High-quality regenerated rubber and its production

A recycled rubber, high-quality technology, applied in the field of waste rubber regeneration, can solve the problems of poor quality of recycled rubber, and achieve the effects of long service life, low noise and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

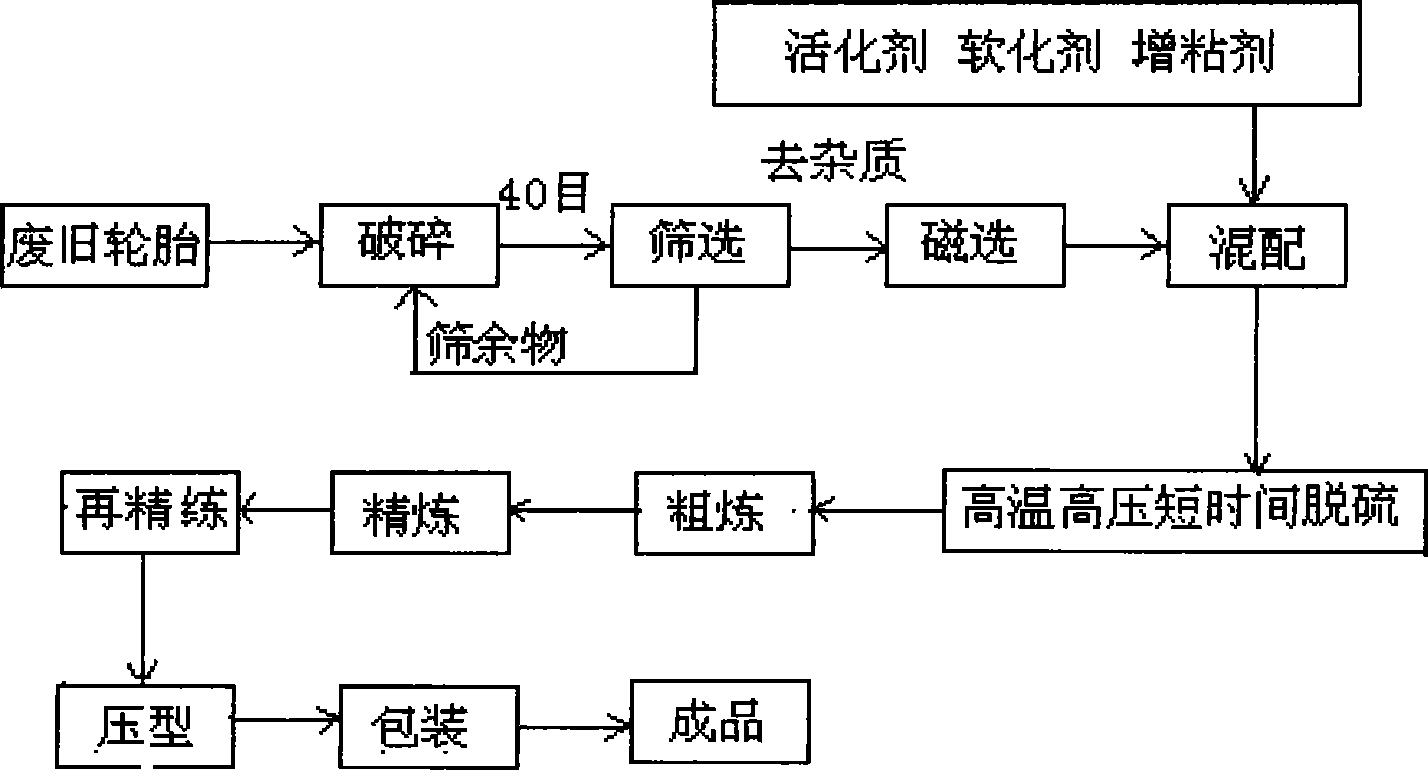

[0015] The technical process of the method of the present invention is given first: waste tires—crushing—screening—magnetic separation—mixing (adding activator and softener)—desulfurization—rough refining—refining—refining—molding—packaging—finished product.

[0016] Example: take back waste tires, crush them with a crusher, pass through a 40-mesh sieve, and remove impurities such as iron wires in waste tires by magnetic separation, prepare 100 parts of rubber powder, add 3 parts of No. 450 activator and 15 parts of solid coal tar softener After mixing 3 parts of rosin tackifier, enter the desulfurization process, and increase the temperature (about 217°C), pressure (1.8-2MPa) and desulfurization time (2-3 hours) parameters of the traditional dynamic desulfurization process to a temperature of 240- 260°C, the pressure is 2.6-3MPa, and the time is reduced to 60-40 minutes. The desulfurization process is to gradually convert the polysulfides of the rubber powder into monosulfide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com