Prestressed reinforced concrete cast-in-place turbine generator base

A technology of reinforced concrete and steam turbine generator, which is applied in basic structural engineering, construction, etc., can solve the problems of high cost, consumption of steel bars and concrete materials, etc., and achieve the effects of short production period, large overall stiffness, and small overall deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

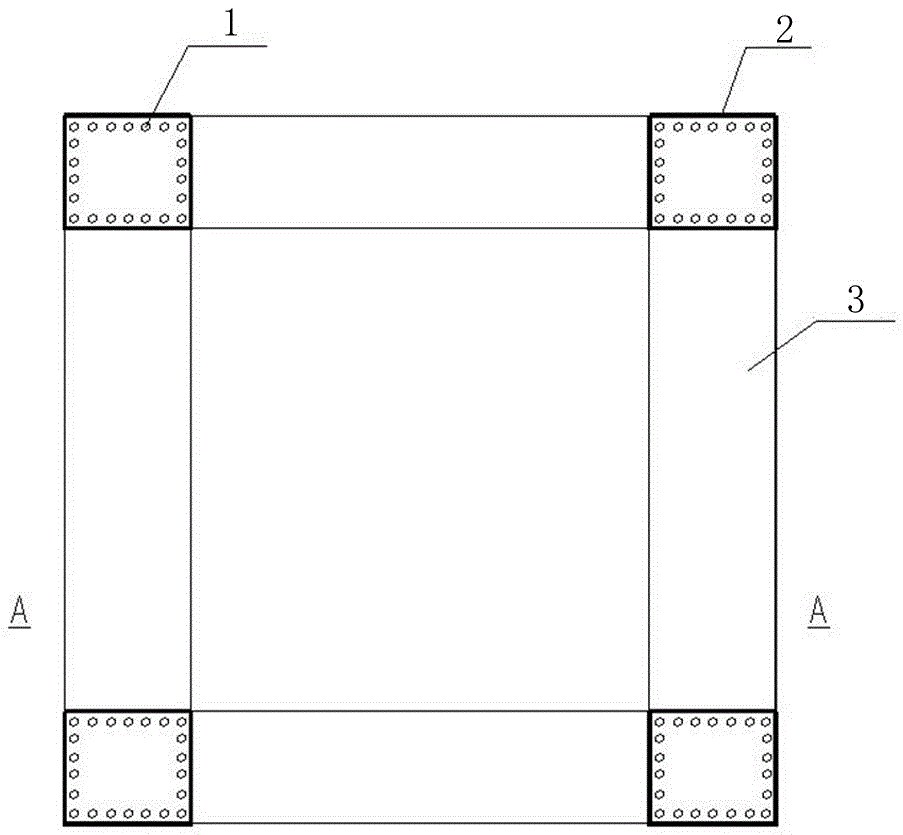

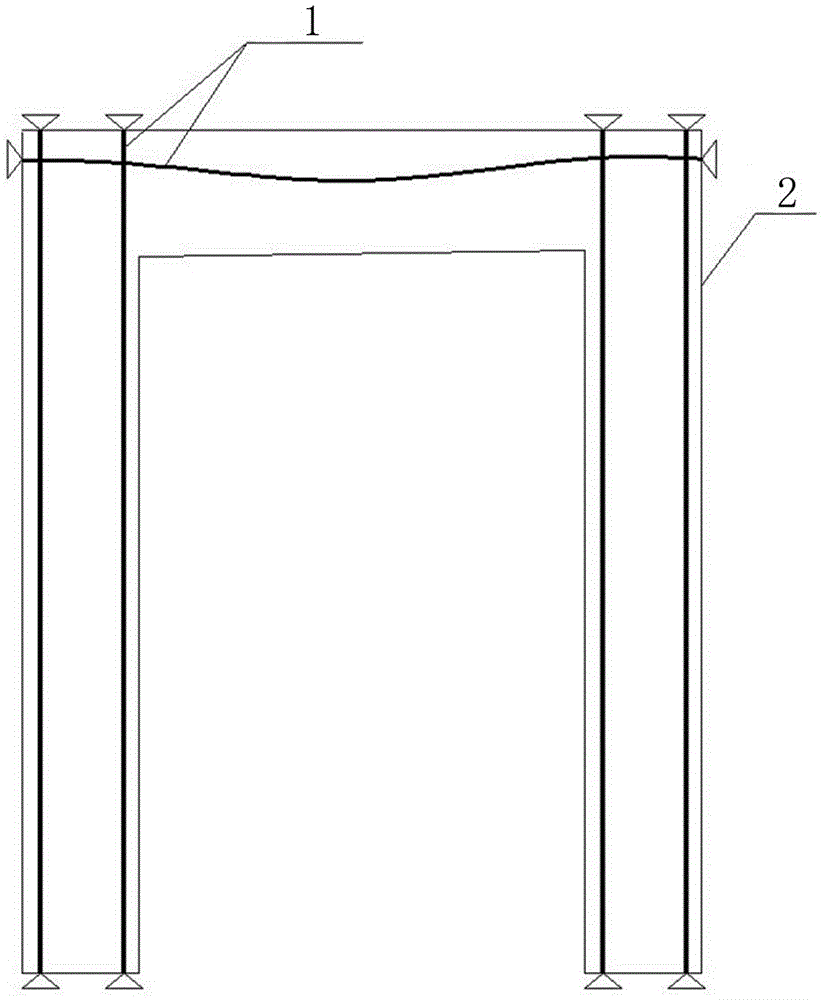

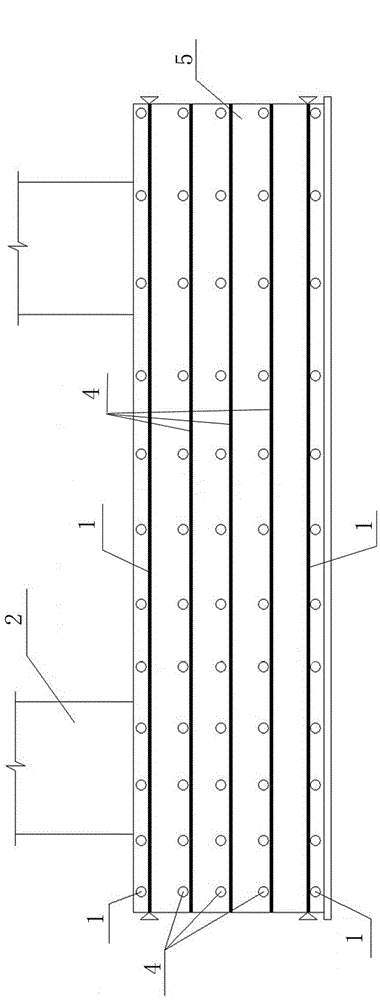

[0018] see figure 1 and image 3 , a prestressed reinforced concrete cast-in-place steam turbine generator base in this embodiment includes a base plate 5, a frame column 2 and a frame beam 3, and is set in the base plate 5, frame column 2 and frame beam 3 There are prestressed steel bars 1 stretched by post-tensioning method, and prestressed steel bars 1 are unbonded prestressed steel bars.

[0019] The two ends of the prestressed steel bar 1 are respectively anchored to the ends of the base floor 5 , the frame column 2 or the frame beam 3 by tension-end anchors and fixed-end anchors.

[0020] The anchorage at the tension end adopts the existing Type I clip-type anchorage, see Figure 4 , The clip-type anchor is mainly composed of clip, anchor ring I6, anchor pad I7 and spiral rib I8.

[0021] The anchorage at the fixed end adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com