer effect, promoting the growth of crops, being low in production cost, and simple in production technology method, and the like. The compound microbial fertilizer can be applied to grains, vegetables, fruits and other various crops.

Owner:YULIN SHIDEFU FERTILIZER CO LTD

90-degree overturning airflow pneumatic conveying line

The invention discloses a 90-degree overturning airflow pneumatic conveying line. The 90-degree overturning airflow pneumatic conveying line comprises a blowing plate, U-shaped boxes and a fan. Each U-shaped box is a cavity with the upper end open and the lower end sealed; an air partition plate is arranged in the middle of each U-shaped box; and an opening of each U-shaped box faces upwards. The blowing plate is mounted at the openings of the U-shaped boxes so that the U-shaped boxes can form pressurizing cavities. The pressurizing cavities are connected with the fan. A plurality of directional blowing ports are formed in the surface of the blowing plate in the conveying direction. The multiple directional blowing ports form an air channel flowing in the conveying direction. Pressure is formed in the pressurizing cavity through an air source provided by the fan pressure so that airflow can flow out through the directional blowing ports in the conveying direction. The U-shaped box and the blowing plate are provided with 90-degree rotation devices. The blowing plate is made form 304 mirror finished stainless steel. Stainless steel barrier strips and macromolecular abrasion-resistant strips are arranged on the surface of the blowing plate to be used as guide rails of ring-pull cans. After the directional blowing ports are disconnected, the directional blowing ports are bent downwards by a certain angle. The 90-degree overturning airflow pneumatic conveying line can reach 2000-3000 CMP, the cost is low, the production period is short, and friction to can bottoms is reduced.

Owner:北京鑫顺盛源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com