Novel universal-deployment fast-assembly door-and-window frame and manufacturing method thereof

A door and window cover, a new type of technology, applied in the direction of window/door frame, etc., can solve the problems of difficult to achieve industrialization and standardization of production and installation, difficult to achieve uniform size and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

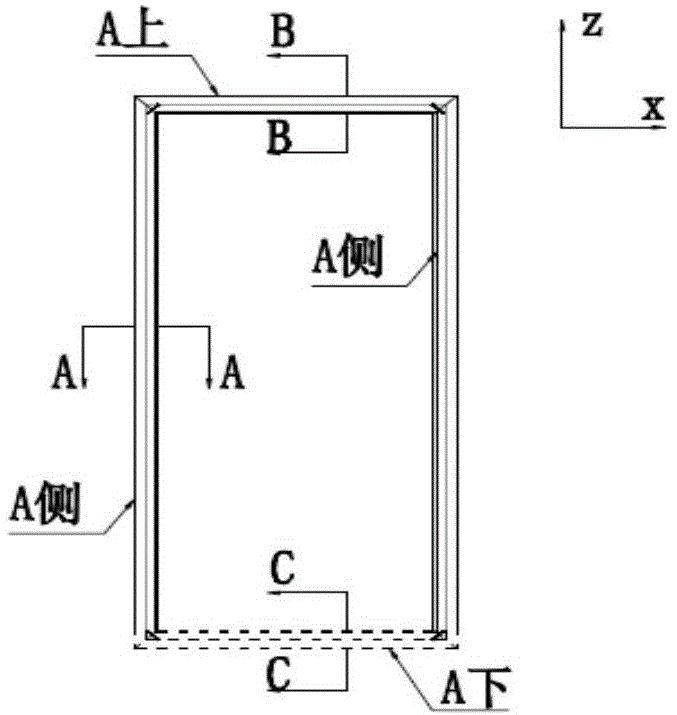

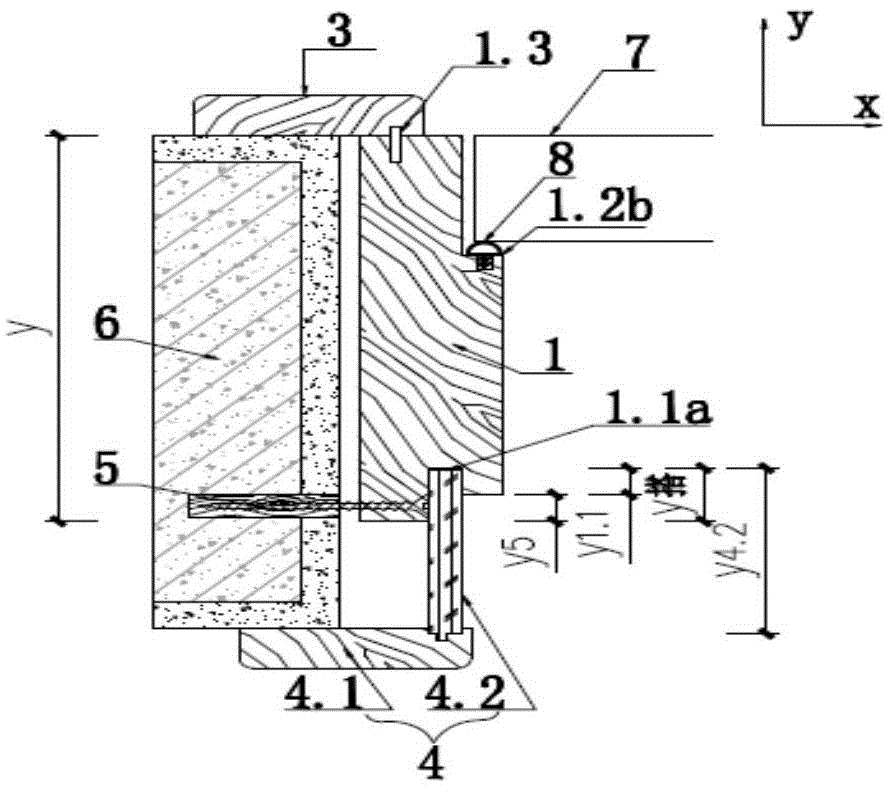

[0027] Embodiment 1: Sliding door cover. See figure 1 , figure 2 ,See Figure 6 ~ see Figure 10 .

[0028] The new universal deployment quick-installation sliding door cover is as follows:

[0029] See figure 2 , The new type of universal deployment and quick installation of the sliding door cover, including: the main board of the sliding door cover 1; , and an anti-collision sound-absorbing strip 8 is provided at this place. Only the front side of each main board 1 shares five wall fixing screws 5 and foam glue to be fixed on the wall 6 along the vertical Z (see also Figure 10 Five wall fixing screws 5) are shared in the middle vertical direction Z, and the features are:

[0030] 1) see figure 2, the casement door cover is provided with an adjustable L-shaped decorative plate 4 along the wall thickness Y to the front side of the main board, and correspondingly inserted into the adjustment groove 1.1a on the front side of the main board. A rectangular decorative...

Embodiment 2

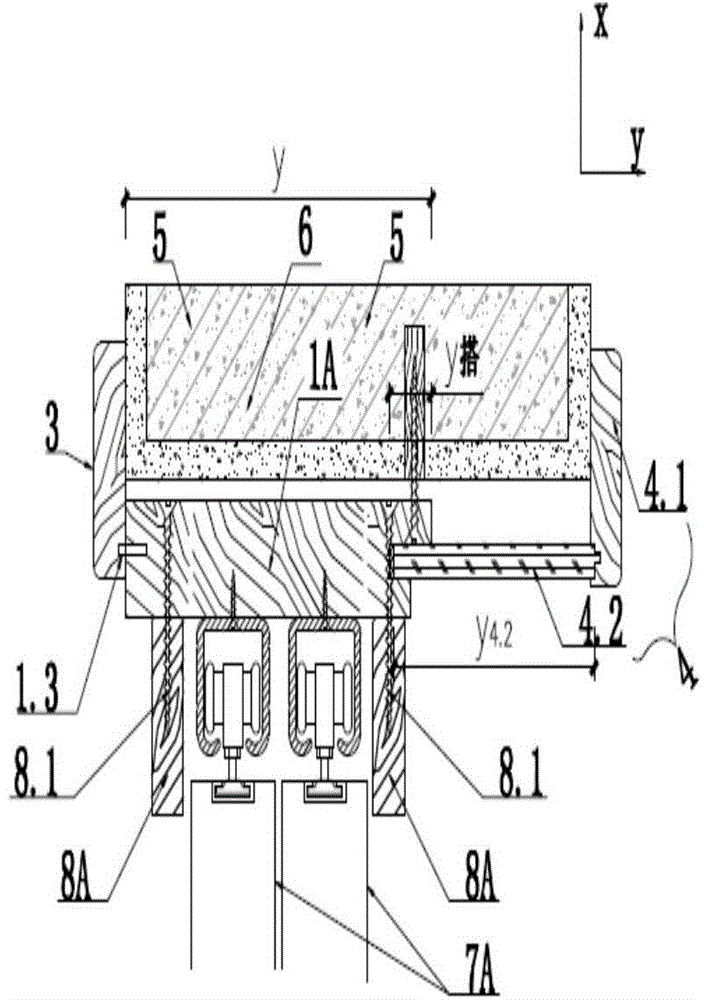

[0037] Embodiment 2: sliding door cover. See image 3

[0038] This embodiment 2 is completely the same as embodiment 1, except for the following features: 1) see image 3 : The motherboard is 1A. Compare image 3 and figure 2 It can be seen that the rear end of each sliding door cover main board 1A is not equipped with a swing door, so the rear end has no figure 2 Back boss 1.2b in (see figure 2 1.2b). 2) see image 3 Install the sliding door 7A on the lower side or the inner side of the main board 1A of the sliding door cover. The sliding door 7A is fixed on the front and rear sides of the main board along the wall thickness Y with two baffles 8A, and each baffle is fixed by five screws 8.1 8A is fixed together with the main board 1A.

[0039] The manufacturing method of the novel universal deployment quick-installation sliding door cover is exactly the same as that of embodiment 1. No more details here.

Embodiment 3

[0040] Embodiment 3: Empty door cover see Figure 4

[0041] The new universal allocating fast-loading empty door cover of the present embodiment 3 is different from the embodiment 1 except the following, which are all the same:

[0042] 1) see Figure 4 , The motherboard is 1B. There is no rectangular decorative panel 3 along the thick rear side of the wall. Adjustable L-shaped decorative panels 4 are provided on the front and rear sides of the empty door cover along the wall thickness, and are correspondingly inserted into the front and rear adjustment grooves 1.1a, 1.1b of the main board 1B of the empty door cover. 2) see Figure 4 , The minimum lap length Y lap between the adjustment plate 4.2 on the rear side of the wall thickness and the main board along the Y direction of the wall thickness is also taken as 20mm. Its overlapping long Y lap=Y1.1+Y5 is identical with embodiment 1 (Y1.1, Y5 mark position can refer to figure 2 ). 3) The width adjustment range of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com