High-efficiency diatomaceous earth clarification tank

A diatomite and clarifier technology, which is applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. , the problem of high cost of sewage treatment, to achieve the effect of stable treatment effect, easy transportation, installation and use, and automatic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

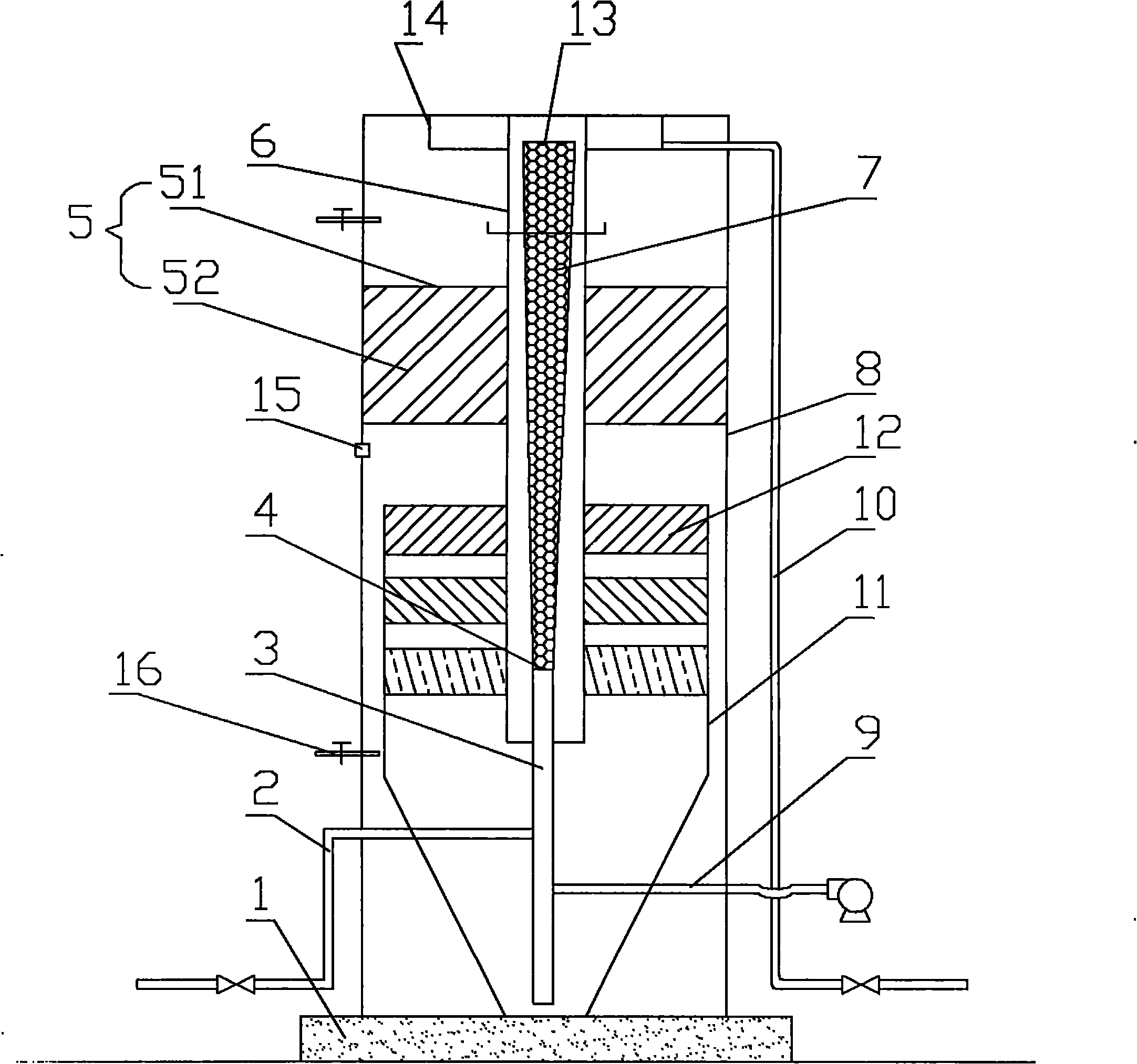

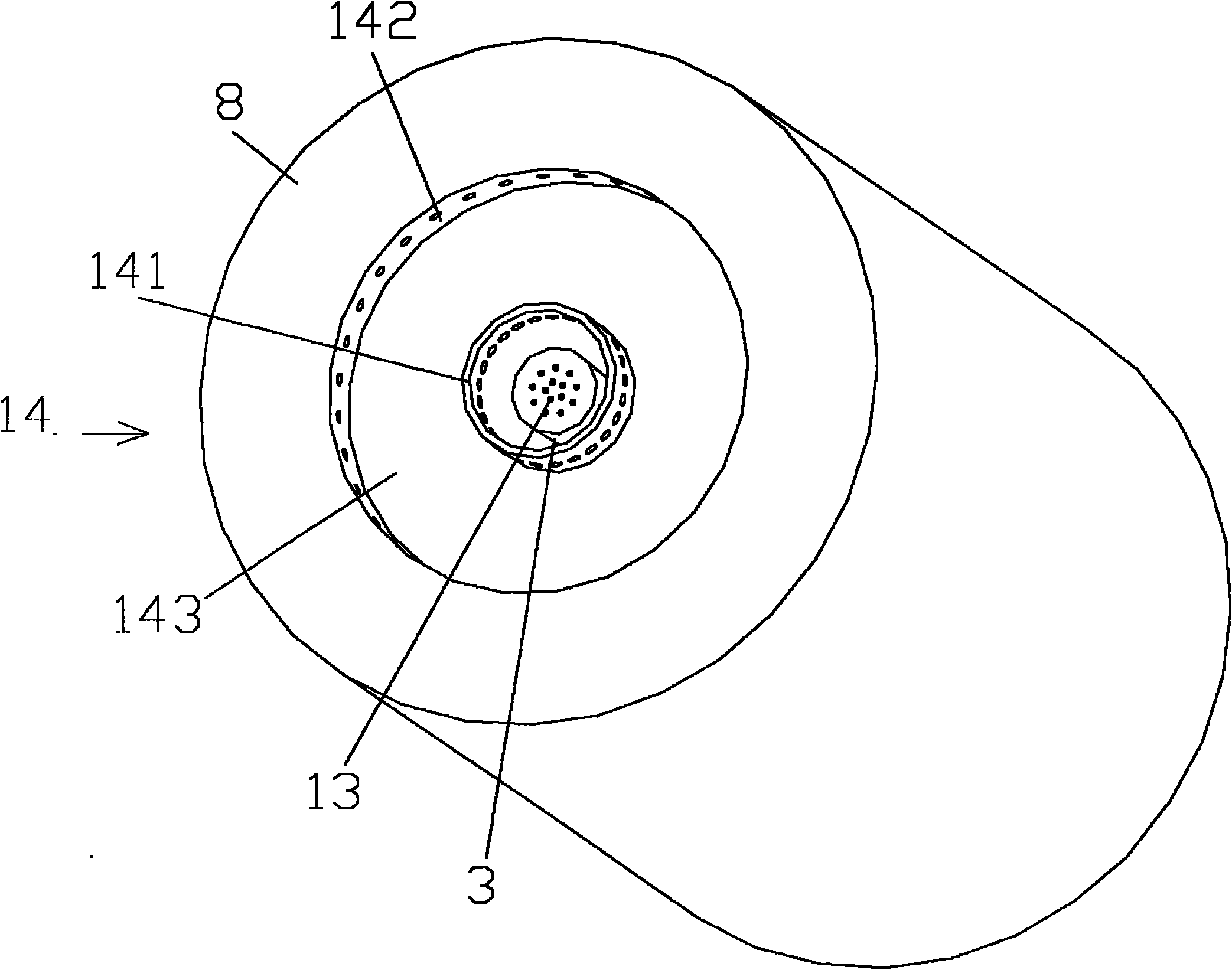

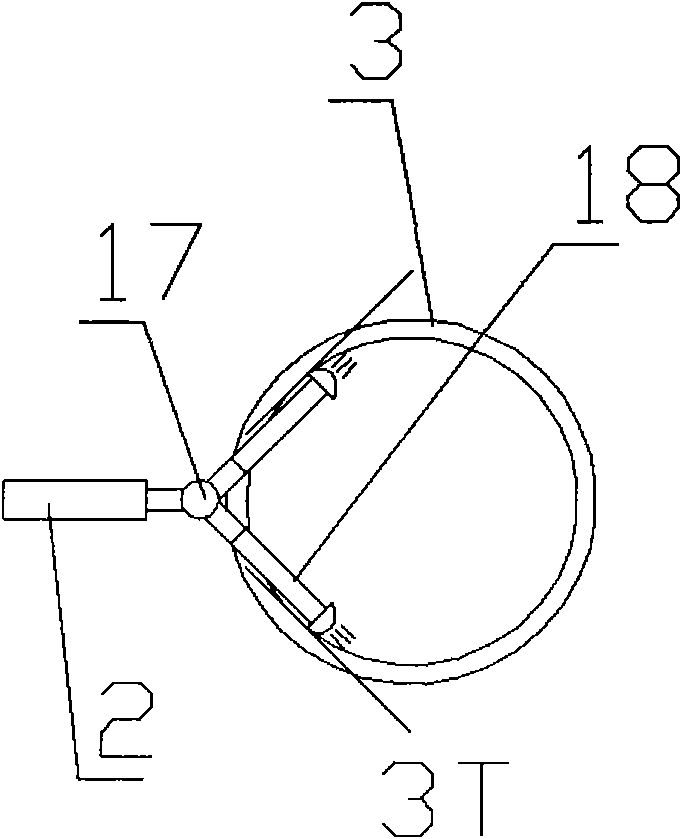

[0032] Example: see Figure 1~4 As shown, the high-efficiency diatomite clarification tank includes a central reaction cylinder 3, a central pipe 6, and a pool body 8. The bottom of the pool body 8 is provided with a sludge tank 1, and a support screen 4 is fixed in the central reaction cylinder 3. The plastic balls 7 with honeycomb holes are placed in the central reaction cylinder 3, the central reaction cylinder 3 is located at the bottom of the support screen 4 and is connected with the sewage water inlet pipe 2 and the air pressure pipe 9, and the central reaction cylinder 3 is placed in the center of the central pipe 6. In the middle, the central tube 6 is fixed on the pool body 8;

[0033] The lower part of the inner diatomite filter chamber 11 is conical and connected to the sludge tank 1. At least two layers of inner inclined pipe filter layers 12 are fixed between the inner diatomite filter chamber 11 and the central pipe 6, and the central pipe 6 protrudes The lowes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com